Professional Documents

Culture Documents

Series 1000 Hinged Closure

Uploaded by

Kavan PatelCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Series 1000 Hinged Closure

Uploaded by

Kavan PatelCopyright:

Available Formats

2930 Hwy 152 West P.O.

Box 1640 Phone 806-665-8446

Pampa, TX 79065 Fax 806-665-9736

Series 1000 Quick Opening Swing Bolt Hinged Closure

Design Crall Quick Opening Swing Bolt Hinged

Closure has an elliptical head hinged to tis own

hub. SA-325 high tensile, heat-treated eye bolts,

are pinned to the lugs on the hub so the head will

swing clear after the bolts are loosened. An O-

ring is placed in a machined groove in the head

so that it will provide a tight sealing fit between

the head and the hub. Both head and hub are

quality machined to provide self-allignment be-

tween the two.

Swing Bolt Crall Quick Opening Swing Bolt Hinged Closure provides a fast, economical, yet

simple means of access to pressure vessels and lines that require frequent opening.

Safety Features The lugs on the head are positioned at a 10 degree angle so the bolts

cannot move off the top lugs under pressure or in the process of tightening. Loosening the nut

a few extra turns to clear the top lugs will permit the head to lift and relieve any residual pres-

sure that might be present while the head remains securely retained.

Certification of Material All material used to make Crall Quick Opening Swing Bolt Hinged

Closures are made to ASME code standards. Other material can be furnished upon request.

Crall Quick Opening Swing Bolt Hinged Closure is made and designed for

ASME code service at various rated working pressures and we will supply ASME code stamp

with Partial Data Report when specified at an extr charge per order.

Internal Taper Bore Weld Bevel to match closure wall thickness is standard. (See dimen-

sion A.)

Stainless Steel 304, 304L, 316 & 316L grade stainless steel available. Prices on request.

Standard with carbon steel bolts, lugs and other exterior components. Also available with

stainless steel trim.

Materials Head - ASME SA-516 GR. 70

Head Lugs - SA-36

Eye Bolts - SA-325

Nuts - SA-194 2H

Lug Pins - SA-193 B7

O-ringBuna-N .275 O.D.

Hub lugs - SA-36

Manufacturer of Oilfield & Industrial Products

www.crallproducts.com

Series 1000 Quick Opening Swing Bolt Hinged Closure

ASME Code Stamp and partial data report fur-

nished (see current price list)

O-Ring Buna N is standard. Neophrene, Kal-

rez to 600 F., Viton, Silicone Rubber, and others

furnished on request.

Carbon Steel Working pressure 200 Psig at

100 F. standard. 300 lb., 400 lb., and 500 lb.

available.

Stainless Steel Available on request.

Economical & Simple Design

The low cost of Crall Swing Bolt Hinged

Closures make them very attractive. A

complete unit costs less than a slip-on

flange and blind and are a lot easier to op-

erate. All you have to do is weld them on.

Parts Available

Crall Closures are simply designed. All

parts can be replaced if necessary. We

crry extra bolts, nuts, washers, bolt pins

and O-rings for quick replacement.

No. &

Wrk. A Dimension Force to

Size B C D E Size Wt.

Press. I.D. O.D Lift Cap

Bolts

8 200 7-5/8 8-5/8 11 10 2-1/2 4-1/2 3-5/8 26 8

10 200 9-3/4 10-3/4 13 13 2-1/2 5-1/2 4-5/8 38 11

12 200 11-3/4 12-3/4 16 15 2-3/4 6 4-3/4 54 17

14 200 13 14 17 16 2-3/4 6-1/2 4-3/4 71 20

16 200 15 16 19 18 2-3.4 7 5-3/4 82 26

18 200 17 18 21 21 3 8 7-3/4 111 32

20 200 19 20 23 23 3 9 51 134 45

22 200 21 22 26 25 3-1/2 10 61 164 48

24 200 23 24 28 27 3-1/2 10-1/2 71 184 57

26 200 25 26 30 29 3-1/2 11 61-1/4 209 65

28 200 27 28 32 31 3-1/2 11-1/2 61-1/4 234 79

30 200 29 30 34 33 3-1/2 11-1/2 71-1/4 333 119

32 200 31 32 36 35 3-1/2 12 81-1/4 356 139

34 200 33 34 38 37 3-1/2 12 101-1/4 404 154

36 200 35 36 40 39 3-1/2 12-1/2 101-1/4 446 174

Larger sizes and 300, 400, 500, and 600 lb. working pressures available in all

but the largest sizes. Contact factory.

Manufacturer of Oilfield & Industrial Products

www.crallproducts.com

2930 Hwy 152 West P.O. Box 1640 Phone 806-665-8446

Pampa, TX 79065 Fax 806-665-9736

Procedures for Installation, Operation & Maintenance

Welding Closurer

Note: Install O-ring only after all welding on

(A) Crall Quick Opening Swing Bolt Hinged

closure is completed.

Closure will have a circumferential butt weld

Caution: Make sure pipe or vessel has

joining it to the vessel nozzle or pipe. When

been relieved of all internal pressure before

this is done, certain standard welding pro-

attempting to open closure. Otherwise it will

cedures should be taken to prevent damage

most likely result in damage or injuries to

to closure. If removal of the hub from the

persons and equipment.

closure is imperative, make sure the head is

(B) Make sure the O-ring is checked prior to

also rejoined with its proper hub.

closing the head to see if its in the correct

(B) O-ring must be removed from groove.

position in the groove.

(C) Make sure the head is closed and bolts

are tight to prevent and protect the seating

Bolt Installation, Operation &

surfaces from welding splatter. Vessel or

pipe ends must line up evenly with hub so Maintenance Procedure

there will be a uniform gap for welding.

(A) inspect the head bolts from time to time

(D) Several tacks should be placed around

for thread wear. We suggest lubricating the

the hub attaching it to the vessel or pipe.

bolts with a hydrocarbon base lubricant in

The number of tacks around the hub for cor-

accordance with the frequency and severity

rect attachment will depend on the size of

of the service involved.

the closure.

Note: Excessive thread wear can be

(E) Code procedure should be used when

caused by over tightening the bolts. Try to

welding and care should be taken to keep

avoid doing so.

weld metal deposition and heat input as

(B) If closure is to be painted make sure

low as possible and practical. Throughout

head is closed so the sealing surface is not

is circumference there should be a welded

damaged.

uniform cross section.

Note: Do not paint bolt threads.

O-ring Installation, Operation &

Closure Opening Procedure

Maintenance Procedure

(A) There will be an O-ring gasket packed (A) When opening of the closure is neces-

separately. It will have a smaller diameter sary make sure all internal pressure or vac-

than the groove. The reason for this is so it uum is relieved in pipe or vessel. Loosen

will have a tighter fit. Install the O-ring at a the bolts, however, do not swing bolts loose

90 quadrant then work it into the groove at from the head lugs until it is certain no pres-

the quadrant. Do not roll the O-ring. Make sure or vacuum exists in the pipe or vessel.

sure the O-ring and groove are clean and Then continue to loose, at the stage you

free from all foreign material. We suggest will become aware of the presence or ab-

coating the O-ring with vaseline for ambient sence of pressure. Proceed to swing bolts

temperatures and silicon for higher levels of loose from head lugs then raise head At

temperatures. this stage the opening cycle is completed.

Manufacturer of Oilfield & Industrial Products

www.crallproducts.com

You might also like

- Series 1000 Hinged ClosureDocument3 pagesSeries 1000 Hinged ClosureMurli RamchandranNo ratings yet

- GD486548NFPDocument1 pageGD486548NFPNoe ANo ratings yet

- Tolerate pipe bending up to 8° when hull sags or hogsDocument8 pagesTolerate pipe bending up to 8° when hull sags or hogsmarcusNo ratings yet

- Double Cartridge Mechanical SealsDocument4 pagesDouble Cartridge Mechanical SealsGoran TesicNo ratings yet

- Single: GLE Range ofDocument8 pagesSingle: GLE Range ofNghia HuynhNo ratings yet

- Orifice PlateDocument4 pagesOrifice Platerehan7777No ratings yet

- 150 Flange Dimensions & SpecsDocument3 pages150 Flange Dimensions & SpecsNikhil PanchalNo ratings yet

- 3.3 Valvula Os&y - SanfloDocument2 pages3.3 Valvula Os&y - SanfloYhonny ValenzuelaNo ratings yet

- WOT - Tech Data Sheets PDFDocument43 pagesWOT - Tech Data Sheets PDFAmbroise RICHARDNo ratings yet

- 250 PSI CWP Iron Body Gate Valve: 250 PSI/17.2 Bar Non-Shock Cold Working PressureDocument1 page250 PSI CWP Iron Body Gate Valve: 250 PSI/17.2 Bar Non-Shock Cold Working PressureStephanie AdkinsNo ratings yet

- Jc-557 Type 5610 TDS-FNL - LowresDocument7 pagesJc-557 Type 5610 TDS-FNL - LowresDaygoro RuizNo ratings yet

- Bridge Plug Piranha Energy Cataloge BPDocument11 pagesBridge Plug Piranha Energy Cataloge BPJohnNo ratings yet

- Power Stream Couplings-Specn SheetsDocument6 pagesPower Stream Couplings-Specn SheetsAmol PatkiNo ratings yet

- BConversionKits Bridge Plug AlphaoiltoolsDocument5 pagesBConversionKits Bridge Plug AlphaoiltoolssitaNo ratings yet

- BJ Model SV-5 Cement Retainer PDFDocument2 pagesBJ Model SV-5 Cement Retainer PDFmohammad teimuriNo ratings yet

- Brass Ball Valve (BBV) V0816Document1 pageBrass Ball Valve (BBV) V0816Saiful Islam SagorNo ratings yet

- Butterfly Valves Series BF-03-M2 Full Lug and BF-04-M2 Wafer Specification SheetDocument2 pagesButterfly Valves Series BF-03-M2 Full Lug and BF-04-M2 Wafer Specification SheetWattsNo ratings yet

- 25 SP650 1 MS Series SeparatorsDocument2 pages25 SP650 1 MS Series SeparatorsLa Ode AdhanNo ratings yet

- Butter Mueller 5bt520e0015wf00g1000Document2 pagesButter Mueller 5bt520e0015wf00g1000Manusawin PinsongNo ratings yet

- Fabricated "Y" Strainers: Features OptionsDocument2 pagesFabricated "Y" Strainers: Features OptionsGourav SharmaNo ratings yet

- Waterstop PVC BalbeckDocument7 pagesWaterstop PVC BalbeckLuis Carlos EsquivelNo ratings yet

- Ductile Iron Gate ValveDocument4 pagesDuctile Iron Gate ValveShuvro SoikotNo ratings yet

- Arctic Cat Parts Manual 1999 TS 770 L W1999TSJLAUS 1999Document60 pagesArctic Cat Parts Manual 1999 TS 770 L W1999TSJLAUS 1999Kevin HarrisNo ratings yet

- Mueller Flanged End Simplex Basket Strainer Models 125F CI 125F B Spec Sheet Ver2Document2 pagesMueller Flanged End Simplex Basket Strainer Models 125F CI 125F B Spec Sheet Ver21819 Roy GordonNo ratings yet

- Knife Gate Valve LVC Figure 93 Stainless Steel Metal Seated - (PRATT)Document2 pagesKnife Gate Valve LVC Figure 93 Stainless Steel Metal Seated - (PRATT)juantamad02No ratings yet

- TYCO Keystone F14.Lined - Butterfly.valve enDocument4 pagesTYCO Keystone F14.Lined - Butterfly.valve enIrina CretuNo ratings yet

- 3 Piece Tube Bore Ball Valves, / "-4": High Purity ApplicationsDocument4 pages3 Piece Tube Bore Ball Valves, / "-4": High Purity ApplicationsrodrurenNo ratings yet

- Hydroflex Catalogue - 2018-PDF FOR TEXTDocument12 pagesHydroflex Catalogue - 2018-PDF FOR TEXTdhaktodesatyajitNo ratings yet

- Brochure - SIL PT BarDocument4 pagesBrochure - SIL PT Barprashant patilNo ratings yet

- Product CatalogueDocument44 pagesProduct CatalogueTo Van TinhNo ratings yet

- Copper Tubular Terminals and Sleeves: XCT and XG7T Type: Application Features and BenefitsDocument3 pagesCopper Tubular Terminals and Sleeves: XCT and XG7T Type: Application Features and Benefitsevan78ilNo ratings yet

- Rotary Lobe ManualDocument19 pagesRotary Lobe ManualKamal UddinNo ratings yet

- Uni FlangeDocument8 pagesUni FlangeBobbie RuckNo ratings yet

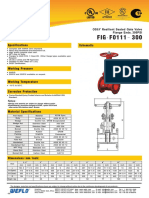

- OS&Y Resilient Seated Gate Valve, Flanged Ends, 300PSI FIG.F0111-300Document1 pageOS&Y Resilient Seated Gate Valve, Flanged Ends, 300PSI FIG.F0111-300Fight FireNo ratings yet

- Nord Lock Steel Construction Washers User ManualDocument4 pagesNord Lock Steel Construction Washers User ManualThoncatNo ratings yet

- CURC 01bDocument8 pagesCURC 01bmontsegranNo ratings yet

- KVC Ball ValvesDocument1 pageKVC Ball ValvesAlex VarHerNo ratings yet

- Style 808 Duo-Lock High Pressure Coupling: Product DescriptionDocument2 pagesStyle 808 Duo-Lock High Pressure Coupling: Product Descriptionnrd9771No ratings yet

- TD-4615 HRDocument8 pagesTD-4615 HRjosfwangNo ratings yet

- Socket Weld O-Ring UnionDocument1 pageSocket Weld O-Ring Unionkrishna kanthNo ratings yet

- F607RWSFPDocument1 pageF607RWSFPleonardo ramirezNo ratings yet

- Nibco Wafer Style Twin Disc Ductile Iron Check ValveDocument1 pageNibco Wafer Style Twin Disc Ductile Iron Check ValveAlbeiro LeivaNo ratings yet

- Process PipingDocument5 pagesProcess PipingkinzaNo ratings yet

- Acme Screws Nuts CatalogDocument18 pagesAcme Screws Nuts CatalogparantapkayalNo ratings yet

- PINACHO Conventional Lathes LRDocument2 pagesPINACHO Conventional Lathes LRAntonio Sanchez Sanchez100% (2)

- BT1100 Teltru 16 17Document2 pagesBT1100 Teltru 16 17Prihartono Danan WingusNo ratings yet

- Slurryflex SA Hard Wall Mining Hose DatasheetDocument2 pagesSlurryflex SA Hard Wall Mining Hose DatasheetBeaver Process EquipmentNo ratings yet

- Celmec Spiral Duct-ComauDocument11 pagesCelmec Spiral Duct-ComauAdrianus DalameNo ratings yet

- ButterflyDocument6 pagesButterflysachin2010No ratings yet

- Válvula de PieDocument2 pagesVálvula de PieGeral TorrezNo ratings yet

- Butterfly ValveDocument1 pageButterfly ValveDnyaneshwar0% (1)

- CPS - Bridge PlugDocument8 pagesCPS - Bridge PlugJOGENDRA SINGHNo ratings yet

- Flanges: SI SMEDocument16 pagesFlanges: SI SMEbalaNo ratings yet

- Kvkew 0089 enDocument4 pagesKvkew 0089 enksathishgreenNo ratings yet

- Boiler Valve CatalogDocument74 pagesBoiler Valve CatalogEduardo DiegoNo ratings yet

- Series YD - YS Instruction ManualDocument16 pagesSeries YD - YS Instruction ManualEnerprec SASNo ratings yet

- Posiflex Reducer Expansion JointsDocument2 pagesPosiflex Reducer Expansion JointsBabyface888No ratings yet

- 601-A-006 - Avk021 - en 2232 - 471287Document2 pages601-A-006 - Avk021 - en 2232 - 471287bre brilianNo ratings yet

- Instrumentation Cable BSDocument42 pagesInstrumentation Cable BSShivaniNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Cat Filtrazione 2017 enDocument80 pagesCat Filtrazione 2017 enTed ThomsonNo ratings yet

- SUPERCITO MMA Electrodes for Structural and Heavy WorkDocument1 pageSUPERCITO MMA Electrodes for Structural and Heavy Workantonio111aNo ratings yet

- 30 - Nguyễn Duy Linh - BANVEDocument12 pages30 - Nguyễn Duy Linh - BANVEloox600No ratings yet

- MODEL 206-F-TYPE 4 Modulating Float Valve: Key FeaturesDocument4 pagesMODEL 206-F-TYPE 4 Modulating Float Valve: Key Featuresชวลิตศ์ จิตรเที่ยงNo ratings yet

- Atlanta Housing Construction PracticesDocument44 pagesAtlanta Housing Construction PracticesDanie RoyNo ratings yet

- BDK ValveDocument12 pagesBDK ValvevinaypNo ratings yet

- ME306 Advanced Manufacturing Technology, September 2020Document2 pagesME306 Advanced Manufacturing Technology, September 2020samnoon muadNo ratings yet

- RENAN ResumeDocument2 pagesRENAN ResumeAlbert AbilarNo ratings yet

- QuoteDocument35 pagesQuoteFaheem KhanNo ratings yet

- FALLSEM2021-22 MEE3001 TH VL2021220103058 Reference Material I 23-Aug-2021 Module 2 Design Against Fluctuating LoadDocument78 pagesFALLSEM2021-22 MEE3001 TH VL2021220103058 Reference Material I 23-Aug-2021 Module 2 Design Against Fluctuating LoadJude JohnNo ratings yet

- Foundation DesignDocument2 pagesFoundation Designhemantmech09No ratings yet

- Answers To Exam-Style Questions: 8 Deforming SolidsDocument2 pagesAnswers To Exam-Style Questions: 8 Deforming SolidsANONYMOUS MOOSENo ratings yet

- GE Circuit Breaker EnclosuresDocument8 pagesGE Circuit Breaker Enclosuresdiscovery198No ratings yet

- BS 368-1971, Precast Concrete Flags PDFDocument25 pagesBS 368-1971, Precast Concrete Flags PDFnickdash09100% (1)

- Aisi 200 SeriesDocument19 pagesAisi 200 Seriessgupta_192494No ratings yet

- TC 2 001961 en 01Document73 pagesTC 2 001961 en 01Baltija MechanikasNo ratings yet

- Basalt Fiber PDFDocument2 pagesBasalt Fiber PDFsalvepramod99No ratings yet

- Avida Centralis PVC Technical EvaluationDocument2 pagesAvida Centralis PVC Technical EvaluationJovenal TuplanoNo ratings yet

- 3.0 Stairways, Ramps, Stiles, Walkways, and Platforms: 3.1 Section ContentsDocument32 pages3.0 Stairways, Ramps, Stiles, Walkways, and Platforms: 3.1 Section ContentsBoy AlfredoNo ratings yet

- IRC-78-2014 Standard Specifications and Code of Practice For Road Bridges, Section VII - Foundations and Substructure (Revised Edition)Document100 pagesIRC-78-2014 Standard Specifications and Code of Practice For Road Bridges, Section VII - Foundations and Substructure (Revised Edition)Saroon Afshan76% (29)

- SS Ni LiteDocument114 pagesSS Ni Litepaeg6512No ratings yet

- Proofex LM: Constructive SolutionsDocument2 pagesProofex LM: Constructive SolutionsSHAIK ASIMUDDINNo ratings yet

- Specification For Concrete (Haunching)Document11 pagesSpecification For Concrete (Haunching)jenNo ratings yet

- Technical Specification For Auxiliary Cooling TowerDocument7 pagesTechnical Specification For Auxiliary Cooling TowerAnonymous vwbLPTpj100% (2)

- ManualDocument44 pagesManualjillianixNo ratings yet

- PROPOSAL SMELTER Project-Bintan Island - ElectDocument314 pagesPROPOSAL SMELTER Project-Bintan Island - Electagung100% (1)

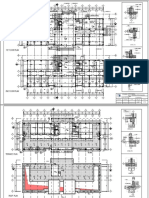

- Project - Bali Chambre Go: BTDC Nusa Dua - BaliDocument44 pagesProject - Bali Chambre Go: BTDC Nusa Dua - BaliYudi Ibo NlfNo ratings yet

- Carbide Banding - Effect On FatigueDocument15 pagesCarbide Banding - Effect On FatigueSteve Green100% (1)

- Design of EHV SwitchyardDocument47 pagesDesign of EHV Switchyardpraveen_1324100% (1)

- Cálculo Sin ModificacionesDocument26 pagesCálculo Sin ModificacionesAngel MingaNo ratings yet