Professional Documents

Culture Documents

07-Unity Check Examples PDF

Uploaded by

atiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

07-Unity Check Examples PDF

Uploaded by

atiCopyright:

Available Formats

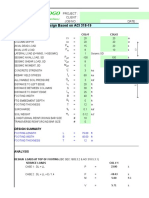

CE 331, Spring 2007 Example ASD & LRFD Failure Checks 1/3

Example problem 1. A simply-supported beam, laterally braced full length.

Dead Load (D) = 2.0 klf wL = 4.0 klf Beam is a steel wide flange, W12x53

wD = 2.0 klf

Live Load (L) = 4.0 klf Yield Stress (Fy) = 50 ksi

15 ft S = 70.6 in3

Z = 77.9 in3

w D L2 2.0klf (15 ft ) 2

MD = = = 56.3k ft

8 8

L 2

w L 4.0 (15 ft ) 2

klf

ML = = = 112.5k ft

8 8

Design Method Load Effect Resistance Failure Check

ASD M D+L y allowable bending stress f b 21.7ksi

fb = = = 0.91 < 1, OK

I Fb 23.8ksi

Allowable Stress (5.63k ft + 14.06k ft ) 4.94in Fb = 0.66 Fy = 23.8 ksi

Design fb = 4

53.8in unity check

f b = 21.7ksi

LRFD Mu = 1.2 MD + 1.6 ML Mn = () Fy Z Mu 29.3k ft

= = 0.86 < 1, OK

M n 34.0k ft

Mn = (0.9) 36ksi 12.6in3 / 12 in/ft

k-ft k-ft

Load and Resistance Mu = 1.2 (5.63 ) + 1.6 (14.06 )

Factor Design

Mu = 29.3k-ft Mn = 34.0k-ft

factored moment nominal moment capacity

strength reduction factor

CE 331, Spring 2007 Example ASD & LRFD Failure Checks 2/3

Example problem 2. A simply-supported beam, laterally braced full length.

Dead Load (D) = 2.0 klf

wL Beam is a steel wide flange, W12x53

Live Load (L) = 4.0 klf

wD

Yield Stress (Fy) = 50 ksi

w D L2 2.0klf (15 ft ) 2

M =D

= = 56.3k ft

8 8 15 ft S = 70.6 in3

section modulus = I / y

w L L2 4.0klf (15 ft ) 2

ML = = = 112.5k ft Z = 77.9 in3

8 8

Design Method Load Effect Resistance Failure Check

Lc = 9.0ft, Lu = 15.9ft (p 132 FE Ref)

D+ L

ASD M unbraced length of compression flange

fb =

S Lc < (Lb = 15ft ) < Lu f b 28.7 ksi

Allowable Stress Fb = 0.60 Fy = 0.6 (50ksi) = = 0.96 < 1

(56.3 k ft + 112.5 k ft ) 12 in / ft Fb 30 ksi

Design fb = = 28.7 ksi

70.6 in 3 Fb = 30ksi OK

Lp = 8.8ft, Lr = 25.6ft (p 128 FE Ref)

LRFD Lp < (Lb = 15ft) < Lr

Load and Resistance Mn = Cb [ Mp BF(Lb Lp)] <

Mu = 1.2 MD + 1.6 ML Mp

Factor Design

Cb = 1.0 (always for this class)

Mu = 1.2 (56.3k-ft) + 1.6 (112.5k-ft)

Mp = 292k-ft (p 128 FE Ref)

Mu = 248k-ft BF = 4.78k (p 128 FE Ref) Mu 248 k ft

= = 0.95 < 1

Mn = (1) [292kpft (4.78k(15ft 8.8ft)] M n 262 k ft

Mn = 262k-ft (< 292k-ft = Mp) OK

CE 331, Spring 2007 Example ASD & LRFD Failure Checks 3/3

Example problem 3. A single column, laterally braced at mid-height for buckling in the weak

direction, no lateral support for buckling in the strong direction.

Beam is a steel wide flange, W6x20

Dead Load PL = 75k

Yield Stress (Fy) = 50 ksi

(D) = 25k PD = 25k

Ixx = 41.4 in4

Live Load Iyy = 13.3 in4

(L) = 75k 9 ft A = 5.87 in2

Lu_x = 18 ft (unbraced length for

buckling in the strong direction)

9 ft

Lu_y = 9 ft (unbraced length for

buckling in the weak direction)

Design Load Effect Resistance Failure Check

Method

ASD P D + L 25k + 75k Ix 41.1in 4 f a 17.0ksi

fa = = rx = = = 2.65in = = 0.91 < 1,

A 5.87 in 2 A 5.87 in 2 Fa 18.7ksi

f a = 17.0ksi

Iy 13.3in 4 OK

ry = = = 1.50in

A 5.87 in 2

12in

k x Lu _ x (1.0)(18 ft )

= 1 ft = 81.5

rx 2.65in controls unity check

slenderness ratio

12in ft

k y Lu _ y (1.0)( 9 )

= 1 ft = 72.0

ry 1.50in

Fa = 18.7ksi

allowable axial stress [ from Table on pg 134 FE Ref.

for Fy = 50ksi and kL/r = 81.5 ]

Pu = 1.2 PD + 1.6 PL kL Pu 150 k

LRFD = 81.5 (from above) = = 0.98 < 1,

Pu = 1.2 (25k) + 1.6 (75k) r max Pn 153.8 k

Pu = 150k c Fcr = 26.16ksi (Table p 131 FE Ref.)

OK

cFcr = 26.16 ksi

factored axial force [from Table on pg 131 FE Ref.

for Fy = 50ksi and kL/r = 81.5 ]

Pn = c Fcr A = 26.2ksi 5.87in2

Pn =153.8kt

nominal axial capacity

You might also like

- Breadth Practice ExamDocument41 pagesBreadth Practice Examuncle ruckusNo ratings yet

- Free PE Exam Unit Conversions PDFDocument18 pagesFree PE Exam Unit Conversions PDFJay PatelNo ratings yet

- Advanced RC Week2Document41 pagesAdvanced RC Week2haloNo ratings yet

- Steel Design For The Civil PE and Structural SE Exams, 2nd EdDocument1 pageSteel Design For The Civil PE and Structural SE Exams, 2nd EdBill Paxton0% (2)

- Dual Broadband Antennas P65-15-XLH-RR: Electrical SpecificationsDocument1 pageDual Broadband Antennas P65-15-XLH-RR: Electrical Specificationspandavision76No ratings yet

- FE Review-Steel Design 2015-2Document23 pagesFE Review-Steel Design 2015-2yhszaNo ratings yet

- Appendix ADocument42 pagesAppendix Ayliu8877100% (1)

- PE Exam Review - Surveying (PDFDrive)Document52 pagesPE Exam Review - Surveying (PDFDrive)Noel Andy SaturnoNo ratings yet

- Engineering Mechanics Statics and DynamiDocument17 pagesEngineering Mechanics Statics and DynamiKirshna JolaniaNo ratings yet

- Selected Homework Problem Answers: Unified Design of Steel Structures, 3rd EditionDocument20 pagesSelected Homework Problem Answers: Unified Design of Steel Structures, 3rd EditionJames CE0% (1)

- Scour CalDocument2 pagesScour CalAnonymous O404LiV4CNo ratings yet

- Military Doc - Cannon Brittle FractureDocument46 pagesMilitary Doc - Cannon Brittle FractureGrafton MontgomeryNo ratings yet

- Sag Inlet Design Worksheet: Combination Inlet at Low PointDocument8 pagesSag Inlet Design Worksheet: Combination Inlet at Low PointMauricio DelgadoNo ratings yet

- Solutions To Fe Exam Review Problems Rev7Document21 pagesSolutions To Fe Exam Review Problems Rev7narjis banoNo ratings yet

- Estimating - Practice Solutions PE CivilDocument8 pagesEstimating - Practice Solutions PE CivilbrunoelageNo ratings yet

- Essential Mathcad for Engineering, Science, and Math: Essential Mathcad for Engineering, Science, and Math w/ CDFrom EverandEssential Mathcad for Engineering, Science, and Math: Essential Mathcad for Engineering, Science, and Math w/ CDNo ratings yet

- Bridge Load Rating PDFDocument43 pagesBridge Load Rating PDFHendra Ginting100% (1)

- Torsion 9Document7 pagesTorsion 9Cheng Por EngNo ratings yet

- Residential Interior Design: A Guide To Planning Spaces: To Download This Book The Link Is On The Last PageDocument6 pagesResidential Interior Design: A Guide To Planning Spaces: To Download This Book The Link Is On The Last PagesamNo ratings yet

- PCI Girder Stability CB-04-20 CalcDocument119 pagesPCI Girder Stability CB-04-20 CalcPurdiansyahNo ratings yet

- Crack Mitigation of Post Tensioned Floors TN454Document40 pagesCrack Mitigation of Post Tensioned Floors TN454kiranNo ratings yet

- RECTBEAMDocument16 pagesRECTBEAMselva84No ratings yet

- 7 - GeometricsDocument44 pages7 - Geometricseye4aneye1989100% (1)

- Specs For Highway and Bridge ConstructionDocument629 pagesSpecs For Highway and Bridge ConstructionmsohaibazizNo ratings yet

- Free WRE PM Practice ProblemsDocument45 pagesFree WRE PM Practice ProblemsKahui LimNo ratings yet

- Teng Method On SANDDocument2 pagesTeng Method On SANDOdspiNo ratings yet

- Chapter 9 - Strength and Serviceability Requirements: CommentaryDocument3 pagesChapter 9 - Strength and Serviceability Requirements: CommentarywaheedamerNo ratings yet

- For Civil PE Exam: Water Resources and Environmental ProblemsDocument5 pagesFor Civil PE Exam: Water Resources and Environmental ProblemsSami SyedNo ratings yet

- Advanced Design of Concrete Structures - UPCDocument5 pagesAdvanced Design of Concrete Structures - UPCRodrigo LameirasNo ratings yet

- Compaction Curve: Test NO. Wet Weight (LB.) Moisture Content (%)Document6 pagesCompaction Curve: Test NO. Wet Weight (LB.) Moisture Content (%)eye4aneye1989No ratings yet

- Load Capacities of Threaded Hanger Rods Are Indicated in The Table BelowDocument1 pageLoad Capacities of Threaded Hanger Rods Are Indicated in The Table Belownt_long76No ratings yet

- Construction-Based On Breadth Portion of ExamDocument14 pagesConstruction-Based On Breadth Portion of ExammovilaNo ratings yet

- Week 1 Problem Set Wsolutions PDFDocument58 pagesWeek 1 Problem Set Wsolutions PDFBrandonNo ratings yet

- Hello: Idaho StandardsDocument3 pagesHello: Idaho StandardsnickNo ratings yet

- JKDocument24 pagesJKWaqas AnjumNo ratings yet

- Traffic Analysis at Signalized IntersectionDocument19 pagesTraffic Analysis at Signalized IntersectionfarahNo ratings yet

- Two Way Slab Design PDFDocument12 pagesTwo Way Slab Design PDFAnand Kumar Pandiri100% (1)

- Designed and Detailed According To IS 456 As An Ordinary Moment Resisting Frame Also Called Ordinary Concrete FrameDocument3 pagesDesigned and Detailed According To IS 456 As An Ordinary Moment Resisting Frame Also Called Ordinary Concrete FrameAnonymous Gye18jNo ratings yet

- Water PDFDocument290 pagesWater PDFSam BarotillaNo ratings yet

- Design of Steel Strctures IIDocument3 pagesDesign of Steel Strctures IIRajiv SawaruthNo ratings yet

- L RFD Bridge UpdateDocument32 pagesL RFD Bridge UpdaterammirisNo ratings yet

- Circular Column Design Based On ACI 318-14: Project: Client: Design By: Job No.: Date: Review byDocument1 pageCircular Column Design Based On ACI 318-14: Project: Client: Design By: Job No.: Date: Review byJuanAlfaroRodríguezNo ratings yet

- Beam 20031213Document8 pagesBeam 20031213John AlexanderNo ratings yet

- Euler BucklingDocument6 pagesEuler Bucklingsuniljha121No ratings yet

- IntroductionDocument34 pagesIntroductionByron MantheyNo ratings yet

- 2013 Fe Review WsuDocument26 pages2013 Fe Review WsuSai KumarNo ratings yet

- Pe StructuralDocument98 pagesPe StructuralHassan Ali SadiqNo ratings yet

- E TN SWD Csa A23 3 94 007 PDFDocument5 pagesE TN SWD Csa A23 3 94 007 PDFRazvan RobertNo ratings yet

- S 239 ContentDocument48 pagesS 239 Contentrina2393No ratings yet

- NS18steeldesign 3 PDFDocument51 pagesNS18steeldesign 3 PDFLemark R.No ratings yet

- Structural Engineering Practice ProblemsDocument2 pagesStructural Engineering Practice ProblemsMansoorNo ratings yet

- TestMasters FE PE BrochureDocument11 pagesTestMasters FE PE BrochureJaneeshVargheseNo ratings yet

- Concrete Design Flowcharts 3-14-17Document19 pagesConcrete Design Flowcharts 3-14-17AbinashNo ratings yet

- Cerm IndexDocument74 pagesCerm IndexAnonymous hESJopNo ratings yet

- Engineering-Civil (0543)Document48 pagesEngineering-Civil (0543)myusuf_engineerNo ratings yet

- 8 Kircher 2015 PDFDocument40 pages8 Kircher 2015 PDFpazz0No ratings yet

- Anchor ForceDocument14 pagesAnchor ForceAdi Mulyadi100% (1)

- Nanofluid in Heat Exchangers for Mechanical Systems: Numerical SimulationFrom EverandNanofluid in Heat Exchangers for Mechanical Systems: Numerical SimulationNo ratings yet

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionFrom EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNo ratings yet

- Combined Footing Design Based On ACI 318-19: Input DataDocument18 pagesCombined Footing Design Based On ACI 318-19: Input Datamarco castilloNo ratings yet

- Yapiray KatalogDocument36 pagesYapiray KatalogatiNo ratings yet

- Catalogo Self Spanning EngDocument10 pagesCatalogo Self Spanning EngatiNo ratings yet

- Operational and Construction Guidelines: London Bus Services LimitedDocument34 pagesOperational and Construction Guidelines: London Bus Services LimitedatiNo ratings yet

- Hampshiire 278 AgreementDocument30 pagesHampshiire 278 AgreementatiNo ratings yet

- Sewers For Adoption - PUMPSDocument25 pagesSewers For Adoption - PUMPSatiNo ratings yet

- Formwork Activities in Construction - Sample Site Safety ChecklistDocument7 pagesFormwork Activities in Construction - Sample Site Safety ChecklistatiNo ratings yet

- Schwing Placing Booms SPBDocument28 pagesSchwing Placing Booms SPBatiNo ratings yet

- On Vertical Formwork: Concr Ete PressureDocument7 pagesOn Vertical Formwork: Concr Ete PressureatiNo ratings yet

- Crs Bps CN TunnelformworksystemDocument11 pagesCrs Bps CN Tunnelformworksystemati100% (1)

- Shore "X" 11-Kip Shoring SystemDocument4 pagesShore "X" 11-Kip Shoring SystematiNo ratings yet

- Alum A Beam Product SheetDocument2 pagesAlum A Beam Product SheetatiNo ratings yet

- Ce6306 Som PDFDocument55 pagesCe6306 Som PDFHemakumar ManoharanNo ratings yet

- Structural Steel: Beam: Types of BeamsDocument7 pagesStructural Steel: Beam: Types of BeamsRafael CuaNo ratings yet

- Design of Steel and Timber Structures Examples PDFDocument78 pagesDesign of Steel and Timber Structures Examples PDFsamson100% (3)

- 4281 - 06 Sandwich StructuresDocument26 pages4281 - 06 Sandwich StructuresAndrew Gilbride100% (1)

- What Is New & Changed in STAAD - ProDocument52 pagesWhat Is New & Changed in STAAD - Proanon_441948462No ratings yet

- STRUCTURALDocument65 pagesSTRUCTURALMarte Jeus Cagas FrescoNo ratings yet

- Joist (BS4 Part 1@1993 Dimensions PropertiesDocument2 pagesJoist (BS4 Part 1@1993 Dimensions PropertiesAristotle MedinaNo ratings yet

- Plan Splice Detail of Rafter I-Beam Wall Footing DetailDocument1 pagePlan Splice Detail of Rafter I-Beam Wall Footing Detailzab04148114No ratings yet

- Timber Design: Canada, Sweden, Finland, Norway and Poland, Where There Is An Abundance of Goodquality TimberDocument25 pagesTimber Design: Canada, Sweden, Finland, Norway and Poland, Where There Is An Abundance of Goodquality Timberlasitha chandima jayasingheNo ratings yet

- 6 Rolled BeamsDocument3 pages6 Rolled BeamsBCXC LLAMNo ratings yet

- SAP2000 Steel DesignDocument169 pagesSAP2000 Steel DesignFrancisco Ignacio Burgos Sepúlveda100% (4)

- CF5243 Jotun AS - 503786 RevisedDocument50 pagesCF5243 Jotun AS - 503786 RevisedOmkar PawarNo ratings yet

- Structural ShapesDocument48 pagesStructural ShapesTimbo6808No ratings yet

- Steel Section-All in OneDocument141 pagesSteel Section-All in OnejagvishaNo ratings yet

- Table 3-2 W Shape Selection by ZXDocument8 pagesTable 3-2 W Shape Selection by ZXMohammed OmerNo ratings yet

- Method Statement For HLT Dismantling WorkDocument3 pagesMethod Statement For HLT Dismantling WorkKelvin LauNo ratings yet

- Interaction Curve DrawingDocument22 pagesInteraction Curve DrawingvodasanketNo ratings yet

- Design of Wing Spar Cross Section For Optimum Fatigue Life Design of Wing Spar Cross Section For Optimum Fatigue LifeDocument6 pagesDesign of Wing Spar Cross Section For Optimum Fatigue Life Design of Wing Spar Cross Section For Optimum Fatigue LifeAwan AJaNo ratings yet

- Structural Designsteel BeamDocument7 pagesStructural Designsteel BeamAtienza Design StudioNo ratings yet

- Question Bank SOM-IIDocument6 pagesQuestion Bank SOM-IISurjit Kumar GandhiNo ratings yet

- Prismatic Beam Design: C 11 D B SDocument8 pagesPrismatic Beam Design: C 11 D B SChristian Jay GamboaNo ratings yet

- Steel Expert ECDocument35 pagesSteel Expert ECglasscrankerNo ratings yet

- Design of Replaceent Scheme of Inadequate GussetDocument9 pagesDesign of Replaceent Scheme of Inadequate GussetPartha GangopadhyayNo ratings yet

- Fabrication of Automatic Spring Rolling MachineDocument45 pagesFabrication of Automatic Spring Rolling MachineANAND KRISHNANNo ratings yet

- Experimental Study of Rigid Beam-To-Box Column Connections With Types of Internal/external StiffenersDocument16 pagesExperimental Study of Rigid Beam-To-Box Column Connections With Types of Internal/external StiffenersJairo MasaNo ratings yet

- Chapter 2. Design of Beams Using WSDDocument25 pagesChapter 2. Design of Beams Using WSDsultishNo ratings yet

- Brochure - INSDAG Architecture Award Competition 2023Document10 pagesBrochure - INSDAG Architecture Award Competition 2023ebinhorrison sNo ratings yet

- Laterally Supported and Unsupported BeamsDocument4 pagesLaterally Supported and Unsupported BeamsJoanne MartinezNo ratings yet

- Especificacion para Construcciones de Acero - Aisc 360-16Document308 pagesEspecificacion para Construcciones de Acero - Aisc 360-16Armando Farías100% (1)

- Steel Design HomeworkDocument6 pagesSteel Design Homeworkafnofghmameqww100% (1)