Professional Documents

Culture Documents

PP Clyrell Rc213m Random Cast Film

Uploaded by

Trung HoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PP Clyrell Rc213m Random Cast Film

Uploaded by

Trung HoCopyright:

Available Formats

LyondellBasell Polymers https://polymers.lyondellbasell.com/portal/site/basell/template.BASE...

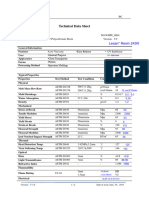

Product Data and Technical Information

Name Clyrell

Grade RC213M

Resin type Polypropylene, Specialty Products

Description Clyrell RC213M is a alpha olefin modified polypropylene random copolymer especially designed for cast

film technology. It offers an excellent clarity and gloss, a very low haze, a wide hot tack range and a

low seal-initiation temperature of 120C. It is designed for quality packaging applications, either as

monolayer film or as welding layer in coextruded structures and is in particular suitable for printing

and metallisation purpose. Clyrell RC213M is easy processable on commercial cast film equipment and

it contains antiblock additives. For regulatory information please refer to Clyrell RC213M Product

Stewardship Bulletin (PSB).

Availability Europe

Technical data

Haze <1.0 % (50 )

Secant modulus MD 660 MPa (30 mm/min)

Tensile Strength @ Brk MD 35.0 MPa

Tensile Strength @ Yld MD 22.0 MPa

Elongation at break MD 750 %

Density 0.900 g/cm

Melt flow rate (MFR) 10 g/10 min (230C/2.16Kg)

Tensile Modulus 1050 MPa (1 mm/min)

Tensile Stress at Yield 27.0 MPa (50 mm/min)

Tensile Strain at Break 600 % (50 mm/min)

Tensile Strain at Yield 10 % (50 mm/min)

Charpy notched impact strength 1.50 kJ/m (-30 C)

Charpy notched impact strength 3.40 kJ/m (23 C)

Heat deflection temperature B (0.45 MPa) Unannealed 65.0 C

Coefficient of Friction 1.0

Vicat softening temperature 130 C (A50 (50C/h 10N))

Shore hardness 66 (Shore D)

Gloss 90 (50 )

Product Data Sheets

ISO Data Sheet

ASTM Data Sheet

MSDS European

(Material Safety Data Sheet)

Clyrell RC213M

Copyright 2007 Basell Service Company B.V. All rights reserved

1 of 1 25-08-2014 12:49

You might also like

- LEXAN 9030 and Lexan 9030 TG Datasheet PDFDocument2 pagesLEXAN 9030 and Lexan 9030 TG Datasheet PDFIbrahim Levent AkkoyunluNo ratings yet

- Ultimaker ABS (TDS)Document3 pagesUltimaker ABS (TDS)reinaldolubeNo ratings yet

- Pe-Uhmw Technical Data SheetDocument1 pagePe-Uhmw Technical Data SheetPrashant MalikNo ratings yet

- General Information: 9.6 PP 100 / 20 PP 1.2Document3 pagesGeneral Information: 9.6 PP 100 / 20 PP 1.2vijayNo ratings yet

- Makrolon 6485 - en - 56978635 00009652 18539090Document4 pagesMakrolon 6485 - en - 56978635 00009652 18539090Lin DanNo ratings yet

- (Jay Shoemaker) Moldflow Design Guide 'A ResourcDocument3 pages(Jay Shoemaker) Moldflow Design Guide 'A ResourcFahri ibişoğluNo ratings yet

- Technical Data Sheet (ABS)Document7 pagesTechnical Data Sheet (ABS)Kelvin Tai Wei LimNo ratings yet

- Makrolon 2607 medium viscosity general purpose gradeDocument4 pagesMakrolon 2607 medium viscosity general purpose gradeMulyadiNo ratings yet

- Ficha Tecnica Um180821 Tds Tough Pla RB v11Document3 pagesFicha Tecnica Um180821 Tds Tough Pla RB v11Servirol CiaNo ratings yet

- Makrolon 2858 ISO enDocument4 pagesMakrolon 2858 ISO enRushyanth KRNo ratings yet

- Makrolon® ET3137: Grades / ExtrusionDocument4 pagesMakrolon® ET3137: Grades / ExtrusionDiegoTierradentroNo ratings yet

- Makrolon® 2607 Medium Viscosity Polycarbonate SheetDocument4 pagesMakrolon® 2607 Medium Viscosity Polycarbonate SheetPatriciaNo ratings yet

- Bakelite PF 31Document3 pagesBakelite PF 31dioguitomsolhaNo ratings yet

- Technical Data Sheet PC: Filament SpecificationsDocument3 pagesTechnical Data Sheet PC: Filament SpecificationsVladimir SarmientoNo ratings yet

- Makrolon 2405: General Purpose Grades / Low Viscosity / High ProductivityDocument4 pagesMakrolon 2405: General Purpose Grades / Low Viscosity / High ProductivityagungNo ratings yet

- Ldpe 2420H PDFDocument1 pageLdpe 2420H PDFjavadmohammadiNo ratings yet

- Wanhua PC Injection Moulding 20 Mfi Clarnate A1227Document2 pagesWanhua PC Injection Moulding 20 Mfi Clarnate A1227lucasNo ratings yet

- Tasnee 1925ASDocument1 pageTasnee 1925ASpolymeianNo ratings yet

- Makrolon 2405 ISO enDocument4 pagesMakrolon 2405 ISO enJuan Daniel Ledezma Alonso100% (1)

- PC 8B35 Ge Lexan PCDocument3 pagesPC 8B35 Ge Lexan PCbalu gunaNo ratings yet

- TP Wanhua Clarnate A1227 vs Lexan 243RDocument2 pagesTP Wanhua Clarnate A1227 vs Lexan 243RMitja GorseNo ratings yet

- Styrolution PS 476L: Technical DatasheetDocument3 pagesStyrolution PS 476L: Technical DatasheetTRUONGNo ratings yet

- Lexan™ Exell™ D - Sheet DatasheetDocument3 pagesLexan™ Exell™ D - Sheet DatasheetAmritraj CharlesNo ratings yet

- Grade: St900 DM311: Polypropylene CompoundDocument1 pageGrade: St900 DM311: Polypropylene Compoundhugo santiago chavez godoyNo ratings yet

- Makrolon 6557 - TDSDocument4 pagesMakrolon 6557 - TDSCassianNo ratings yet

- SABIC® PPcompound - H1030 - Global - Technical - Data - SheetDocument2 pagesSABIC® PPcompound - H1030 - Global - Technical - Data - SheetRobertoNo ratings yet

- Flame retardant Makrolon® 1952Document3 pagesFlame retardant Makrolon® 1952DiegoTierradentroNo ratings yet

- Dow Ldpe 0 75 Mfi Non Slip 310eDocument3 pagesDow Ldpe 0 75 Mfi Non Slip 310eaman.chaudhary3663No ratings yet

- Luran 368R: Technical DatasheetDocument3 pagesLuran 368R: Technical DatasheetVictor PuertoNo ratings yet

- DOW™ Butene 1221P: Linear Low Density Polyethylene ResinDocument3 pagesDOW™ Butene 1221P: Linear Low Density Polyethylene ResinMinh TranNo ratings yet

- CG60 Contact Grease Offers Enhanced Electrical and Mechanical PropertiesDocument3 pagesCG60 Contact Grease Offers Enhanced Electrical and Mechanical Propertiesouss oussNo ratings yet

- DOWLEX™ 2038.68G: Polyethylene ResinDocument3 pagesDOWLEX™ 2038.68G: Polyethylene ResinJosé PalmaNo ratings yet

- Makrolon 6265 X - en - 83439336 05122261 16125443Document4 pagesMakrolon 6265 X - en - 83439336 05122261 16125443solar4meNo ratings yet

- Bayer Makrolon - AL2447 - LensDocument4 pagesBayer Makrolon - AL2447 - LensLeandro LacerdaNo ratings yet

- 42crmo6 : Steel GradeDocument2 pages42crmo6 : Steel GradeYonas Dwiananta YuwonoNo ratings yet

- TDS Infinam ST 6100 LDocument5 pagesTDS Infinam ST 6100 LKacperNo ratings yet

- PC Makrolon 2458 - 2006Document4 pagesPC Makrolon 2458 - 2006countzeroaslNo ratings yet

- CEFOR™ 1221P: Linear Low Density Polyethylene ResinDocument3 pagesCEFOR™ 1221P: Linear Low Density Polyethylene ResincuppycuppycupNo ratings yet

- Makrolon 3206 - en - 56817747 00003433 19231690Document4 pagesMakrolon 3206 - en - 56817747 00003433 19231690noto.sugiartoNo ratings yet

- Duracon M90 44Document2 pagesDuracon M90 44PradeepNo ratings yet

- Scotch Heavy Duty Mining Tape 31: Data Sheet June 2013Document2 pagesScotch Heavy Duty Mining Tape 31: Data Sheet June 2013Kishan MohtaNo ratings yet

- PBT GF30 - Vampter 3026 V0 DFDocument1 pagePBT GF30 - Vampter 3026 V0 DFarmandoNo ratings yet

- TDS Nylon v3.011-enDocument3 pagesTDS Nylon v3.011-enmartinf090574No ratings yet

- UL 83 Specifications (Diameter) 1Document2 pagesUL 83 Specifications (Diameter) 1abdullahswais100No ratings yet

- Emerge™ Pc/Abs 7740: Technical InformationDocument3 pagesEmerge™ Pc/Abs 7740: Technical InformationbobNo ratings yet

- Cork SheetDocument2 pagesCork Sheetsaurabh bondeNo ratings yet

- Styrolution Basf Terluran GP-22Document3 pagesStyrolution Basf Terluran GP-22medo.k016No ratings yet

- UHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteelDocument4 pagesUHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteeldangdinhthyNo ratings yet

- Rowad HDSDocument1 pageRowad HDSsellami walidNo ratings yet

- TDS PC - LEXAN+141R - enDocument2 pagesTDS PC - LEXAN+141R - enSơn Nguyễn ĐắcNo ratings yet

- Durolon HFR 1910Document2 pagesDurolon HFR 1910elrolo3000No ratings yet

- Technical Data Sheet Polycarbonate: Benefits ApplicationsDocument2 pagesTechnical Data Sheet Polycarbonate: Benefits ApplicationsjackNo ratings yet

- Tasnee LD 4025as Polyethylene: DescriptionDocument2 pagesTasnee LD 4025as Polyethylene: Descriptiontrần hải namNo ratings yet

- Nylon 6-BAYER DURATHAN BKV130-901510Document3 pagesNylon 6-BAYER DURATHAN BKV130-901510dcrypto2022No ratings yet

- Makrolon 2407 - en - 86286874 00009645 19213223Document4 pagesMakrolon 2407 - en - 86286874 00009645 19213223fernandoincesaNo ratings yet

- Material Data Sheet: Item: DescriptionDocument1 pageMaterial Data Sheet: Item: DescriptionHiren MistryNo ratings yet

- Acoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsFrom EverandAcoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsNo ratings yet

- Functional Polymer Coatings: Principles, Methods, and ApplicationsFrom EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsRating: 1 out of 5 stars1/5 (1)

- Dự Đoán Và Bài Mẫu Writing Tháng 1 Và 2 2018Document7 pagesDự Đoán Và Bài Mẫu Writing Tháng 1 Và 2 2018Trung Ho100% (1)

- Infrared Spectroscopy: WWU ChemistryDocument34 pagesInfrared Spectroscopy: WWU ChemistryTrung HoNo ratings yet

- PlasticDocument18 pagesPlasticCesar Guevara GamarraNo ratings yet

- PP Clyrell Rc6034Document1 pagePP Clyrell Rc6034Trung HoNo ratings yet

- PlasticDocument18 pagesPlasticCesar Guevara GamarraNo ratings yet

- Collocations Cực Chất Cho Chủ Đề Environment - ngoc BachDocument6 pagesCollocations Cực Chất Cho Chủ Đề Environment - ngoc BachThao Phuong DaoNo ratings yet

- HighretortCPP A EasypeelDocument4 pagesHighretortCPP A EasypeelTrung HoNo ratings yet

- PP Cast FilmDocument24 pagesPP Cast FilmTrung HoNo ratings yet

- Infineon Unveils World's Smallest Nanotube TransistorDocument2 pagesInfineon Unveils World's Smallest Nanotube TransistorTrung HoNo ratings yet

- Flexible Pin Bush CouplingsDocument3 pagesFlexible Pin Bush CouplingsMAYURANDULKARNo ratings yet

- Castversusblownfilm 160815160537Document36 pagesCastversusblownfilm 160815160537Trung HoNo ratings yet

- Caùc Nguyeân Toá Phaân Nhoùm ViaDocument25 pagesCaùc Nguyeân Toá Phaân Nhoùm ViaTrung HoNo ratings yet

- Adverbs of FrequencyDocument27 pagesAdverbs of FrequencyTrung HoNo ratings yet

- The Role of Pets in PreadolescentDocument17 pagesThe Role of Pets in PreadolescentshimmyNo ratings yet

- FY&ZM JofHY (ASCE) 1943-7900Document12 pagesFY&ZM JofHY (ASCE) 1943-7900DM1988MM1No ratings yet

- Limiting Reagents 1Document17 pagesLimiting Reagents 1Aldrin Jay Patungan100% (1)

- Template 8dDocument165 pagesTemplate 8dLuis Alberto Quiroz GranadosNo ratings yet

- Efectele Pe Termen Lung Ale Alaptatului OMSDocument74 pagesEfectele Pe Termen Lung Ale Alaptatului OMSbobocraiNo ratings yet

- Ace Signal and System PDFDocument144 pagesAce Signal and System PDFYash Rai100% (1)

- Engineering Physics Question BankDocument10 pagesEngineering Physics Question BankReji K DhamanNo ratings yet

- Series - Parallel-RLC CKT EquationDocument13 pagesSeries - Parallel-RLC CKT EquationEjaz MahfuzNo ratings yet

- Automobile Engg-UNIT-1Document28 pagesAutomobile Engg-UNIT-1Muthuvel MNo ratings yet

- Tensile Properties of Ground Coffee Waste Reinforced Polyethylene CompositeDocument4 pagesTensile Properties of Ground Coffee Waste Reinforced Polyethylene CompositemhmmdzulvaNo ratings yet

- Human Skin Structure & FunctionsDocument3 pagesHuman Skin Structure & FunctionsIshansi AgrawalNo ratings yet

- Quickin: 3D/2D Modelling Suite For Integral Water SolutionsDocument110 pagesQuickin: 3D/2D Modelling Suite For Integral Water SolutionscocoNo ratings yet

- Application Research of MRAC in Fault-Tolerant Flight ControllerDocument1 pageApplication Research of MRAC in Fault-Tolerant Flight ControlleradcadNo ratings yet

- CBIP draft meter standardsDocument22 pagesCBIP draft meter standardslalit123indiaNo ratings yet

- Library System Case StudyDocument55 pagesLibrary System Case StudyUmakanth Nune50% (6)

- Atmospheric, Gage, and Absolute PressureDocument13 pagesAtmospheric, Gage, and Absolute PressureJefrie Marc LaquioNo ratings yet

- Chevalier FSG-1224ADIIIDocument12 pagesChevalier FSG-1224ADIIIOsvaldo MarinNo ratings yet

- Non-Performing Assets: A Comparative Study Ofsbi&Icici Bank From 2014-2017Document8 pagesNon-Performing Assets: A Comparative Study Ofsbi&Icici Bank From 2014-2017Shubham RautNo ratings yet

- Junction boxes gas group IIC selectionDocument16 pagesJunction boxes gas group IIC selectionkskadryNo ratings yet

- Effects of Nimodipine, Vinpocetine and Their Combination On Isoproterenol-Induced Myocardial Infarction in RatsDocument9 pagesEffects of Nimodipine, Vinpocetine and Their Combination On Isoproterenol-Induced Myocardial Infarction in RatsBilal AbbasNo ratings yet

- Deep Learning: Huawei AI Academy Training MaterialsDocument47 pagesDeep Learning: Huawei AI Academy Training Materialsfadhil muhammad hanafiNo ratings yet

- DRV IpDocument23 pagesDRV IpTim MarshallNo ratings yet

- Transportation Installation R2000iC210FDocument25 pagesTransportation Installation R2000iC210FMeet PAtel100% (2)

- Particle Size Reduction TechniquesDocument10 pagesParticle Size Reduction TechniquesJay ShahNo ratings yet

- CBCS StatisticsDocument79 pagesCBCS StatisticsXING XINGNo ratings yet

- Use Jinja2 To Create TemplatesDocument44 pagesUse Jinja2 To Create TemplatesmNo ratings yet

- Week 2Document11 pagesWeek 2KISHANo ratings yet

- Emphatic Struct and InversionDocument11 pagesEmphatic Struct and InversionMaria Veronica BustosNo ratings yet

- Puppo, F. (2012) - Dalla Vaghezza Del Linguaggio Alla Retorica Forense. Saggio Di Logica GiuridicaDocument3 pagesPuppo, F. (2012) - Dalla Vaghezza Del Linguaggio Alla Retorica Forense. Saggio Di Logica GiuridicaAldunIdhunNo ratings yet