Professional Documents

Culture Documents

DME From Syngas Japan

Uploaded by

eniOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DME From Syngas Japan

Uploaded by

eniCopyright:

Available Formats

RECENT ADVANCES in ENERGY & ENVIRONMENT

Direct Synthesis of Dimethyl Ether (DME) from Syngas

Kaoru TAKEISHI, and Yoshimi AKAIKE

Department of Materials Science and Chemical Engineering

Shizuoka University

3-5-1, Jouhoku, Naka-ku, Hamamatsu-shi, Shzuoka-ken, 432-8561

JAPAN

tcktake@ipc.shizuoka.ac.jp

Abstract: We have developed appropriate and excellent catalysts for direct DME synthesis. The catalysts,

Cu-Zn/Al2O3 catalysts prepared by the sol-gel method, produce DME with high DME activity and high DME

selectivity under milder reaction temperature and pressure compared with the usual direct DME synthesis catalysts

(mixed catalysts of methanol synthesis catalysts and methanol dehydration catalysts). It will be the reason why the

methanol synthesis active sites (copper) and the methanol dehydration active sites (alumina) on the sol-gel

Cu/Al2O3 catalysts exist closer than those of the mixed catalysts.

Key-Words: Dimethyl ether, DME, hydrogen, clean fuel, catalyst, sol-gel method, alumina, copper, direct

synthesis, syngas.

1 Introduction used. This mixed catalyst is similar catalysts for patent

Dimethyl ether (DME) is slightly expensive chemical catalysts for direct DME synthesis [4]. The all

now, because DME is manufactured by dehydration catalysts were calcined at 500 oC for 5 h and were

process of methanol. However, DME is expected as a reduced by flowing H2 at 450 oC for 10 h. This severe

clean fuel for the 21st century, from the reasons that pretreatment was particularly performed for reactive

DME does not contain poisonous substances, and comparison to avoid the catalytic deterioration with

DME burns without particulate matters (PM) [1]. sintering of the catalysts by the reaction heat on

DME will be used as substitutes of liquefied continuous experiments with the same catalysts. A

petroleum gas (LPG) and diesel oil, and will be used flow reactor was used for CO hydrogenation. The used

for hydrogen carrier. Therefore, demand of DME will weight of catalysts was 0.5 g, and the supply of the

increase rapidly, and it is necessary to mass-produce reaction gas flow was mainly H2/CO/Ar = 7.5/7.5/1.5

DME economically. There is a method, direct ml min-1. Argon gas was an internal standard for gas

synthesis of DME, that DME is synthesized directly chromatography. The reaction gas and products were

from syngas (hydrogen and carbon monoxide), not analyzed by gas chromatographs (TCD and FID).

synthesized by dehydration of methanol. Excellent Scanning electron microscopy - energy dispersion

catalysts for the direct synthesis are necessary. In this X-ray spectrometry (SEM-EDS) analysis was

study, copper alumina catalysts prepared by the performed for the surface characterization.

sol-gel method that is appropriate for DME steam

reforming [2, 3] are applied for direct DME synthesis 3 Results and discussion

(3H2 + 3CO CH3OCH3 + 2CO2) that is similar 3.1 CO hydrogenation

reaction of DME steam reforming (CH3OCH3 + 3H2O The single type catalyst and the mixed catalyst were

3H2 + 2CO2). carried out for CO hydrogenation. The part of the

results is shown in Fig. 1. Much amount of DME was

2 Experimenals produced over Cu-Zn(36-4wt.%)/Al2O3 catalyst

prepared by the sol-gel method at 250 oC of the lower

For hydrogenation of carbon monoxide, Cu-Zn

reaction temperature. The less amount of DME was

(36-4wt.%)/Al2O3 catalyst prepared by the sol-gel

produced over the mixed catalyst of the methanol

method was used in single, not mixed with other

synthesis catalyst (N211) and the methanol

catalysts such as alumina. As the comparison, a mixed

dehydration catalyst (BK-105) at 310 oC of the higher

catalyst with a commercial catalyst CuO-ZnO

reaction temperature. In other experiments, even if the

(50-50wt.%) (N211, Nikki Chemical Co., Ltd.) and

reaction gases contain some oxygen, the sol-gel

alumina (BK-105, Sumitomo Chemical Co., Ltd.) was

ISSN: 1790-5095 408 ISBN: 978-960-474-159-5

RECENT ADVANCES in ENERGY & ENVIRONMENT

Cu-Zn/Al2O3 catalysts produce DME effectively with Durability test for direct DME synthesis, catalyst

long durability. The single type catalysts that have life-time test was carried out. Fig.5 and Fig. 6 show the

copper sites for methanol synthesis and alumina sites part of the results. In case of DME production rate,

for methanol dehydration on the surface are more there was a decrease of about 100 mol g-cat-1 h-1 from

appropriate and more excellent for direct DME the first biggest rate. However, the DME rate

synthesis than the mixed catalysts that are one of the production is almost constant after this decrease. Rate

patent catalysts for direct DME synthesis. production of methane and methanol also slightly

decreased. However, there is no obvious big

3.2 Hydrogen ratio for direct DME synthesis deactivation such as less production. The further

Dependency of H2/(H2+CO) ratio was investigated on development is still need, but the catalysts are stable

Cu-Zn(36-4wt.%)/Al2O3 catalyst prepared by the and they have enough capability for practical use.

sol-gel method. Fig. 2 shows the part of the results.

DME is produced with the fastest production rate at 4 Conclusion

the ratio of H2/(H2+CO) = 0.5. It is suggested that We have developed the appropriate and excellent

DME is produced over Cu-Zn/Al2O3 catalyst prepared catalyst for direct DME synthesis. The catalysts,

by the sol-gel method, with the reaction of the Cu-Zn/Al2O3 catalysts prepared by the sol-gel method,

chemical equation, 3H2 + 3CO CH3OCH3 + CO2. produce DME with high activity and high selectivity

under the mild reaction temperature and pressure.

3.3 Surface analysis of the catalysts

SEM-EDS analysis confirmed that copper sites for References:

methanol synthesis (and water gas shift reaction) and [1] T. H. Fleisch, A. Basu, M. J. Gradassi, J. G. Masin,

alumina sites for methanol dehydration are co-existing Dimethyl ether: A fuel for the 21st century, Studies

and the both sites are dispersed well on the surface of in Surface Science and Catalysis, Vol. 107, 1997,

Cu-Zn/Al2O3 catalyst prepared by the sol-gel method. pp. 117-125.

The distances of the sites for each reaction (methanol [2] K. Takeishi, H. Suzuki, Steam reforming of

synthesis, methanol dehydration, and water gas shift dimethyl ether, Applied Catalysis A: General, Vol.

reaction) are shorter than those of the mixed catalyst, 260, 2004, pp. 111-117.

so the reactions are more sequentially and [3] K. Takeishi, K. Yamamoto, Catalysts for hydrogen

systematically occurred, and the DME production rate production from dimethyl ether, Japan Patent No.

will be faster. 3951127; US Patent No. 7,241,718; etc.

[4] WO93/10069; JP1991-8446; JP1991-181435;

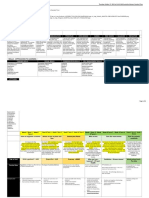

3.4 Pressure effect for direct DME synthesis JP1992-264046; etc.

Dependency of pressure for CO hydrogenation was [5] K. Takeishi, Dimethyl ether and catalyst

investigated on Cu-Zn(36-4wt.%)/Al2O3 catalyst development for production from syngas, Biofuels,

prepared by the sol-gel method. Fig. 3 and Fig. 4 show Vol. 1, No. 1, 2010, pp. 217-226.

the part of the results. Rate of DME production is

linearly increased with increasing of the reaction

absolute pressure. Production rate of methanol also

increases with increasing the pressure. Methane

production rate is almost stable. (Cf. Fig. 3) From

these phenomena, selectivity for DME is increased to

100% depending on the increase of the reaction

pressure. The DME selectivity is 98% under the

pressure of 1.6 MPa. (Cf. Fig. 4) This value is very

high compared with some companies data and the

reaction condition is milder than those of the

companies (Cf. Table 1 [5]).

3.5 Durability test of the catalyst for direct

DME synthesis

ISSN: 1790-5095 409 ISBN: 978-960-474-159-5

RECENT ADVANCES in ENERGY & ENVIRONMENT

-1

30 500 10

Rate of DME production / C . mol g -cat h

-1

Me2O(Sol) Me2O

-1

Production rate / C .mol g-cat h

25 C1

CH4

-1 -1

-1

Me2O(N211)

Rate of methane or methanol

400 8

production / C . mol g -cat h

MeOH

MeOH(N211)

20

300 6

15

10 200 4

5

100 2

0

140 180 220 260 300 340 380 0 0

Temperature / 0.0 0.3 0.6 0.9 1.2 1.5 1.8

Fig. 1. Activity of CO hydrogenation over Absolute pressure / MPa

Cu-Zn(36-4wt.%)/Al2O3 (Sol), and a catalyst (N211) Fig. 3. Effect of pressure on activity of CO

physically mixed CuO-ZnO(50-50wt.%) and Al2O3. hydrogenation over Cu-Zn(36-4wt.%)Al2O3 catalyst

Catalyst: 0.5 g, H2/CO/Ar = 7.5/7.5/1.5 ml min-1. at 220 oC. Catalyst: 0.5g, H2/CO/Ar = 7.5/7.5/1.5 ml

min-1.

45 100 20

-1

40 90 18

Production rate / C . mol g-cat h

Selectivity for DME / C . %

Selectivity for methane or

-1

35 80 16

70 14

methanol / C . %

Me2O

30

Me2O 60 CH4

C1 12

25 50 MeOH 10

CH4

20 40 8

15 30 6

20 4

10

10 2

5 0 0

0 0.0 0.3 0.6 0.9 1.2 1.5 1.8

0.2 0.3 0.4 0.5 0.6 0.7 0.8 Absolute pressure / MPa

H2/(H2+CO)

Fig. 4. Effect of pressure on selectivity of CO

Fig. 2. H2/(H2+CO) and activity of CO hydrogenation hydrogenation over Cu-Zn(36-4wt.%)Al2O3

over Cu-Zn(36-4wt%)/Al2O3 at 220 oC. Catalyst: catalyst at 220 oC. Catalyst: 0.5g, H2/CO/Ar =

0.5 g, (H2+CO)/Ar = (Total 15 ml min-1)/1.5 ml 7.5/7.5/1.5 ml min-1.

min-1.

ISSN: 1790-5095 410 ISBN: 978-960-474-159-5

RECENT ADVANCES in ENERGY & ENVIRONMENT

100 10

-1

600 50

Rate of DME production/ C . mol g -cat- h

-1 -1

-1

Rate of methane or methanol

Me2O CH4 45

Selectivity for DME / C . %

Selectivity for methane or

produtcion / C . mol g -cat h

500 MeOH

40 80 8

Me2O CH4 MeOH

methanol / C . %

400 35

60 6

30

300 25 40 4

20

200 15 20 2

100 10

0 0

5

0 40 80 120 160 200

0 0

Reaction time / h

0 40 80 120 160 200

Reaction time / h Fig. 6. Time course of selectivity on CO

hydrogenation over Cu-Zn(36-4wt.%)Al2O3 catalyst

Fig. 5. Time course of activity on CO hydrogenation at 220 oC under 1.1 MPa. Catalyst: 0.5g, H2/CO/Ar =

over Cu-Zn(36-4wt.%)Al2O3 catalyst at 220 oC under 7.5/7.5/1.5 ml min-1.

1.1 MPa. Catalyst: 0.5g, H2/CO/Ar = 7.5/7.5/1.5 ml

min-1.

Table 1 Comparison of reaction results on direct DME synthesis between our single-type catalyst and

some mixed catalysts developed by some companies [5]

Catalystr Single type Mixed type

(Cu-Zn/Al2O3

(Methanol-synthesis, dehydration condensation, and

prepared using

water-gas shift reaction catalysts)

sol-gel method)

Haldor

Developer Shizuoka Univ. JFE (NKK) Air Products KOGAS

Topsoe

H2/CO Ratio 1.0 1.0 0.7 2 1.0

Fixed bed Slurry Slurry Fixed bed Fixed bed

Reactor type

reactor reactor reactor reactor reactor

Reaction temperature (oC) 220 250-280 250-280 210-290 240-260

Reaction pressure (MPa) 1.6 5-6 5-10 7-8 5-6

One-pass conversion (%) 5-15 55-60 33 18 ?

DME/(DME+Methanol)(%) 98 90 30-80 60-70 85-95

ISSN: 1790-5095 411 ISBN: 978-960-474-159-5

You might also like

- Direct Dimethyl Ether SynthesisDocument9 pagesDirect Dimethyl Ether SynthesissltnrmnNo ratings yet

- Experimental Study of Improved Two Step Synthesis For DME ProductionDocument6 pagesExperimental Study of Improved Two Step Synthesis For DME Productionmoman_1031No ratings yet

- Deactivation of A Cuo-Zno-Al O / O Catalyst in The Synthesis of Dimethyl EtherDocument10 pagesDeactivation of A Cuo-Zno-Al O / O Catalyst in The Synthesis of Dimethyl EtheryahyaNo ratings yet

- JUrnal CO2 Metanol Katalis CO Shoujie PDFDocument14 pagesJUrnal CO2 Metanol Katalis CO Shoujie PDFMuhammad NurliNo ratings yet

- Direct DME Synthesis from Natural GasDocument9 pagesDirect DME Synthesis from Natural GasM Alim Ur RahmanNo ratings yet

- Alamo L Hoda 2012Document10 pagesAlamo L Hoda 2012akzaNo ratings yet

- Direct synthesis of dimethyl ether from syngas over mechanical mixtures of CuO - ZnO - Al2O3 and γ-Al2O3 - Process optimization and kinetic modellingDocument10 pagesDirect synthesis of dimethyl ether from syngas over mechanical mixtures of CuO - ZnO - Al2O3 and γ-Al2O3 - Process optimization and kinetic modellingAngie Paola AcostaNo ratings yet

- 2019 - ECN - Boon - Reversible Deactivation of Gamma-Alumina - Catalysis CommDocument6 pages2019 - ECN - Boon - Reversible Deactivation of Gamma-Alumina - Catalysis CommNMDNo ratings yet

- Direct Dimethyl Ether Synthesis From Syngas On Copper-Zeolite HybridDocument12 pagesDirect Dimethyl Ether Synthesis From Syngas On Copper-Zeolite HybridJulian De BedoutNo ratings yet

- 2010 HosseininejadDocument14 pages2010 HosseininejadLeonard SaftaNo ratings yet

- Yadollah Tavan, Reza Hasanvandian: SciencedirectDocument7 pagesYadollah Tavan, Reza Hasanvandian: SciencedirectdanaosajoNo ratings yet

- Overcoming Thermodynamic Limitations in Dimethyl CDocument7 pagesOvercoming Thermodynamic Limitations in Dimethyl CKaleemNo ratings yet

- 10.1016@j.jcou.2016.01.006Document6 pages10.1016@j.jcou.2016.01.006Himadri SahaNo ratings yet

- DME Synthesis from Natural GasDocument8 pagesDME Synthesis from Natural GasNeha MadanNo ratings yet

- 2010 Moradi - Equilibrium Constant DMEDocument8 pages2010 Moradi - Equilibrium Constant DMEOliver FermaniNo ratings yet

- Equilibrium Calculation For DMEDocument8 pagesEquilibrium Calculation For DMEAbhishek KumarNo ratings yet

- Destilación Reactiva Metanol - DMEDatos ExperimentalesDocument11 pagesDestilación Reactiva Metanol - DMEDatos ExperimentalesAngie Paola AcostaNo ratings yet

- Development of An Efficient Methanol Production PRDocument31 pagesDevelopment of An Efficient Methanol Production PRKorean Drama TVNo ratings yet

- 2 2 2 Raphael Idem, Malcolm Wilson, Paitoon Tontiwachwuthikul, Amit Chakma, Amornvadee Veawab, Adisorn Aroonwilas, and Don GelowitzDocument7 pages2 2 2 Raphael Idem, Malcolm Wilson, Paitoon Tontiwachwuthikul, Amit Chakma, Amornvadee Veawab, Adisorn Aroonwilas, and Don GelowitznakurawNo ratings yet

- Methanol Formation in The Water Gas Shift Reaction Over Copper Containing CatalystsDocument2 pagesMethanol Formation in The Water Gas Shift Reaction Over Copper Containing CatalystsDAYAMOY APLNo ratings yet

- Microporous and Mesoporous Materials: Heqing Jiang, Hans Bongard, Wolfgang Schmidt, Ferdi SchüthDocument6 pagesMicroporous and Mesoporous Materials: Heqing Jiang, Hans Bongard, Wolfgang Schmidt, Ferdi SchüthyahyaNo ratings yet

- Microporous and Mesoporous Materials: Heqing Jiang, Hans Bongard, Wolfgang Schmidt, Ferdi SchüthDocument6 pagesMicroporous and Mesoporous Materials: Heqing Jiang, Hans Bongard, Wolfgang Schmidt, Ferdi SchüthyahyaNo ratings yet

- 1999 XD PengDocument8 pages1999 XD PengLeonard SaftaNo ratings yet

- DMC Direct Synthesis 3Document5 pagesDMC Direct Synthesis 3naushadtamboli05No ratings yet

- Process Design Report 1 - Group 1Document11 pagesProcess Design Report 1 - Group 1Həşim SeyidovNo ratings yet

- Dme Report Word Own LATESTDocument73 pagesDme Report Word Own LATESTvyas reddyNo ratings yet

- CCT Overview of Dimethyl Ether Production Technology (DMEDocument2 pagesCCT Overview of Dimethyl Ether Production Technology (DMEM Usman ChaudhryNo ratings yet

- Simulation of DME Synthesis From Coal Syngas by Kinetics ModelDocument8 pagesSimulation of DME Synthesis From Coal Syngas by Kinetics ModelLuigi RussoNo ratings yet

- Chanchal Dmepetrofedpaper2014Document7 pagesChanchal Dmepetrofedpaper2014Luis Miguel Silva FernandezNo ratings yet

- Global Kinetics of Direct Dimethyl Ether Synthesis Process From Syngas in Slurry Reactor Over A Novel Cu ZN Al ZR Slurry CatalystDocument7 pagesGlobal Kinetics of Direct Dimethyl Ether Synthesis Process From Syngas in Slurry Reactor Over A Novel Cu ZN Al ZR Slurry Catalystkrishna_nimeshNo ratings yet

- Computers and Chemical EngineeringDocument11 pagesComputers and Chemical EngineeringEla syNo ratings yet

- Methanol Steam Reforming On Cu/Zno/Al O Catalysts. Part 2. A Comprehensive Kinetic ModelDocument20 pagesMethanol Steam Reforming On Cu/Zno/Al O Catalysts. Part 2. A Comprehensive Kinetic ModelYovitaAyuningtyasNo ratings yet

- Paper 2do Reactor PDFDocument16 pagesPaper 2do Reactor PDFJuanpi15No ratings yet

- M.I.P.I. Vol.15 - Effect of DME as LPG substitution on household stove efficiencyDocument10 pagesM.I.P.I. Vol.15 - Effect of DME as LPG substitution on household stove efficiencywinart000No ratings yet

- Slurry Phase Reactor Technology For DME Direct SynthesisDocument13 pagesSlurry Phase Reactor Technology For DME Direct SynthesischusnuhNo ratings yet

- Applied Catalysis A: General: Enrico Catizzone, Alfredo Aloise, Massimo Migliori, Girolamo GiordanoDocument6 pagesApplied Catalysis A: General: Enrico Catizzone, Alfredo Aloise, Massimo Migliori, Girolamo GiordanoSandra Ruiz RubioNo ratings yet

- Full Length Article: SciencedirectDocument12 pagesFull Length Article: SciencedirectAmir RahbariNo ratings yet

- Applied Catalysis A: GeneralDocument9 pagesApplied Catalysis A: GeneralCatur Budi KusumoNo ratings yet

- Fei Wang, Junming Xu, Jianchun Jiang, Peng Liu, Fanglin Li, Jun Ye, Minghao ZhouDocument9 pagesFei Wang, Junming Xu, Jianchun Jiang, Peng Liu, Fanglin Li, Jun Ye, Minghao ZhouNoviNo ratings yet

- 1 s2.0 S0360319921019510 MainDocument13 pages1 s2.0 S0360319921019510 MainSadegh AhmadiNo ratings yet

- Dimethyl Ether Synthesis from CO2 Hydrogenation on a CuO-ZnO-Al2O3-ZrO2/HZSM-5 Bifunctional CatalystDocument8 pagesDimethyl Ether Synthesis from CO2 Hydrogenation on a CuO-ZnO-Al2O3-ZrO2/HZSM-5 Bifunctional CatalystshaNo ratings yet

- Journal of Industrial and Engineering Chemistry: Mohammad Ghavipour, Reza Mosayebi BehbahaniDocument10 pagesJournal of Industrial and Engineering Chemistry: Mohammad Ghavipour, Reza Mosayebi BehbahaniJhonatan Romero HuarcayaNo ratings yet

- 7 цитирований Impregnation vs. sol-gel and sol-gel-plasma dispersion of nickel nanoparticles over Al2O3 employed in combined dry reforming and partial oxidation of greenhouse gases to syngasDocument16 pages7 цитирований Impregnation vs. sol-gel and sol-gel-plasma dispersion of nickel nanoparticles over Al2O3 employed in combined dry reforming and partial oxidation of greenhouse gases to syngasПитон КиришевскийNo ratings yet

- Intrinsic Kinetics of Dimethyl Ether Synthesis From SyngasDocument7 pagesIntrinsic Kinetics of Dimethyl Ether Synthesis From SyngasJayeshNo ratings yet

- Syngas Production Via Combined Steam and Carbon Dioxide Reforming of Methane Over Ni-Ce - MgAl2O4 Catalysts With Enhanced Coke ResistanceDocument7 pagesSyngas Production Via Combined Steam and Carbon Dioxide Reforming of Methane Over Ni-Ce - MgAl2O4 Catalysts With Enhanced Coke ResistanceWassachol SumarasinghaNo ratings yet

- Assessment of Solvent Degradation Within A Global Process Model of Post-Combustion CO CaptureDocument6 pagesAssessment of Solvent Degradation Within A Global Process Model of Post-Combustion CO Capturecosmicbabe_2000No ratings yet

- Catalytic Steam Reforming of Methanol To Produce Hydrogen On Supported Metal CatalystsDocument26 pagesCatalytic Steam Reforming of Methanol To Produce Hydrogen On Supported Metal CatalystsedwinNo ratings yet

- Simulation and Experiment Study of Dimethyl Ether Synthesis From SyngasDocument10 pagesSimulation and Experiment Study of Dimethyl Ether Synthesis From Syngasmoman_1031No ratings yet

- Journal of Co Utilization: SciencedirectDocument9 pagesJournal of Co Utilization: SciencedirectGustavo gomesNo ratings yet

- Catalytic Dehydration of Methanol To Dimethyl Ether Dme Using The Alcufe Quasicrystalline Alloy 2157 7048.1000164Document8 pagesCatalytic Dehydration of Methanol To Dimethyl Ether Dme Using The Alcufe Quasicrystalline Alloy 2157 7048.1000164Aditya BayuNo ratings yet

- Catalytic Performance of Hierarchical H-ZSM-5/MCM-41 For Methanol Dehydration To Dimethyl EtherDocument9 pagesCatalytic Performance of Hierarchical H-ZSM-5/MCM-41 For Methanol Dehydration To Dimethyl EthersergioNo ratings yet

- 2010 HosseininejadDocument9 pages2010 HosseininejadLeonard SaftaNo ratings yet

- CFD study of low-temperature combustion and DME-diesel blends in a diesel engineDocument10 pagesCFD study of low-temperature combustion and DME-diesel blends in a diesel engineMohammad Abdul RazackNo ratings yet

- Amine Degradation in CO2 Service - HuntsmanDocument16 pagesAmine Degradation in CO2 Service - Huntsmanvictor nuñezNo ratings yet

- Oksidasi Parsial Methama Dengan CoZSM-5Document8 pagesOksidasi Parsial Methama Dengan CoZSM-5Roby Ilham ZuliantoNo ratings yet

- Direct Dimethyl Ether (DME) Synthesis Through A Thermally Coupled Heat Exchanger ReactorDocument13 pagesDirect Dimethyl Ether (DME) Synthesis Through A Thermally Coupled Heat Exchanger ReactorHector100% (1)

- New Direct Synthesis Technology For DME (Dimethyl Ether) and Its Application TechnologyDocument7 pagesNew Direct Synthesis Technology For DME (Dimethyl Ether) and Its Application TechnologyYiğit IlgazNo ratings yet

- Li 2017Document7 pagesLi 2017IscienceNo ratings yet

- Carbon DioxideDocument10 pagesCarbon DioxideMohd Bismillah AnsariNo ratings yet

- Hydrogen Production TechnologiesFrom EverandHydrogen Production TechnologiesMehmet SankirNo ratings yet

- Strategi Pengelolaan Optimal Pegunungan DiengDocument14 pagesStrategi Pengelolaan Optimal Pegunungan Diengeni sumarsihNo ratings yet

- Kode HS Deskripsi HS January Nil/Val (US $) January BRT/WGT (KG)Document7 pagesKode HS Deskripsi HS January Nil/Val (US $) January BRT/WGT (KG)eniNo ratings yet

- Surat Lamaran OTKDocument1 pageSurat Lamaran OTKeni sumarsihNo ratings yet

- Surat Lamaran OTKDocument1 pageSurat Lamaran OTKeni sumarsihNo ratings yet

- Cie - Publist - 2008 Penerangan PDFDocument11 pagesCie - Publist - 2008 Penerangan PDFAli RosidiNo ratings yet

- Microstation GuideDocument158 pagesMicrostation GuideMishra KirtiwardhanNo ratings yet

- REEM Document SubmissionDocument8 pagesREEM Document Submissionkiller120No ratings yet

- Sda-02-Dd-02 - Pile & Pile Cap - Sheet-1 - R0Document1 pageSda-02-Dd-02 - Pile & Pile Cap - Sheet-1 - R0Himani PatelNo ratings yet

- 2019 Planning OverviewDocument7 pages2019 Planning Overviewapi-323922022No ratings yet

- Effect of CSR on Corporate Reputation and PerformanceDocument13 pagesEffect of CSR on Corporate Reputation and PerformanceAnthon AqNo ratings yet

- WebSphere Installation InstructionsDocument1 pageWebSphere Installation InstructionsjcalaqNo ratings yet

- InRoom Tech Data 31010 ApcDocument92 pagesInRoom Tech Data 31010 ApcRolandoNo ratings yet

- High-Temp, Non-Stick Ceramic Cookware CoatingDocument3 pagesHigh-Temp, Non-Stick Ceramic Cookware CoatingTomescu MarianNo ratings yet

- 1302 FF6SF6DosingMachine 0Document3 pages1302 FF6SF6DosingMachine 0Fawzi ChakirNo ratings yet

- CAS PDII - Owners ManualDocument6 pagesCAS PDII - Owners ManualRoberto SalaNo ratings yet

- Fire Fighting System Case StudyDocument8 pagesFire Fighting System Case StudyBhakti WanaveNo ratings yet

- Skynex SkyknightDocument2 pagesSkynex SkyknightMOHSENNo ratings yet

- Monitoring Critical Applications at SeaDocument3 pagesMonitoring Critical Applications at SeaMohamed AliNo ratings yet

- Ajjarapu1998 PDFDocument11 pagesAjjarapu1998 PDFDanielXaveriusSagalaNo ratings yet

- Be 2K OEM's Manual: Bernini Design SRL - ItalyDocument48 pagesBe 2K OEM's Manual: Bernini Design SRL - ItalySergio Ricardo IbañezNo ratings yet

- Request Documents or InfoDocument6 pagesRequest Documents or InfoRashika RampalNo ratings yet

- Ladybug5 DatasheetDocument2 pagesLadybug5 DatasheetEloy Ricardo Franco FigueiraNo ratings yet

- GRT8100 Product Guide Imperial PDFDocument32 pagesGRT8100 Product Guide Imperial PDFSijumon sijuNo ratings yet

- Space Exploration-DebateDocument2 pagesSpace Exploration-Debateadhil afsalNo ratings yet

- AIR Intelligence Manual 33 308100 004 RemoteDocument88 pagesAIR Intelligence Manual 33 308100 004 RemoteLeChancheNo ratings yet

- Class B BiosolidsDocument9 pagesClass B BiosolidsGissmoNo ratings yet

- Rigging View Modular Overland ConveyorDocument84 pagesRigging View Modular Overland Conveyorrtyuibnm100% (2)

- Bitcoin Thesis FinalDocument18 pagesBitcoin Thesis Finalapi-319365102No ratings yet

- CSD Counter Drone Systems ReportDocument23 pagesCSD Counter Drone Systems ReportmrkuroiNo ratings yet

- Bennic (Bi-Polar Radial) PB-PX SeriesDocument3 pagesBennic (Bi-Polar Radial) PB-PX Seriesester853No ratings yet

- BIT3251 BIT3251 BIT3251 BIT3251 應用指南 應用指南 應用指南 應用指南: Beyond Innovation TechnologyDocument10 pagesBIT3251 BIT3251 BIT3251 BIT3251 應用指南 應用指南 應用指南 應用指南: Beyond Innovation TechnologyHamza AbbasiNo ratings yet

- Track The 5 Most Important Call Center MetricsDocument3 pagesTrack The 5 Most Important Call Center Metricssalesforce.comNo ratings yet

- Tensile TestDocument15 pagesTensile Testdwimukh360No ratings yet

- Spokane County Sheriff's Internal Communication PlanDocument11 pagesSpokane County Sheriff's Internal Communication Planjmcgrath208100% (1)