Professional Documents

Culture Documents

5S Audit Scorecard: Organizing for Safety and Productivity

Uploaded by

TarunaiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5S Audit Scorecard: Organizing for Safety and Productivity

Uploaded by

TarunaiCopyright:

Available Formats

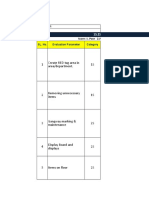

5S AUDIT SCORECARD

Date Area Audit by

Date of Last Audit Score of Last Audit

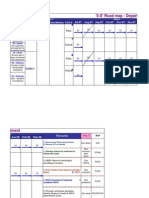

AUDIT SCORE

SORT SET IN ORDER SHINE STANDARDIZE SUSTAIN TOTAL

TOTAL SCORE (A)

# OF QUESTIONS (B) 6 11 10 7 5 39

AVERAGE SCORE (C)

To determine score, add score of all questions in each category and write that number in the Total Score field below each category (A). Divide this number by the

Number of Questions in the category (B) and you will get the Average score of each category (C). Add the numbers from each category together and you will find the

Total Score and finally, the Total Average Score, which should be used as the final score for this Audit.

QUESTIONS

SORT

Eliminate all the things in the workspace that are not being used and store them away.

SCORE

Only the required EQUIPMENT is present in the area. All obsolete, broken or unnecessary equipment not

1 required for current projects are removed from the area or red tagged for removal.

Only the required TOOLS are present in the area. Tools not required for current projects are removed from

2 the area or red tagged for removal.

Only the required FURNITURE is present in the area. All obsolete, broken or unnecessary workbenches,

3 shelves, chairs, lockers, etc. not required for current projects are removed from the area or red tagged for

removal.

Only the required SPARE PARTS and MATERIALS are present in the area. Items not required for current

4 projects are removed from the area or red tagged for removal.

Only the required PAPERWORK is present in the area. Outdated or unnecessary memos, instructions,

5 reports, posters, etc. are removed from the area.

All TRIPPING HAZARDS such as electrical wires and equipment cables are removed from all working,

6 standing, and walking areas.

SORT TOTAL SCORE

Page 1/4 www.creativesafetysupply.com

SET IN ORDER

Arrange the items used on a daily basis so that they can be easily accessed and quickly stored.

SCORE

EQUIPMENT/MACHINERY is clearly identified (numbered, named, color coded, etc.) and placed in a

1 properly identified location. Critical maintenance points are clearly marked.

TOOLS have a designated storage area that is within reach of the user/operator. The location is properly

2 labeled and a system is in place to identify tools that are absent (shadowboard, etc.).

When applicable, FURNITURE is clearly identified (numbered, named, color coded, etc.) and placed in a

3 properly identified location.

Locations for CONTAINERS, WIPs, BOXES, BINS, etc. are clearly defined via signs or marked/taped lines

4 and properly labeled.

5 PAPERWORK is properly labeled and has a clearly identified location that is away from work surfaces.

Work areas requiring PERSONAL PROTECTIVE EQUIPMENT (PPE) are clearly marked (floor tape, safety

6 signs/labels, etc.)

7 STOP SWITCHES AND BREAKERS are highly visible and located for easy access in case of emergency.

FIRE HOSES, FIRE EXTINGUISHERS and other emergency equipment are prominently displayed and are

8 unobstructed.

FLOORS/AISLES are clearly marked; forklift lanes, exits, dangerous areas, paths of egress, walkways, aisles,

9 etc. are all marked with visible lines (floor tape/floor paint).

Working conditions are ERGONOMICALLY FRIENDLY- Tools and other items needed for daily work are

10 stored at appropriate heights, anti-fatigue mats are in place where applicable, related safety signage is

displayed clearly, etc.

The workplace layout accommodates EASY UNOBSTRUCTED EXIT in case of emergency. The emergency

11 exit route is posted in a conspicuous location for all to see.

SET IN ORDER TOTAL SCORE

SHINE

Everything is cleaned and functioning properly.

SCORE

All TOOLS are kept clean and in good working order. When possible, tools are stored in a manner to keep

1 them clean and free from risk of damage.

WORK SURFACES (Machines, workbenches, dies, and other equipment including electrical boxes) are kept

2 clean and painted.

3 WALLS, PARTITIONS, RAILS, ETC. are kept clean and painted.

FLOORS are free from dirt, debris, oil, parts, hardware, empty boxes, etc. and all drains (if applicable) are

4 clear of debris and clogs.

CONTINUED ON NEXT PAGE

Page 2/4 www.creativesafetysupply.com

SHINE (cont.)

Everything is cleaned and functioning properly.

SCORE

5 PAPERWORK is not torn, and is kept clean and protected from dirt and other contaminants.

CONTAINERS, BOXES, BINS, ETC. are clean and not cracked, torn, or otherwise damaged. When stored,

6 they are neatly stacked in their correct location.

All PERSONAL PROTECTIVE EQUIPMENT (PPE) is maintained in a sanitary and reliable condition and is

7 properly stored in an easily accessible and labeled location when not in use.

8 All CLEANING EQUIPMENT is neatly stored and is readily available when needed.

All EQUIPMENT SAFETY-related warnings, signs, labels, floor lines, etc. are all clean, easy to read, not torn

9 or damaged, and provide adequate protection.

There is a posted SCHEDULE showing times, frequency, and responsibilities to clean areas of the work-

10 place such as windows, corners, walls, doors, tops of cabinets, etc.

SHINE TOTAL SCORE

STANDARDIZE

Develop a routine for sorting, setting, and shining.

SCORE

TOOLS, EQUIPMENT, PAPERWORK, FURNITURE, ETC is stored neatly in designated areas and are returned

1 to their proper homes immediately after use.

2 Equipment MAINTENANCE RECORDS are visible and clearly state when maintenance last occurred.

PRODUCT WASTE (shavings, containers, liquids, wrappers, etc.) is consistently and regularly cleaned up

3 and removed from the workplace.

PREVENTATIVE MEASURES have been implemented to ensure the workplace meets 5S guidelines (e.g.

4 systems that do not allow waste to accumulate such as containers to collect product debris from

machines)

The WORK ENVIRONMENT satisfies the requirements of the work being performed- Lighting brightness

5 and color, temperature, air flow and quality, etc.

6 The RESULTS OF THE PREVIOUS AUDIT are posted and clearly visible for the entire team.

7 AREAS FOR IMPROVEMENT identified during the previous audit have been addressed and completed.

STANDARDIZE TOTAL SCORE

Page 3/4 www.creativesafetysupply.com

SUSTAIN

Create a culture that follows the steps of 5S on a daily basis.

SCORE

A member of MANAGEMENT has participated in a 5S activity such as an audit or other activity within the

1 past 3 audit periods.

2 RECOGNITION is given to teams who get involved in 5S activities.

TIME AND RESOURCES are allocated to 5S activities (e.g. designated daily/weekly clean-up time, 5S Team

3 Leader).

All operators, team leaders, supervisors, etc. are assigned 5S ACTIVITIES to be completed at least once a

4 week.

The team took the INITIATIVE to make improvements to the workplace that were NOT identified during

5 the last audit.

SUSTAIN TOTAL SCORE

NOTES

a)

b)

c)

d)

e)

f)

Questions? Looking for 5S tools? Call us today: (866) 777-1360 or visit www.creativesafetysupply.com

Page 4/4 www.creativesafetysupply.com

You might also like

- 1S2S3S - Check SheetDocument1 page1S2S3S - Check SheetManoj KaushikNo ratings yet

- 5S Evaluation SheetDocument8 pages5S Evaluation SheetNashwa SaadNo ratings yet

- 5S Audit ChecklistDocument4 pages5S Audit ChecklistAjay Krishnan100% (3)

- 5S Guidelines, Checklist, Rules & ResponsibilityDocument14 pages5S Guidelines, Checklist, Rules & ResponsibilityNurin Afzani Makrai71% (7)

- 5S Audit Checklist Documents Standardization and Continuous ImprovementDocument10 pages5S Audit Checklist Documents Standardization and Continuous ImprovementJamal AbdullahNo ratings yet

- 5S Audit ChecklistDocument12 pages5S Audit Checklistmogul_hunkNo ratings yet

- 5s Audit Check ListDocument2 pages5s Audit Check Listravi.rimc3869100% (2)

- BF Area - 5S Check ListDocument30 pagesBF Area - 5S Check ListVi KraNo ratings yet

- 6s AuditchecklistDocument14 pages6s Auditchecklisthasan_waqar20040% (1)

- 5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityFrom Everand5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityRating: 5 out of 5 stars5/5 (3)

- 5S Audit FormDocument1 page5S Audit FormViorel IosubNo ratings yet

- 5S Audit SheetDocument3 pages5S Audit Sheetleansensei67% (3)

- 5S - Levels of ExcellenceDocument2 pages5S - Levels of ExcellenceHartoyo SwiNo ratings yet

- 5S audit sheet optimizationDocument1 page5S audit sheet optimizationManoj ShahNo ratings yet

- 6S (5S+1) Audit Check Sheet AdaptiveBMSDocument4 pages6S (5S+1) Audit Check Sheet AdaptiveBMSAndrugrasu GrasuNo ratings yet

- 5S Monthly Audit ChecklistDocument6 pages5S Monthly Audit ChecklistZahid Hussain50% (2)

- 5S/TPM Meeting Summary and Audit ToolsDocument5 pages5S/TPM Meeting Summary and Audit ToolsChatnoir NoirNo ratings yet

- 5S Audit Checklist - ShopfloorDocument6 pages5S Audit Checklist - Shopfloortony s0% (1)

- 5s CSRDocument69 pages5s CSRFadzilahMohamadNo ratings yet

- 5S ManualDocument23 pages5S ManualBittuNo ratings yet

- 5S Levels of ExcellenceDocument2 pages5S Levels of ExcellenceAshokNo ratings yet

- 5S Audit SheetDocument3 pages5S Audit SheetMohamed SalaheldinNo ratings yet

- 5S Implementation Plan at Work PlaceDocument18 pages5S Implementation Plan at Work PlacemanishlmehtaNo ratings yet

- FLOOR MARKING GUIDE FOR SAFETY AND ORGANIZATIONDocument5 pagesFLOOR MARKING GUIDE FOR SAFETY AND ORGANIZATIONBaalaji RajanNo ratings yet

- QE (5S) Responsibilities and RolesDocument3 pagesQE (5S) Responsibilities and RolesAdie Caberte0% (1)

- 5S Checklist OkDocument2 pages5S Checklist Okmichelle ann100% (1)

- 5S Implementation Master Plan SummaryDocument2 pages5S Implementation Master Plan SummaryMayur12345dt80% (5)

- UNI-DIL 5S REVAMP MASTER PLANDocument1 pageUNI-DIL 5S REVAMP MASTER PLANDayal Weerasooriya100% (4)

- 5S Red Tag RegisterDocument4 pages5S Red Tag Register87KippenbergerNo ratings yet

- 5s Training Slides 432Document60 pages5s Training Slides 432vg_raj100% (3)

- 5S Audit FormDocument2 pages5S Audit Formsigmasundar100% (1)

- 5'S ManualDocument44 pages5'S ManualSayan KonarNo ratings yet

- 5S Shop Floor Audit ChecklistDocument2 pages5S Shop Floor Audit ChecklistAbhishekNo ratings yet

- 5S Audit TemplateDocument1 page5S Audit Templateashblack160No ratings yet

- 1st Team Leader Standard WorkDocument1 page1st Team Leader Standard Workwayneseal1No ratings yet

- 5S TrainingDocument81 pages5S Trainingamresh kumar tiwari100% (1)

- 5S Implementation Plan at Work PlaceDocument18 pages5S Implementation Plan at Work Placebrock100% (24)

- Guide 5SDocument33 pagesGuide 5SGUILLERMO VAZQUEZNo ratings yet

- 5S Training OfficeDocument21 pages5S Training OfficeDhiraj Pradhan100% (1)

- 5 S Presentation Basic TrainingDocument82 pages5 S Presentation Basic TrainingEmman Bosito100% (1)

- 5S ImplementationDocument35 pages5S ImplementationPrateek Gupta100% (1)

- 5S Audit Checklist and Report PDFDocument2 pages5S Audit Checklist and Report PDFshahiraNo ratings yet

- Lean 5s ChecklistDocument1 pageLean 5s ChecklistLean Training100% (8)

- 5S Audit FormDocument2 pages5S Audit Formmounirs719883No ratings yet

- Office 5S ChecklistDocument15 pagesOffice 5S ChecklistAkhilesh Yadav100% (1)

- Optimized 5S Office AuditDocument2 pagesOptimized 5S Office AuditWaqar DarNo ratings yet

- Red Tag Item Information FormDocument1 pageRed Tag Item Information FormcomyahoothanhNo ratings yet

- Kaizen Structure Rev0Document86 pagesKaizen Structure Rev0hiattolaNo ratings yet

- 5 S & Lean 6 SigmaDocument16 pages5 S & Lean 6 SigmaAkshay KumarNo ratings yet

- 6S Audit Draft)Document3 pages6S Audit Draft)pikeman666100% (3)

- Presentation 6 S STARTER TrainingDocument96 pagesPresentation 6 S STARTER Trainingm_ramas2001No ratings yet

- 5S For OfficesDocument3 pages5S For OfficesckopoletoNo ratings yet

- 5S Audit Report - V3Document1 page5S Audit Report - V3Rachmat Boerhan100% (1)

- 5SDocument67 pages5SAnonymous Ln4luWFd100% (3)

- 5 Saud It ChecklistDocument5 pages5 Saud It Checklistclara_cahuaNo ratings yet

- 5S Audit Checklist: Sort Set in Order Shine Standardize Sustain Total Total Score No. of Questions Average ScoreDocument4 pages5S Audit Checklist: Sort Set in Order Shine Standardize Sustain Total Total Score No. of Questions Average ScoreCaroline Eliza MendesNo ratings yet

- 5S Audit Checklist: Sort Set in Order Shine Standardize Sustain Total Total Score No. of Questions Average ScoreDocument4 pages5S Audit Checklist: Sort Set in Order Shine Standardize Sustain Total Total Score No. of Questions Average ScoreJamsari SulaimanNo ratings yet

- 5s AuditchecklistDocument8 pages5s AuditchecklistDINESH SHARMANo ratings yet

- 5S Audit Checklist - SafetyCultureDocument8 pages5S Audit Checklist - SafetyCultureKen CruzNo ratings yet

- Colours Name List PDFDocument4 pagesColours Name List PDFTarunaiNo ratings yet

- Transitioning To Iatf 16949 Whitepaper - Aiag PDFDocument16 pagesTransitioning To Iatf 16949 Whitepaper - Aiag PDFFernando Cruz Cortes100% (1)

- 1s To 5s Audit Sheet MarathiDocument2 pages1s To 5s Audit Sheet MarathiTarunai100% (7)

- Suchana WorkerDocument2 pagesSuchana WorkerTarunaiNo ratings yet

- ISO/TS 16949 and VDA 6.1 Quality Standard ComparisonDocument22 pagesISO/TS 16949 and VDA 6.1 Quality Standard ComparisonTarunaiNo ratings yet

- Iso 9001 2015Document4 pagesIso 9001 2015TarunaiNo ratings yet

- Iso 9001-2015 - How To Use ItDocument12 pagesIso 9001-2015 - How To Use Itdavid100% (1)

- Formats & Lists - PageDocument6 pagesFormats & Lists - PageTarunaiNo ratings yet

- Basics of green sand testingDocument5 pagesBasics of green sand testingTarunaiNo ratings yet

- SPC PDFDocument17 pagesSPC PDFTarunaiNo ratings yet

- Iso 14000Document171 pagesIso 14000moha23No ratings yet

- Guide To Statistical Process Control TechniquesDocument45 pagesGuide To Statistical Process Control TechniquesAnonymous FFMmIJyNo ratings yet

- Transisi Iso 2001 TH 2008 Ke 2015 PDFDocument32 pagesTransisi Iso 2001 TH 2008 Ke 2015 PDFsellen34No ratings yet

- The Book of SPC Complimentary EbookDocument208 pagesThe Book of SPC Complimentary EbookTarunaiNo ratings yet

- SPC PDFDocument17 pagesSPC PDFTarunaiNo ratings yet

- Check List Sample by RameshDocument4 pagesCheck List Sample by RameshTarunaiNo ratings yet

- Validation Part 3: Process Validation: Supplementary Training Modules On Good Manufacturing PracticesDocument22 pagesValidation Part 3: Process Validation: Supplementary Training Modules On Good Manufacturing PracticesTarunaiNo ratings yet

- ISO/TS 16949 and VDA 6.1 Quality Standard ComparisonDocument22 pagesISO/TS 16949 and VDA 6.1 Quality Standard ComparisonTarunaiNo ratings yet

- Validation Part 3: Process Validation: Supplementary Training Modules On Good Manufacturing PracticesDocument22 pagesValidation Part 3: Process Validation: Supplementary Training Modules On Good Manufacturing PracticesTarunaiNo ratings yet

- Marathi OkrutDocument1 pageMarathi OkrutTarunaiNo ratings yet

- 10 Self Improvement Activities to Achieve a Better LifeDocument6 pages10 Self Improvement Activities to Achieve a Better LifeTarunaiNo ratings yet

- VLDocument5 pagesVLTarunaiNo ratings yet

- Math8 Q1 Module8of8 SolvingRationalALgebraicEquationsIn2Variables v2Document24 pagesMath8 Q1 Module8of8 SolvingRationalALgebraicEquationsIn2Variables v2Jumar MonteroNo ratings yet

- DEA462F - EntelliGuard G Circuit Breakers - Lo-ResDocument8 pagesDEA462F - EntelliGuard G Circuit Breakers - Lo-Resyasser foudaNo ratings yet

- Build Ubuntu for Ultra-96 FPGA DevelopmentDocument5 pagesBuild Ubuntu for Ultra-96 FPGA Developmentksajj0% (1)

- Solution Manual Contemporary Issues in Accounting 1st Edition by Michaela Rankin slw1027 PDF FreeDocument46 pagesSolution Manual Contemporary Issues in Accounting 1st Edition by Michaela Rankin slw1027 PDF Free--bolabola100% (1)

- Jurnal BE ValsartanDocument10 pagesJurnal BE ValsartanFutisya AlvitaNo ratings yet

- Mike-Rose - The-Language-of-Exclusion (Edited)Document20 pagesMike-Rose - The-Language-of-Exclusion (Edited)abankiNo ratings yet

- Operation: ManualDocument43 pagesOperation: Manualsolmolina20100% (1)

- Datasheet - LNB PLL Njs8486!87!88Document10 pagesDatasheet - LNB PLL Njs8486!87!88Aziz SurantoNo ratings yet

- 4Ps of Marketing Among Selected Resorts in Cabanatuan CityDocument5 pages4Ps of Marketing Among Selected Resorts in Cabanatuan CityKomal sharmaNo ratings yet

- Comparing and Contrasting in EnglishDocument3 pagesComparing and Contrasting in EnglishZita JeremiásNo ratings yet

- Dogtooth Film ReviewDocument6 pagesDogtooth Film ReviewAstrid JohnsonNo ratings yet

- CA2005 User Manual 1.3-Custom-FDocument34 pagesCA2005 User Manual 1.3-Custom-FDinesh SreedharanNo ratings yet

- KVH TracPhone V7-HTS - Installation ManualDocument59 pagesKVH TracPhone V7-HTS - Installation ManualMarcelo RANo ratings yet

- INDUSTRIAL VISIT TO ESCORTS TRACTOR ASSEMBLYDocument5 pagesINDUSTRIAL VISIT TO ESCORTS TRACTOR ASSEMBLYShane Khan50% (2)

- 004.7 - VCE150 Session 7 Cabin LiftDocument24 pages004.7 - VCE150 Session 7 Cabin LiftMahmoud Elpop ElsalhNo ratings yet

- Laterricaedwards Teacher ResumeDocument3 pagesLaterricaedwards Teacher Resumeapi-627213926No ratings yet

- BS 812-110-1990 Testing AggregatesDocument12 pagesBS 812-110-1990 Testing Aggregatesbatara2007No ratings yet

- Origin and Meaninng of Little P in PH PDFDocument2 pagesOrigin and Meaninng of Little P in PH PDFlNo ratings yet

- Latifa's Thesis PDFDocument182 pagesLatifa's Thesis PDFنذير امحمديNo ratings yet

- Rt380T 230/400 PCB Rohs: Analog Three-Phase Thyristor Trigger ModuleDocument3 pagesRt380T 230/400 PCB Rohs: Analog Three-Phase Thyristor Trigger ModuleFelipe CasasNo ratings yet

- Lion Dam Gate Seals - INTLDocument3 pagesLion Dam Gate Seals - INTLIoannis SanoudosNo ratings yet

- PBS 1.1 Quiz Review (Sickels) 23Document158 pagesPBS 1.1 Quiz Review (Sickels) 23tyson.bergsrudNo ratings yet

- PBL62 1 30M3Document1 pagePBL62 1 30M3Hai Tran HongNo ratings yet

- Nmsgcbok 440Document1 pageNmsgcbok 440Xk CNo ratings yet

- Factors Affecting Reading at Elsie Lund SchoolDocument3 pagesFactors Affecting Reading at Elsie Lund SchoolLouise Mikylla LimNo ratings yet

- Dynamic Analysis of Loads and Stresses in Connecting RodsDocument10 pagesDynamic Analysis of Loads and Stresses in Connecting RodsJuan Pablo Cano MejiaNo ratings yet

- Resilience Advantage Guidebook HMLLC2014Document32 pagesResilience Advantage Guidebook HMLLC2014Alfred Schweizer100% (3)

- Draft User Manual MISDocument306 pagesDraft User Manual MISkhajuriaonlineNo ratings yet

- W3 Deep FoundationDocument42 pagesW3 Deep FoundationTeoh Zhi TongNo ratings yet

- QuestionsDocument10 pagesQuestionsmfoNo ratings yet