Professional Documents

Culture Documents

Fiberglass Compositions Properties

Uploaded by

A.Subin DasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fiberglass Compositions Properties

Uploaded by

A.Subin DasCopyright:

Available Formats

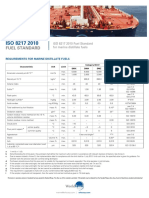

Fiberglass Compositions and Their Comparative Properties

Fiberglass composition Description, definition and characterization. A Typical soda-lime silica glass, limited for reinforcement owing to poor resistance to water.

C Chemical glasspossesses improved durability, making it preferred composition for applications requiring corrosion resistance. D Glass with improved dielectric

strength and low density, developed for improved electrical performance. E Borosilicate type, used for major share of all reinforcement applications. E-CR Modified E

glass having superior long term resistance to strain crack corrosion in acid conditions. R High-strength, high-modulus glass at a lower cost than S. S & S2 Glass with

high tensile strength and modulus, developed for aerospace applications

Chemical Properties A C D E E-CR R S & S2

Chemical Composition %

SiO2 72 65 74 52-56 58-63 60 65

CaO 10 14 0.5 16-25 21-23 9 -

Al2O3 0.6 4 0.3 12-16 10-13 25 25

MgO 2.5 3 - 0-5 2-4 6 10

B2O3 - 6 22 5-10 - - -

TiO2 - - - 0-1.5 1.0-2.5 - -

Na2O 14.2 8 1.0 0-2 0-1.2 - -

K2O - - 1.5 0-2 0-1.2 - -

Fe2O3 - 0.2 tr 0-0.8 0-0.4 - -

ZnO - - (Li2O-0.5) - 0-3.5 - -

SO3 0.7 0.1 - - - - -

F2 - - - 0-1.0 - - -

Chemical resistance14 m m fiber; % weight loss after 1 hr boil in

H2O 11.1 0.13 - 1.7 0.2 - -

1.04 N H2SO4 6.2 0.10 - 48.2 0 - -

0.1 N NaOH 15.0 2.28 - 9.7 0.2-0.6 - -

Physical Properties

Specific gravity (bare fiber) 2.50 2.49 2.16 2.52-2.61 2.63 2.55 2.49

Pristine tensile strength, psi 350,000 400,000 350,000 500,000 510,000 640,000 665,000

Tensile elastic modulus, psi 9,800,000 10,000,000 7,500,000 10,500,000 10,500,000 12,475,000 12,670,000

Elongation at 72 F, % - - 3-4 - - 5.4

Poissons ratio - - - 0.22 - - -

Thermal Properties

Softening Point, F 1300 1380 1420 1540-1555 1635 1481 1778

Coefficient of thermal expansion - in/in/ F x 10-7 90 40 17 28-33 29 74 31

Specific heat at 72 F [(k) BTU-in/hr/ft2/ F - - - 7.2 - 6.9 -

BTU/lb/ F - - - 0.197 - - -

Optical Properties

Index of refraction 1.512 1.541 1.47 1.55-1.56 (a 550 nm) 1.57 - 1.523

Electrical Properties

Dielectric constant, 72 F, 106 Hz 6.90 6.24 3.56 6.1-6.7 7.01 6.2 5.34

Loss tangent, 72 F, 106 Hz 0.0085 0.0052 0.0005 0.001 0.002 0.0015 0.002

Source: Handbook of Reinforcement for Plastics, Katz and Milewski, 1987.

You might also like

- Glass Composition, Glass TypesDocument4 pagesGlass Composition, Glass TypesKhiZra ShahZadNo ratings yet

- Technical Data Sheet: Accutherm ST-SP/521-DSDocument1 pageTechnical Data Sheet: Accutherm ST-SP/521-DSStutee NandaNo ratings yet

- Hervé Et Al. (2010a)Document22 pagesHervé Et Al. (2010a)Gabriel GonzálezNo ratings yet

- AFR Fact Sheet: Fly Ash AFR Co-Processed Volume ('000 T)Document1 pageAFR Fact Sheet: Fly Ash AFR Co-Processed Volume ('000 T)Safrin SangiaNo ratings yet

- 1-Mix Design UHPGC (W-B (0.35) (Ca 0.3) - Effect of MolarityDocument93 pages1-Mix Design UHPGC (W-B (0.35) (Ca 0.3) - Effect of MolaritySawa Zayia MichaelNo ratings yet

- En Assets ANE4 18328 Analysis of Major and Minor Elements in Cement Pressed Powders Tcm50-55501Document2 pagesEn Assets ANE4 18328 Analysis of Major and Minor Elements in Cement Pressed Powders Tcm50-55501JGGNo ratings yet

- MulcoaDocument2 pagesMulcoaRolando Cordova100% (1)

- Factors Affecting Silicomanganese Production Using Manganese Rich SlagDocument9 pagesFactors Affecting Silicomanganese Production Using Manganese Rich SlagbamboNo ratings yet

- Chemical KineticsDocument12 pagesChemical KineticsJenna MooreNo ratings yet

- MDLDocument2 pagesMDLpxng4xg9ttNo ratings yet

- KTV1Document3 pagesKTV1pxng4xg9ttNo ratings yet

- SEMIKRON Material Content Data Sheet SEMITRANS® 2 EN 2019-07-13 Rev-05Document2 pagesSEMIKRON Material Content Data Sheet SEMITRANS® 2 EN 2019-07-13 Rev-05erode els erodeNo ratings yet

- Find similar insulating brick to SkamolDocument1 pageFind similar insulating brick to SkamolpsaayoNo ratings yet

- Insulating Brick Example PDFDocument1 pageInsulating Brick Example PDFpsaayoNo ratings yet

- Chemical composition of silica sand in site 11Document3 pagesChemical composition of silica sand in site 11mohamed kassemNo ratings yet

- Ash Analysis by Atomic Absorption SpectrofotometricDocument4 pagesAsh Analysis by Atomic Absorption SpectrofotometricErnhy ErnhyNo ratings yet

- Material OptimDocument4 pagesMaterial OptimAurica FlorentinaNo ratings yet

- Raw Mix Design SoftwareDocument6 pagesRaw Mix Design SoftwareIrfan Ahmed100% (1)

- 21 PDFDocument8 pages21 PDFRoushan KumarNo ratings yet

- How To Get The Most Out of Orbis Micro-Xrf Measurements With Multiple Acquisition ConditionsDocument2 pagesHow To Get The Most Out of Orbis Micro-Xrf Measurements With Multiple Acquisition Conditionstaufiq_hidayat_1982No ratings yet

- Hitachi skd61 PDFDocument12 pagesHitachi skd61 PDFHieu Nguyen MinhNo ratings yet

- Phosphate RockDocument3 pagesPhosphate RockManoj Kumar AcharyNo ratings yet

- 1 Yield Strength Should Be The Lower Yield Point R. If It Is Not Distinct Then Choose The 0.2 % - Yield Strength RDocument3 pages1 Yield Strength Should Be The Lower Yield Point R. If It Is Not Distinct Then Choose The 0.2 % - Yield Strength RmusheerNo ratings yet

- VDM Nickel 200 VDM Nickel 201Document14 pagesVDM Nickel 200 VDM Nickel 201ivanoliveira3261No ratings yet

- DC 140223Document1 pageDC 140223pxng4xg9ttNo ratings yet

- CIPW Norm Calculation TableDocument1 pageCIPW Norm Calculation Tableguguj348No ratings yet

- Cracking EvaluationDocument17 pagesCracking Evaluationهوا عجلون-المهندسNo ratings yet

- GS 715 U-1Document1 pageGS 715 U-1Bhoomaiah SunkenapalliNo ratings yet

- Attention Sample Data: Lube Oil Analysis ReportDocument1 pageAttention Sample Data: Lube Oil Analysis ReportnurdinzaiNo ratings yet

- Attention Sample Data: Lube Oil Analysis ReportDocument1 pageAttention Sample Data: Lube Oil Analysis ReportnurdinzaiNo ratings yet

- Yojin Myanmar Cement Co.,Ltd. Slag Powder Test Results December 2021Document1 pageYojin Myanmar Cement Co.,Ltd. Slag Powder Test Results December 2021Kyaw KhineNo ratings yet

- WTP ReportDocument6 pagesWTP ReportPOWERPLANT REPORTNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardschetanNo ratings yet

- Contoh Neraca MassaDocument36 pagesContoh Neraca MassaSanji SagaNo ratings yet

- Silica/Sand Specifications: Particle Size Analysis and PropertiesDocument1 pageSilica/Sand Specifications: Particle Size Analysis and PropertiesforuzzNo ratings yet

- Effect of Slag Basicity Adjusting On Inclusions in Tire Cord Steels During Ladle Furnace Re Fining ProcessDocument7 pagesEffect of Slag Basicity Adjusting On Inclusions in Tire Cord Steels During Ladle Furnace Re Fining ProcessBoujemaa DrifNo ratings yet

- 6.5 Hasil Percobaan Dan Perhitungan 6.5.1 Hasil PercobaanDocument2 pages6.5 Hasil Percobaan Dan Perhitungan 6.5.1 Hasil PercobaanHeru JuliawanNo ratings yet

- Purification of Alumina Production Solutions: G.M. Rubinstein, N.A. Sabirzyanov, S.P. Yatsenko, S.V. LuzhbinDocument3 pagesPurification of Alumina Production Solutions: G.M. Rubinstein, N.A. Sabirzyanov, S.P. Yatsenko, S.V. Luzhbingullipalli srinivasa raoNo ratings yet

- Can Fluorspar be replaced in steelmaking.pdfDocument21 pagesCan Fluorspar be replaced in steelmaking.pdfmehdihaNo ratings yet

- Experimental Studies On Properties of Geopolymer Concrete With GGBS and Fly AshDocument8 pagesExperimental Studies On Properties of Geopolymer Concrete With GGBS and Fly AshIAEME PublicationNo ratings yet

- Lafarge Process Engg ManualsDocument132 pagesLafarge Process Engg ManualsYhane100% (1)

- Ceramic Fiber Blanket CatalogDocument7 pagesCeramic Fiber Blanket Catalogevelyn reksaNo ratings yet

- TDS - Mulcoa - 47 - Rev 1Document1 pageTDS - Mulcoa - 47 - Rev 1유유재하No ratings yet

- Contoh Soal ATKDocument6 pagesContoh Soal ATKDavid Hoktua Siregar siregarNo ratings yet

- Trubka Ocel ST 37 4 Bezesva Cerna Uk Katalogovy ListDocument2 pagesTrubka Ocel ST 37 4 Bezesva Cerna Uk Katalogovy ListVratislav Němec ml.No ratings yet

- SKD11, D2, SKH59, M42Document2 pagesSKD11, D2, SKH59, M42QA LAB ISMNo ratings yet

- Lime StoneDocument40 pagesLime StoneCygnus BackofficeNo ratings yet

- Technical Data: SilverbondDocument2 pagesTechnical Data: SilverbondI Love MusicNo ratings yet

- Data Sheet VDM Alloy 59Document16 pagesData Sheet VDM Alloy 59Iniyan Thiruselvam Navaladi KarthikeyanNo ratings yet

- Tugas - 2: Surface FacilitiesDocument5 pagesTugas - 2: Surface FacilitiesStephanie VirganaNo ratings yet

- The Preparation of The Double Sulphates of Tin and Certain Bivalent MetalsDocument3 pagesThe Preparation of The Double Sulphates of Tin and Certain Bivalent Metalscicero gomes de souzaNo ratings yet

- Uses of Natural and Industrial Byproducts in ConcreteDocument150 pagesUses of Natural and Industrial Byproducts in ConcreteIsmail MohammedNo ratings yet

- Reaksi Kimia LimestoneDocument6 pagesReaksi Kimia LimestoneRifka FadillahNo ratings yet

- B - Boehler NiMo 1-IG - de - en - 5Document1 pageB - Boehler NiMo 1-IG - de - en - 5cristian popescuNo ratings yet

- Material Safety Data Sheet: For Welding Consumables and Related ProductsDocument2 pagesMaterial Safety Data Sheet: For Welding Consumables and Related ProductsVinodhkanna GandhiNo ratings yet

- 16 Bs en 10025 2 2004 Hot Rolled Products of Structural Steel PDFDocument5 pages16 Bs en 10025 2 2004 Hot Rolled Products of Structural Steel PDFmaga2000No ratings yet

- ISO 8217 2010 Tables 1 Amp 2 1Document2 pagesISO 8217 2010 Tables 1 Amp 2 1Prashant Kumar SinghNo ratings yet

- Data Sheet VDM Alloy 80 ADocument8 pagesData Sheet VDM Alloy 80 Agigi gigioNo ratings yet

- GCE Chemistry Data Booklet Issue 2Document35 pagesGCE Chemistry Data Booklet Issue 2purityplus89% (9)

- Design and Failure Analysis of Composite Tank CoversDocument18 pagesDesign and Failure Analysis of Composite Tank CoversA.Subin DasNo ratings yet

- Reinforcing Method of Rock Slope Using FRP PipeDocument8 pagesReinforcing Method of Rock Slope Using FRP PipeA.Subin DasNo ratings yet

- Durability of FRP Rods For Concrete Structures: Francesco Micelli, Antonio NanniDocument13 pagesDurability of FRP Rods For Concrete Structures: Francesco Micelli, Antonio NannialpegambarliNo ratings yet

- Design and Failure Analysis of Composite Tank CoversDocument18 pagesDesign and Failure Analysis of Composite Tank CoversA.Subin DasNo ratings yet

- Introduction To Isometric DrawingsDocument10 pagesIntroduction To Isometric Drawingsbarnibar1No ratings yet

- PDF LV PVC Cables PDFDocument35 pagesPDF LV PVC Cables PDFsarvaryaNo ratings yet

- Is 1893 - Tanks & Water RetainingDocument667 pagesIs 1893 - Tanks & Water RetainingSwagat Mohapatra100% (3)

- Machcalc 1Document11 pagesMachcalc 1Yogesh ChaudhariNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- GRG Half Round Column Details PDFDocument1 pageGRG Half Round Column Details PDFA.Subin DasNo ratings yet

- Global FRP Standard - A Comparison Between Four Different Design Codes For FRP VesselsDocument18 pagesGlobal FRP Standard - A Comparison Between Four Different Design Codes For FRP VesselsMahadevan RamananNo ratings yet

- CAPA Processes for Medical Device QualityDocument56 pagesCAPA Processes for Medical Device QualityKristof MCNo ratings yet

- Structural design process and analysisDocument34 pagesStructural design process and analysisdave4359No ratings yet

- ISO 9001 Checklist for Quality Management SystemsDocument38 pagesISO 9001 Checklist for Quality Management SystemsZia MalikNo ratings yet

- Access Panel Specs & SizesDocument1 pageAccess Panel Specs & SizesA.Subin DasNo ratings yet

- Capa Corrective ActioDocument2 pagesCapa Corrective ActioA.Subin DasNo ratings yet

- West Region: Bruce Russell Blaine Russell Eric Stuck Steve Maybee Canada: AB, BC & SKDocument1 pageWest Region: Bruce Russell Blaine Russell Eric Stuck Steve Maybee Canada: AB, BC & SKA.Subin DasNo ratings yet

- Finance FormulasDocument5 pagesFinance FormulasA.Subin DasNo ratings yet

- Joining MethodsDocument14 pagesJoining Methodsshivam.nagarNo ratings yet

- 2 4 18 3Document3 pages2 4 18 3amr_scorpion_engNo ratings yet

- Access Panel Specs & SizesDocument1 pageAccess Panel Specs & SizesA.Subin DasNo ratings yet

- Polyester Resins For Filled Fire Retardant Applications: Firepel K320-A Series Polyester ResinDocument3 pagesPolyester Resins For Filled Fire Retardant Applications: Firepel K320-A Series Polyester ResinA.Subin DasNo ratings yet

- Follow These 5 Yoga Poses To Reduce Stubborn Belly Fat: 1.cobra Posture (Bhujang Asana)Document3 pagesFollow These 5 Yoga Poses To Reduce Stubborn Belly Fat: 1.cobra Posture (Bhujang Asana)A.Subin DasNo ratings yet

- MFG Technical Design Guide FRP Composite 0Document25 pagesMFG Technical Design Guide FRP Composite 0thiyakiNo ratings yet

- CorelDRAW X7Document699 pagesCorelDRAW X7Naveen Sajja RsaNo ratings yet

- bs4994 Case Study PDFDocument4 pagesbs4994 Case Study PDFA.Subin DasNo ratings yet

- Steel Cals SimpleDocument53 pagesSteel Cals SimpleVashish RamrechaNo ratings yet

- Capa Corrective ActioDocument2 pagesCapa Corrective ActioA.Subin DasNo ratings yet

- 3M PolyurethaneSealantsDocument12 pages3M PolyurethaneSealantsCesar MartinezNo ratings yet

- CAPA Processes for Medical Device QualityDocument56 pagesCAPA Processes for Medical Device QualityKristof MCNo ratings yet

- BS 7079-0 1990Document11 pagesBS 7079-0 1990Олег СоловьевNo ratings yet

- Architectural Powder - Mike WithersDocument36 pagesArchitectural Powder - Mike WithersPaulNo ratings yet

- Advantages of The Use of Lighter Materials in The Automotive IndustryDocument11 pagesAdvantages of The Use of Lighter Materials in The Automotive IndustryLogan JD Tdf TdayNo ratings yet

- Bend Angles 0.3 1-Dec. (.X) 0.3 Bend Radiuses 0.3 2-Dec. (.XX) 0.1 Unspecified 0.3 3-Dec. (.XXX) 0.05Document1 pageBend Angles 0.3 1-Dec. (.X) 0.3 Bend Radiuses 0.3 2-Dec. (.XX) 0.1 Unspecified 0.3 3-Dec. (.XXX) 0.05Quoc VinhNo ratings yet

- Concrete Manufacturers Association Membership ListDocument37 pagesConcrete Manufacturers Association Membership ListForbes KambaNo ratings yet

- Aluminim Welding Filler Material PDFDocument20 pagesAluminim Welding Filler Material PDFvishal bailurNo ratings yet

- Chair Making ProceduresDocument17 pagesChair Making ProceduresabduNo ratings yet

- 3 - Architectural SpecificationDocument44 pages3 - Architectural SpecificationKing RickNo ratings yet

- Norsok M 120 Material Data Sheets For Structural Steel EdDocument47 pagesNorsok M 120 Material Data Sheets For Structural Steel EdOlanrewaju OkunolaNo ratings yet

- Chiranj Shah Only Material - Rev1Document39 pagesChiranj Shah Only Material - Rev1RIMAL SHALWALANo ratings yet

- Three Storey Commercial Building (Concrete) - 18-009 - PinagsamaDocument21 pagesThree Storey Commercial Building (Concrete) - 18-009 - PinagsamaJohn Michael TalanNo ratings yet

- Qcs 2010 Section 5 Part 3 CementDocument5 pagesQcs 2010 Section 5 Part 3 Cementbryanpastor106No ratings yet

- Exploratory Study of Periwinkle Shells As Coarse Aggregates in Concrete WorksDocument5 pagesExploratory Study of Periwinkle Shells As Coarse Aggregates in Concrete WorksLoyd Rebutar MenesesNo ratings yet

- On FRCDocument59 pagesOn FRCpraful0% (1)

- 6063 VS 63400Document1 page6063 VS 63400siju1974No ratings yet

- A 5562500 PH 207Document37 pagesA 5562500 PH 207Sridharan VenkatNo ratings yet

- ACI 334.3R-05 Construction of Concrete Shells Using Inflated Forms - MyCivil - IrDocument13 pagesACI 334.3R-05 Construction of Concrete Shells Using Inflated Forms - MyCivil - IringetabascoNo ratings yet

- Glasroc X - Technical & Safety Datasheet - 21SEP21Document6 pagesGlasroc X - Technical & Safety Datasheet - 21SEP21Janna BakeerNo ratings yet

- A.K. Automatic LTD, RohtakDocument39 pagesA.K. Automatic LTD, RohtakTinku Budhwar0% (1)

- World Refining-Rocket ScienceDocument3 pagesWorld Refining-Rocket ScienceIndunil WarnasooriyaNo ratings yet

- SSH KPKNL 2021Document12 pagesSSH KPKNL 2021Taufik GeodetikNo ratings yet

- Ethacure 300Document12 pagesEthacure 300scorpionbadshahNo ratings yet

- Snag ListDocument14 pagesSnag ListAndrew TorranceNo ratings yet

- Spiraltec Non-Metallic FillersDocument1 pageSpiraltec Non-Metallic FillersJakir HossainNo ratings yet

- Cadweld Welded Electrical Connections: Quick Reference Product GuideDocument12 pagesCadweld Welded Electrical Connections: Quick Reference Product GuideEstebanNo ratings yet

- Thermal Conductivity and Hardened Behavior of Eco-Friendly Concrete Incorporating Waste Polypropylene As Fine AggregateDocument6 pagesThermal Conductivity and Hardened Behavior of Eco-Friendly Concrete Incorporating Waste Polypropylene As Fine AggregateShaker QaidiNo ratings yet

- Rasco Intl Usd 4 SyscompDocument127 pagesRasco Intl Usd 4 Syscompdaniela hritucNo ratings yet

- Aurum CatalogueDocument139 pagesAurum CatalogueSAHIR INAMDARNo ratings yet

- System Data SheetsDocument59 pagesSystem Data SheetsIng Admir MatoshiNo ratings yet

- Why materials matterDocument4 pagesWhy materials matterMoch RizaNo ratings yet