Professional Documents

Culture Documents

286-Results of The Analysis On Stylus Calibration of A Coordinate Measuring Machine (CMM)

Uploaded by

Muhammad Sohail TariqOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

286-Results of The Analysis On Stylus Calibration of A Coordinate Measuring Machine (CMM)

Uploaded by

Muhammad Sohail TariqCopyright:

Available Formats

34th INTERNATIONAL CONFERENCE ON

PRODUCTION ENGINEERING

28. - 30. September 2011, Ni, Serbia

University of Ni, Faculty of Mechanical Engineering

RESULTS OF THE ANALYSIS ON STYLUS CALIBRATION OF A COORDINATE

MEASURING MACHINE (CMM)

Miodrag HADZISTEVIC, Janko HODOLIC, Igor BUDAK, Djordje VUKELIC, Branko STRBAC

Department of Production Engineering, University of Novi Sad, Trg Dositeja Obradovia 6, Novi Sad, Serbia

miodrags@uns.ac.rs, hodolic@uns.ac.rs, budaki@uns.ac.rs, vukelic@uns.ac.rs, strbacb@uns.ac.rs

Abstract: The result of the measurement on a coordinate measuring machine (CMM) depends on many

factors. Calibration accuracy of the styli is one component of inaccuracy. The exact calibration of the

styli is the basic requirement for all measurements. Inaccuracies occurring during the calibration and

verification have an effect on all measuring results. Influential factors in the calibration process, such as

the accuracy of the calibration sphere and the environmental conditions in this study will be ignored. This

paper analyses the results of the calibration depending on the calibration sphere direction on the

machine table and the displacement of calibration contact starting point in the positive direction of the x

axis. The appropriate conclusions will be made based on the analysis of the results.

Key words: calibration styli, probe, accuracy, CMM.

1. INTRODUCTION conditions as the performance of the subsequent

measurement. This procedure is called the probing system

Coordinate measurement machines are complex machines calibration (Figure 1).[3]

with a large number of error sources affecting the Calibration is a fundamental action in the management of

accuracy of measurement results. Many factors have been sensors and of the entire measuring cycle. Calibration

identified as the source of measurement errors on CMM consists in the identification of diameter and of the

and can be summarized in five groups: measuring position of the centre artefact with respect to the origins

machine (measuring range, reference sphere, machine of the CMM reference system. In essence, calibration

geometry, linear measuring system, etc.), environment defines where the probe (stylus) is located in space, and

(room temperature, thermal radiation, humidity, floor nullifies the effect of probing forces on accuracy.

vibration, etc.), workpiece (soiling of the workpiece, It is very important that the correct reference sphere is

linear stability, roughness, elasticity, etc.), measurement used and that its latest calibrated size is entered into the

strategy (stylus selection, measuring method, number of software. It is also essential that the stylus tip and

probing, evaluation method, etc.) and operator training calibration artefacts are scrupulously clean. The smallest

(further training, shaft probing, measuring run planning, amount of dust can lead to an incorrect probe calibration.

stylus calibration, etc.). [2] One of the errors includes the Measuring the length of a known artefact e.g. a calibrated

probing system calibration (stylus calibration) and it has a block or plain setting ring, is a simple check on the probe

critical role in the CMM measurement, not only in terms calibration. If the difference between the calibrated size of

of its functionality, but also its contribution towards the the gauge block and the length you measure is not within

overall measurement error. The probing system in CMM the machine uncertainty at this length, the probe should be

includes a stylus and a stylus tip which have their own recalibrated and the check repeated [6].

dynamic characteristics during the measuring process [4]. For reliable calibration 25 to 50 touch points are

The stylus tip contact with the detected surface is the recommended for each stylus tip.

source of signals that will develop the pattern on the

working objects. Hence, the performance of the CMM

overall system is very much dictated by the motion

precision of the probe tip and its actuator. Therefore, the

probe stylus tip is laterally at the centre of the CMM

operation and a key element of coordinate measurements

[5]. The exact calibration of the styli is the basic

requirement for all measurements. Any deviation caused

by an inadequate or not correctly performed calibration

process will affect every measurement to be done with the

probing system, i.e. the measurement results could have

significant errors.

This paper analyses the results of the calibration contact

starting point in the positive direction of the x axis and the

orientation reference sphere. The standard deviation is

considered as a calibration value. Influential factors in the Figure 1. Probing system calibration

calibration process, such as the accuracy of the calibration

sphere and the environmental conditions will be ignored 2.1. Calibration of the styli of CMM "Carl Zeiss

in this study. CONTURA G2 RDS"

The experimental tests have been carried out on a CMM

The CONTURA G2 is a mid-range bridge type CMM

Carl Zeiss CONTURA G2 RDS in the Metrology

with advanced features and design strengths. All axes

Laboratory of the Department of Production Engineering

have 4-sided Carl Zeiss air bearings providing maximum

at the University of Novi Sad.

stability and a very precise measurement. Ceramic

guideways are thermally stable, minimizing the effect of

2. CALIBRATION STYLUS temperature variation.

The calibration process of the measuring stylus depends

The position of the tip ball centre point related to the on the type of the measuring head with the inserted

reference point of the probing system and the radius of probing system. This experiment utilizes the RDS turning

the tip ball must be known in order to perform correct measuring head with the combination of VAST XXT

measurements. These parameters are dependent on the scanning measuring sensor. As a replacement for trigger

probing force (magnitude and direction), elastic behaviour sensors, the VAST XXT offers the unmatched

of a probing system, styli, workpiece and other measurement capability, reliability, and accuracy. With a

influences. Their origin can be materials, components, large deflection range and a low measuring force, it is a

arrangement of components in the probing system, very robust scanning sensor. It uses the styli lengths up to

dimensions like length, diameter of styli, material 250 mm, side and star styli, and a minimum ball radius of

properties, and elastic flexibility of stylus joins, including 0.3 mm. The VAST XXT has very low measuring forces

suspension and roundness deviations of the tip ball. and there is little influence when swivelling. When the

Due to the necessary accuracy and the complexity of RDS head is used, the CMM can probe the workpiece

interactions, they cannot be calculated. They can be from a large number of different directions by adjusting A

determined experimentally for a virtually ideal probing and B angles. Every RDS position wanted to be utilized

system with a virtually stiff stylus with an effective tip for probing is considered to be its own stylus and must be

ball diameter using a calibrated artefact under the same calibrated separately. A stylus must be qualified when and

if there is a new stylus system installed and there is a need larger than 3.5 mm, there is an angle deviation during the

for the re-calibration of a stylus system, for example after calibration, i.e. the software will signal an error and the

a collision or due to thermal changes. The calibration of value of the standard deviation reaches even the tenth part

the measuring stylus is performed with the reference of the millimetre [1]. Changing the angle to zero tells

sphere. The reference sphere of the CMM is a sphere of a Calypso to rotate the stylus system path by the deviation

known diameter mounted on the measuring table via a angle, ensuring that the sphere measurement path follows

stem. The software (Calypso) must know the exact the centre line of the sphere and does not touch the shank

position of this reference sphere for the orientation and in of the stylus [9]. Software uses the information to

order to analyze the calibration correctly. The position of calculate the centre of the sphere, which, relative to this

the reference sphere on a measuring table is determined centre, will look at the first point. If the first point lies

by the calibration of the master measuring stylus. After within an internal tolerance of where it should be, the full

this calibration id s performed, the next step is the sphere is measured.

calibration of measuring styli. In order to decide whether

the calibration result is acceptable, standard deviation can

be used as a basic for the decision. Acceptable standard

deviation depends at least on the following factors:

quality of the calibration, length and stability of the styli

and extensions used, value of the temperature deviations

and temporal thermal fluctuations on the CMM, degree of

soiling, wear, damage of the reference spheres, existence

of loose or damaged stylus and/or extension elements.

The standard deviation should lie in the range of a few

micrometers.

The first calibration of a stylus must be done manually.

Once the stylus has been calibrated for the first time,

future calibration can be done automatically [7].

3. EXPERIMENTAL WORK

The calibration of the measuring stylus is an obligatory

procedure preceding every measuring task. The procedure Figure 2. Experiment performance procedure

is performed automatically, although with the first After the calibration of the master stylus, the next

calibration, the operator has to provide the contact calibration is the one of the styli with the radius of 3 mm

between the measuring stylus and the reference sphere. (Figure 3). The calibration process for the styli is

This contact should happen at the point at the top of the performed in every contact point of the measuring stylus

calibration sphere, passed through by the axis line of the and the reference sphere with the deviation of 0.5 mm in

measuring sensor containing the measuring stylus centre the positive direction of the x axis until the value of 3.5

and the axis line of the reference sphere. Since this is mm (Figure 2). The value of the standard deviation is

relative, this paper determines the dependence of the monitored for every deviation of the contact point that

calibration results in relation to the deviated contact point begins the calibration process. For static analysis of the

in the positive direction of the x axis (Figure 2). Previous results to be performed, the same procedure has been

researches have determined that, for the deviation value repeated six times.

Figure 3. CMM Carl Zeiss CONTURA G2 RDS, reference sphere and styli

The second variation parameter in the experiment is the As a calibration method, all cases utilize the qualify

orientation of the reference sphere. Reference sphere has passive stylus method. Four points are first probed for

four different orientations, while the position on the position determination, followed by the required number

measuring table of the machine remains unchanged of points for stylus calibration.

(Figure 4). Previously described calibration procedure has The paper presents the influence of the calibration results

been repeated for all four diverse orientations. by varying the starting point calibration and the

orientations reference sphere. Other influential factors

determining the standard deviation value are neglected or

maintained at a constant level. The ambient

environmental conditions during the experiments in the

laboratory have been recorded. The room temperature is

maintained within the range 20.00.5C; while the

humidity is maintained at 502%.

3.1. Calibration results

It has been observed that in the total of 192 calibration

procedures, the standard deviation did not have the value

larger than the tenth part of millimetre. Results are

presented by the number of different orientations

Figure 4. Different orientations of the reference sphere[7]

reference sphere. The table overview is presented for

standard deviations for the first orientation calibration

sphere (Table 1).

Table 1. Standard deviation for first orientation reference sphere [mm]

No. of measurement

________________

1 2 3 4 5 6

Starting point

calibration

0.0 [mm] 0.0000 0.0001 0.0001 0.0000 0.0000 0.0001

0.5 [mm] 0.0000 0.0001 0.0000 0.0000 0.0001 0.0001

1.0 [mm] 0.0000 0.0001 0.0000 0.0001 0.0000 0.0001

1.5 [mm] 0.0000 0.0001 0.0001 0.0000 0.0001 0.0001

2.0 [mm] 0.0000 0.0000 0.0000 0.0001 0.0000 0.0001

2.5 [mm] 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001

3.0 [mm] 0.0001 0.0001 0.0001 0.0001 0.0000 0.0001

3.5 [mm] 0.0002 0.0003 0.0002 0.0003 0.0005 0.0001

The software package MiniTab is used for the static data representations for the analysis of variance. A Multi-Vari

processing. The influence of the contact point between the chart allows the user to observe patterns of variation in

measuring stylus and the reference sphere in initiating the the output of a process that can correlate with

calibration procedure and the orientation reference sphere simultaneous multiple potential input variables. The

onto the standard deviation is presented in a Multi-Vari advantage of a Multi-Vari chart over other graphical

chart (Figure 5). Multi-Vari charts are powerful graphical methods is that it allows the graphical representation

multiple families of variation on a single chart. A Multi- down to a precious few by focusing the attention on the

Vari analysis can help narrowing a list of potential causes sources of variation that need further study [8].

Figure 5. Multi-Vari chart for standard deviation by starting point calibration-orientation reference sphere

The presented diagram refers that the starting calibration Update. CIRP Annals-Manufacturing Technology, 57,

contact point between the stylus and the reference sphere 660-675.

does not have any influence on the standard variation [5] SALAH H. R. ALI (2010). Probing System

value until the measure of 3.5 mm. It can be observed that Characteristics in Coordinate Metrology.

with the first orientation reference sphere there appears a Measurement Science Review. Vol. 10, No 4.

greater result dispersion, while with the other three, the [6] DAVID FLACK (2001). Cmm Probing. Measurement

standard deviation values are constant. However, it can be Good Practice Guide No. 43. National Physical

concluded that even the diverse orientation reference Laboratory Queens Road, Teddington, Middlesex,

sphere at the same position on the measuring machine United Kingdom.

table does not influence the calibration value. [7] CARL ZEISS (2008). Calypso Basics, Operating

Instruction. Revision 4.8. Oberkochen, Germany.

4. CONCLUSION [8] WALTER W. MCLNTYRE (2009). Lean and Mean

Process Improvement. United States of America.

From all the above it can be concluded that the [9] http://www.cms-home.com/Applications_Tip_2.pdf

parameters like starting calibration point and the

orientation reference sphere insignificantly influence the Acknowledgement

standard deviation. The confirmation of this hypothesis

should be presented by mathematical values, which is the Results of investigation presented in this paper are part of

objective of future research, same as the research aimed at the research realized in the framework of the project

the position deviation of the reference sphere on a Research and Development of Modelling Methods and

machines measuring table and the usage of diverse stylus Approaches in Manufacturing Dental Recoveries with the

configurations. Application of Modern Technologies and Computer Aided

Systems TR 035020, financed by the Ministry of

REFERENCES Science and Technological Development of the Republic

of Serbia.

[1] STRBAC, B., HADZISTEVIC, M.,HODOLI J.,

VRBA ,I. (2010) Influence of Stylus Calibration on

Overall CMM Error, International Scientific

Conference "Mechanical Engineering", Bratislava,

Vol. 1, pp 80-86.

[2] CARL ZEISS 3D AKADEMIE. (2009) Measurement

Strategies in Contact Coordinate Metrology, Aalen.

[3] WECKENMANN, A., ESTLER, T., PEGGS, G.,

MCMURTRY, D. (2004). Probing System in

Dimensional Metrology. CIRP Annals-Manufacturing

Technology, 53 (2), 657-684.

[4] SCHWENKE, H., KNAPP, W., HAITJEMA, H.,

WECKENMANN, A., SCHMITT, R.,

DELBRESSINE, F (2008). Geometric Error

Measurement and Compensation of Machines-An

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Gat Sample Paper 2Document12 pagesGat Sample Paper 2Muhammad Ashraf100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Corrosion Types and Prevention Methods in 40 CharactersDocument75 pagesCorrosion Types and Prevention Methods in 40 CharactersCipri Croitor0% (1)

- SiliconeSurfactants SILTECHDocument6 pagesSiliconeSurfactants SILTECHA MahmoodNo ratings yet

- BS3974 Pipe SupportsDocument20 pagesBS3974 Pipe SupportsTony100% (1)

- Hotpoint Service Manual Fridge FreezerDocument36 pagesHotpoint Service Manual Fridge FreezerMANUEL RODRIGUEZ HERRERA100% (1)

- McqsDocument2 pagesMcqsMuhammad Sohail TariqNo ratings yet

- Sample Test PaperDocument4 pagesSample Test PaperMuhammad Sohail TariqNo ratings yet

- Solution Manual For Engineering Fundamentals of The Internal Combustion Engine PDFDocument13 pagesSolution Manual For Engineering Fundamentals of The Internal Combustion Engine PDFHector Hidalgo33% (3)

- Theoratical Project WorthDocument4 pagesTheoratical Project WorthMuhammad Sohail TariqNo ratings yet

- Multiple ChoiceDocument66 pagesMultiple ChoiceMuhammad Sohail TariqNo ratings yet

- Challan Form-21-05-2014 PDFDocument1 pageChallan Form-21-05-2014 PDFAila DarNo ratings yet

- Power PlantDocument3 pagesPower PlantMuhammad Sohail TariqNo ratings yet

- To Determine The Coefficient of Performance of Heat Pump and Production of Heat Pump Performance Curves Over A Range of Source and Delivery TemperaturesDocument11 pagesTo Determine The Coefficient of Performance of Heat Pump and Production of Heat Pump Performance Curves Over A Range of Source and Delivery TemperaturesMuhammad Sohail Tariq0% (1)

- List of FYP For 2014 SessionDocument3 pagesList of FYP For 2014 SessionMuhammad Sohail TariqNo ratings yet

- Course Plan - Machine Design-LDocument2 pagesCourse Plan - Machine Design-LMuhammad Sohail TariqNo ratings yet

- (211102669) Experiment1-4 - HvacDocument10 pages(211102669) Experiment1-4 - HvacMuhammad Sohail TariqNo ratings yet

- Final Year Project Registration Form 2014Document1 pageFinal Year Project Registration Form 2014Muhammad Sohail TariqNo ratings yet

- Power PlantDocument3 pagesPower PlantMuhammad Sohail TariqNo ratings yet

- MM Lab Ex 1 & 2Document8 pagesMM Lab Ex 1 & 2Muhammad Sohail TariqNo ratings yet

- New Microsoft Word DocumentDocument4 pagesNew Microsoft Word DocumentMuhammad Sohail TariqNo ratings yet

- RAC LAB ASSIGNMENT ComponentsDocument5 pagesRAC LAB ASSIGNMENT ComponentsMuhammad Sohail TariqNo ratings yet

- New Microsoft Word DocumentDocument5 pagesNew Microsoft Word DocumentMuhammad Sohail TariqNo ratings yet

- PMS Past Papaer 2016 English Eassy PDFDocument1 pagePMS Past Papaer 2016 English Eassy PDFMuhammad Sohail TariqNo ratings yet

- (211102669) Experiment1-4 - HvacDocument10 pages(211102669) Experiment1-4 - HvacMuhammad Sohail TariqNo ratings yet

- Theoratical Project WorthDocument4 pagesTheoratical Project WorthMuhammad Sohail TariqNo ratings yet

- PMS Past Papaer 2016 English EassyDocument1 pagePMS Past Papaer 2016 English EassyMuhammad Sohail TariqNo ratings yet

- Engg - CW Date Sheet (29 Aug2016)Document2 pagesEngg - CW Date Sheet (29 Aug2016)Muhammad Sohail TariqNo ratings yet

- New Microsoft Word DocumentDocument2 pagesNew Microsoft Word DocumentMuhammad Sohail TariqNo ratings yet

- New Microsoft Word DocumentDocument4 pagesNew Microsoft Word DocumentMuhammad Sohail TariqNo ratings yet

- QuestionnaireDocument7 pagesQuestionnaireMuhammad Sohail TariqNo ratings yet

- Engg CW DetailsDocument26 pagesEngg CW DetailsMuhammad Sohail TariqNo ratings yet

- Pakistan Energy Policy Energy Conservation TaxationDocument1 pagePakistan Energy Policy Energy Conservation TaxationMuhammad Sohail TariqNo ratings yet

- PMS Past Papaer 2016 English EassyDocument1 pagePMS Past Papaer 2016 English EassyMuhammad Sohail TariqNo ratings yet

- Carcass Chilling Systems and Their Impact On Meat Quality - Pig Articles From The Pig SiteDocument3 pagesCarcass Chilling Systems and Their Impact On Meat Quality - Pig Articles From The Pig SiteJose Romanillos VelascoNo ratings yet

- Um String Code 2 0 eDocument46 pagesUm String Code 2 0 ehydrasearchNo ratings yet

- Acer Ferrari 3400 Laptop ManualDocument113 pagesAcer Ferrari 3400 Laptop Manualmoming1No ratings yet

- HE Hydra Jar Manual 6-80Document31 pagesHE Hydra Jar Manual 6-80Yuri KostNo ratings yet

- Industrial Hose Products - DAYCODocument200 pagesIndustrial Hose Products - DAYCOHebert CcahuanaNo ratings yet

- Geotech Final ReportDocument38 pagesGeotech Final Reportapi-320590292No ratings yet

- Andrews General Usability HeuristicsDocument1 pageAndrews General Usability HeuristicsGhaniNo ratings yet

- XT316 Air SockerDocument4 pagesXT316 Air Sockeryudiar djamaldilliahNo ratings yet

- MC Lab Manual ModifiedDocument64 pagesMC Lab Manual ModifiedBaswamy CseNo ratings yet

- Cal Val Refile ValveDocument1 pageCal Val Refile Valvesourav samadderNo ratings yet

- CAD (ME2155) Lab ManualDocument18 pagesCAD (ME2155) Lab Manualharishj93No ratings yet

- 12 ElectrostaticsDocument24 pages12 ElectrostaticsTanvi ShahNo ratings yet

- Customer service records for auto repairsDocument30 pagesCustomer service records for auto repairsAsad LaghariNo ratings yet

- Lecture Notes 2 Nano MaterialsDocument21 pagesLecture Notes 2 Nano MaterialsHuzaifa ShabbirNo ratings yet

- Espectrómetro FT-IR Nicolet Is 10Document1 pageEspectrómetro FT-IR Nicolet Is 10Adriano BludegardNo ratings yet

- Lecture - Force MethodDocument73 pagesLecture - Force MethodF FNo ratings yet

- Kinematics equations motion problemsDocument3 pagesKinematics equations motion problemsAhmed HossainNo ratings yet

- OpenDSS Level 1 TrainingDocument85 pagesOpenDSS Level 1 Trainingraul_bsu100% (1)

- HTML DOM TutorialDocument11 pagesHTML DOM Tutorialapi-3819971100% (1)

- Furniture Plans How To Build A Rocking ChairDocument10 pagesFurniture Plans How To Build A Rocking ChairAntónio SousaNo ratings yet

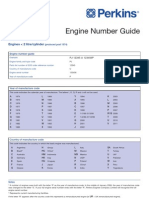

- Perkins Engine Number Guide PP827Document6 pagesPerkins Engine Number Guide PP827Muthu Manikandan100% (1)

- Singly Linked Lists AlgorithmDocument18 pagesSingly Linked Lists AlgorithmGSX-R 1100No ratings yet

- Farris 2700 ManualDocument12 pagesFarris 2700 ManualNelson AlvarezNo ratings yet

- Traffic Engineering Bachelor of Science in Civil EngineeringDocument22 pagesTraffic Engineering Bachelor of Science in Civil EngineeringDaisy AstijadaNo ratings yet

- SeminarDocument4 pagesSeminarmukulNo ratings yet

- Monarch Industrial Products (I) Pvt. Ltd. Decorative Floor Toppings Supply Order Price ListDocument1 pageMonarch Industrial Products (I) Pvt. Ltd. Decorative Floor Toppings Supply Order Price ListgangadevimgmNo ratings yet