Professional Documents

Culture Documents

Pump Bearing Housing BP Poster

Uploaded by

api-372195253100%(1)100% found this document useful (1 vote)

90 views1 pageOriginal Title

pump bearing housing bp poster

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

90 views1 pagePump Bearing Housing BP Poster

Uploaded by

api-372195253Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

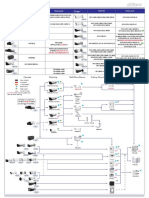

Best Practices for Pump Bearing Housings Date: 08/10/2016

Refer to full document for additional information

Bearings Lubrication system

Out of tolerance shaft fits should be avoided as they impact bearing The OEM operation manual should be consulted for

preload. Follow OEM shaft and bearing bore fit tolerance guidelines. recommendations on lubrication viscosity. Viscosity of the oil to

Thermal difference between inner and outer bearing races increases the be used is dependent on the oil sump operating temperature. The

preload in high temperature applications. Unless specified by the viscosity of synthetic oil is less sensitive to temperature

manufacturer, the exterior of a bearing housing shouldnt be cooled since changes and should be considered when large temperature

it will also cool the bearing outer race. This will reduce the internal radial fluctuations exist. If temperature also exceeds 212F (100C), a

bearing operating clearances and increase the bearing load. synthetic is recommended for improved reliability.

For general-purpose chemical process equipment, bearings should be If the oil bath level is changed for any reason, small changes and

replaced at each equipment rebuild if shaft runout is out of tolerance. careful monitoring of operating temperature and vibration levels

Thrust bearing design variations include steeper 40-deg contact angles are necessary to make sure the bearings are operating reliably.

for increased thrust capacity; machined brass cages to offer robust The bearings should not be submerged in the oil more than one-

performance in heavy-duty and poor lubrication conditions; reduced axial half the diameter of the lowest rolling element or ball bearing.

internal clearances to promote load sharing between the two rows of balls The constant level oiler control point should be aligned with

and a reduced possibility of skidding in the inactive ball set. the proper oil level of the equipment. Even if the instrument is

When properly installed, lock nuts and wave springs can be used to locate installed correctly and there is oil in the reservoir, the lubricant

bearings onto the shaft and prevent unintentional loosening. The pressure level should be checked through the bearing housing sight glass

from wave springs removes play between ball bearings and bearing races. in case the instruments supply pathway is blocked.

A breather model should be chosen with a CFM rating greater

than the CFM requirements of the tank or reservoir. Installing a

Storage breather with inadequate airflow will create excessive pressure

Rebuilt pumps should come from the clean room and be stored in a weather- or vacuum and will cause damage to the equipment.

protected environment. In the event the equipment will be stored for an Desiccant breather filters should be checked for clogs

extended period of time the pump should be sealed to prevent moisture from periodically. With a clogged breather, pressure in bearing

building in the bearing housing and in other critical component areas. compartment may deviate due to thermal changes etc, resulting

Circulating systems of any size should generally be filled with the appropriate in over feeding or under feeding.

lubricating oil and 10 percent by volume of vapor phase concentrate oil. Pump bearing housing shaft seals must be installed and

A best practice to reduce damage of bearing race is to rotate stored maintained properly in order to prevent lubricant contamination

equipment by hand every six weeks to two months. A 270 rotation is optimal. from process fluids, moisture, dirt particles, or other impurities.

Alignment Level pump, base, and motor

Alignment should be checked before grouting the baseplate, after grouting the baseplate, after connecting the piping, after the first run, and Foundation mass for centrifugal pumps should be at least five times the mass of the pump, driver, and baseplate system.

after each repair. Vertical offset, vertical angularity, horizontal offset, and horizontal angularity should be checked during each alignment. The foundation should be approximately six inches longer and wider than the baseplate.

Lasers-optic Devices should be used whenever possible. Generally, the laser is helpful when aligning shafts that are separated by more than a The foundation should rest on solid or stabilized earth completely independent of other foundations, pads, walls, or platforms.

few inches. A minimum of 3,000 psi steel reinforced concrete should be used.

Straight edges and feeler gauges should only be used for very small pump / motor combinations where there is not enough room to use larger, All mounting surfaces should be coplanar to 0.002 in. All baseplate welds should be continuous and free of cracks.

but more accurate, alignment methods.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Giordan Pergola Resume UpdatedDocument1 pageGiordan Pergola Resume Updatedapi-372195253No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team22 FpppsDocument59 pagesTeam22 Fpppsapi-372195253No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Monthly Meeting TopicDocument20 pagesMonthly Meeting Topicapi-372195253No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Pump Bearing HousingDocument9 pagesPump Bearing Housingapi-372195253No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Electrical Machines Multiple Choice Questions - Mcqs - QuizDocument10 pagesElectrical Machines Multiple Choice Questions - Mcqs - Quiztooba mukhtarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Dorian Auto production model with either-or constraints optimizationDocument1 pageDorian Auto production model with either-or constraints optimizationyanurarzaqaNo ratings yet

- Typhoon Ulysses Philippines Deadly StormDocument2 pagesTyphoon Ulysses Philippines Deadly Stormjai mansosNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- CV1000 CV2000 CV3000 Ice Cube Machines SpecsDocument12 pagesCV1000 CV2000 CV3000 Ice Cube Machines SpecsAriel Godoy100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Indian Oil Corporation Limited: Bhubaneswar Divisional OfficeDocument3 pagesIndian Oil Corporation Limited: Bhubaneswar Divisional OfficeBinay SahooNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- BiologyDocument21 pagesBiologyHrituraj banikNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Quill Vol. LVIII Issue 1 1-12Document12 pagesThe Quill Vol. LVIII Issue 1 1-12Yves Lawrence Ivan OardeNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Masturbation It Might Feel Good But ItsDocument7 pagesMasturbation It Might Feel Good But ItsKshivam KhandelwalNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Blood Group 3Document29 pagesBlood Group 3Hamirie JoshuaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Biology BIOL 1003 CH 1-3 QuizDocument14 pagesBiology BIOL 1003 CH 1-3 QuizYummyWords100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Wirkungen FlechtenstoffeDocument21 pagesWirkungen FlechtenstoffeLogge UliNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 2nd Quarter Summative Test in MusicDocument2 pages2nd Quarter Summative Test in MusicIverAlambraNo ratings yet

- LOGARITHMS, Exponentials & Logarithms From A-Level Maths TutorDocument1 pageLOGARITHMS, Exponentials & Logarithms From A-Level Maths TutorHorizon 99No ratings yet

- 1 John 2:15-27 - Bible Commentary For PreachingDocument6 pages1 John 2:15-27 - Bible Commentary For PreachingJacob D. GerberNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Qualtrics Ebook Employee Lifecycle Feedback Apj - q8uL5iqE4wt2ReEuvbnIwfG4f5XuMyLtWvNFYuM5Document18 pagesQualtrics Ebook Employee Lifecycle Feedback Apj - q8uL5iqE4wt2ReEuvbnIwfG4f5XuMyLtWvNFYuM5RajNo ratings yet

- Adeptus Evangelion 2.5 - Operations ManualDocument262 pagesAdeptus Evangelion 2.5 - Operations ManualGhostwheel50% (2)

- Desiderata: by Max EhrmannDocument6 pagesDesiderata: by Max EhrmannTanay AshwathNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Chapter 1Document33 pagesChapter 1Salihah AbdullahNo ratings yet

- Cricothyroidotomy and Needle CricothyrotomyDocument10 pagesCricothyroidotomy and Needle CricothyrotomykityamuwesiNo ratings yet

- PC Poles: DescriptionDocument2 pagesPC Poles: DescriptionSantoso SantNo ratings yet

- How Does Marijuana Affect The BrainDocument3 pagesHow Does Marijuana Affect The BrainWanNurAtikahNo ratings yet

- Dahua Pfa130 e Korisnicko Uputstvo EngleskiDocument5 pagesDahua Pfa130 e Korisnicko Uputstvo EngleskiSaša CucakNo ratings yet

- History: Ludwig Hunger: About Us: Home - Ludwig Hunger GMBHDocument3 pagesHistory: Ludwig Hunger: About Us: Home - Ludwig Hunger GMBHPatrizio MassaroNo ratings yet

- 2.gantry Rotation Safety CheckDocument2 pages2.gantry Rotation Safety CheckLê Hồ Nguyên ĐăngNo ratings yet

- AS 1418.2 Cranes, Hoists and Winches Part 2 Serial Hoists and WinchesDocument31 pagesAS 1418.2 Cranes, Hoists and Winches Part 2 Serial Hoists and WinchesDuy PhướcNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- IIT2019 RIT-1-CPM Chemistry TestDocument15 pagesIIT2019 RIT-1-CPM Chemistry TestPRAKHAR GUPTANo ratings yet

- Time and Work Assignments PDFDocument8 pagesTime and Work Assignments PDFpavan0% (1)

- Palm Wine SpecificationDocument10 pagesPalm Wine SpecificationUday ChaudhariNo ratings yet

- 44 Sounds Aus EnglishDocument2 pages44 Sounds Aus EnglishAlfie Arabejo Masong LaperaNo ratings yet

- Combustion Cat 2008Document32 pagesCombustion Cat 2008Miguel LinaresNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)