Professional Documents

Culture Documents

Rotary Vacuum Dryer #

Uploaded by

PeterWangCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rotary Vacuum Dryer #

Uploaded by

PeterWangCopyright:

Available Formats

Rotary Vacuum Dryer

RVD (size 12 m3) manufactured and exported as per PED, CE marked

Dalal Rotary Vacuum Dryer offers clean, simple and effective method of

drying filtered/centrifuged wet cakes, wet powders and slurries. Operating

under vacuum, the dryer effectively dries heat sensitive materials to very low

LOD levels. Solvents are condensed and recovered. Operation is batch and

drying time depends on material being dried, amount of solvent or water to be

removed, desired LOD level, permissible jacket temperature, etc.

Larger sizes available on request.

Optionals

l Shaft sealing by mechanical seal

Dryer body being machined l Dust filter (a) Standard bag type (b) Self cleaning pulse jet type

l Internal polishing

l Pneumatically operated bottom discharge valve or actuated ball valve

Rotor / Agitator

Flush bottom discharge valve

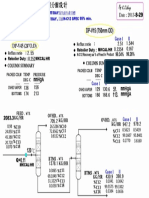

How it works Gross Loading Approx Dimensions (MM)

Rotary vacuum dryer is a horizontal cylindrical jacketed shell with Volume Volume

W L H

hollow agitator, rotating in close clearance. A batch operation,

100 40 485 1850 1430

drying is done under vacuum, heating is through jacket. The

250 100 535 2600 1270

dryer offers a simple but effective method of drying wet cakes

500 280 700 2800 1420

and sometimes slurries. Due to vacuum and agitation, it is 1000 400 800 4000 1675

possible to dry heat sensitive materials. 1500 600 1000 3800 1875

2000 800 1100 4100 1975

Advantages

2500 1000 1100 4700 1975

l Uniform drying 3000 1200 1330 4100 2200

l Short cycle time 4000 1600 1330 5000 2370

5000 2000 1520 4800 2550

l No degradation due to over-exposure, more temperature

6000 2400 1520 5500 2550

and time 9000 3600 1750 5450 4660

l Automated discharge, ease of handling, with condenser and 12000 4800 1875 7700 3590

receiver, recovery of solvents

Features / Accesssories

Direct drive

Mechanical seal

GMP design

Pulse jet dust filter

Sampling valve

Breaker bars

Product temperature probe

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Time ManagementDocument20 pagesTime Managementchristopher templarNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Study SkillsDocument32 pagesStudy SkillsAmer Al-Fawakheery80% (5)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Salesforce Platform Developer 1Document15 pagesSalesforce Platform Developer 1Kosmic PowerNo ratings yet

- Ab Initio Interview Questions - HTML PDFDocument131 pagesAb Initio Interview Questions - HTML PDFdigvijay singhNo ratings yet

- West Systems Fiberglass Boat Repair & MaintenanceDocument91 pagesWest Systems Fiberglass Boat Repair & MaintenanceDonát Nagy100% (2)

- Asme b16.36Document0 pagesAsme b16.36IPINo ratings yet

- NFPA 99 Risk AssessmentDocument5 pagesNFPA 99 Risk Assessmenttom ohnemusNo ratings yet

- Hydrogen Sulphide HazardsDocument9 pagesHydrogen Sulphide HazardsPeterWangNo ratings yet

- Soil Nailing and Rock Anchors ExplainedDocument21 pagesSoil Nailing and Rock Anchors ExplainedMark Anthony Agnes AmoresNo ratings yet

- Habawel V Court of Tax AppealsDocument1 pageHabawel V Court of Tax AppealsPerry RubioNo ratings yet

- Restructuring The Circular Economy Into The Resource Based Economy (Michaux, 2021)Document126 pagesRestructuring The Circular Economy Into The Resource Based Economy (Michaux, 2021)CliffhangerNo ratings yet

- Handling of Hydrochloric AcidDocument30 pagesHandling of Hydrochloric AcidbbmokshNo ratings yet

- Cumene Aspen PDFDocument50 pagesCumene Aspen PDFUlises ValienteNo ratings yet

- HR PlanningDocument47 pagesHR PlanningPriyanka Joshi0% (1)

- Aspen Tutorial Unit 1Document9 pagesAspen Tutorial Unit 1vsraochemical1979No ratings yet

- Travel Itinerary: Departing FlightDocument2 pagesTravel Itinerary: Departing FlightPeterWangNo ratings yet

- Pipeline RulesDocument56 pagesPipeline RulesPeterWangNo ratings yet

- Dimensions Are Critical: Cluster ControlDocument3 pagesDimensions Are Critical: Cluster ControlPeterWangNo ratings yet

- Health and Safety Incident Reporting System Users' Guide: 2004 DataDocument30 pagesHealth and Safety Incident Reporting System Users' Guide: 2004 DataPeterWangNo ratings yet

- Tank Mix and Nozzle Effects On Droplet Size: A Summary ofDocument6 pagesTank Mix and Nozzle Effects On Droplet Size: A Summary ofPeterWangNo ratings yet

- SMT-04-1006 RevA3 (App 11-08 Vacuum Trap Water Removal)Document2 pagesSMT-04-1006 RevA3 (App 11-08 Vacuum Trap Water Removal)PeterWangNo ratings yet

- LOUS 2013 Hoering Phenol ####Document100 pagesLOUS 2013 Hoering Phenol ####PeterWangNo ratings yet

- Six Sigma For SmallbusinessDocument224 pagesSix Sigma For SmallbusinessSaqueib KhanNo ratings yet

- Stolt Tank Containers B.V. General Terms & ConditionsDocument12 pagesStolt Tank Containers B.V. General Terms & ConditionsPeterWangNo ratings yet

- Cooling Coil Spec ###Document2 pagesCooling Coil Spec ###PeterWangNo ratings yet

- Abrasive Nature of Slurries and Pump SelectionDocument4 pagesAbrasive Nature of Slurries and Pump SelectionPeterWangNo ratings yet

- United States Patent (191: Briickner Et A1Document6 pagesUnited States Patent (191: Briickner Et A1PeterWangNo ratings yet

- Nc12 From CPCDocument1 pageNc12 From CPCPeterWangNo ratings yet

- Exploit The Benefits of MethanolDocument21 pagesExploit The Benefits of MethanolElvira Rossa KiranaNo ratings yet

- HYSYS - Multiple Reactions - Styrene Prepared by Robert P. Hesketh Spring 2005 Styrene Reactor SystemDocument9 pagesHYSYS - Multiple Reactions - Styrene Prepared by Robert P. Hesketh Spring 2005 Styrene Reactor SystemCarlos GonzalezNo ratings yet

- United States Patent 0: Patented July 29, 1969Document5 pagesUnited States Patent 0: Patented July 29, 1969PeterWangNo ratings yet

- Seamless or Welded Pipes PDFDocument4 pagesSeamless or Welded Pipes PDFPeterWangNo ratings yet

- Surface GrapherDocument4 pagesSurface GrapherPeterWangNo ratings yet

- GT BriefDocument2 pagesGT BriefPeterWangNo ratings yet

- SvchostDocument5 pagesSvchostPeterWangNo ratings yet

- Hex 17Document8 pagesHex 17PeterWangNo ratings yet

- Indian Chemical CouncilDocument21 pagesIndian Chemical CouncilPeterWangNo ratings yet

- RIE 2013 Dumping and AD DutiesDocument21 pagesRIE 2013 Dumping and AD Dutiessm jahedNo ratings yet

- Unit 4 Probability AssignmentsDocument8 pagesUnit 4 Probability AssignmentsSumycheen BhusalNo ratings yet

- Environmental Pollution and Need To Preserve EnvironmentDocument3 pagesEnvironmental Pollution and Need To Preserve EnvironmentLakshmi Devar100% (1)

- HOS Dials in The Driver App - Samsara SupportDocument3 pagesHOS Dials in The Driver App - Samsara SupportMaryNo ratings yet

- Machine Problem 6 Securing Cloud Services in The IoTDocument4 pagesMachine Problem 6 Securing Cloud Services in The IoTJohn Karlo KinkitoNo ratings yet

- A Survey of The Advancing Use and Development of Machine Learning in Smart ManufacturingDocument32 pagesA Survey of The Advancing Use and Development of Machine Learning in Smart Manufacturingbeben_19No ratings yet

- Lessee Information StatementDocument1 pageLessee Information Statementmja.carilloNo ratings yet

- Application For Freshman Admission - PDF UA & PDocument4 pagesApplication For Freshman Admission - PDF UA & PVanezza June DuranNo ratings yet

- Cache Memory in Computer Architecture - Gate VidyalayDocument6 pagesCache Memory in Computer Architecture - Gate VidyalayPAINNo ratings yet

- Day / Month / Year: Certificate of No Criminal Conviction Applicant Data Collection Form (LOCAL)Document4 pagesDay / Month / Year: Certificate of No Criminal Conviction Applicant Data Collection Form (LOCAL)Lhea RecenteNo ratings yet

- Manual Centrifugadora - Jouan B4i - 2Document6 pagesManual Centrifugadora - Jouan B4i - 2Rita RosadoNo ratings yet

- How To Generate Your First 20,000 Followers On InstagramDocument44 pagesHow To Generate Your First 20,000 Followers On InstagramAdrian Pratama100% (1)

- Offer Letter - Kunal Saxena (Gurgaon)Document5 pagesOffer Letter - Kunal Saxena (Gurgaon)Neelesh PandeyNo ratings yet

- NSTP 1: Pre-AssessmentDocument3 pagesNSTP 1: Pre-AssessmentMaureen FloresNo ratings yet

- Dues+&+Bylaws+Committee+Packet ICPI John@bestadmix Com Tholyfield@Document52 pagesDues+&+Bylaws+Committee+Packet ICPI John@bestadmix Com Tholyfield@Greefield JasonNo ratings yet

- Family health assessment nursing problemsDocument8 pagesFamily health assessment nursing problemsMari MazNo ratings yet

- November 2022 Examination: Indian Institution of Industrial Engineering Internal Assignment For IIIE StudentsDocument19 pagesNovember 2022 Examination: Indian Institution of Industrial Engineering Internal Assignment For IIIE Studentssatish gordeNo ratings yet

- Ibad Rehman CV NewDocument4 pagesIbad Rehman CV NewAnonymous ECcVsLNo ratings yet

- Infineon ICE3BXX65J DS v02 - 09 en PDFDocument28 pagesInfineon ICE3BXX65J DS v02 - 09 en PDFcadizmabNo ratings yet

- 2.1 Elements of Computational ThinkingDocument25 pages2.1 Elements of Computational ThinkingHamdi QasimNo ratings yet

- Ganbare Douki Chan MALDocument5 pagesGanbare Douki Chan MALShivam AgnihotriNo ratings yet

- Chapter 2 FlywheelDocument24 pagesChapter 2 Flywheelshazwani zamriNo ratings yet