Professional Documents

Culture Documents

Sleeve Bearing Clearances Specification PDF

Uploaded by

sujit5584Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sleeve Bearing Clearances Specification PDF

Uploaded by

sujit5584Copyright:

Available Formats

Shaft to bearing clearances for babbitted sleeve bearing horizontal motors shall be

determined in this order of preference:

1. Customer Specification

2. Manufacturer's Specification for that specific motor

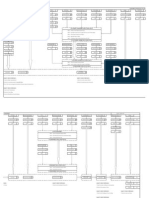

3. Manufacturer's Specification per chart Table 1 and EASA Figure 4

4. General Specification per Table 2.

TABLE 1 Babbitt Bearing Shaft Clearances per Manufacturer

MANUFACTURER MINIMUM (NEW/REBUILT AND IN SERVICE)) MAXIMUM (IN SERVICE)

GE 0.002 per shaft diameter inch 0.004 per shaft diameter inch

US Electric Motor 0.002 per shaft diameter inch

Kingsbury Max 0.002 plus 0.0010 per shaft diameter inch 0.003 plus 0.0015 per shaft diameter inch

EASA Tech Paper

(chart) Figure 4 0.003 plus 0.0010 per shaft diameter inch 0.005 plus 0.0010 per shaft diameter inch

Teco Min 0.001 plus 0.0010 per shaft diameter inch 0.0015 plus 0.0015 per shaft diameter inch

Westinghouse Min

(< 8") 0.003 plus 0.0010 per shaft diameter inch 0.005 plus 0.0010 per shaft diameter inch

Above 8" (W) lines curve toward .004 plus .001 Max & .002 plus .001 Min.

Where a minimum and maximum are given the minimum shall be interpreted as the

correct size for a new or newly rebuilt babbitted bearing in horizontal service.

TABLE 2 Babbitt Bearing General Shaft Clearances

MINIMUM

MOTOR (NEW/REBUILT AND IN SERVICE)) MAXIMUM (IN SERVICE)

For motors 600 RPM and slower with

bearing length greater than bearing inside

diameter 0.002 per shaft diameter inch 0.004 per shaft diameter inch

0.001 plus 0.0010 per shaft 0.0010 plus 0.0015 per shaft

For motors rated at 3000 RPM or higher diameter inch diameter inch

All other motors 0.0015 per shaft diameter inch 0.002 per shaft diameter inch

EASA Figure 4 Attached

SLEEVE BEARING CLEARANCES BABBITT LINED

EASA FIGURE 4 WITH NAMES

GE Maximum Tolerance

Service Center A Max

GE Minimum

USEM

Service Cntr

A Min

Kingsbury Max

TTEECCO

OMMaaxx

.0015/inch

Max

Westinghouse

Min

Kingsbury Min

TTEECCO

OMMiinn

C = Smeaton

You might also like

- Understanding End Play and Its Impact On Axial Alignment: Sleeve BearingsDocument3 pagesUnderstanding End Play and Its Impact On Axial Alignment: Sleeve Bearingsemiljanlaze100% (1)

- Thrust Bearing End PlayDocument3 pagesThrust Bearing End PlayKrishnan SanthanarajNo ratings yet

- EASA Motor Repair and Motor Efficiency PDFDocument16 pagesEASA Motor Repair and Motor Efficiency PDFflash_24014910No ratings yet

- EM 67 - Recommended Practices For A Bump TestDocument4 pagesEM 67 - Recommended Practices For A Bump TestChad Hunt100% (2)

- Journal Bearing LubricationDocument5 pagesJournal Bearing LubricationYorman Hernandez100% (1)

- Ge Runout BasicsDocument14 pagesGe Runout BasicsRajagopal100% (1)

- Cojinetes de Generador Renk Manual de AplicacionesDocument39 pagesCojinetes de Generador Renk Manual de AplicacionesMiguel Angel PonceNo ratings yet

- Alignment Protocol: Siemens LTDDocument6 pagesAlignment Protocol: Siemens LTDhalder_kalyan9216100% (1)

- Adre BrochureDocument12 pagesAdre BrochurenuesteNo ratings yet

- Tilting Pad BearingDocument11 pagesTilting Pad BearingDharmendra JainNo ratings yet

- Sleeve Bearing Specification For MotorDocument45 pagesSleeve Bearing Specification For MotorThiMinhKhuyen100% (2)

- RENK Catalog Size E-EFDocument20 pagesRENK Catalog Size E-EFAlex SeguidaNo ratings yet

- SMP 7Document5 pagesSMP 7gullipalli srinivasa raoNo ratings yet

- Vibration Shaft Vs MotorDocument1 pageVibration Shaft Vs Motoralexmontell100% (1)

- Datasheet de Motor Sincrono de Media TensionDocument40 pagesDatasheet de Motor Sincrono de Media TensionKamal ArreazaNo ratings yet

- Machinery VibrationsDocument33 pagesMachinery VibrationsDanish AfrozNo ratings yet

- Understanding Journal BearingsDocument26 pagesUnderstanding Journal BearingsΡαφαηλ Καμ.100% (1)

- Run OutDocument2 pagesRun OutMohamed BorhamNo ratings yet

- VibrationDocument24 pagesVibrationDaniel Codina100% (1)

- Bend Shaft Vibration SpectrumDocument6 pagesBend Shaft Vibration SpectrumAvnish DubeyNo ratings yet

- VACUUM PUMP DIAGNOSIS (Overall V Spectrum) - Case - Study - 10Document1 pageVACUUM PUMP DIAGNOSIS (Overall V Spectrum) - Case - Study - 10ho-faNo ratings yet

- Orbit V33N3 2013 Q3Document64 pagesOrbit V33N3 2013 Q3Adhitya DwijayanthoNo ratings yet

- Shaft Alignment ManualDocument76 pagesShaft Alignment Manualmjerkan100% (11)

- Predictive Maintenance Solutions for RM ChemicalsDocument25 pagesPredictive Maintenance Solutions for RM ChemicalsAnant Jain100% (1)

- Vibration Basic (IRD Mechanalysis)Document142 pagesVibration Basic (IRD Mechanalysis)Joppu Thomas100% (1)

- Bearing Failure Fault TreeDocument1 pageBearing Failure Fault TreeKris TrezegoalNo ratings yet

- E BearingsDocument20 pagesE BearingsEyad Amen100% (1)

- High Vibration at Main Gear Box of Gas TurbineDocument9 pagesHigh Vibration at Main Gear Box of Gas TurbineJJNo ratings yet

- SCHENCK SmartBalancer V3Document117 pagesSCHENCK SmartBalancer V3Teodor Bochev100% (1)

- Timebase Plots ExplainedDocument18 pagesTimebase Plots ExplainedManuel L LombarderoNo ratings yet

- Vibxpert 2 Manual English 112010Document170 pagesVibxpert 2 Manual English 112010santiago6767% (3)

- Condition Monitoring of Centrifugal Blower Using Vibration Analysis PDFDocument10 pagesCondition Monitoring of Centrifugal Blower Using Vibration Analysis PDFJose PradoNo ratings yet

- Dynamic Absorber DesignDocument14 pagesDynamic Absorber DesignLarry Deem0% (1)

- Generator Rotor RemovalDocument8 pagesGenerator Rotor RemovalnuesteNo ratings yet

- Generator TestingDocument11 pagesGenerator TestingYugandhara Chakravarthy Kancherla100% (1)

- Manual IRD 258Document72 pagesManual IRD 258Jaime GonzálezNo ratings yet

- Ams Machinery Manager v5 71 Installation Guide en 4236422 PDFDocument68 pagesAms Machinery Manager v5 71 Installation Guide en 4236422 PDFgspozoNo ratings yet

- Gear Box CouplingDocument30 pagesGear Box Couplingdeepthik27100% (2)

- BSM-N Servos MotorDocument1 pageBSM-N Servos MotorHéctor AraujoNo ratings yet

- Machine Data SheetDocument3 pagesMachine Data SheetThaslimNo ratings yet

- Wykrawarka Ramienna Atom G999-BroszuraDocument4 pagesWykrawarka Ramienna Atom G999-BroszuraSeba O.No ratings yet

- John Crane Met A StreamDocument4 pagesJohn Crane Met A StreamGNo ratings yet

- CW18 PDFDocument2 pagesCW18 PDFjbsb2No ratings yet

- Avery BM MetersDocument8 pagesAvery BM MetersCak LontongNo ratings yet

- Platform 2100Document4 pagesPlatform 2100Eduardo MxlNo ratings yet

- TDC 09 - R1 - S690 QL & Weldox 700Document2 pagesTDC 09 - R1 - S690 QL & Weldox 700Thennarasu VelloreNo ratings yet

- Acl Bearing 2018Document16 pagesAcl Bearing 2018LEONARDO CANDORNo ratings yet

- ABS Tuning SheetDocument18 pagesABS Tuning SheetOrlandoNo ratings yet

- SEBF8149 - Specifications For Connecting Rods Used in 3500 Family of EnginesDocument24 pagesSEBF8149 - Specifications For Connecting Rods Used in 3500 Family of Enginesyahmanmahira4No ratings yet

- Examples of Selecting A Ball Screw: High-Speed Transfer Equipment (Horizontal Use)Document26 pagesExamples of Selecting A Ball Screw: High-Speed Transfer Equipment (Horizontal Use)tarunNo ratings yet

- Bost VTCDocument13 pagesBost VTCPrasannaNo ratings yet

- Bolts Torque CalculatorDocument3 pagesBolts Torque CalculatorAlexandre LaraNo ratings yet

- Technical Service Information: Automatic Transmission Service GroupDocument4 pagesTechnical Service Information: Automatic Transmission Service GroupJOSE GARVCVIANo ratings yet

- Power Plant EnginesDocument3 pagesPower Plant EnginesManuel Armando Salazar BravoNo ratings yet

- Catálogo BOST 2017 - BajaDocument13 pagesCatálogo BOST 2017 - BajaDavid S. Valenzuela PortilloNo ratings yet

- Slick Line Rig UpDocument1 pageSlick Line Rig UpWookie VanNo ratings yet

- Introductie Weichai WHM6160 EngelsDocument40 pagesIntroductie Weichai WHM6160 EngelsParAld100% (2)

- Plastic Injection Moulding Machines: Mega NH SeriesDocument12 pagesPlastic Injection Moulding Machines: Mega NH SeriesMarcelo BoneNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Design Buckstay in Steam BoilersDocument9 pagesDesign Buckstay in Steam BoilerszaidinNo ratings yet

- Crane Training Book-Rev. 2014Document338 pagesCrane Training Book-Rev. 2014arjun100% (1)

- Hoisting Rigging FundamentalsDocument89 pagesHoisting Rigging FundamentalsRoger Loomis100% (2)

- Thrust Bearings at High Operating SpeedsDocument8 pagesThrust Bearings at High Operating SpeedszaidinNo ratings yet

- Bullivants Fabricated HandbookDocument80 pagesBullivants Fabricated HandbookMarco ViniciusNo ratings yet

- Rigging Field GuideDocument64 pagesRigging Field GuidezaidinNo ratings yet

- 4 1aDocument226 pages4 1ahydroturbinesNo ratings yet

- Asset Integrity Management HandbookDocument107 pagesAsset Integrity Management Handbookpokeboy1995% (20)

- GMP Implementation Plan 2011Document6 pagesGMP Implementation Plan 2011zaidinNo ratings yet

- International Pricelist 2012 V3Document2 pagesInternational Pricelist 2012 V3zaidinNo ratings yet

- Process Level ChartDocument2 pagesProcess Level ChartzaidinNo ratings yet

- Numerical Test 1 QuestionsDocument5 pagesNumerical Test 1 QuestionsSamuel DambaniNo ratings yet

- Transit Insurance - ExcelDocument1 pageTransit Insurance - ExcelzaidinNo ratings yet

- Unit 01-Computer BasicsDocument14 pagesUnit 01-Computer BasicsLavish MiddhaNo ratings yet

- What Are Microservices - An Introduction To Microservice Architecture - DZone MicroservicesDocument5 pagesWhat Are Microservices - An Introduction To Microservice Architecture - DZone MicroservicesAbhishek BharadwajNo ratings yet

- Isotensoid FormulationDocument12 pagesIsotensoid Formulationnhung_33No ratings yet

- Lecture9 SIQ3003 PDFDocument18 pagesLecture9 SIQ3003 PDFFion Tay0% (1)

- Watson IEC 1943Document9 pagesWatson IEC 1943mostafa shahrabiNo ratings yet

- Jasraj Grade VIII Nile Time Table Teachers ContactsDocument1 pageJasraj Grade VIII Nile Time Table Teachers ContactsSandeep Singh CheemaNo ratings yet

- Robust Vibration Isolation by Frequency-Shaped ControlDocument6 pagesRobust Vibration Isolation by Frequency-Shaped Controlvenkatb7No ratings yet

- An Introduction To Conveyor FundamentalsDocument18 pagesAn Introduction To Conveyor Fundamentalscakendri100% (2)

- ID Pengaruh Persistensi Laba Alokasi Pajak Antar Periode Ukuran Perusahaan PertumbuDocument21 pagesID Pengaruh Persistensi Laba Alokasi Pajak Antar Periode Ukuran Perusahaan PertumbuGheaMarisyaPuteriNo ratings yet

- Day 3 - SV AgreementDocument19 pagesDay 3 - SV Agreementpaulina besty fortinasariNo ratings yet

- Inquiries, Investigation, and ImmersionDocument6 pagesInquiries, Investigation, and ImmersioniNo ratings yet

- Disclosure To Promote The Right To InformationDocument20 pagesDisclosure To Promote The Right To InformationkarthisekarNo ratings yet

- Understanding Vibration Orders and HarmonicsDocument7 pagesUnderstanding Vibration Orders and HarmonicsSantiago MolinaNo ratings yet

- Lab Manual Introduction to Information & Communication TechnologiesDocument5 pagesLab Manual Introduction to Information & Communication Technologiesmehreen attiaNo ratings yet

- SD - FI IntegrationDocument21 pagesSD - FI IntegrationSivaNo ratings yet

- Manufacturing Forecasting SheetDocument10 pagesManufacturing Forecasting SheetArun kumar rouniyar100% (1)

- Hana PDFDocument7 pagesHana PDFDevender5194No ratings yet

- CSPP Geo GEOCAT Installation Guide v1.0bDocument20 pagesCSPP Geo GEOCAT Installation Guide v1.0bWasfi QordowiNo ratings yet

- Sae J2527Document19 pagesSae J2527Jose CuellarNo ratings yet

- 10 1016@j CCR 2017 03 018Document24 pages10 1016@j CCR 2017 03 018jhenyNo ratings yet

- Transaction Processing Systems IPT HSCDocument84 pagesTransaction Processing Systems IPT HSCJessNo ratings yet

- Solution Fall 2010 621 HW 3Document4 pagesSolution Fall 2010 621 HW 3alexNo ratings yet

- Sem 1 Syllabus-2019Document29 pagesSem 1 Syllabus-2019Rishi RupareliyaNo ratings yet

- IPRC Musanze Electrical Workshop Student's HandoutDocument87 pagesIPRC Musanze Electrical Workshop Student's HandoutIsaac P PlanNo ratings yet

- DC Course File (R16) 2019-20 New FormatDocument39 pagesDC Course File (R16) 2019-20 New FormatNandini ReddyNo ratings yet

- 65° Panel Antenna 1710-2200 MHz X-polarized Adjustable Electrical DowntiltDocument2 pages65° Panel Antenna 1710-2200 MHz X-polarized Adjustable Electrical DowntiltKhawar WaheedNo ratings yet

- Programs in FortranDocument12 pagesPrograms in FortranAnil Pal100% (1)

- OOAD Review: Tcs InternalDocument36 pagesOOAD Review: Tcs InternalSourav DasNo ratings yet

- Buderus Split Planning Guide GermanDocument180 pagesBuderus Split Planning Guide GermanReInvie100% (1)

- Mathematics 2016 June P1 PDFDocument9 pagesMathematics 2016 June P1 PDFMichael TimsonNo ratings yet