Professional Documents

Culture Documents

Eye Nut DIN 582

Uploaded by

prajakt_pieCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eye Nut DIN 582

Uploaded by

prajakt_pieCopyright:

Available Formats

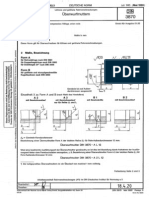

DIN 582 Lifting eye nuts

Steel / Stainless Steel

2.1

2.2

2.3

2.4

1

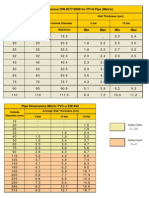

d1 d2 d3 d4 e h k m F1 max. F 2 max. F 3 max.

Steel ST St. Steel NI St. Steel A4 in N in N in N

2.5

M8 M8 - 20 36 20 8,5 36 8 10 1400 1000 700

M 10 M 10 M 10 25 45 25 10 45 10 12 2300 1700 1150

M 12 M 12 M 12 30 54 30 11 53 12 14 3400 2400 1700

M 16 M 16 M 16 35 63 35 13 62 14 16 7000 5000 3500

M 20 M 20 M 20 40 72 40 16 71 16 19 12000 8600 6000

2.6

M 24 M 24 M 24 50 90 50 20 90 20 24 18000 12900 9000

M 30 - - 65 108 60 25 109 24 28 32000 23000 16000

M 36 - - 75 126 70 30 128 28 32 46000 33000 23000

Specification 2 Information

2.7

Steel C 15 E ST The following guidelines of the lifting eye nuts DIN 582 have to be

-- drop-forged observed in addition to the load values given in the above table:

-- annealed The eye nut must be of fully screwd in to achieve a perfect contact

-- contact face machined between the two mating faces.

-- zinc plated, blue passivated

Both threads must be of a equal length and the base material of equal

2.8

Stainless Steel A2 NI strength to that of the nut.

-- drop-forged

Operating instructions with more details and specifications are included

-- contact face machined

with every delivery (see also www.ganter-griff.com/service).

Stainless Steel A4 A4

The official DIN standard sheet specifies the additional sizes M42, M48,

-- drop-forged

M56, M64, M72 x 6, M80 x 6 und M100 x 6.

-- contact face machined

2.9

Stainless Steel characteristics Page 1144 see also...

Lifting eye nuts (rotating) GN 583 Page 616

RoHS compliant

Lifting eye nut 1 d1

1 2

DIN 582-M36-ST 2 Material

2.2 Screws and Nuts, Washers, Lifting accessories | Page 611

You might also like

- Din 5685Document2 pagesDin 5685aleksandar_djordjic100% (1)

- DIN 124 - Flat Round Head RivetsDocument1 pageDIN 124 - Flat Round Head RivetsVitorMenezesNo ratings yet

- DIN 94 StahlDocument1 pageDIN 94 Stahlqian heNo ratings yet

- DIN 94 EdelstahlDocument1 pageDIN 94 Edelstahlqian heNo ratings yet

- DIN 137 EdelstahlDocument1 pageDIN 137 Edelstahlqian heNo ratings yet

- Din 6885Document1 pageDin 6885adh3ckNo ratings yet

- Din 15400Document9 pagesDin 15400aleksandar_djordjicNo ratings yet

- Din Flanges PDFDocument4 pagesDin Flanges PDFlals2No ratings yet

- Din 908 (1992) (Ger) PDFDocument3 pagesDin 908 (1992) (Ger) PDFgooseNo ratings yet

- Flange Din 2573Document4 pagesFlange Din 2573Braz Pataro NetoNo ratings yet

- DIN 8077 PipesDocument1 pageDIN 8077 Pipesvsaju100% (1)

- DIN 2458 Gelaste Buis DimensiesDocument19 pagesDIN 2458 Gelaste Buis Dimensiesstudent_blNo ratings yet

- Din 2635 PN 40 PDFDocument3 pagesDin 2635 PN 40 PDFJorgeNo ratings yet

- Din 5686Document1 pageDin 5686danielNo ratings yet

- DIN 127 EdelstahlDocument1 pageDIN 127 Edelstahlqian heNo ratings yet

- DIN 15090 Roti PDFDocument28 pagesDIN 15090 Roti PDFilehadusNo ratings yet

- Din2632 PN10Document2 pagesDin2632 PN10hardik5818No ratings yet

- Fixtures Standard Din2Document8 pagesFixtures Standard Din2dsschultzNo ratings yet

- Standarde Din FlangeDocument45 pagesStandarde Din Flangeadri2No ratings yet

- Besavne Cevi Din 2448Document1 pageBesavne Cevi Din 2448Boris AgbabaNo ratings yet

- Din 3066Document2 pagesDin 3066aleksandar_djordjic100% (2)

- Din-6885 Cuñeros PDFDocument2 pagesDin-6885 Cuñeros PDFCesar Dominguez Paredes100% (2)

- Din ADocument60 pagesDin AJoseNo ratings yet

- Molas Prato Din 2093Document3 pagesMolas Prato Din 2093marcosmac100% (1)

- Din 440Document3 pagesDin 440Abi ThomasosNo ratings yet

- Arruela Lisa DIN 126Document1 pageArruela Lisa DIN 126rafaelNo ratings yet

- Din 2501 PN 10 PDFDocument2 pagesDin 2501 PN 10 PDFAkmal Zuhri100% (1)

- Catálogo Elementos - DINDocument5 pagesCatálogo Elementos - DINpiero_rs100% (1)

- Din1688 3Document4 pagesDin1688 3Shankar V IyerNo ratings yet

- Din 6885 1Document2 pagesDin 6885 1Reyner Loza100% (1)

- Moletage DIN 82Document6 pagesMoletage DIN 82fmeylanNo ratings yet

- Besavne Cevi Din 2448Document1 pageBesavne Cevi Din 2448Dejan LukićNo ratings yet

- Lumiglas DIN 28120 PDFDocument2 pagesLumiglas DIN 28120 PDFspantiusNo ratings yet

- Din 741 + Din 1142Document1 pageDin 741 + Din 1142brotaccristianNo ratings yet

- Din 3870Document3 pagesDin 3870aleksandar_djordjic100% (2)

- Flange Din 2576Document1 pageFlange Din 2576Braz Pataro NetoNo ratings yet

- Din2634 PN25Document2 pagesDin2634 PN25naveen kumarNo ratings yet

- Castle Nuts Din935-1Document2 pagesCastle Nuts Din935-1DhanrajKumbhareNo ratings yet

- Din 5901Document16 pagesDin 5901aleksandar_djordjic100% (1)

- Din 2573 PN6Document2 pagesDin 2573 PN6Angela MarkovskaNo ratings yet

- Din MaterialDocument110 pagesDin Materialdnageshm4n244100% (1)

- Hidrant Subteran DN100Document3 pagesHidrant Subteran DN100Adrian StanescuNo ratings yet

- Imbinare Rigida Grinda - Stalp: Calculul EforturilorDocument6 pagesImbinare Rigida Grinda - Stalp: Calculul EforturilorIonela BaiesNo ratings yet

- Hexagon Lock Nuts Din439-2 PDFDocument2 pagesHexagon Lock Nuts Din439-2 PDFbkprodhNo ratings yet

- Arc SigurantaDocument4 pagesArc SigurantaPetrus UngureanuNo ratings yet

- PROIECT FilegatDocument11 pagesPROIECT FilegatloredanagraurNo ratings yet

- Klupa Delegat-1 KomadDocument1 pageKlupa Delegat-1 KomadAldin AvdićNo ratings yet

- DIN - 2080 Cono MorseDocument34 pagesDIN - 2080 Cono MorseJozmel Blancas CamarenaNo ratings yet

- Probleme Set - 2 - RezolvateDocument10 pagesProbleme Set - 2 - RezolvateRaul PopNo ratings yet

- CALCULUL ORGANOLOGIcDocument57 pagesCALCULUL ORGANOLOGIcARNNo ratings yet

- BRD - Klee-Datablad DIN 6330Document2 pagesBRD - Klee-Datablad DIN 6330LaviNo ratings yet

- Declaratia de Conformitate AT 336-2016 (FIBRE CARBON) - Stizo NuclearDocument2 pagesDeclaratia de Conformitate AT 336-2016 (FIBRE CARBON) - Stizo NuclearCorneliuPopaNo ratings yet

- Diametre Teava OtelDocument4 pagesDiametre Teava OtelLucianIonitaNo ratings yet

- Proiect TCM-Anul 4Document66 pagesProiect TCM-Anul 4Șerban GabrielNo ratings yet

- Proiect Licenta Iir Toader G Gabriel Cristian 82390 PDFDocument120 pagesProiect Licenta Iir Toader G Gabriel Cristian 82390 PDFToader GabrielNo ratings yet

- Streasina - Metoda ComponentelorDocument22 pagesStreasina - Metoda ComponentelorZsuzsanna MihalceaNo ratings yet

- Fixari Cu Suruburi MetriceDocument5 pagesFixari Cu Suruburi MetriceAnonymous whyn70No ratings yet

- Proiect Seghedin Sistem ModularDocument14 pagesProiect Seghedin Sistem ModularCotună SergiuNo ratings yet

- DinDocument2 pagesDinShreyas IyengarNo ratings yet

- DIN Flange Data ChartsDocument3 pagesDIN Flange Data ChartsmarcalpiNo ratings yet