Professional Documents

Culture Documents

Worm Gears PDF

Uploaded by

Jaime Andrés Andrade Cuji0 ratings0% found this document useful (0 votes)

39 views5 pagesOriginal Title

Worm-Gears.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

39 views5 pagesWorm Gears PDF

Uploaded by

Jaime Andrés Andrade CujiCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

Call us at (800) 491-1073 and ask for Design Support * commercialgear.

com

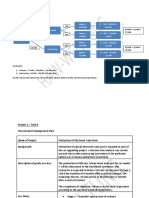

WORM GEARS

TO GET HAVING RULE FORMULA

Lead & number Divide the lead

Linear pitch

of threads in by the no. of Px = L / Nw

(circular axial)

worm threads in worm

Divide the axial

Axial diametral diametral pitch

Normal Pnd = Pxd /

pitch & worm by the cosine of

diametral pitch Cos.

gear helix angle the work helix

angle

Multiple normal

Normal

diametral pitch

Axial diametral diametral pitch Pxd = Pnd Cos.

by the cosine of

pitch & worm helix

the worm helix

angle

angle

Multiply the no.

No. of teeth in of teeth in the

wormwheel & wormwheel by

Pxd = NG /D

pitch diameter pitch diameter

of wormwheel of the

wormwheel

Multiply the

worm pitch

diameter by

and divide the

Hilix angle of Worm pitch product by the CoTan = * Dw

worm diameter & lead lead. The /L

quotient is the

co-tangent of

the helix angle

of the worm.

Normal Divide the axial cos = Pxd /

diametral pitch diametral pitch Pnd

and axial by the normal

diametral pitch diametral pitch

Subtract the

Pitch diameter pitch diameter

Pitch diameter of wormwheel of the

Dw = 2C - DG

of worm and center wormwheel from

distance twice the center

distance

Subtract twice

Outside

the addendum

diameter and Dw = D - 2

from the outside

addendum

diameter

Multiply the

number of teeth

in the wheel by

Linear pitch and the linear pitch DG = NG * PG /

number of teeth of the worm,

Pitch diameter then divide by

of wormwheel Pitch diameter

of worm and Divide the worm

center distance pitch diameter DG = C * 2 - Dw

by 2 minus the

center distance,

multiplied by 2

Add pitch

diameter of

Center distance Pitch diameter

worm and C = Dwt * DG /

between worm of worm and

wormwheel, 2

and wormwheel wormwheel

then divide the

sum by 2

Addendum of Multiply the

Linear Pitch = .3183 * Px

worm tooth pitch by 0.318

Whole depth of Multiply linear

Linear pitch W = 0.6866 * P

worm tooth pitch by 0.6866

Subtract twice

Bottom diameter Whole depth and the whole depth

B = O - 2 (WD)

of worm O.D. of tooth from

the outside

diameter

Multiply the

End width of

Linear pitch linear pitch T = 0.31 * P

thread tool

by .31

Add twice the

addendum of

Wormwheel P.D.

Throat diameter the worm tooth

and worm O" = D * 2S

of worm wheel to the pitch

addendum

diameter of the

wormwheel

Subtract the

addendum of

Radius of worm Worm O.D. and the worm tooth U = O / 2 -2

wheel throat addendum from half the (ADD)

ouside diameter

of the worm

Add together the

Outside

Pitch diameter pitch diameter O = D1 + 2

diameter of

and addendum and two times (ADD)

worm

the addendum

Multiply the

radius curvature

of the

wormwheel

throat by the

cosine of half

the face ange.

Radius of

Diameter of Subtract theis

curvature face O = 2U -ux cos

worm wheel to qunatity from

angle and throat A + O'

sharp corners the radius of

diameter

curvature,

multiply the

remainder by 2.

Then add the

product to the

wormwheel

throat diameter.

Worm lead and Divide the lead

Wormwheel tan (HA) = L /

circumference of of the worm by

helix angle D1

the pitch circle the

of worm circumference of

the pitch circle.

The result will

be the tangent

of the angle.

Multiply the

Linear pitch and

linear pitch by

Lead of worm number of L = Px * Nw

the number of

threads in worm

threads in worm

Divide the lead

of worm by the

Lead and helix Dw = (L / tan )

Worm PD tangent of the

angle of worm /

helix angle then

divide by

Multiply the

worm PD by

Worm Pd and

then multiply L = Dw * Tan

Lead of worm helix angle of

by the tangent

worm

of the helix

angle

Divide the lead

Number of Lead and axial

by the axial Nw = L / Px

threads in worm circular pitch

circular pitch

Divide the

Number of teeth number of teeth

in wormwheel in the Nw = Ng / mG

and ratio wormwheel by

the ratio

Multiply the

Ratio and

Number of teeth number of teeth

number of Ng = mG * Nw

in wormwheel in the worm by

threads in wheel

ratio

Divide the

number of teeth

Number of teeth

in the

in wormwheel

Ratio wormwheel by mG = NG / NW

and number of

the number of

threads in worm

teeth in the

worm

DISCLAIMER AND LIMITED LIABILITY

Commercial Gear and Sprocket Company, Inc. has provided this Designers & Engineers Resource in an effort to

help you conceptualize your design. Due to the complex nature of designing and its interaction with an

assortment of components, Commercial Gear and Sprocket Company, Inc. does not warrant that the usage of

this site and the information therein is completely error free or fit for your specific design. Commercial Gear and

Sprocket Company, Inc. makes no warranties, express or implied, with respect to the usage of the information

provided or as to its fitness for any particular purpose. Commercial Gear and Sprocket Company, Inc. shall not be

liable for any damage or loss of any kind, whether direct or indirect, incidental or consequential, regardless of

whether such liability is based in Tort, Contract or otherwise including without limitation damages for loss of

business, business profits, business interruption, or any other pecuniary loss arising out of or relating to the use

of this site. Commercial Gear and Sprocket Company, Inc. is however, standing by to assist you or

design and fabricate to your specifications. Our third generation family owned company has been

producing quality gears and other power transmission products at competitive prices since 1946. Call

us at (800) 491-1073 and ask for Design Support

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Sucession AllDocument865 pagesSucession AllMark MlsNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Introduction To The Law of ContractDocument100 pagesIntroduction To The Law of Contractruban bob100% (3)

- Evidence Set2Document20 pagesEvidence Set2Michelle Valdez AlvaroNo ratings yet

- Contract of LeaseDocument4 pagesContract of LeasePita BreadNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Principles in Legal WritingDocument11 pagesPrinciples in Legal WritingAlbert BolanteNo ratings yet

- Tomas N. Joson III vs. Commission On Audit G.R. No. 223762 November 7, 2017 Case DigestDocument3 pagesTomas N. Joson III vs. Commission On Audit G.R. No. 223762 November 7, 2017 Case Digestbeingme2No ratings yet

- Exclusive Sale AuthorityDocument8 pagesExclusive Sale AuthorityKatharina Sumantri100% (2)

- BP Road Safety - Contractor Hse Management ProgrammeDocument49 pagesBP Road Safety - Contractor Hse Management ProgrammeKama EfendiyevaNo ratings yet

- Table of Defective ContractsDocument2 pagesTable of Defective Contractsgelaaiiii100% (8)

- Sibiya CoJ Internal Forensic Report OCRDocument48 pagesSibiya CoJ Internal Forensic Report OCRjillian100% (2)

- Arwood vs. ConsunjiDocument1 pageArwood vs. ConsunjiFloyd Mago100% (1)

- TYPES OF TENDERS EXPLAINEDDocument5 pagesTYPES OF TENDERS EXPLAINEDRohan Shinde50% (2)

- Espina V HighlandsDocument2 pagesEspina V HighlandsAllen Windel Bernabe100% (1)

- SPES IMO Rev Ed 2017 PDFDocument102 pagesSPES IMO Rev Ed 2017 PDFJereme Villareal Soriao100% (1)

- Indian Evidence Act oral documentaryDocument9 pagesIndian Evidence Act oral documentaryShivanya SinghNo ratings yet

- PMP Project 1Document7 pagesPMP Project 1julybaby8679% (14)

- Legal Research ProcessDocument3 pagesLegal Research ProcessChristianneDominiqueGravosoNo ratings yet

- Bay' al-Salam Contract in Islamic FinanceDocument8 pagesBay' al-Salam Contract in Islamic FinanceSaadat ShaikhNo ratings yet

- SC Rules Prescriptive Period for Rescission of Donations Begins from Moment Creditor Learns Judgment Can't be SatisfiedDocument5 pagesSC Rules Prescriptive Period for Rescission of Donations Begins from Moment Creditor Learns Judgment Can't be SatisfiedcrisgondaNo ratings yet

- Pakistan SC's Judgment Against The PMDocument90 pagesPakistan SC's Judgment Against The PMBar & BenchNo ratings yet

- Malkan V Mutua Plaintiff-Appellant's Brief, Second Circuit, Filed 2-17-2017Document57 pagesMalkan V Mutua Plaintiff-Appellant's Brief, Second Circuit, Filed 2-17-2017Jeffrey MalkanNo ratings yet

- CHAPTER II Geneva Convention Awards 53Document2 pagesCHAPTER II Geneva Convention Awards 53mrunalpanchalNo ratings yet

- Concreting of Flood-Free 2.50 KM Sitio Kigawhat (Ani-E) To Villa Irene (Rizal) FMRDocument119 pagesConcreting of Flood-Free 2.50 KM Sitio Kigawhat (Ani-E) To Villa Irene (Rizal) FMREilla Marie GomosNo ratings yet

- Confidential Printer AgreementDocument4 pagesConfidential Printer AgreementKM GomezNo ratings yet

- Centro Medico Del Turabo, Inc. v. Union General de Trabajadores Local 1199 - Document No. 11Document6 pagesCentro Medico Del Turabo, Inc. v. Union General de Trabajadores Local 1199 - Document No. 11Justia.comNo ratings yet

- Chapter 5 Preparation of Legal Documents and InstrumentsDocument23 pagesChapter 5 Preparation of Legal Documents and InstrumentsLizadette Balanci LazoNo ratings yet

- A-1 ARTICLE 1320-1340 Jonathan ParbaDocument64 pagesA-1 ARTICLE 1320-1340 Jonathan ParbaPeniel ParbaNo ratings yet

- Aa - Req - 000131 - Quality Requirements Third Party Design VerificationDocument11 pagesAa - Req - 000131 - Quality Requirements Third Party Design Verificationjonodo89No ratings yet

- E-Contracts: An OverviewDocument17 pagesE-Contracts: An OverviewLavanya Anand100% (1)

- Outline: I. Presidential Decree No. 242Document10 pagesOutline: I. Presidential Decree No. 242Ronald FloresNo ratings yet