Professional Documents

Culture Documents

Wireline Grease Injection Control Head

Uploaded by

ngueadoumCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wireline Grease Injection Control Head

Uploaded by

ngueadoumCopyright:

Available Formats

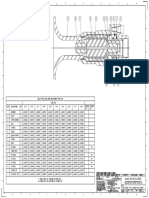

PRESSURE CONTROL Wireline Grease Injection

EQUIPMENT Control Head

The Elmar Grease Injection Control Head is designed to create a seal around a moving wireline,

allowing intervention access to wells under pressure.

Positioned at the uppermost point of the pressure control

equipment string, the Elmar Grease Injection Control Head

comprises two major sub-assemblies, the stuffing box or

pack-off and the flotube assembly.

Gland (1) The stuffing box is designed to pack-off on a stationary

Line Rubber (1) wireline by means of a pack-off rubber energised by hydraulic

pressure.

Interlocking

Seat (1) Two types of flotube assemblies are available, the "solid

type and the concentric type, as described in this data sheet.

The concentric flotube assembly is made up of an inner

flotube sized to fit tightly around the wireline and an outer

sleeve to support the assembly.

Flotube To prepare for operations, the wireline is threaded through the

components of the Elmar Grease Injection Control Head

before the rope socket and wireline head are made-up. When

entering a well under pressure, viscous grease is injected into

the flotubes at a pressure greater than the existing well

pressure. The grease fills the annular space between the

inner wall of the flotube and the outside surface of the

wireline, forming a liquid seal that contains the well fluids

while allowing wireline movement.

The Elmar Grease Injection Control Head is supplied with pin

threaded connections top and bottom. The upper pin is 2" line

pipe for connection of a line wiper. The bottom connection can

be mated to a quick-union, or a ball check valve/tool catcher

Injection Check combination. An optional Line Wiper is normally connected on

35

Valve top of Stuffing Box.

4

When changing line size, a different line size kit is needed for

the stuffing box, identified by the Line Size Code letter.

See overleaf for details.

Flotubes recommended ID = Wireline OD + 0.003" to 0.008".

ORDERING INFORMATION

Part No. of Grease Injection Control Head (from table below)

Line size (kit) to be specified - L-971278* L (see table overleaf)

Additional Flotube size to be specified (see table overleaf)

Flotube If dual injection is required, order separately (Qty 1) L-971218 in

and Injection addition to the standard grease head with 1 x manifold

Coupling

PART NUMBERS

Assembly

L-971218 Part Number of Working Bottom Top Seal

Number Flow Tubes Pressure Service Connection Connection Kit

2-10TPI 2 Line

L-979470 3 10,000 psi H2S L-979470K

Acme Pin Pipe Pin

2-10TPI 2 Line

L-978385 4 10,000 psi H2S L-978385K

Acme Pin Pipe Pin

Ball Check Valve L-970635 5 10,000 psi H2S

2-10TPI

Acme Pin

2 Line

Pipe Pin

L-970635K

2-10TPI 2 Line

L-971229 6 10,000 psi H2S L-971229K

Acme Pin Pipe Pin

Note: Parts included in line size kit (1). Seal Kit (O-Ring and BURs) does not include line size kit. 2-10TPI 2-10TPI

L-971218 1 10,000 psi H2S L-971218K

Acme Pin Acme Box

TEST FIXTURE

L-972410 Test Plug (Dummy Packer) for Stuffing Box

L-971281 Test Rod Assembly for Stuffing Box, 3/16 - 15/32 Line Range

L-972264 Test Cap 2-10TPI Box for flotube/sleeve connection

ACCESSORIES (Other sizes available on request)

L-971641 Flotube Go-NoGo gauge 0.233 and 0.235

L-971642 Flotube Go-NoGo gauge 0.237 and 0.240

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL Wireline Grease Injection

EQUIPMENT Control Head Contd

ORDERING TABLE

*Line Size Line Line Inter-locking Flotube

Gland (1) Flotube

Code Size Rubber (1) Seat (1) ID

.177 -

3/16 .183 L-976184

Gland (1) B 0.188 L-971840 L-972200 L-972240 .186 L-974570

(1-18) .189 L-972380

Line Rubber (1) .193 L-974571

Interlocking .196 L-976696

.199 L-976650

Seat (1) .201 L-976163

.204 L-977167

.208 -

.211 -

.216 L-975439

7/32 .219 L-975440

0.219 .222 L-974572

C (1-20) L-972150 L-972200 L-972250 .224 L-974538

.226 L-971129

(1-22) .228 L-972370

(2-23) .231 L-972680

Flotube .232

.236

L-978002

L-977887

.239 L-977899

.240 L-971130

.243 L-977315

.248 L-974573

.254 L-972868

.256 L-974507

.258 L-972869

1/4 .260 L-972871

D L-972160 L-972200 L-972260 .261 L-973449

0.250

.262 L-973571

.264 L-973572

.267 -

.287 L-978175

9/32 .295 L-971312

E L-971232 L-978180 L-978181

0.281 .298 L-971436

.306 L-979643

.312 L-976938

36 .315 L-976538

.316 L-976539

4 Injection Check 5/16

.321

.326

L-976258

L-976605

Valve F 0.312 L-972170 L-972210 L-972270 .329 L-973937

(1-32) .332 L-976606

.335 L-973234

.337 L-976607

.341 L-980217

.366 -

3/8 .373 -

G L-972180 L-972220 L-972280

0.375 .376 L-970429

.384 L-978176

.399 L-970946

.404 -

.411 -

7/16 .416 -

.423 L-970571

H 0.438 L-972190 L-972230 L-972290

.425 L-970572

(7-42) .427 L-970573

.433 L-970106

.436 L-971639

Additional

Flotube 15/32 .467 L-972906

J 0.469 L-976291 L-976295 L-976292 .472 L-979388

and Injection (7-46) .477 L-979088

Coupling

Assembly

OPTION: LINE WIPER

L-971218

Part Number Wire Size

L-831210 3/16 wire

L-831200 7/32 wire

L-831220 5/16 wire

Ball Check Valve

Note: Parts included in line size kit (1). Seal Kit (O-Ring and BURs) does not include line size kit.

Copyright Varco International Inc, 2002 www.elmar.co.uk

You might also like

- Slickline Guide: Everything You Need to KnowDocument40 pagesSlickline Guide: Everything You Need to Knowwilliam MadingNo ratings yet

- Safety Management Plan TemplateDocument36 pagesSafety Management Plan TemplatengueadoumNo ratings yet

- 3 Ok-6 PDFDocument16 pages3 Ok-6 PDFYovaraj KarunakaranNo ratings yet

- Wireline PCE PDFDocument56 pagesWireline PCE PDFMuhammad ShahrukhNo ratings yet

- Baker D and DB Retainer Production Packers H43210 PDFDocument7 pagesBaker D and DB Retainer Production Packers H43210 PDFwasayrazaNo ratings yet

- AMSLA595 Manual Thresher 2019-12-11Document137 pagesAMSLA595 Manual Thresher 2019-12-11Fabio ParceroNo ratings yet

- PEANUT PROCESSING: A Profitable Small BusinessDocument8 pagesPEANUT PROCESSING: A Profitable Small BusinesskalaamolNo ratings yet

- PEANUT PROCESSING: A Profitable Small BusinessDocument8 pagesPEANUT PROCESSING: A Profitable Small BusinesskalaamolNo ratings yet

- Series 150 Overshots: Instruction Manual 1150Document25 pagesSeries 150 Overshots: Instruction Manual 1150Rares PetreNo ratings yet

- Minor Losses in Piping SystemsDocument19 pagesMinor Losses in Piping Systemsphanirajinish100% (1)

- Anc Storm ValveDocument9 pagesAnc Storm ValveCarlos Holguin100% (1)

- Soft Set B Hangers PDFDocument1 pageSoft Set B Hangers PDFazze bouzNo ratings yet

- FB2 Standing Valve Parts GuideDocument3 pagesFB2 Standing Valve Parts GuideLuis ChavarroNo ratings yet

- Cement Retainer Bridge Plug PDFDocument6 pagesCement Retainer Bridge Plug PDFcacalot93100% (1)

- ELMAR CatalogDocument62 pagesELMAR Catalogngueadoum93% (15)

- Enviro Dual Compact Pack-OffDocument1 pageEnviro Dual Compact Pack-Offngueadoum100% (1)

- Enviro Dual Compact Pack-OffDocument1 pageEnviro Dual Compact Pack-Offngueadoum100% (1)

- SABP-Q-010 Mix Design and Construction of Sulfur Extended Asphalt ConcreteDocument26 pagesSABP-Q-010 Mix Design and Construction of Sulfur Extended Asphalt ConcreteMr. Moses Imagoro100% (1)

- Cerberus WirelineDocument6 pagesCerberus Wirelinejavier100% (2)

- Esso Slickline SOPDocument16 pagesEsso Slickline SOPDonald TchiroueNo ratings yet

- Slickline 1 Intro.Document19 pagesSlickline 1 Intro.Slim.BNo ratings yet

- Design Overview: Basic Design and Maintenance InstructionsDocument5 pagesDesign Overview: Basic Design and Maintenance Instructionsazze bouzNo ratings yet

- CKE6150 Spare Parts ManualDocument74 pagesCKE6150 Spare Parts ManualVanessa RiveraNo ratings yet

- 6.37 Combi Bop ManualDocument23 pages6.37 Combi Bop ManualDEATH ASSASSIN GAMERNo ratings yet

- Section 3: Wellhead Control, Test and Injection UnitsDocument34 pagesSection 3: Wellhead Control, Test and Injection UnitsOvRrj Ahmed100% (3)

- Jarring IntroductionDocument8 pagesJarring IntroductionRafael NavasNo ratings yet

- MP16 PartsDocument22 pagesMP16 PartsJorge Ovando100% (1)

- Archer Modular TractorDocument2 pagesArcher Modular TractorYovaraj KarunakaranNo ratings yet

- Standing ValvesDocument12 pagesStanding ValvesAli AliNo ratings yet

- PCE - WL Spring JarDocument1 pagePCE - WL Spring JaryeriamaloNo ratings yet

- Liner Hanger Systems: C-2 Setting Sleeve and ExtensionDocument11 pagesLiner Hanger Systems: C-2 Setting Sleeve and ExtensionMohamed ElabbasyNo ratings yet

- Bolts - SlidesDocument133 pagesBolts - SlidesImran BabarNo ratings yet

- Universal Blowout Preventers: Instruction Manual 8520Document23 pagesUniversal Blowout Preventers: Instruction Manual 8520G100% (2)

- SV250V 600 Operations Manual V1.3Document22 pagesSV250V 600 Operations Manual V1.3Giorgiana Rosu0% (1)

- Guidelines for Safe Handling of LPG CylindersDocument4 pagesGuidelines for Safe Handling of LPG CylindersngueadoumNo ratings yet

- Project vs Fixed Term EmploymentDocument3 pagesProject vs Fixed Term EmploymentJechel TanNo ratings yet

- Evo-Trieve® EB0 Retrievable Straddle - HalliburtonDocument2 pagesEvo-Trieve® EB0 Retrievable Straddle - HalliburtonYovaraj KarunakaranNo ratings yet

- Man-10000527 7447362 02Document77 pagesMan-10000527 7447362 02Didik safdali100% (2)

- Slickline Care 3Document22 pagesSlickline Care 3Slim.B100% (3)

- 3in Elamr Drawing Illustration in One FileDocument43 pages3in Elamr Drawing Illustration in One FileusamakhattakNo ratings yet

- Weatherford Overshot - ReleasableDocument10 pagesWeatherford Overshot - ReleasableYovaraj KarunakaranNo ratings yet

- Technical Specification 3.5 CompletionDocument43 pagesTechnical Specification 3.5 Completionbasil ameenNo ratings yet

- Operations and Maintenance Manual Asep Elmar Hydraulic Wireline Tool Catcher AssemblyDocument54 pagesOperations and Maintenance Manual Asep Elmar Hydraulic Wireline Tool Catcher AssemblyAbhinav Kumar100% (1)

- Transportation of ConcreteDocument12 pagesTransportation of Concretesagar devidas khot100% (3)

- Kick Over ToolDocument2 pagesKick Over ToolEvan GonzalesNo ratings yet

- 5.DD9701971846 - Lub Assy 4.06 E12 LW 10K H2SDocument2 pages5.DD9701971846 - Lub Assy 4.06 E12 LW 10K H2SAbhinav KumarNo ratings yet

- PB Valve Brochure - 243Document11 pagesPB Valve Brochure - 243Nwakile Chukwuebuka100% (1)

- Casing Collar LocatorsDocument13 pagesCasing Collar LocatorshaudvNo ratings yet

- Posiset Ds PDFDocument2 pagesPosiset Ds PDFariosabzNo ratings yet

- 370 The Red Book - Basics of Foundation Design Fellenius 2017 PDFDocument468 pages370 The Red Book - Basics of Foundation Design Fellenius 2017 PDFTomasz Cz100% (1)

- Ubsurface Lickline Ools S S TDocument2 pagesUbsurface Lickline Ools S S Tbreynner100% (1)

- Enviro EquipmentDocument3 pagesEnviro Equipmentngueadoum100% (2)

- 013 Wireline Tool StringDocument1 page013 Wireline Tool StringSoon Han CheanNo ratings yet

- Hydraulic JarDocument2 pagesHydraulic JarDragonNo ratings yet

- WPCE Wireline Lubricator With Threaded Unions PDFDocument1 pageWPCE Wireline Lubricator With Threaded Unions PDFDidik safdaliNo ratings yet

- Kickover Tools KOT SeriesDocument6 pagesKickover Tools KOT SeriesfelipeNo ratings yet

- Kea Oilfield Engineering Pte LTDDocument9 pagesKea Oilfield Engineering Pte LTDFabio ParceroNo ratings yet

- 4.06in Tech Illustration (DRAWINGS)Document39 pages4.06in Tech Illustration (DRAWINGS)usamakhattakNo ratings yet

- PRS Series Pulling ToolDocument1 pagePRS Series Pulling Toolazze bouzNo ratings yet

- RB2 Standing Valve Parts and Sizes GuideDocument3 pagesRB2 Standing Valve Parts and Sizes GuideLuis ChavarroNo ratings yet

- Normal - Slickline ManualDocument3 pagesNormal - Slickline ManualKaystain Chris IhemeNo ratings yet

- Flyline DD Base Assy Parts ListDocument24 pagesFlyline DD Base Assy Parts ListhardevNo ratings yet

- C 2 Hipstock Ystems: HapterDocument16 pagesC 2 Hipstock Ystems: HapterRazvan Radu100% (1)

- 2024 - 13.375 TST-2 Service PackerDocument15 pages2024 - 13.375 TST-2 Service PackerDhenny FarialNo ratings yet

- WPCE Slickline Pressure Control Equipment String BDocument2 pagesWPCE Slickline Pressure Control Equipment String BRrelic100% (1)

- Hydraquaker: Hydraulic Drilling Jar Delivers High ImpactDocument4 pagesHydraquaker: Hydraulic Drilling Jar Delivers High ImpactPavin PiromNo ratings yet

- Cabeza de Inyeccion de GrasaDocument100 pagesCabeza de Inyeccion de GrasaPierre MejiaNo ratings yet

- Kuster K10 Gauge Software ManualDocument12 pagesKuster K10 Gauge Software Manualfarhad2004No ratings yet

- Am3K Combined Depth/Tension Measurement Device: With Differential Tension AmplifierDocument139 pagesAm3K Combined Depth/Tension Measurement Device: With Differential Tension AmplifiermarcioNo ratings yet

- Hydraulic Tubing PunchDocument19 pagesHydraulic Tubing Punchu2006262918No ratings yet

- Section 230 Coiled Tubing Lifting FramesDocument11 pagesSection 230 Coiled Tubing Lifting FramessadiNo ratings yet

- Ireline EquipmentDocument20 pagesIreline Equipmentsaid.swekNo ratings yet

- Gemini enDocument4 pagesGemini enImre VarnjuNo ratings yet

- Quotation For QT4-24 Block Machine-150423-GADocument3 pagesQuotation For QT4-24 Block Machine-150423-GAngueadoumNo ratings yet

- Service Textile Machinery and Equipment: Skstex24 - SQA Unit Code H9ER 04Document5 pagesService Textile Machinery and Equipment: Skstex24 - SQA Unit Code H9ER 04ngueadoumNo ratings yet

- Reforming Chad's Cotton SectorDocument5 pagesReforming Chad's Cotton SectorngueadoumNo ratings yet

- g7 FinalDocument101 pagesg7 FinalngueadoumNo ratings yet

- g7 FinalDocument101 pagesg7 FinalngueadoumNo ratings yet

- Lube Oil System Inspection ChecklistDocument1 pageLube Oil System Inspection ChecklistngueadoumNo ratings yet

- g7 FinalDocument101 pagesg7 FinalngueadoumNo ratings yet

- 1 FiverrNightclub Business Plan PDFDocument10 pages1 FiverrNightclub Business Plan PDFngueadoumNo ratings yet

- A Guide Book On Backhaul DesignDocument6 pagesA Guide Book On Backhaul Designkushwaha01No ratings yet

- Agro BusinessDocument28 pagesAgro BusinessngueadoumNo ratings yet

- Printing ModelDocument3 pagesPrinting ModelngueadoumNo ratings yet

- Youth in Agribusiness Within An African Agricultural Transformation AgendaDocument28 pagesYouth in Agribusiness Within An African Agricultural Transformation AgendangueadoumNo ratings yet

- Resume E-Guide 2012 0Document37 pagesResume E-Guide 2012 0ngueadoumNo ratings yet

- The Red Eye Differential DiagnosisDocument22 pagesThe Red Eye Differential DiagnosisngueadoumNo ratings yet

- Resume E-Guide 2012 0Document37 pagesResume E-Guide 2012 0ngueadoumNo ratings yet

- Print ImageDocument1 pagePrint ImagengueadoumNo ratings yet

- AutoCAD 2010 FRDocument2,188 pagesAutoCAD 2010 FRSamir KhNo ratings yet

- Employment Application WirelineDocument2 pagesEmployment Application WirelinengueadoumNo ratings yet

- Autocad - Guide de Personal Is at IonDocument644 pagesAutocad - Guide de Personal Is at Ionyan11122000No ratings yet

- Guide D 'InstallationDocument68 pagesGuide D 'InstallationngueadoumNo ratings yet

- Ritter Solar GMBH & Co. KGDocument30 pagesRitter Solar GMBH & Co. KGMagdyNo ratings yet

- Design of Machine Elements for Fluctuating Load Stress ConcentrationDocument76 pagesDesign of Machine Elements for Fluctuating Load Stress ConcentrationPraveenNo ratings yet

- Ontario Aggregate Standard Specification GuideDocument15 pagesOntario Aggregate Standard Specification GuideJonathan Enrique Canales SanchezNo ratings yet

- PMBI WorkflowDocument3 pagesPMBI WorkflowBrian MigueNo ratings yet

- Visco Crete For UHPCDocument3 pagesVisco Crete For UHPCKarnalPreethNo ratings yet

- Form 1 - Architect's CertificationDocument4 pagesForm 1 - Architect's CertificationAkshata Patil ParvatikarNo ratings yet

- Assignment-2 Shear StrengthDocument3 pagesAssignment-2 Shear StrengthRabindraSubediNo ratings yet

- GC Guy Wire (US) Catalog Sheet FinalDocument1 pageGC Guy Wire (US) Catalog Sheet FinalAde 'aiyie' SasmitaNo ratings yet

- Do CSG 25 Sep 2023Document3 pagesDo CSG 25 Sep 2023cahbagus1267No ratings yet

- Sheikh Abdullah Al Salem Cultural Centre Case StudyDocument7 pagesSheikh Abdullah Al Salem Cultural Centre Case StudyAnudeep ChandraNo ratings yet

- Wright State Statics Final Exam SolutionsDocument5 pagesWright State Statics Final Exam Solutionsandi suntoroNo ratings yet

- QFD ThesisDocument90 pagesQFD ThesisIrshad AliNo ratings yet

- SECTION 16110 Residential Wiring Connections, Rev 0Document12 pagesSECTION 16110 Residential Wiring Connections, Rev 0Ahmed HashimNo ratings yet

- CONSEAL 300 Pure Bitumen WaterproofingDocument2 pagesCONSEAL 300 Pure Bitumen WaterproofingGodwin IwekaNo ratings yet

- FLOW CONTROL VALVESDocument6 pagesFLOW CONTROL VALVESkulkarni278No ratings yet

- Application: Heat-Shrinkable Three Core Xlpe Straight Joint Up To 36 KVDocument2 pagesApplication: Heat-Shrinkable Three Core Xlpe Straight Joint Up To 36 KVHồ ThànhNo ratings yet

- 19G412-1180-E2 Parts ListDocument31 pages19G412-1180-E2 Parts ListNeilNo ratings yet

- Full Thesis PDFDocument215 pagesFull Thesis PDFArzath SajeerNo ratings yet

- Detail Ground TankDocument1 pageDetail Ground TankRully SaputraNo ratings yet

- SHU Complete Troubleshooting GuideDocument282 pagesSHU Complete Troubleshooting GuideSteven L. Johnson100% (1)

- Handle InstallationDocument36 pagesHandle InstallationNoz KiNo ratings yet

- Review of Maximum Punching Capacity of Slabs Reinforced With ShearailDocument23 pagesReview of Maximum Punching Capacity of Slabs Reinforced With ShearailMatthew WoodNo ratings yet

- DRCS Cover - To Author PDFDocument1 pageDRCS Cover - To Author PDFAJAY SHINDENo ratings yet