Professional Documents

Culture Documents

Section 7. Ultrasonic Inspection

Uploaded by

blackhawkCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section 7. Ultrasonic Inspection

Uploaded by

blackhawkCopyright:

Available Formats

9/8/98 AC 43.

13-1B

CHAPTER 5. NONDESTRUCTIVE INSPECTION (NDI)

SECTION 7. ULTRASONIC INSPECTION

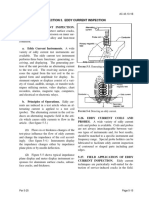

5-89. GENERAL. Ultrasonic inspection is b. Through-Transmission Inspection.

an NDI technique that uses sound energy This inspection employs two transducers, one

moving through the test specimen to detect to generate and a second to receive the ultra-

flaws. The sound energy passing through the sound. A defect in the sound path between the

specimen will be displayed on a Cathode Ray two transducers will interrupt the sound trans-

Tube (CRT), a Liquid Crystal Display (LCD) mission. The magnitude (the change in the

computer data program, or video/camera me- sound pulse amplitude) of the interruption is

dium. Indications of the front and back sur- used to evaluate test results. Through-

face and internal/external conditions will ap- transmission inspection is less sensitive to

pear as vertical signals on the CRT screen or small defects than is pulse-echo inspection.

nodes of data in the computer test program.

There are three types of display patterns; A 5-92. FLAW DETECTION. Ultrasonic in-

scan, B scan, and C scan. Each scan pro- spection can easily detect flaws that produce

vides a different picture or view of the speci- reflective interfaces. Ultrasonic inspection is

men being tested. (See figure 5-15.) used to detect surface and subsurface disconti-

nuities, such as: cracks, shrinkage cavities,

5-90. SOUND REFLECTION. The bursts, flakes, pores, delaminations, and po-

amount of reflection that occurs when a sound rosity. It is also used to measure material

wave strikes an interface depends largely on thickness and to inspect bonded structure for

the physical state of the materials forming the bonding voids. Ultrasonic inspection can be

interface and to a lesser extent on the specific performed on raw material, billets, finished,

physical properties of the material. For exam- and semi-finished materials, welds, and in-

ple: sound waves are almost completely re- service assembled or disassembled parts. In-

flected at metal/gas interfaces; and partial re- clusions and other nonhomogeneous areas can

flection occurs at metal/liquid or metal/solid also be detected if they cause partial reflection

interfaces. or scattering of the ultrasonic sound waves or

produce some other detectable effect on the

5-91. ULTRASONIC INSPECTION ultrasonic sound waves. Ultrasonic inspection

TECHNIQUES. Two basic ultrasonic in- is one of the more widely-used methods of

spection techniques are employed: pulse-echo NDI.

and through-transmission. (See figure 5-16.)

5-93. BASIC EQUIPMENT. Most ultra-

a. Pulse-Echo Inspection. This process sonic inspection systems include the following

uses a transducer to both transmit and receive basic equipment; portable instruments (fre-

the ultrasonic pulse. The received ultrasonic quency range 0.5 to 15 MHz), transducers

pulses are separated by the time it takes the (longitudinal and shear wave), positioners, ref-

sound to reach the different surfaces from erence standards, and couplant.

which it is reflected. The size (amplitude) of a

reflection is related to the size of the reflecting a. Ultrasonic Instruments. A portable,

surface. The pulse-echo ultrasonic response battery-powered ultrasonic instrument is used

pattern is analyzed on the basis of signal am- for field inspection of airplane structure. (See

plitude and separation. figure 5-17.) The instrument generates an

Par 5-89 Page 5-41

AC 43.13-1B 9/8/98

CHAPTER 5. NONDESTRUCTIVE INSPECTION (NDI)

SECTION 7. ULTRASONIC INSPECTION

FIGURE 5-15. Ultrasound.

FIGURE 5-16. Pulse-echo and through-transmission ultrasonic inspection techniques.

Page 5-42 Par 5-93

9/27/01 AC 43.13-1B CHG 1

CHAPTER 5. NONDESTRUCTIVE INSPECTION (NDI)

SECTION 7. ULTRASONIC INSPECTION

or is a configuration that provides an ultrasonic

response pattern representative of the test

structure. The reference standard contains a

simulated defect (notch) that is positioned to

provide a calibration signal representative of

the expected defect. The notch size is chosen

to establish inspection sensitivity (response to

the expected defect size). The inspection pro-

cedure gives a detailed description of the re-

quired reference standard.

d. Couplants. Inspection with ultrasonics

is limited to the part in contact with the trans-

FIGURE 5-17. Typical portable ultrasonic inspection in- ducer. A layer of couplant is required to cou-

strument. ple the transducer to the test piece because ul-

ultrasonic pulse, detects and amplifies the re- trasonic energy will not travel through air.

turning echo, and displays the detected signal Some typical couplants used are: water, glyc-

on a cathode ray tube or similar display. Pie- erin, motor oils, and grease.

zoelectric transducers produce longitudinal or

shear waves, which are the most commonly 5-94. INSPECTION OF BONDED

used wave forms for aircraft structural inspec- STRUCTURES. Ultrasonic inspection is

tion. finding increasing application in aircraft

bonded construction and repair. Detailed tech-

b. Positioning Fixtures. To direct ultra- niques for specific bonded structures should be

sound at a particular angle, or to couple it into obtained from the OEMs manuals, or FAA re-

an irregular surface, transducer positioning quirements. In addition, further information

fixtures and sound-coupling shoes are em- on the operation of specific instruments should

ployed. (See figure 5-18.) Shoes are made of be obtained from the applicable equipment

a plastic material that has the necessary sound- manufacturer manuals.

transmitting characteristics. Positioning fix-

tures are used to locate the transducer at a pre- a. Types of Bonded Structures. Many

scribed point and can increase the sensitivity configurations and types of bonded structures

of the inspection. (See figure 5-19.) If a are in use in aircraft. All of these variations

transducer shoe or positioning fixture is re- complicate the application of ultrasonic in-

quired, the inspection procedure will give a spections. An inspection method that works

detailed description of the shoe or fixture. well on one part or one area of the part may

not be applicable for different parts or areas of

c. Reference Standards. Reference stan- the same part. Some of the variables in the

dards are used to calibrate the ultrasonic in- types of bonded structures are as follows.

strument (see figure 5-20), reference standards

serve two purposes to provide an ultrasonic re- (1) Top skin material is made from dif-

sponse pattern that is related to the part being ferent materials and thickness.

inspected, and to establish the required inspec-

tion sensitivity. To obtain a representative re- (2) Different types and thickness of ad-

sponse pattern, the reference standard configu- hesives are used in bonded structures.

ration is the same as that of the test structure,

Par 5-93 Page 5-43

AC 43.13-1B 9/8/98

CHAPTER 5. NONDESTRUCTIVE INSPECTION (NDI)

SECTION 7. ULTRASONIC INSPECTION

Note:

All dimensions in inches followed by centimeters in parentheses.

FIGURE 5-18. Example of position fixture and shoe.

FIGURE 5-19. Example of the use if a transducer positioning fixture.

FIGURE 5-20. Example of a typical reference standard.

Page 5-44 Par 5-94

9/8/98 AC 43.13-1B

CHAPTER 5. NONDESTRUCTIVE INSPECTION (NDI)

SECTION 7. ULTRASONIC INSPECTION

(3) Underlying structures contain dif- containing: closure members, core splices,

ferences in; core material, cell size, thickness, stepped skins, and internal ribs similar to the

and height, back skin material and thickness, test part if bonded areas over or surrounding

doublers (material and thickness), closure these details are to be inspected.

member attachments, foam adhesive, steps in (2) The reference standard must contain

skins, internal ribs, and laminates (number of bonds of good quality except for controlled ar-

layers, layer thickness, and layer material). eas of unbond fabricated as explained below.

(4) The top only or top and bottom skin (3) The reference standard must be

of a bonded structure may be accessible. bonded using the adhesive and cure cycle pre-

b. Application of Ultrasonic Inspection. scribed for the test part.

Application to bonded structures must be ex-

amined in detail because of the many inspec- e. Types of Defects. Defects can be sepa-

tion methods and structural configurations. rated into five general types to represent the

The advantages and limitations of each in- various areas of bonded sandwich and laminate

spection method should be considered, and structures as follows:

reference standards (representative of the

structure to be inspected) should be ultrasoni- (1) Type I. Unbonds or voids in an

cally inspected to verify proposed techniques. outer skin-to-adhesive interface.

c. Internal Configuration. Complete in-

formation on the internal configuration of the (2) Type II. Unbonds or voids at the

bonded test part must be obtained by the in- adhesive-to-core interface.

spector. Drawings should be reviewed, and

(3) Type III. Voids between layers of a

when necessary, radiographs of the test part

laminate.

should be taken. Knowledge of details such as

the location and boundaries of doublers, ribs, (4) Type IV. Voids in foam adhesive or

etc., is required for valid interpretation of ul- unbonds between the adhesive and a closure

trasonic inspection results. The boundaries of member at core-to-closure member joints.

internal details should be marked on the test

part using a grease pen or other easily remov- (5) Type V. Water in the core.

able marking. f. Fabrication of NDI Reference Stan-

dards. Every ultrasonic test unit should have

d. Reference Standards. Standards can

sample materials that contain unbonds equal to

be a duplicate of the test part except for the

the sizes of the minimum rejectable unbonds

controlled areas of unbond. As an option,

for the test parts. Information on minimum

simple test specimens, which represent the

rejectable unbond sizes for test parts should be

varied areas of the test part and contain con-

obtained from the OEMs manuals, FAA re-

trolled areas of unbond, can be used. Refer-

quirements, or the cognizant FAA Aircraft

ence standards must meet the following re-

Certification Office (ACO) engineer. One or

quirements.

more of the following techniques can be used

(1) The reference standard must be in fabricating reference defects; however, since

similar to the test part regarding material, ge- bonding materials vary, some of the methods

ometry, and thickness. This includes may not work with certain materials.

Par 5-94 Page 5-45

AC 43.13-1B 9/8/98

CHAPTER 5. NONDESTRUCTIVE INSPECTION (NDI)

SECTION 7. ULTRASONIC INSPECTION

(1) Standards for Types I, II, III, and IV suggested methods contained in figure 5-21

unbonds can be prepared by placing discs and table 5-7 are for reference only. Details of

of 0.006 inch thick (maximum) Teflon sheets the inspection coverage and inspections for a

over the adhesive in the areas selected for un- particular assembly should be obtained from

bonds. For Type II unbonds, the Teflon is the OEMs manuals, or other FAA-approved

placed between the core and adhesive. The requirements.

components of the standard are assembled and h. Inspection Methods. Table 5-8 lists

the assembly is then cured. the various inspection methods for bonded

(2) Types I, II, and III standards can structures along with advantages and disad-

also be produced by cutting flat-bottomed vantages of each inspection method.

holes of a diameter equal to the diameter of the 5-95. BOND TESTING INSTRUMENTS.

unbonds to be produced. The holes are cut Standard ultrasonic inspection instruments can

from the back sides of bonded specimens, and be used for bond testing as previously noted;

the depths are controlled to produce air gaps at however, a wide variety of bond testing in-

the applicable interfaces. When using this struments are available for adaptation to spe-

method, patch plates can be bonded to the rear cific bonded structure inspection problems.

of the reference standard to cover and seal

each hole. a. General Principle. Two basic operat-

(3) Type II standards can be produced ing principles are used by a variety of bond

by locally undercutting (before assembly) the testers for single-sided bond inspection.

surface of the core to the desired size unbond.

The depth of the undercut should be sufficient (1) Ultrasonic resonance. Sound waves

to prevent adhesive flow causing bonds be- from a resonant transducer are transmitted into

tween the undercut core and the skin. and received from a structure. A disbond in

the structure will alter the sound wave charac-

(4) Type IV standards can be produced teristics, which in turn affect the transducer

by removing the adhesive in selected areas impedance.

prior to assembly.

(2) Mechanical impedance. Low-

(5) Type V standards can be produced frequency, pulsed ultrasonic energy is gener-

by drilling small holes in the back of the stan- ated into a structure. Through ultrasonic me-

dard and injecting varying amounts of water chanical vibration of the structure, the imped-

into the cells with a hypodermic needle. The ance or stiffness of the structure is measured,

small holes can then be sealed with a small analyzed, and displayed by the instrumenta-

amount of water-resistant adhesive. tion.

g. Inspection Coverage. Examples of b. Operation. In general, operation of the

several different configurations of bonded adhesive bond test instruments noted is simi-

structure along with suggested inspection cov- lar. The test probe is moved over the surface

erages with standard ultrasonic test instru- in smooth overlapping strokes. The direction

ments are shown in figure 5-21. In many of the stroke with regard to the surface is gen-

cases, access limitations will not permit appli- erally immaterial; however, when using the

cation of the suggested inspections in all of the Sondicator models, the direction of the stroke

areas shown. The inspection coverages and becomes critical when the test probe is

Page 5-46 Par 5-94

9/8/98 AC 43.13-1B

CHAPTER 5. NONDESTRUCTIVE INSPECTION (NDI)

SECTION 7. ULTRASONIC INSPECTION

FIGURE 5-21. Examples of bonded structure configurations and suggested inspection coverage.

Par 5-95 Page 5-47

AC 43.13-1B 9/8/98

CHAPTER 5. NONDESTRUCTIVE INSPECTION (NDI)

SECTION 7. ULTRASONIC INSPECTION

TABLE 5-7. Acceptable ultrasonic inspection methods associated with the example bonded structure configurations

shown in figure 5-21.

NUMBER ACCEPTABLE METHODS

1 Either

(a) Pulse-echo straight or angle beam, on each side

or

(b) Through-transmission.

2 Pulse-echo, straight beam, on each skin.

3 Refer to 1 for methods. If all these methods fail to have sufficient penetration

power to detect reference defects in the reference standard, then the ringing

method, applied from both sides, should be used. Otherwise, the ringing method

is unacceptable.

4 Either

(a) Ringing, on each skin of the doubler.

or

(b) Through-transmission

or

(c) Damping.

5 Ringing.

6 Through-transmission. Dotted Line represents beam direction.

7 Either

(a) Through-transmission

or

(b) Damping.

NOTE

A variety of ultrasonic testing methods and instruments are available for adaptation to specific inspection

problems. Other bond inspection instruments can be used if detailed procedures are developed and

proven on the applicable reference standards for each configuration of interest. Some representative in-

struments, which can be used for the inspection of bonded structures are; the Sondicator, Harmonic Bond

Tester, Acoustic Flaw Detector, Audible Bond Tester, Fokker Bond Tester, 210 Bond Tester, and Bon-

dascope 2100.

Page 5-48 Par 5-95

9/8/98 AC 43.13-1B

CHAPTER 5. NONDESTRUCTIVE INSPECTION (NDI)

SECTION 7. ULTRASONIC INSPECTION

TABLE 5-8. Ultrasonic inspection methods for bonded structures.

INSPECTION METHOD

THROUGH- PULSE-ECHO RINGING DAMPING

TRANSMISSION

Advantages Applicable to Applicable to struc- Applicable to com- Applicable to

structures with ei- tures with either thick plex shapes. structures with ei-

ther thick or thin or thin facing sheets. ther thick or thin

facing sheets. Detects small near facing sheets.

Determines which surface unbonds

Applicable to side is unbonded. (larger than di- Applicable to mul-

structures with ameter of search tiple-layered (more

multiple layers Detects small un- unit). than two layers)

bonded over hon- bonds. structures.

eycomb core.

Detects broken, Detects unbonds

Detects unbonds crushed, and cor- on either side.

on either side roded core.

Detects small un-

Detects broken, In some cases water bonds (larger than

crushed, and cor- in core can be de- diameter of re-

roded core. tected. ceiving search

unit).

In some cases

water in core can

be detected.

Disadvantages Access to both Inspection from both Applicable only to Applicable only to

sides of part is re- sides required, does near surface un- doublers and lami-

quired. not detect far side bonds, works best nate-type struc-

unbonds. on unbonds be- tures.

Does not deter- tween top sheet

mine layer position Applicable only to and adhesive, may Access to both

of unbonds. skin-to-honeycomb miss other un- sides required.

core structures. bonds.

Alignment of Does not deter-

search units is Reduced effective- Reduced effective- mine layer posi-

critical. ness on structures ness on thick skins. tions of unbonds.

with multiple skins

Couplant is re- over honeycomb Couplant required. Couplant required.

quired. core.

Inspection rate is Couplant required.

slow.

Par 5-95 Page 5-49

AC 43.13-1B 9/8/98

CHAPTER 5. NONDESTRUCTIVE INSPECTION (NDI)

SECTION 7. ULTRASONIC INSPECTION

operated near a surface edge. Edge effects on is a constant, the time between these signals is

vibration paths give a test reading that may be directly proportional to the thickness. Cali-

misinterpreted. To avoid edge effects, the test bration procedures are used to obtain direct

probe should be moved so that the inspection readout of test part thickness.

path follows the surface edge, giving a con- c. Thickness Measurement Instrument

stant edge for the test probe to inspect. Edge Types. Pulse-echo instruments designed ex-

effects are more pronounced in thicker mate- clusively for thickness measurements are gen-

rial. To interpret meter readings correctly, the erally used in lieu of conventional pulse-echo

operator should determine whether there are instruments; however, some conventional

variations in the thickness of the material. pulse-echo instruments also have direct thick-

c. Probe Sending Signal. With the ex- ness measurement capabilities. Conventional

ception of the Sondicator models, the test pulse-echo instruments without direct thick-

probes of the testers emit a sending signal that ness measuring capabilities can also be used

radiates in a full circle. The sending signal of for measuring thickness by using special pro-

the Sondicator probe travels from one trans- cedures.

ducer tip to the other. For this reason, the test

d. Thickness Measurement Ranges.

probe should be held so that the transducer tips Dependent upon the instrument used and the

are at right angles to the inspection path. material under test, material thickness

When inspecting honeycomb panels with a from 0.005 inches to 20 inches (or more) can

Sondicator model, the transducer tips should be measured with pulse-echo instruments de-

be moved consistently in the direction of the signed specifically for thickness measuring.

ribbon of the honeycomb or at right angles to

the ribbon so that a constant subsurface is pre- 5-97. LEAK TESTING. The flow of a

sented. pressurized gas through a leak produces sound

of both sonic and ultrasonic frequencies. If the

5-96. THICKNESS MEASUREMENTS.

gas leak is large, the sonic frequency sound it

Ultrasonic inspection methods can be used for

produces can probably be detected with the ear

measurement of material thickness in aircraft

or with such instruments as stethoscopes or

parts and structures.

microphones; however, the ear and these in-

a. Applications. Ultrasonic thickness struments have limited ability to detect and lo-

measurements are used for many applications, cate small leaks. Ultrasonic leak detectors are

such as: checking part thickness when access frequently used to detect leaks that cannot be

to the back side is not available; checking large detected by the above methods, because they

panels in interior areas where a conventional are very sensitive to ultrasonic energy and, un-

micrometer cannot reach; and in maintenance der most conditions, background noise at other

inspections for checking thickness loss due to frequencies does not affect them.

wear and/or corrosion. a. Standard Method. A standard method

b. Pulse-Echo Method. The most com- of testing for leaks using ultrasonics is pro-

monly used ultrasonic thickness measurement vided in ASTM E 1002. The method covers

method. The ultrasonic instrument measures procedures for calibration, location, and esti-

time between the initial front and back surface mated measurements of leakage by the ultra-

signals or subsequent multiple back reflection sonic technique (sometimes called ultrasonic

signals. Since the velocity for a given material translation).

Page 5-50 Par 5-95

9/8/98 AC 43.13-1B

CHAPTER 5. NONDESTRUCTIVE INSPECTION (NDI)

SECTION 7. ULTRASONIC INSPECTION

b. Detection Distance. Ultrasonic energy

in the relatively low-frequency range of

30-50 KHz travels easily through air; there-

fore, an ultrasonic leak detector can detect

leakage with the probe located away from the

leak. The maximum detection distance de-

pends on the leakage rate.

c. Typical Applications. Some typical

applications for the ultrasonic leak detector on

aircraft are: fuel system pressurization tests, air

ducts and air conditioning systems, emergency

evacuation slides, tire pressure retention, elec-

trical discharge, oxygen lines and valves, in-

ternal leaks in hydraulic valves and actuators,

fuel cell testing, identifying cavitation in hy-

draulic pumps, arcing in wave guides, cabin

and cockpit window and door seals, and cabin

pressurization testing.

5-104. [RESERVED.]

5-98.

Par 5-97 Page 5-51 (and 5-52)

You might also like

- Ultrasonic Sampling Phased Array Testing As A Replacement For X-Ray Testing of Weld Joints in Ship ConstructionDocument4 pagesUltrasonic Sampling Phased Array Testing As A Replacement For X-Ray Testing of Weld Joints in Ship ConstructionRiza KhanNo ratings yet

- Chapter 5. Nondestructive Inspection (Ndi) : Section 8. Tap Testing 5-105. GENERAL. Tap Testing Is WidelyDocument3 pagesChapter 5. Nondestructive Inspection (Ndi) : Section 8. Tap Testing 5-105. GENERAL. Tap Testing Is WidelyblackhawkNo ratings yet

- Sa 745.sa 745MDocument6 pagesSa 745.sa 745MWagner Renato AraújoNo ratings yet

- Standard Practice For Ultrasonic Examination of Austenitic Steel ForgingsDocument6 pagesStandard Practice For Ultrasonic Examination of Austenitic Steel ForgingssyyouNo ratings yet

- Astm e 1001Document9 pagesAstm e 1001KEN KNo ratings yet

- Paut Total ProcedureDocument25 pagesPaut Total ProcedureMassimo Fumarola100% (1)

- 0544 11th Icnde Paper - Implementation of Special Pa Ut Techniques For Welds in Thick Wall Components - 2015Document10 pages0544 11th Icnde Paper - Implementation of Special Pa Ut Techniques For Welds in Thick Wall Components - 2015Rupam BaruahNo ratings yet

- Random Mtrasonic Examination of Butt Welds: Prepared Pipe Fabrication Institute Engineering CommitteeDocument9 pagesRandom Mtrasonic Examination of Butt Welds: Prepared Pipe Fabrication Institute Engineering CommitteeДенис ПекшуевNo ratings yet

- SB 548Document5 pagesSB 548Edson Julio S RNo ratings yet

- Ut Proceduregeneral 141118232235 Conversion Gate02Document24 pagesUt Proceduregeneral 141118232235 Conversion Gate02Danem HalasNo ratings yet

- Ultrasonic Phased Array Inspection for Pipe WeldsDocument25 pagesUltrasonic Phased Array Inspection for Pipe WeldsphanthanhhungNo ratings yet

- Eddy Current Inspection Techniques for Aircraft StructuresDocument4 pagesEddy Current Inspection Techniques for Aircraft StructuresByronNo ratings yet

- Development and Design MetholodogyDocument6 pagesDevelopment and Design MetholodogynopNo ratings yet

- PAUT - Full Notes PDFDocument118 pagesPAUT - Full Notes PDFRamesh mudunuri100% (5)

- List NDT Techniques Commonly Used For Inspecting and ComponentsDocument12 pagesList NDT Techniques Commonly Used For Inspecting and ComponentscollinsNo ratings yet

- Reference Standards PDFDocument1 pageReference Standards PDFChandrashekhar ThiramdasuNo ratings yet

- Single Sided Weld Inspection using Advanced Ultrasonic MethodsDocument10 pagesSingle Sided Weld Inspection using Advanced Ultrasonic MethodsRamakrishnan AmbiSubbiahNo ratings yet

- Use of The Ultrasonic Time of Flight Diffraction (TOFD) TechniqueDocument12 pagesUse of The Ultrasonic Time of Flight Diffraction (TOFD) TechniqueDavidMontillaNo ratings yet

- ASME BPVC Section V (526-530)Document5 pagesASME BPVC Section V (526-530)Reza Elang HangkosoNo ratings yet

- PAUT - Full NotesDocument118 pagesPAUT - Full NotesRamesh mudunuri75% (4)

- Paut Procedure - Asme 31.3 Process PipingDocument26 pagesPaut Procedure - Asme 31.3 Process PipingKarthikeyan Ganesan100% (3)

- JSSG-2010-5-Crew Systems Part 2Document8 pagesJSSG-2010-5-Crew Systems Part 2JGarridoRubioNo ratings yet

- Nondestructive TestingDocument35 pagesNondestructive TestingabyNo ratings yet

- Eddy Current TestDocument4 pagesEddy Current TestFasil ParuvanathNo ratings yet

- Sonar: Firestone (1940) and Simons (1945)Document9 pagesSonar: Firestone (1940) and Simons (1945)Tom JonesNo ratings yet

- NDT Composite ComponentsDocument37 pagesNDT Composite ComponentsNarendra Palande100% (1)

- Sa 435Document3 pagesSa 435KHALED OSMANNo ratings yet

- Application Notes: Nondestructive Bond Testing For Aircraft CompositesDocument5 pagesApplication Notes: Nondestructive Bond Testing For Aircraft CompositesPDDELUCANo ratings yet

- Nondestructive Bond Testing For Aircraft Composites-OlympusDocument6 pagesNondestructive Bond Testing For Aircraft Composites-OlympusAhmad DanielNo ratings yet

- Iwex 3D UsDocument10 pagesIwex 3D UsHermann LeonardoNo ratings yet

- Ultrasonic TestingDocument4 pagesUltrasonic TestingSyahmie AzreeNo ratings yet

- Detection of Corrosion Damage in AircraftDocument17 pagesDetection of Corrosion Damage in AircraftLibin LalNo ratings yet

- NDT AmtDocument26 pagesNDT AmtRammohan YSNo ratings yet

- Mehmet Cagirici Department of Metallurgical and Materials Engineering, METU, 06800 Ankara, TurkeyDocument5 pagesMehmet Cagirici Department of Metallurgical and Materials Engineering, METU, 06800 Ankara, TurkeyErickNo ratings yet

- Manual Phased Array Ultrasonic Technique For Weld ApplicationDocument7 pagesManual Phased Array Ultrasonic Technique For Weld ApplicationphanthanhhungNo ratings yet

- Section 2. Visual InspectionDocument5 pagesSection 2. Visual InspectionblackhawkNo ratings yet

- Random Vibration TestingDocument3 pagesRandom Vibration TestingsueudemonNo ratings yet

- Only SCI Publications Single FileDocument6 pagesOnly SCI Publications Single FileVibhor BhardwajNo ratings yet

- Eddycurrent TestingDocument4 pagesEddycurrent TestingnvemanNo ratings yet

- NDE FORGED COMPONENTSDocument5 pagesNDE FORGED COMPONENTSveeramalaiNo ratings yet

- ISO 9001 2015 TrainingDocument242 pagesISO 9001 2015 TrainingDurgamadhaba MishraNo ratings yet

- Aedt Paut TrainingDocument22 pagesAedt Paut TrainingKeng LengNo ratings yet

- Paper NDTDocument11 pagesPaper NDTAllwin AntonyNo ratings yet

- Automated aluminum plate testingDocument6 pagesAutomated aluminum plate testingraneshNo ratings yet

- General Phased Array Questions PDFDocument7 pagesGeneral Phased Array Questions PDFMarcus AntoniusNo ratings yet

- Ultrasound Equipment Quality Assurance - CHAPTER 14Document3 pagesUltrasound Equipment Quality Assurance - CHAPTER 14Pengcab PARI Kota BekasiNo ratings yet

- 2.1 Definitions: Non-Des Truc Five Testing FNDT), Non-Destruc Five Examination fNDEJ or Non-Destructive InspectionDocument5 pages2.1 Definitions: Non-Des Truc Five Testing FNDT), Non-Destruc Five Examination fNDEJ or Non-Destructive InspectionGetapo RaminNo ratings yet

- Art 23 AsmeDocument10 pagesArt 23 AsmeKirvi16No ratings yet

- Astm E2192-13Document23 pagesAstm E2192-13Stephen LewellenNo ratings yet

- PAUT Procedure EEISDocument13 pagesPAUT Procedure EEISZakirUllahNo ratings yet

- Asme2a Sa 388Document8 pagesAsme2a Sa 388Dipankar ChakrabortyNo ratings yet

- Euronorm 186-87Document4 pagesEuronorm 186-87Pedro OliveiraNo ratings yet

- It0404 20 PDFDocument5 pagesIt0404 20 PDFIvan MauricioNo ratings yet

- Ac43.13-1b Visual TestingDocument5 pagesAc43.13-1b Visual TestingByronNo ratings yet

- Brochure AstarDocument18 pagesBrochure AstarKarthick PandiyarajNo ratings yet

- 4-5-6. Non Destructive TestingDocument59 pages4-5-6. Non Destructive TestingTEZ ANALYSIS AND STORIES100% (1)

- Asme Section V B Se-1211Document6 pagesAsme Section V B Se-1211Monica SuarezNo ratings yet

- Planar Flaw Height Sizing by Ultrasonics: Standard Guide ForDocument22 pagesPlanar Flaw Height Sizing by Ultrasonics: Standard Guide ForAnonymous gQTQ8cbUNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Document84 pagesTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)blackhawkNo ratings yet

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Document16 pagesTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)blackhawkNo ratings yet

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Document30 pagesTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)blackhawkNo ratings yet

- SMS ToolkitDocument40 pagesSMS ToolkitSushant PradhanNo ratings yet

- 072 90 00 EngineAcessoryDocument30 pages072 90 00 EngineAcessoryblackhawkNo ratings yet

- 04removal InstallationDocument28 pages04removal InstallationblackhawkNo ratings yet

- (EMM Book1 TOC) (Chapter 72 TOC) : TB3 - 117 Engine Maintenance ManualDocument65 pages(EMM Book1 TOC) (Chapter 72 TOC) : TB3 - 117 Engine Maintenance ManualblackhawkNo ratings yet

- 由陆-32MTBE: AbcdefghDocument1 page由陆-32MTBE: AbcdefghblackhawkNo ratings yet

- (EMM Book1 TOC) (Chapter 72 TOC) : (Main Menu)Document43 pages(EMM Book1 TOC) (Chapter 72 TOC) : (Main Menu)blackhawkNo ratings yet

- (EMM Book1 TOC) (Chapter 72 TOC) : TB3 - 117 Engine Maintenance ManualDocument25 pages(EMM Book1 TOC) (Chapter 72 TOC) : TB3 - 117 Engine Maintenance ManualblackhawkNo ratings yet

- 01descrjption and OperationDocument15 pages01descrjption and OperationblackhawkNo ratings yet

- 072 90 13 ChipDetectorDocument6 pages072 90 13 ChipDetectorblackhawkNo ratings yet

- AW119Kx ASMTCDocument888 pagesAW119Kx ASMTCblackhawkNo ratings yet

- Stage 2 NGV A Sembly. - Rotor.: - Engine Third Suppor1 AssemblyDocument10 pagesStage 2 NGV A Sembly. - Rotor.: - Engine Third Suppor1 AssemblyblackhawkNo ratings yet

- Engine Accessory Drives GuideDocument12 pagesEngine Accessory Drives GuideblackhawkNo ratings yet

- TM 1 1500 328 23Document99 pagesTM 1 1500 328 23blackhawk100% (1)

- 072 58 00 ExhaustSectionDocument22 pages072 58 00 ExhaustSectionblackhawkNo ratings yet

- Turbine Assembly Maintenance ManualDocument1 pageTurbine Assembly Maintenance ManualblackhawkNo ratings yet

- EASA Approved MMEL for Airbus EC135/635 HelicoptersDocument114 pagesEASA Approved MMEL for Airbus EC135/635 HelicoptersblackhawkNo ratings yet

- TB3-117 Maintenance Manual: (5) (2) 4) End (3) (2) End 4)Document59 pagesTB3-117 Maintenance Manual: (5) (2) 4) End (3) (2) End 4)blackhawkNo ratings yet

- A119Document1,060 pagesA119blackhawk100% (1)

- Combustion Chamber Description and Operation: L. GeneralDocument14 pagesCombustion Chamber Description and Operation: L. GeneralblackhawkNo ratings yet

- Arriel 1 Training Manual L1 PDFDocument354 pagesArriel 1 Training Manual L1 PDFblackhawk86% (7)

- NYCO ProductsCatalogue Issue-4Document70 pagesNYCO ProductsCatalogue Issue-4Piyush50% (2)

- 155b1 FLM EasaDocument1,548 pages155b1 FLM EasarobinyNo ratings yet

- Inspection and Repaer of Control Cables and TurnbucklesDocument13 pagesInspection and Repaer of Control Cables and TurnbucklesblackhawkNo ratings yet

- Fuel and Control System - Schematic Diagram: From Neighboring EngineDocument1 pageFuel and Control System - Schematic Diagram: From Neighboring EngineblackhawkNo ratings yet

- Tables 7-12Document6 pagesTables 7-12blackhawkNo ratings yet

- TM 1 1500 323 24 1Document1,032 pagesTM 1 1500 323 24 1blackhawkNo ratings yet

- BoltsDocument6 pagesBoltsblackhawkNo ratings yet

- Knuckle Joint ProjectDocument9 pagesKnuckle Joint ProjectDANGER M.K.SNo ratings yet

- HW3 20220367 신동민Document4 pagesHW3 20220367 신동민sdongmin488No ratings yet

- Tolerances To EN 10029 For Hot Rolled Plate 3mm and Above: GeneralDocument5 pagesTolerances To EN 10029 For Hot Rolled Plate 3mm and Above: GeneralKumar NawneetNo ratings yet

- N-G-HE - 200 - EN Pressure Safety ReliefDocument77 pagesN-G-HE - 200 - EN Pressure Safety ReliefMEGAN ASBROCK100% (1)

- Presentation On Process 2Document8 pagesPresentation On Process 2Sourav SutradharNo ratings yet

- Resume MedisDocument6 pagesResume MedisRina ekaNo ratings yet

- Lesson Plan Che463Document3 pagesLesson Plan Che463Rafiqah RahimNo ratings yet

- NASA Understanding Earth - Whats Up With PrecipitationDocument16 pagesNASA Understanding Earth - Whats Up With PrecipitationSB CarmzNo ratings yet

- Acoustic ReportDocument17 pagesAcoustic Reportgia hân phamNo ratings yet

- 01 Exercises VectorsDocument3 pages01 Exercises VectorsaneNo ratings yet

- 17.11.2016 - Päikesekiirgusega Seotud Aspektide Analüüsivõimalustest Hoonete KavandamiselDocument137 pages17.11.2016 - Päikesekiirgusega Seotud Aspektide Analüüsivõimalustest Hoonete KavandamiselJaanus HallikNo ratings yet

- Baroid Basic Mud Engineering 3Document17 pagesBaroid Basic Mud Engineering 3Alexander KlmNo ratings yet

- Eltex B4020N1332: Product Technical InformationDocument2 pagesEltex B4020N1332: Product Technical InformationAndres Giovanni Romero MuñozNo ratings yet

- Iso 5199 2002Document15 pagesIso 5199 2002jccarrillocNo ratings yet

- Introduction To Stress Linearization - FEA For AllDocument10 pagesIntroduction To Stress Linearization - FEA For AllpajadhavNo ratings yet

- Difference Between Dry Type Transformers VsDocument4 pagesDifference Between Dry Type Transformers Vsmilad rouhiniaNo ratings yet

- PCS120 Midterm Additional Review QuestionsDocument12 pagesPCS120 Midterm Additional Review QuestionsBetty WangNo ratings yet

- Brochure Ftir Cary 630 5990-8570en Us AgilentDocument12 pagesBrochure Ftir Cary 630 5990-8570en Us AgilentMarcela RobayoNo ratings yet

- Gas Pressure Regulators For Inlet Pressures Up To 100 Bar: British Standard Bs en 334:2005+A1:2009Document108 pagesGas Pressure Regulators For Inlet Pressures Up To 100 Bar: British Standard Bs en 334:2005+A1:2009vinay1999No ratings yet

- Flash and Fire Point Test StandardDocument3 pagesFlash and Fire Point Test StandardKaterin HernandezNo ratings yet

- Tutorial 2 (ME332) : Problems On Strain Rate, Stokes Laws, Surface Forces and Basic Equations & Boundary ConditionsDocument2 pagesTutorial 2 (ME332) : Problems On Strain Rate, Stokes Laws, Surface Forces and Basic Equations & Boundary ConditionsPrateeksha ShakyaNo ratings yet

- Flare - Reduced Purge Rates in StacksDocument13 pagesFlare - Reduced Purge Rates in StacksGary JonesNo ratings yet

- CHAPTER 4 Introduction To ChromatographyDocument62 pagesCHAPTER 4 Introduction To ChromatographyfieyaNo ratings yet

- Summary of Prior Work On Joiningof Oxide Dispersion-Strengthened AlloysDocument98 pagesSummary of Prior Work On Joiningof Oxide Dispersion-Strengthened Alloysarun_prasath_41No ratings yet

- Chap 6 SteelDocument18 pagesChap 6 SteelDaniel VasquezNo ratings yet

- Types of HVAC SystemsDocument6 pagesTypes of HVAC Systemsm2110100% (1)

- OlympiadDocument2 pagesOlympiadRajeev GangwarNo ratings yet

- Aluminium Pipe FittingsDocument12 pagesAluminium Pipe Fittingsrahult19No ratings yet

- Ultra - Temp Installation and Maintenance Manual IOM 101.2Document16 pagesUltra - Temp Installation and Maintenance Manual IOM 101.2Abdiel Kadir Martinez MendozaNo ratings yet

- Overview of Solid State PhysicsDocument1 pageOverview of Solid State PhysicsHenkVriesNo ratings yet