Professional Documents

Culture Documents

Sealbond 218 P Pressure Injection Epoxy

Uploaded by

Leoven Jef Suzara Lorin0%(1)0% found this document useful (1 vote)

468 views1 pageseal bond ito

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentseal bond ito

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0%(1)0% found this document useful (1 vote)

468 views1 pageSealbond 218 P Pressure Injection Epoxy

Uploaded by

Leoven Jef Suzara Lorinseal bond ito

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

PRODUCT DATA - Structural Epoxy Adhesives

SEALBOND 218-P

PRESSURE INJECTION EPOXY

SEALBOND PRESSURE INJECTION EPOXY (218P) is a two component adhesive system composed of 100%

solids Epoxy that contains polyamide curing agent ensuring a tough and durable bond resistant to chemicals and

corrosion. This unique low viscosity adhesive is primarily designed for the all around remedy of structural concrete

defects and flaws particularly the repair of cracks by pressure injection. Aside from sealing cracks and crevices and

filling voids, it can also be combined with fine aggregates or silica sand to result in an Epoxy Mortar for high strength

grouting.

APPLICATION MIXING AND CLEANING

PRESSURE INJECTION: Blow compressed air along the crack MIXING: Mix thoroughly by volume 2 parts of

lines to completely clean, dry and remove dirt and other loose resin to 1 part of hardener for 3 to 4 minutes.

contaminating materials. Provide temporary seal on crack surface Any changes from the recommended

except entry and exit ports. Inject Sealbond 218-P starting at the proportion will affect its quality. Scrape the

lowest entry port up to the proceeding ports until the voids are bottoms, sides and corners of the container to

completely filled. ensure complete and full blending. Prepare

EPOXY GROUTING V-CUT SYSTEM: V-cut all cracks for repair. only enough quantities that can be used within

Blow compressed air along the crack lines to completely clean, the pot-life period. Do not delay application.

dry and remove dirt and other loose contaminating materials. CLEAN-UP: Pressure injection tools and other

Apply by brush pure Sealbond Epoxy 218-P to serve as primer equipment maybe cleaned with Sealbond

then apply Sealbond Epoxy 218-P mixed with silica sand or Epoxy Reducer while the mixture has not yet

patching compound on v-cut surface. hardened. Wash off hands with detergent and

EPOXY GROUTING ON CONCRETE HONEYCOMB: warm water.

Chip off loose concrete. Remove dust, dirt and other loose CAUTION: Avoid contact with eyes and skin

contaminating materials. Install formworks on honeycomb and avoid breathing its vapor. This product

providing for a small opening on the upper portion. Pour may cause severe skin irritation after prolonged

Sealbond Epoxy 218-P mixed with silica sand. Remove or repeated exposure. Keep containers tightly

formworks upon curing of epoxy grout. closed and store in a cool dry place.

PHYSICAL PROPERTIES & CHEMICAL PROPERTIES

Packaging Gallon kit

Mix Ratio Two (2) parts resin base to one (1) part hardener by volume

Color Component A Light Straw

Component B Amber

Pot Life 1-2 hours @ 25C (admixture)

Tack Free Time 4 hours @ 25C

Full Cure Time 24 hours @ 25C; 72 hours load pressure

Shelf Life Minimum of 12 months under normal condition (80F)

Shrinkage Negligible

Compressive Strength Minimum: 8,000 11,000 psi

(ASTM C109-95/D695) @ 7 days full curing Maximum: 11,000 12,000 psi

Tensile Strength 3,000 5,000 psi (ASTM D638-91) @ 7 days full curing

Flexural Strength 6,000 9,000 psi (ASTM D790-92) @ 7 days full curing

Bond Strength (Slant Shear Test) 3,000 5,000 psi (ASTM C882-99) @ 7 days full curing

Hardness (ASTM D2240) 80 Shore D

Resistance to Chemical Resistant to most organic solvents, mild acids and alkalis

% Solids by volume 100%

........Technical Solutions for Structural Concrete Repair

You might also like

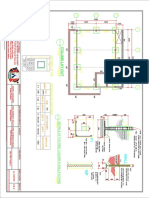

- General notes and dimension detailingDocument1 pageGeneral notes and dimension detailingMuhammad SulaimanNo ratings yet

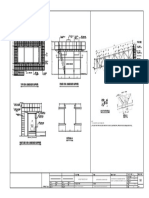

- Foundation reinforcement detailsDocument1 pageFoundation reinforcement detailsArnulfo Jose Pi DiNo ratings yet

- Rocla RKO Pits BrochureDocument4 pagesRocla RKO Pits Brochurechillerz69No ratings yet

- Technological University of The PhilippinesDocument50 pagesTechnological University of The PhilippinesBillie Ian. Salamante JrNo ratings yet

- Architectural and Floor Plan With Details For Buildings PDFDocument1 pageArchitectural and Floor Plan With Details For Buildings PDFWilbert ReuyanNo ratings yet

- Footing Tie Beam Schedule (F'C 27.56 Mpa)Document1 pageFooting Tie Beam Schedule (F'C 27.56 Mpa)Joshua VacaroNo ratings yet

- Roof deck plumbing layoutsDocument1 pageRoof deck plumbing layoutsLalisa MNo ratings yet

- Natipuan MPBDocument10 pagesNatipuan MPBinhisimage01No ratings yet

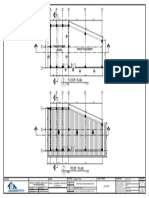

- SCHEDULE of Roof BeamDocument1 pageSCHEDULE of Roof BeamJoseph Cloyd LamberteNo ratings yet

- 3 Storey BuildingDocument4 pages3 Storey BuildingManuelito ZapataNo ratings yet

- Design Analysis SummaryDocument47 pagesDesign Analysis SummaryRolly Marc G. SoteloNo ratings yet

- 4ar8 STDDocument4 pages4ar8 STDJAVIN CALUYANo ratings yet

- ComputationDocument2 pagesComputationrmrv valdez100% (1)

- C-Purlins Spaced at 600mm O.CDocument1 pageC-Purlins Spaced at 600mm O.Calezandro del rossiNo ratings yet

- 05 B Bar ChartDocument2 pages05 B Bar ChartsandeeprainaNo ratings yet

- Roof Framing Plan - Low CostDocument1 pageRoof Framing Plan - Low CostJeremy BuelbaNo ratings yet

- Two Storey Residence Foundation and Floor PlansDocument1 pageTwo Storey Residence Foundation and Floor PlansNina Angelica FianzaNo ratings yet

- Bedroom 2 Bedroom 1: Ground Floor Mechanical LayoutDocument4 pagesBedroom 2 Bedroom 1: Ground Floor Mechanical LayoutO. QuiritNo ratings yet

- Location: M. H. Del Pilar Street, Polillo, Quezon Project Owner: Mrs. Necerina T. AzagraDocument11 pagesLocation: M. H. Del Pilar Street, Polillo, Quezon Project Owner: Mrs. Necerina T. Azagramy dlNo ratings yet

- Staircase DrawingDocument1 pageStaircase Drawingsrinivas pNo ratings yet

- Ilide - Info 361741524 Sample Structural Analysis and Design Criteria PRDocument5 pagesIlide - Info 361741524 Sample Structural Analysis and Design Criteria PRRobert V. AbrasaldoNo ratings yet

- Roof Framing Plan PasamanoDocument1 pageRoof Framing Plan PasamanojdvalmontNo ratings yet

- Perimeter FenceDocument1 pagePerimeter FenceKenneth RagosNo ratings yet

- Architect'S Perspective: Republic of The PhilippinesDocument1 pageArchitect'S Perspective: Republic of The PhilippinesAlexxis LipuraNo ratings yet

- Price List - Royu Electrical July 2021 IssueDocument16 pagesPrice List - Royu Electrical July 2021 IssueArphy Renz Gavina MenesesNo ratings yet

- Metal WorksDocument4 pagesMetal WorksKhristine Lerie PascualNo ratings yet

- Footing Detail: Along WidthDocument1 pageFooting Detail: Along WidthRRCDC JEEFRYNo ratings yet

- Top View (Condenser Support) Front View (Condenser Support) : T1 DetailsDocument1 pageTop View (Condenser Support) Front View (Condenser Support) : T1 DetailsJan GarciaNo ratings yet

- Dee - E1Document1 pageDee - E1Rycca DeeNo ratings yet

- Structural plans for building right wing roofDocument1 pageStructural plans for building right wing roofArjelyNo ratings yet

- Longitudinal Section: Ceiling LineDocument1 pageLongitudinal Section: Ceiling LineMJian VergaraNo ratings yet

- Details of Wall Footing: Proposed Two-Storey Residential Mr. & Mrs. Julius Cesar ClaravallDocument1 pageDetails of Wall Footing: Proposed Two-Storey Residential Mr. & Mrs. Julius Cesar ClaravallChester AtienzaNo ratings yet

- Rainwater and Domestic Water Storage Tank DetailsDocument1 pageRainwater and Domestic Water Storage Tank DetailsGarduque AngreysNo ratings yet

- C-PURLINS 75MM X 50MM X 1.2 THK SPACED @ 600MMDocument1 pageC-PURLINS 75MM X 50MM X 1.2 THK SPACED @ 600MMalezandro del rossiNo ratings yet

- MERS Goodwill - EurekaDocument1 pageMERS Goodwill - EurekaLindsay TolerNo ratings yet

- Improvement of The Building (Provincial Counterpart To PRDP)Document14 pagesImprovement of The Building (Provincial Counterpart To PRDP)Nikka FerrerNo ratings yet

- Rule 1240 Power Piping LinesDocument3 pagesRule 1240 Power Piping LinesGemiah SubistaNo ratings yet

- Front Elevation Rear Elevation: SCALE 1:100 SCALE 1:100Document1 pageFront Elevation Rear Elevation: SCALE 1:100 SCALE 1:100Sasheen Dela CruzNo ratings yet

- Schedule of columns and footingsDocument1 pageSchedule of columns and footingsJude TicseNo ratings yet

- 2 Storey StructuralDocument14 pages2 Storey StructuralOL RACNo ratings yet

- Column Detailed 3Document1 pageColumn Detailed 3Azaina1No ratings yet

- Program of Works of Covered CourtDocument2 pagesProgram of Works of Covered CourtMark Edson AboyNo ratings yet

- Module 1 Quiz Solution PDFDocument4 pagesModule 1 Quiz Solution PDFBanana QNo ratings yet

- Table ListDocument16 pagesTable ListMavelyn TolentinoNo ratings yet

- Highway Network SystemDocument12 pagesHighway Network SystemAvinash NoubadeNo ratings yet

- Floor Plan: Transformer Room Space For GensetDocument1 pageFloor Plan: Transformer Room Space For GensetAnony MousNo ratings yet

- BEAM SCHEDULE (C21:Fy414) (LEVEL: 2m)Document1 pageBEAM SCHEDULE (C21:Fy414) (LEVEL: 2m)janrayC13No ratings yet

- Spot Detail Section: (Roofing Sheets and Corbel Conn.)Document1 pageSpot Detail Section: (Roofing Sheets and Corbel Conn.)Robert Christopher NiebresNo ratings yet

- Typical Beam DetailsDocument1 pageTypical Beam DetailsJohn Carl SalasNo ratings yet

- Circular OrificeDocument20 pagesCircular OrificeAsanka Jayasinghe100% (1)

- Ground Floor Plan: UP T&B Lanai Service AreaDocument1 pageGround Floor Plan: UP T&B Lanai Service AreaLhewiz BrionesNo ratings yet

- Stair Foundation Detail at Beam: Rosario L. RostataDocument1 pageStair Foundation Detail at Beam: Rosario L. RostataJesusAntonioJugosNo ratings yet

- Sample Flood Control Plan (From DPWH) - Layout1Document1 pageSample Flood Control Plan (From DPWH) - Layout1Alfie Angelo ReyesNo ratings yet

- Full Truss Diagram (Ft1)Document1 pageFull Truss Diagram (Ft1)SimjanNo ratings yet

- Pfence PG 3Document1 pagePfence PG 3Rogie PeñosaNo ratings yet

- Exterior Perspective: DEE Construction and Design Four Bedroom Two-Storey Residential HomeDocument1 pageExterior Perspective: DEE Construction and Design Four Bedroom Two-Storey Residential HomeRycca DeeNo ratings yet

- CMPM CompilationDocument80 pagesCMPM CompilationTrisha MaeNo ratings yet

- Construction of Covered Court-SDocument1 pageConstruction of Covered Court-SAlbert Christian BesmanosNo ratings yet

- Quito Epoxy TDSDocument2 pagesQuito Epoxy TDSNader ToutounjiNo ratings yet

- Roles and ResponsibilityDocument1 pageRoles and ResponsibilityLeoven Jef Suzara LorinNo ratings yet

- Personal Financial StatementDocument9 pagesPersonal Financial StatementLeoven Jef Suzara LorinNo ratings yet

- 4 Cylinder Deutz 50 KW - 90 KWDocument2 pages4 Cylinder Deutz 50 KW - 90 KWLeoven Jef Suzara LorinNo ratings yet

- Ebook Business Guide v4Document23 pagesEbook Business Guide v4Sheldon MagayonNo ratings yet

- 4 Subcontract Agreement Short Form BlankDocument2 pages4 Subcontract Agreement Short Form BlankrthomsanNo ratings yet

- LRFD STEEL DESIGNDocument43 pagesLRFD STEEL DESIGNJohn Abao93% (14)

- Safety Data Sheet Hazard SummaryDocument9 pagesSafety Data Sheet Hazard SummaryLeoven Jef Suzara Lorin100% (1)

- Tamrez 220-220tg Part A Msds r20151021Document10 pagesTamrez 220-220tg Part A Msds r20151021Leoven Jef Suzara LorinNo ratings yet

- Traffic MG T Plan TempDocument4 pagesTraffic MG T Plan TempLeoven Jef Suzara LorinNo ratings yet

- Trial Excavation Findings Near SS15Document6 pagesTrial Excavation Findings Near SS15Leoven Jef Suzara LorinNo ratings yet

- ACAD2014 TipsnTricks Final PDFDocument17 pagesACAD2014 TipsnTricks Final PDFLeoven Jef Suzara LorinNo ratings yet

- ReadmeDocument1 pageReadmesaid6789No ratings yet

- This Document Has Been Supplied Under License by Shell ToDocument1 pageThis Document Has Been Supplied Under License by Shell ToLeoven Jef Suzara LorinNo ratings yet

- Business Plan WorkbookDocument15 pagesBusiness Plan WorkbookDarkchild HeavensNo ratings yet

- Traffic Management Plan Form 01-12-2004Document3 pagesTraffic Management Plan Form 01-12-2004Leoven Jef Suzara LorinNo ratings yet

- Simplified Reinforced Concrete Design 2010 NSCPDocument258 pagesSimplified Reinforced Concrete Design 2010 NSCPKevin CalpitoNo ratings yet

- Contractors Proposal Form 2 Rev1Document3 pagesContractors Proposal Form 2 Rev1Leoven Jef Suzara LorinNo ratings yet

- Construction ScheduleDocument5 pagesConstruction ScheduleLinsey D OrBoNo ratings yet

- Business Plan WorkbookDocument15 pagesBusiness Plan WorkbookDarkchild HeavensNo ratings yet

- Barsched 86662Document29 pagesBarsched 86662Leoven Jef Suzara LorinNo ratings yet

- Const Estimate Made Easy by Engr. Ronald John R. CajillaDocument25 pagesConst Estimate Made Easy by Engr. Ronald John R. CajillaRonna Mae100% (2)

- Painting WorksDocument1 pagePainting WorksLeoven Jef Suzara LorinNo ratings yet

- Lehx6429 00Document6 pagesLehx6429 00fatos_sejdajNo ratings yet

- 18 Vetogrout EG340 - 180321Document2 pages18 Vetogrout EG340 - 180321Maha MuflehNo ratings yet

- Particular Specifications For Expanssion Joint Waterproofing - Sikadur CombiflexDocument5 pagesParticular Specifications For Expanssion Joint Waterproofing - Sikadur CombiflexEIL DORCNo ratings yet

- Sikadur 752: Low Viscosity Epoxy Resin InjectionDocument2 pagesSikadur 752: Low Viscosity Epoxy Resin InjectionMike AlarNo ratings yet

- Diversified Wood Cat 2017Document59 pagesDiversified Wood Cat 2017codeethylNo ratings yet

- Food and Beverage Can Coatings A Review On Chemicalanalysis, Migration, and Risk AssessmentDocument54 pagesFood and Beverage Can Coatings A Review On Chemicalanalysis, Migration, and Risk AssessmentAna Julia Mayumi PupinNo ratings yet

- High Build Epoxy Coating For Pipelines: Product Data SheetDocument2 pagesHigh Build Epoxy Coating For Pipelines: Product Data SheetChegg ChemNo ratings yet

- 1010810Document229 pages1010810jaragumuraNo ratings yet

- Polymer-G EP520Document2 pagesPolymer-G EP520yoniNo ratings yet

- High Strength, Low Viscous Epoxy Injection GroutDocument2 pagesHigh Strength, Low Viscous Epoxy Injection Groutraahul_nNo ratings yet

- Mold DesignDocument9 pagesMold DesignA MahmoodNo ratings yet

- Disclosure To Promote The Right To InformationDocument11 pagesDisclosure To Promote The Right To InformationNileshNo ratings yet

- Rotafix Crack RepairDocument12 pagesRotafix Crack RepairNorthstar71No ratings yet

- EPIKOTE™ Resin 874-X-90Document1 pageEPIKOTE™ Resin 874-X-90Lê TiếnNo ratings yet

- CBPS-206 CBPS-206: Adhesive Bonding of Nutplates, Studs, Standoffs, Cable Tie Mounts, Bushings, and Other FastenersDocument15 pagesCBPS-206 CBPS-206: Adhesive Bonding of Nutplates, Studs, Standoffs, Cable Tie Mounts, Bushings, and Other Fastenersjaved alamNo ratings yet

- Nichrome Wire IgnitersDocument3 pagesNichrome Wire IgnitersI wont write my name here :P100% (2)

- RAP-1 (Structural Crack Repair by Epoxy Injection (ACI RAP-1) )Document7 pagesRAP-1 (Structural Crack Repair by Epoxy Injection (ACI RAP-1) )Paolo Cortes Parrera100% (1)

- 5.2.2 MIO Coatings - What Types Are ThereDocument2 pages5.2.2 MIO Coatings - What Types Are ThereRama HidayatNo ratings yet

- Smoothon CatalogDocument48 pagesSmoothon CatalogPierre MackenzieNo ratings yet

- BrederoShaw PDS FBE PDFDocument2 pagesBrederoShaw PDS FBE PDFJR RZNo ratings yet

- Epofine 556 FR/ FInehard 951Document3 pagesEpofine 556 FR/ FInehard 951Karishma Prabhu100% (1)

- Intro To PolyurethaneDocument26 pagesIntro To PolyurethaneKatie Ramirez100% (4)

- COVESTRO Desmodur BL 3272 MPA - en - 04109147 12978291 13410124Document3 pagesCOVESTRO Desmodur BL 3272 MPA - en - 04109147 12978291 13410124massimodinelliNo ratings yet

- Full Brochure PDFDocument15 pagesFull Brochure PDFFrancia LugoNo ratings yet

- Mastertop 1230 AseanDocument2 pagesMastertop 1230 AseanDoby YuniardiNo ratings yet

- 5.+cable TiesDocument32 pages5.+cable TiesalimalihiNo ratings yet

- Ifan Rifandi - Pertamina Hulu Energi ONWJDocument30 pagesIfan Rifandi - Pertamina Hulu Energi ONWJRizky SyahputraNo ratings yet

- Interline 399+ds+eng PDFDocument4 pagesInterline 399+ds+eng PDFMohamed NouzerNo ratings yet

- PCS6000e - 6 Part MarkingDocument13 pagesPCS6000e - 6 Part MarkingRobyn NashNo ratings yet

- Patti 110Document24 pagesPatti 110Supriyo PNo ratings yet