Professional Documents

Culture Documents

Design & Analysis of Precast Concrete Pile

Uploaded by

প্রিয়দীপ প্রিয়মOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design & Analysis of Precast Concrete Pile

Uploaded by

প্রিয়দীপ প্রিয়মCopyright:

Available Formats

DESIGN & ANALYSIS OF PRECAST DRIVEN PILE

(350mm X 350mm)

CHECK FOR DRIVING STRESS:

Formula for use with Diesel Hammer:

Ru= [12efEn/ (s+0.5(C1+C2+C3)] x [(Wr+e Wp) / (Wr+Wp)] ---------(I)*

Where,

Ru = ultimate carrying capacity of pile (considered as ultimate resistance to driving)

Wr= weight of falling mass, lb = 3.5 x 2240=7714 lb

En=Rated energy per blow, ft-lb=10.5 Ton-m=75768 lb-ft

ef= hammer efficiency =100 percent for diesel hammer.

Wp= weight of pile=[0.35x0.35x25x25] kN= 76.56 kN. = 17187.5 lb

L = length of pile = 25m=984.25 inch.

e = coefficient of restitution = 0.4

s = set value =0.25 inch

C1= temporary compression allowance for pile head and cap. = 0.1

C2= temporary compression of pile, in= Ru L/ AE= 1.1910-6 Ru

C3= temporary compression allowance for quake of ground, =0.1

A= average cross section of pile =13.78x13.78=189.89 sq. inch

E= modulus of elasticity for pile material=4.34x106psi

[*REF: FOUNDATION ENGINEERING-G.A. LEONARDS-PAGE (655-657)]

From equation no (I)

5.95x 10-7 Ru2 + 0.35 Ru 536437.44=0

Solving the above equation, Ru = 699904.85 lb =3117757.99 N

So, Stress on concrete = 3117757.99/ (350x350) = 25.45 Mpa < 40 MPa

HENCE SAFE FOR CONCRETE COMPRESSIVE STRENGTH AT DRIVING.

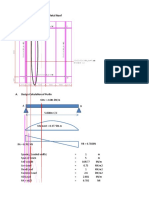

CHECK FOR LIFTING & PITCHING STRESS:

Total dead weight of pile, W =[0.35x0.35x25x25] kN=76.56 kN

Factored Dead Weight of Pile, W =1.4x76.56= 107.184 [ACI-318-14-TABLE 5.3.1]

For one point pitching at L/5, maximum developed moment = WL/14 (II)*

=76.5625/14 = 136.71 kN-m

[REF.: PILE DESIGN & CONSTRUCTION PRACTICES BY M.J. TOMLINSON]

Maximum Developed Moment, Mu=136.71 kN-m

According to ACI-318-14,

Moment Capacity of the section, Mc = As fy (d-a/2)

DESIGN & ANALYSIS OF PRECAST DRIVEN PILE

(350mm X 350mm)

Where, a= As fy / (0.85 fc b)

Here, = 0.9 [According to ACI-318- 14-21.2]

Using 8 Nos d-25mm bar

As = 1963.5 mm2 [Considering the reinforcement of the tension zone only.]

d = 287.5mm, b = 350 mm,

So Moment Capacity of the section, Mc = 217.58> 136.71 kN-m.

HENCE SAFE FOR ONE POINT PITCHING (AT 0.2 L).

For two point lifting at L/5, maximum developed moment = WL/40 [<WL/14]

HENCE SAFE FOR TWO-POINT LIFTING (AT 0.2 L).

CHECK FOR AXIAL STRESS:

According to ACI-318-14-10.3.6 & ACI-318-14-22.4.2,

Axial Capacity of Pile with lateral ties,

Pn = 0.80 [0.85fC(Ag-Ast) + fyAst]

So, Pn = 0.80 X 0.65 X [0.85 X40 X (122500-3927) +500 X 3927)]

= 3121 kN =312.1 Ton.

CHECK FOR UPLIFT CAPACITY:

According to ACI 543-R-4.3.3.1, the uplift capacity of the section can be determined from the

following equation,

Pup =0.5 x fy x Ast =0.5x500x3927 =981750 N =981.75 kN.

CHECK FOR LATERAL CAPACITY:

Here Vu=27 kN 6.5 Kip (Design Maximum Lateral Load)

fc=40 MPa=5800 psi

fy=500 MPa=72000 psi

According to ACI-318-14, lateral capacity of the section,

Vc= 2 fcbw d

=(.752580013.7811.18)/1000 [ = 0.75 {ACI-318-14-21.2.1}]

=17.60 Kips>Vu

Smax =6 inches (ACI 318-02, Section 7.10.4.3)

Smin =1 inches (ACI 318-02, Section 7.10.4.3)

Hence, provide 10 mm dia bar @ 75 mm C/C.

You might also like

- Design of 26m Precast Piles for Bangladesh Power PlantDocument6 pagesDesign of 26m Precast Piles for Bangladesh Power PlantcivixxNo ratings yet

- Analyze Driving Stress in Pre-Cast Concrete PilesDocument1 pageAnalyze Driving Stress in Pre-Cast Concrete PilesChowdhury PriodeepNo ratings yet

- 05.01.04. Differential SettlementDocument2 pages05.01.04. Differential SettlementAsif Mostafa AnikNo ratings yet

- Analysis of Bearing Capacity Driven PileDocument22 pagesAnalysis of Bearing Capacity Driven PileGEOMAHESHNo ratings yet

- Column Input Data: No Area of Each ReinforcementDocument12 pagesColumn Input Data: No Area of Each ReinforcementMatiur Rahman BasumNo ratings yet

- Hilley's FormulaDocument4 pagesHilley's FormulaFaeez ZainNo ratings yet

- Combine Footing DeasignDocument24 pagesCombine Footing DeasignSabir HussainNo ratings yet

- Design of Irregular SlabsDocument5 pagesDesign of Irregular SlabsEngr. Md. Mahmdudul Hasan ShawonNo ratings yet

- Vehicular Barrier WallDocument1 pageVehicular Barrier Walljklo12No ratings yet

- 1 Design Calculation For Metal RoofDocument29 pages1 Design Calculation For Metal RoofAlishaNo ratings yet

- Seismic Design of RC Structures 2Document15 pagesSeismic Design of RC Structures 2Wasimur rahmanNo ratings yet

- Lateral Force For One-Story Wall Based On ASCE 7-16 & 2018 IBCDocument2 pagesLateral Force For One-Story Wall Based On ASCE 7-16 & 2018 IBCxaviernpNo ratings yet

- Building Seismic Design v1.0Document1 pageBuilding Seismic Design v1.0Tabish IslamNo ratings yet

- Isoleted Footing Design 02 WSD+USDDocument6 pagesIsoleted Footing Design 02 WSD+USDMd. Nahid HossainNo ratings yet

- Wildlife Crossing Design Based On AASHTO-17th & ACI 318-14Document1 pageWildlife Crossing Design Based On AASHTO-17th & ACI 318-14jklo12No ratings yet

- Proposed Industrial Building Soil ReportDocument21 pagesProposed Industrial Building Soil ReportABDUL JABBERNo ratings yet

- GG - Serviceability ChecksDocument8 pagesGG - Serviceability ChecksGelo GuansingNo ratings yet

- Notes For CheckersDocument10 pagesNotes For CheckersSajoyan HaqueNo ratings yet

- CE325 - 16 Pile CapacityDocument45 pagesCE325 - 16 Pile CapacityRobert PrinceNo ratings yet

- Pile Load Capacity Below Scour For PUMP ROOM - Ncorrected-0.21Document17 pagesPile Load Capacity Below Scour For PUMP ROOM - Ncorrected-0.21P Allen Samuel IgnatiusNo ratings yet

- PDA Test Report ObservationsDocument5 pagesPDA Test Report ObservationsVenkat PalliNo ratings yet

- Precast Pile Driving Equipment InfoDocument4 pagesPrecast Pile Driving Equipment InfocivixxNo ratings yet

- Report of Kurigram, Sonahat Bridge - Pier-02 To Pier-13Document100 pagesReport of Kurigram, Sonahat Bridge - Pier-02 To Pier-13Shamsul IslamNo ratings yet

- Shallow Foundation Design 2: SettlementDocument32 pagesShallow Foundation Design 2: SettlementPhanna MongNo ratings yet

- Water Tank Load CalculationDocument2 pagesWater Tank Load CalculationsamNo ratings yet

- Calculating Method SetPileDocument1 pageCalculating Method SetPileNordin Ahmad100% (1)

- Young's ModuleDocument12 pagesYoung's Modulelazy catNo ratings yet

- Pile Testing For Driven or Jack-In Pile PDFDocument25 pagesPile Testing For Driven or Jack-In Pile PDFBMZNo ratings yet

- Pile Cap Design Calculations With CSI SAFEDocument7 pagesPile Cap Design Calculations With CSI SAFEEhsan ShNo ratings yet

- Load DistributionDocument44 pagesLoad Distributionሽታ ዓለሜNo ratings yet

- STRUCTURAL CALCULATION REPORTDocument20 pagesSTRUCTURAL CALCULATION REPORTBenedict OgbaghaNo ratings yet

- Piled Raft Case Study in MalaysiaDocument6 pagesPiled Raft Case Study in Malaysiasuman33No ratings yet

- 3.1-Pile Design Calculation For Boundary (p1 To p50)Document24 pages3.1-Pile Design Calculation For Boundary (p1 To p50)layaljamal2No ratings yet

- Anchore Bolt FROM MEHEDIDocument89 pagesAnchore Bolt FROM MEHEDIhabibur Rahman KhanNo ratings yet

- Modified IDOT Pile LengthDocument4 pagesModified IDOT Pile LengthPaco OzïlNo ratings yet

- ANCHORED Sheet Pile WallDocument11 pagesANCHORED Sheet Pile WallFranklyn GenoveNo ratings yet

- Wind Load Analysis: Wind Parameters: Wind (ASCE 7-10 / NSCP 2015) Velocity of Wind 300 KPH I 1.0 Exposure BDocument4 pagesWind Load Analysis: Wind Parameters: Wind (ASCE 7-10 / NSCP 2015) Velocity of Wind 300 KPH I 1.0 Exposure BErol VasquezNo ratings yet

- ch7 Deep Foundation Piles PDFDocument24 pagesch7 Deep Foundation Piles PDFJonathan SantosNo ratings yet

- Dynamic pile formulas estimate capacityDocument11 pagesDynamic pile formulas estimate capacityFaheem Ali AsgharNo ratings yet

- Design Calc Sheet - Septic Tank Rev1 15-03-09 - 200Document12 pagesDesign Calc Sheet - Septic Tank Rev1 15-03-09 - 200Bok MortegaNo ratings yet

- "Brgplt9" - Beam Bearing Plate DesignDocument3 pages"Brgplt9" - Beam Bearing Plate DesignPhanikrishnab100% (2)

- DU Swimming Pool Complex Cost EstimationDocument33 pagesDU Swimming Pool Complex Cost EstimationRezwanul IslamNo ratings yet

- PPTDocument21 pagesPPTKunwarKhaliqeAhmadNo ratings yet

- 1) Deep FoundationsDocument30 pages1) Deep FoundationsmehtabhumikaaNo ratings yet

- Lateral Loads on Piles MethodsDocument21 pagesLateral Loads on Piles MethodsCarlos FilipusNo ratings yet

- Permitted Design Methods: Method 1-Simplified ProcedureDocument39 pagesPermitted Design Methods: Method 1-Simplified ProcedureAlex Arma del CarpioNo ratings yet

- Wind Load - BNBC-2020-All Height - Slope Less Than 10 DegDocument8 pagesWind Load - BNBC-2020-All Height - Slope Less Than 10 DegFaridUddinNo ratings yet

- Hiley TableDocument5 pagesHiley TableHanafiahHamzahNo ratings yet

- RCC Bore Cast in Situ Pile Capacity Design ExcelDocument8 pagesRCC Bore Cast in Situ Pile Capacity Design ExcelMahibul HasanNo ratings yet

- ERSS-Lecture 2 (ChiewSP 5mar20)Document30 pagesERSS-Lecture 2 (ChiewSP 5mar20)sunilarunaNo ratings yet

- Paper For Bearing Capacity PDFDocument4 pagesPaper For Bearing Capacity PDFernestnsabimana74No ratings yet

- Deck Slab DesignDocument19 pagesDeck Slab DesignManvendra NigamNo ratings yet

- Era View Brochure, Apartments For Rent and Sale Across Bahrain.Document20 pagesEra View Brochure, Apartments For Rent and Sale Across Bahrain.Era Rea EstateNo ratings yet

- 518 PileCapacity PDFDocument7 pages518 PileCapacity PDFمرتضى التميميNo ratings yet

- Axial Capacity of Pile FoundationDocument32 pagesAxial Capacity of Pile FoundationChowdhury Priodeep100% (1)

- Design of Gantry Girder and RCC Overhead WatertankDocument9 pagesDesign of Gantry Girder and RCC Overhead WatertankISFAQUL AHMEDNo ratings yet

- Design Gantry Girder Industrial Building CraneDocument28 pagesDesign Gantry Girder Industrial Building Cranes_bharathkumar75% (12)

- Precast Pile Analysis & Design.400Document4 pagesPrecast Pile Analysis & Design.400civixxNo ratings yet

- Desain Pondasi PileDocument9 pagesDesain Pondasi PilegembulflowNo ratings yet

- Bearing Spark SiapDocument5 pagesBearing Spark SiapShamsul AimanNo ratings yet

- Ab-2 Re Wall DrawingDocument8 pagesAb-2 Re Wall Drawingপ্রিয়দীপ প্রিয়মNo ratings yet

- Flexible Pavement DesignDocument15 pagesFlexible Pavement Designপ্রিয়দীপ প্রিয়ম100% (1)

- Serial Number Search Certificate SummaryDocument2 pagesSerial Number Search Certificate SummaryYasith AbeywickramaNo ratings yet

- XCMG DwallDocument1 pageXCMG Dwallপ্রিয়দীপ প্রিয়মNo ratings yet

- Load Test Data SheetDocument4 pagesLoad Test Data Sheetপ্রিয়দীপ প্রিয়মNo ratings yet

- 3 PDFDocument1 page3 PDFপ্রিয়দীপ প্রিয়মNo ratings yet

- Foundation Consultants LTD.: M/S Kakoli Dying and Printing Works Ltd. Report OnDocument53 pagesFoundation Consultants LTD.: M/S Kakoli Dying and Printing Works Ltd. Report Onপ্রিয়দীপ প্রিয়মNo ratings yet

- Precast Pile Capacity 350mm Zone1Document2 pagesPrecast Pile Capacity 350mm Zone1প্রিয়দীপ প্রিয়মNo ratings yet

- Report v-1Document10 pagesReport v-1প্রিয়দীপ প্রিয়মNo ratings yet

- Equipment List-For One RigDocument10 pagesEquipment List-For One Rigপ্রিয়দীপ প্রিয়মNo ratings yet

- Content Foe Soil ReportDocument1 pageContent Foe Soil Reportপ্রিয়দীপ প্রিয়মNo ratings yet

- Applied Calculus Math 215: Karl Heinz DovermannDocument302 pagesApplied Calculus Math 215: Karl Heinz DovermannthanananNo ratings yet

- Pile Capacity Analysis Appendix DDocument1 pagePile Capacity Analysis Appendix Dপ্রিয়দীপ প্রিয়মNo ratings yet

- 1 PDFDocument1 page1 PDFপ্রিয়দীপ প্রিয়মNo ratings yet

- Equipment List-For One RigDocument3 pagesEquipment List-For One Rigপ্রিয়দীপ প্রিয়মNo ratings yet

- BH 1,1 PDFDocument1 pageBH 1,1 PDFপ্রিয়দীপ প্রিয়মNo ratings yet

- Average Daily Traffic (ADT) and other key roadway design termsDocument3 pagesAverage Daily Traffic (ADT) and other key roadway design termsপ্রিয়দীপ প্রিয়মNo ratings yet

- Project-Epc Jetty. Geotechnical Engineering Laboratory. DhakaDocument1 pageProject-Epc Jetty. Geotechnical Engineering Laboratory. Dhakaপ্রিয়দীপ প্রিয়মNo ratings yet

- Civil HandbookDocument24 pagesCivil Handbookপ্রিয়দীপ প্রিয়ম100% (1)

- UGhandbook2015 2016 FinalDocument68 pagesUGhandbook2015 2016 Finalপ্রিয়দীপ প্রিয়মNo ratings yet

- Curve FormulasDocument4 pagesCurve Formulasপ্রিয়দীপ প্রিয়মNo ratings yet

- Geometry Formula SheetDocument1 pageGeometry Formula SheetArun KumarNo ratings yet

- Curing of ConcreteDocument3 pagesCuring of Concreteপ্রিয়দীপ প্রিয়মNo ratings yet

- Uu Fee Structure Spring 2016Document1 pageUu Fee Structure Spring 2016প্রিয়দীপ প্রিয়মNo ratings yet

- Bangladesh National ParliamentDocument8 pagesBangladesh National Parliamentপ্রিয়দীপ প্রিয়মNo ratings yet

- Classifications of SoilDocument6 pagesClassifications of Soilpriodeep chowdhuryNo ratings yet

- Canteen Final ReportDocument14 pagesCanteen Final Reportপ্রিয়দীপ প্রিয়ম100% (3)

- Soil Profile - 02Document1 pageSoil Profile - 02প্রিয়দীপ প্রিয়মNo ratings yet

- Rev LayoutDocument1 pageRev Layoutপ্রিয়দীপ প্রিয়মNo ratings yet

- Railway Bridge Over Rupsha River DesignDocument1 pageRailway Bridge Over Rupsha River Designপ্রিয়দীপ প্রিয়মNo ratings yet

- Diffusion Ion Implantation PDFDocument49 pagesDiffusion Ion Implantation PDFSudhanshu ShekharNo ratings yet

- Usp (1118) Monitoring Devices-Time, Temperature, and HumidityDocument3 pagesUsp (1118) Monitoring Devices-Time, Temperature, and HumiditySara OchoaNo ratings yet

- VCR System For Low Temperature Applications: (Cascaded VCRS)Document10 pagesVCR System For Low Temperature Applications: (Cascaded VCRS)Akshay GeraNo ratings yet

- Chem1Chap1L1-States of MatterDocument10 pagesChem1Chap1L1-States of MatterLevegail SanchezNo ratings yet

- Part Wave Transformation-01Document6 pagesPart Wave Transformation-01Shivam PundirNo ratings yet

- Static Analysis of Transmission Tower BeDocument9 pagesStatic Analysis of Transmission Tower BecivildepartmentmycemNo ratings yet

- Product Data Sheet DRE80 EPDM Rubber SheetDocument1 pageProduct Data Sheet DRE80 EPDM Rubber Sheetvivashwanth paiNo ratings yet

- Aakash Kaliraman Seminar Presentation-1Document18 pagesAakash Kaliraman Seminar Presentation-1Ajay PGI/15/CV/006No ratings yet

- Jee MainsDocument32 pagesJee Mainsjhaayushbhardwaj9632No ratings yet

- J. Subbiah,: Thermal Power Station-Ii Neyveli Lignite Corporation Limited NeyveliDocument55 pagesJ. Subbiah,: Thermal Power Station-Ii Neyveli Lignite Corporation Limited Neyvelidreamboy87No ratings yet

- Quark ConfinementDocument4 pagesQuark ConfinementtachyonicsNo ratings yet

- Lupol® GP3156FDocument3 pagesLupol® GP3156FYo ANo ratings yet

- Weather in EgyptDocument4 pagesWeather in Egyptnadya farhhaNo ratings yet

- Thesis ReportDocument51 pagesThesis ReportSøüRãv JãløTrã100% (1)

- Filtration Handbook: Awareness of FluidsDocument22 pagesFiltration Handbook: Awareness of Fluidsmatteo_1234No ratings yet

- Calibration BlocksDocument3 pagesCalibration BlocksvenkatNo ratings yet

- Youngs ModulusDocument10 pagesYoungs Modulusconnectrix.gohetrixNo ratings yet

- UFC 3-570-06 - Cathodic Protection - (Draft)Document63 pagesUFC 3-570-06 - Cathodic Protection - (Draft)Johnny WalkerNo ratings yet

- Impact Test RequirementDocument6 pagesImpact Test RequirementmansurNo ratings yet

- Background To Rock Roughness EquationDocument8 pagesBackground To Rock Roughness EquationMuhammad Sya FiqNo ratings yet

- Laser Telemetric SystemDocument2 pagesLaser Telemetric Systemdellibabu509No ratings yet

- NanoCoat Leaflet PDFDocument1 pageNanoCoat Leaflet PDFProsun RoyNo ratings yet

- Bearing Angle Model For Bond of Reinforcing Bars To ConcreteDocument4 pagesBearing Angle Model For Bond of Reinforcing Bars To ConcreteRicardo EscobarNo ratings yet

- 1011 Chapter 3Document38 pages1011 Chapter 3Eman Sarmiento0% (1)

- Daikin Air Cooled Liquid Screw Chiller EWAD400D-XS-CUALDocument4 pagesDaikin Air Cooled Liquid Screw Chiller EWAD400D-XS-CUALBibin VijayakumarNo ratings yet

- What Is Filtration?Document17 pagesWhat Is Filtration?Muhammad Awais SiddiquiNo ratings yet

- Many Body ApproachDocument596 pagesMany Body Approachchvar80No ratings yet

- AFT Impulse 8 Data SheetDocument2 pagesAFT Impulse 8 Data SheetdelitesoftNo ratings yet

- Data Sheet: In-Line Proportional Chemical FeedersDocument2 pagesData Sheet: In-Line Proportional Chemical FeedersChancedaniels EmunaNo ratings yet

- API 653 Effectivity SheetDocument1 pageAPI 653 Effectivity SheetIsmail MemonNo ratings yet