Professional Documents

Culture Documents

Bombas 2

Uploaded by

Gabriel LopezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bombas 2

Uploaded by

Gabriel LopezCopyright:

Available Formats

GENERAL REQUIREMENTS 2019

4.25.5.7 The isolation valves serving the pressure mainte- 4.27.2.2 An air gap shall be provided in accordance with the

nance pump shall not be required to be supervised. manufacturers recommendations.

4.25.6 The primary or standby fire pump shall not be used as 4.27.2.3 Water discharge from the relief valve shall be readily

a pressure maintenance pump. visible or easily detectable.

4.25.7 The controller for a pressure maintenance pump shall 4.27.2.4 Performance of the requirements in 4.27.2.1

be listed but shall not be required to be listed for fire pump ser- through 4.27.2.3 shall be documented by engineering calcula-

vice. tions and tests.

4.25.8 The pressure maintenance pump is not required to 4.27.3 Devices in Suction Piping. Where located in the suc-

have secondary or standby power. tion pipe of the pump, check valves and backflow prevention

devices or assemblies shall be located a minimum of 10 pipe

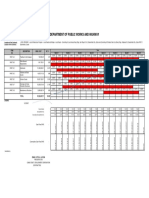

4.26 Summary of Centrifugal Fire Pump Data. The sizes indi-

diameters from the pump suction flange.

cated in Table 4.26(a) and Table 4.26(b) shall be used as a

minimum. 4.27.3.1 Where a backflow preventer with butterfly control

valves is installed in the suction pipe, the backflow preventer is

4.27 Backflow Preventers and Check Valves.

required to be at least 50 ft (15.2 m) from the pump suction

4.27.1 Check valves and backflow prevention devices and as- flange (as measured along the route of pipe) in accordance

semblies shall be listed for fire protection service. with 4.14.5.2.

4.27.2 Relief Valve Drainage. 4.27.4 Evaluation.

4.27.2.1 Where the backflow prevention device or assembly 4.27.4.1 Where the authority having jurisdiction requires the

incorporates a relief valve, the relief valve shall discharge to a installation of a backflow prevention device or assembly in con-

drain appropriately sized for the maximum anticipated flow nection with the pump, special consideration shall be given to

from the relief valve. the increased pressure loss resulting from the installation.

Table 4.26(a) Summary of Centrifugal Fire Pump Data (U.S. Customary)

Minimum Pipe Sizes (Nominal) (in.)

Number and Hose

Pump Rating Relief Valve Size of Hose Header

(gpm) Suction* Discharge* Relief Valve Discharge Meter Device Valves Supply

25 1 1

34 1 114 1 112 1

50 112 114 114 112 2 1 112 112

100 2 2 112 2 212 1 212 212

150 212 212 2 212 3 1 212 212

200 3 3 2 212 3 1 212 212

250 312 3 2 212 312 1 212 3

300 4 4 2 1 2 312 312 1 212 3

400 4 4 3 5 4 2 212 4

450 5 5 3 5 4 2 212 4

500 5 5 3 5 5 2 212 4

750 6 6 4 6 5 3 212 6

1000 8 6 4 8 6 4 212 6

1250 8 8 6 8 6 6 212 8

1500 8 8 6 8 8 6 212 8

2000 10 10 6 10 8 6 212 8

2500 10 10 6 10 8 8 212 10

3000 12 12 8 12 8 12 212 10

3500 12 12 8 12 10 12 212 12

4000 14 12 8 14 10 16 212 12

4500 16 14 8 14 10 16 212 12

5000 16 14 8 14 10 20 212 12

Notes:

(1) The pressure relief valve shall be permitted to be sized in accordance with 4.18.2.1.

(2) The pressure relief valve discharge shall be permitted to be sized in accordance with 4.18.6.2.

(3) The flowmeter device shall be permitted to be sized in accordance with 4.19.2.2.

(4) The hose header supply shall be permitted to be sized in accordance with 4.19.3.4.

*Actual diameter of pump flange is permitted to be different from pipe diameter.

Applies only to that portion of suction pipe specified in 4.14.3.4.

2010 Edition

Copyright National Fire Protection Association

Provided by IHS under license with NFPA

No reproduction or networking permitted without license from IHS

The Standard is downloaded from www.bzfxw.com Standard Sharing

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Bills of Quantity (Quantity Surveying)Document459 pagesBills of Quantity (Quantity Surveying)Amanda Ong100% (3)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Listening and Reading Practice SupplementDocument224 pagesListening and Reading Practice SupplementGabriel LopezNo ratings yet

- Horizontal Boring Specification - 02315 PDFDocument17 pagesHorizontal Boring Specification - 02315 PDFSen HuNo ratings yet

- Cres Subj 5.5 Planning & Design Standards For Residential SubdivisionProject Under PD 957Document9 pagesCres Subj 5.5 Planning & Design Standards For Residential SubdivisionProject Under PD 957Richard VillaverdeNo ratings yet

- HYDRAULIC BRIDGE DETAILSDocument4 pagesHYDRAULIC BRIDGE DETAILSPurdiansyah100% (1)

- Hydraulic Sprinkler CalculationDocument16 pagesHydraulic Sprinkler CalculationGabriel LopezNo ratings yet

- The Temple of Mentuhotep at Deir El-BahariDocument146 pagesThe Temple of Mentuhotep at Deir El-Bahariel-gamelyan100% (2)

- C 76M - 15 PDFDocument11 pagesC 76M - 15 PDFIan TumulakNo ratings yet

- Tep 900 Spe CV BP4 0004 - B04Document30 pagesTep 900 Spe CV BP4 0004 - B04Teguh WiradinataNo ratings yet

- Design Considerations For Hot Water Plumbing PDFDocument105 pagesDesign Considerations For Hot Water Plumbing PDFdanateoNo ratings yet

- Air Curtain Guide DesignDocument8 pagesAir Curtain Guide Designanton7786No ratings yet

- Pay When PaidDocument10 pagesPay When PaidZinck HansenNo ratings yet

- SPP Pumps - Mod. TD15F - Información TécnicaDocument7 pagesSPP Pumps - Mod. TD15F - Información TécnicaGabriel LopezNo ratings yet

- E 90 21 - FireDocument2 pagesE 90 21 - FireEdwin ValdiviaNo ratings yet

- COVIDDocument2 pagesCOVIDGabriel LopezNo ratings yet

- History of Fire Safety Engineering: Session JT1Document28 pagesHistory of Fire Safety Engineering: Session JT1Gabriel LopezNo ratings yet

- NuevoDocumento 2020-02-20 11.49.40Document1 pageNuevoDocumento 2020-02-20 11.49.40Gabriel LopezNo ratings yet

- TFP220 10 2018 PDFDocument8 pagesTFP220 10 2018 PDFGabriel LopezNo ratings yet

- TFP220 10 2018 PDFDocument8 pagesTFP220 10 2018 PDFGabriel LopezNo ratings yet

- DRAINSUtility SpreadsheetDocument96 pagesDRAINSUtility SpreadsheetShahabShoaeeNo ratings yet

- NFPA 99 - Health Care Facilities Code 2000 - 2012Document56 pagesNFPA 99 - Health Care Facilities Code 2000 - 2012Gabriel LopezNo ratings yet

- Evernote - Oct 27, 2017 at 20:27Document8 pagesEvernote - Oct 27, 2017 at 20:27Gabriel LopezNo ratings yet

- NFPA 99 - Health Care Facilities Code 2000 - 2012Document56 pagesNFPA 99 - Health Care Facilities Code 2000 - 2012Gabriel LopezNo ratings yet

- LONGMAN 2001 Complete - Course.for - The.toefl - Test Preparation - For.the - Computer.and - Paper.testsDocument5 pagesLONGMAN 2001 Complete - Course.for - The.toefl - Test Preparation - For.the - Computer.and - Paper.testsGabriel Lopez0% (1)

- A-100 Sprinkler Spray Patterns PDFDocument22 pagesA-100 Sprinkler Spray Patterns PDFGabriel LopezNo ratings yet

- NFPA 99 - Health Care Facilities Code 2000 - 2012Document56 pagesNFPA 99 - Health Care Facilities Code 2000 - 2012Gabriel LopezNo ratings yet

- Bombas 1Document1 pageBombas 1Gabriel LopezNo ratings yet

- Chart 3Document1 pageChart 3Gabriel LopezNo ratings yet

- MST 1Document1 pageMST 1Gabriel LopezNo ratings yet

- 7 BRE Fire Conf 2015 Water Mist Systems As An Alternative To SprinklersDocument31 pages7 BRE Fire Conf 2015 Water Mist Systems As An Alternative To SprinklersGabriel LopezNo ratings yet

- Global Lithium Production: CostsDocument1 pageGlobal Lithium Production: CostsGabriel LopezNo ratings yet

- Spodumene: "Kunzite" Redirects Here. For The Sailor Moon Character, See ShitennouDocument4 pagesSpodumene: "Kunzite" Redirects Here. For The Sailor Moon Character, See ShitennouGabriel LopezNo ratings yet

- 7-11 Conveyors: Single Belt Double Tier, Belt With Barrier 4 FT (1.2 M) Belt Enclosed in Dust Control HoodDocument1 page7-11 Conveyors: Single Belt Double Tier, Belt With Barrier 4 FT (1.2 M) Belt Enclosed in Dust Control HoodGabriel LopezNo ratings yet

- FM Global Property Loss Prevention Data Sheets: List of FiguresDocument17 pagesFM Global Property Loss Prevention Data Sheets: List of FiguresGabriel LopezNo ratings yet

- GX610K1 - GX620K1 - GX670 GXV610K1 - GXV620K1 - GXV670 Low Oil PressureDocument8 pagesGX610K1 - GX620K1 - GX670 GXV610K1 - GXV620K1 - GXV670 Low Oil PressureRussell JohnNo ratings yet

- Triad Series: 3 Piece Ball ValvesDocument8 pagesTriad Series: 3 Piece Ball Valvesevilnemesis133No ratings yet

- Investment Cases-For Students - Tasks and MaterialsDocument94 pagesInvestment Cases-For Students - Tasks and MaterialsannaNo ratings yet

- Fox Running Manual: Wed, 13 May 2020 12:46:25 +0000 Valid at Time of DownloadDocument14 pagesFox Running Manual: Wed, 13 May 2020 12:46:25 +0000 Valid at Time of Downloadcorsini999No ratings yet

- Manual Del Porton Electrico 1120e LiftmasterDocument64 pagesManual Del Porton Electrico 1120e LiftmasterClaudio Bravo MoreiraNo ratings yet

- TSN StiffClip ALDocument2 pagesTSN StiffClip ALmurdicksNo ratings yet

- Department of Public Works and Highway: Contract I.D. Location of The Contract: Location of The ContractDocument1 pageDepartment of Public Works and Highway: Contract I.D. Location of The Contract: Location of The ContractAdrian Louie Laganzo AquinoNo ratings yet

- 01 084r34 PDFDocument60 pages01 084r34 PDFviniciuspariz100% (1)

- Kat-A 4102 Rotovalve Edition3!12!02-2013 enDocument4 pagesKat-A 4102 Rotovalve Edition3!12!02-2013 enWalter PiracocaNo ratings yet

- Understanding Boat Design 101 PDFDocument1 pageUnderstanding Boat Design 101 PDFŁukasz ZygielNo ratings yet

- PV-KK Blast Valve - Product FamilyDocument2 pagesPV-KK Blast Valve - Product FamilyyousufbashaNo ratings yet

- Daily Concrete Pouring Schedule - 19-Apr-2020Document2 pagesDaily Concrete Pouring Schedule - 19-Apr-2020Micheal B HaizenNo ratings yet

- Sockolet Gap Control Threaded Joints - PR - 0XXDocument14 pagesSockolet Gap Control Threaded Joints - PR - 0XXRAMAKRISHNANo ratings yet

- Appendix I. References: J. Struct. Eng., 1988, 114 (8) : 1804-1826Document1 pageAppendix I. References: J. Struct. Eng., 1988, 114 (8) : 1804-1826Ronal J Clavijo RNo ratings yet

- Types of BoltsDocument7 pagesTypes of BoltsPranshu JainNo ratings yet

- Hot Water Storage TankDocument4 pagesHot Water Storage TankRajesh TipnisNo ratings yet

- Certex Product Catalogue Chapter 001 PDFDocument69 pagesCertex Product Catalogue Chapter 001 PDFAther AliNo ratings yet

- Wood Tooling CatalogDocument32 pagesWood Tooling CatalogLam NguyenNo ratings yet

- Section 10 Instant FoundationsDocument14 pagesSection 10 Instant Foundationslive232No ratings yet

- Gate, Globe and Check Valves (Amendments/Supplements To Iso 15761)Document13 pagesGate, Globe and Check Valves (Amendments/Supplements To Iso 15761)윤규섭100% (1)

- 20160215052429-En 10025 en PDFDocument5 pages20160215052429-En 10025 en PDFShirish GosaviNo ratings yet