Professional Documents

Culture Documents

United States Patent: Simpson

Uploaded by

احمد عبدالكريم0 ratings0% found this document useful (0 votes)

18 views5 pagesThis patent describes a ship's hull design comprising a flat bottom plate with an opening, and a hollow keel portion attached above the plate. The keel portion consists of three sections - a bow section, a cylindrical main section, and a conical stern section. These sections are constructed from metal tubing and plates and welded together to form the hull, which has advantages over conventional designs in stability and water flow around the propeller for improved maneuverability.

Original Description:

142424

Original Title

Us 3822661

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis patent describes a ship's hull design comprising a flat bottom plate with an opening, and a hollow keel portion attached above the plate. The keel portion consists of three sections - a bow section, a cylindrical main section, and a conical stern section. These sections are constructed from metal tubing and plates and welded together to form the hull, which has advantages over conventional designs in stability and water flow around the propeller for improved maneuverability.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views5 pagesUnited States Patent: Simpson

Uploaded by

احمد عبدالكريمThis patent describes a ship's hull design comprising a flat bottom plate with an opening, and a hollow keel portion attached above the plate. The keel portion consists of three sections - a bow section, a cylindrical main section, and a conical stern section. These sections are constructed from metal tubing and plates and welded together to form the hull, which has advantages over conventional designs in stability and water flow around the propeller for improved maneuverability.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

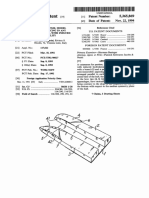

United States Patent [19] [11] 3,822,661

Simpson [45] July 9, 1974

[54] SHIPS HULL

[76] inventor: Robert Simpson, PO. Box 159, [561 References CM

Lantzville, British Columbia, UNITED STATES PATENTS

Canada 3,133,130 6/1964 Morgan ............................... .1 115/39

[22] Filed: Oct. 4, 1972

_ Primary Examiner-George E. A. Halvosa

[21] Appl NO" 294884 Assistant Examiner-Sherman D. Basinger

Attorney, Agent, or Firmf-Fetherstonhaugh & C0.

[30] Foreign Application Priority Data

0C1. 2, 1972 Canada .............................. .. 152973 [57] ABSTRACT

'A ships hull having a ?at plate mounted above a keel

[52] US. Cl ...................... .. 114/56, 1 14/56, 11114406613, kc portion formed of a rounded bow Section, a cylim

drical main section, and a conical stern section, The

[51] lnt.Cl .......................... .. B6311 1/04 B63b l/l2 th d ff b- t- d bl- th h IL

[58] Field 61 Search ....... .. 114/56, 61, 6,3, 65 R, 40, me o a "ca mg 8 assem mg 6 u

114/42; 9/6; 115/11, 34R 4 (Ilaims, 9 Drawing Figures

Pmmmm 919" ' 3.822.661

SHEH 2 (IF 2

3,822,661

1 2

SHIPS HULL sides of the section with upper edges 38 both which are

disposed at the same acute angle to longitudinal axis 39

My invention relates to an improved hull design and of the section. Front edge 40 of section 31 slopes rear

particularly to an inexpensive and effective method of wardly at an oblique angle to axis 39 while rear edge 41

constructing same. of said section is perpendicular thereto. It should be

A vessel used for towing normally is provided with a noted that bow section 30 and main section 31 have

hull of fairly conventional design which often lacks substantially the same radius of curvature.

some of the characteristics needed in a boat intended The tubular metal cone used to form the stern section

for pulling heavy loads, usually at relatively low speeds, 32 has an upper portion cut away to provide a curved

and frequently in rough or at least choppy water. Such upper edge 45 which is parallel to longitudinal axis 46

vessels are costly to build and operate and should be of said section. Front edge 47 of the section 32 is nor

provided with above average stability since there is al mal to axis 46 and so is rear edge 48 which de?nes the

ways the danger that they might be capsized by their small, open end of the conical section 32.

The edges 35 and 40 are welded together to form a

tows.

My hull design allows the engine and other weighty strong, watertight seal therebetween. Similarly the

components of the vessel to be mounted so as to ensure edges 41 and 47 are joined together. The upper edges

a very low center of gravity which provides maximum 34, 38 and 45 of the three sections making up the keel

stability. The hull has a keel portion constructed to re portion 16 de?ne an opening 50 (FIG. 8) having a mar

duce friction and provide a maximum ?ow of water ginal edge 51 which conforms in shape to marginal

over and around the propeller which decreases propel 20 edge 52 of the opening 20, and these two marginal

ler slip and results in greater manoeuvrability. The de edges are securely welded together again to form a

sign lends itself to manufacture by a simple cutting and strong, watertight seal. The axis 36 of the bow section

welding process which elminates the need for costly is disposed at an obtuse angle to the axis 39 of the main

lofting, cutting and assembling as in conventional con section. Preferably, axis 39 is disposed at an acute

25 angle to the plate 14 so as to extend downwardly and

struction methods.

In drawings which illustrate a preferred embodiment rearwardly therefrom. .

of the invention, -

The hull 12 contains the engine 60 for the tug 10, the

FIG. 1 is a side elevation of a vessel provided with av engine being shown by dotted lines in FIG. 1 enclosed

hull in accordance with the present invention, by and suitably mounted in the main section 31. Pro

FIG. 2 is a front elevation of the vessel, 30 peller shaft 61 of the engine 60 extends rearwardly

FIG. 3 is a plan taken on the line 33 of FIG. 1, through the stern section 32 and is properly sealed and

FIG. 4 is a longitudinal section taken on the line 4-4 journalled therein, this shaft being fitted with the usual

of FIG. 3, propeller 62. A keel strip 64 is secured to the underside

FIGS. 5, 6 and 7 are vertical sections taken respec of the main section 31 to extend rearwardly therefrom '

35 and the rear end of this strip, plus the bottom plate 14,

tively on the lines 5-5, 66 and 77 of FIG. 4,

FIG. 8 is an exploded perspective view showing the rotatably supports a rudder v65.

assembly of parts of the hull, and As the tug 10 is driven forward through the water by

FIG. 9 is a perspective view of a modified form of the the propeller 62, the rounded and enlarged bow section

30 breaks through the water and causes it to flow

hull. 40 around the cylindrical main section 31 as well as over

The numeral 10 indicates generally a small tug pro

vided with a hull 12 which forms the basis of the pres and around the conical stern section 32 whereby near

ent invention; the hull comprising two major parts, a maximum driving ef?ciency is achieved by the deeply

bottom plate 14 and a keel portion 16. immersed propeller. There is relatively little interrup

Plate 14 is formed of metal, preferably steel, which tion in water flow beneath the plate 14 and longitudi

45 nally of the keel portion 16 and this reduces friction to

may be one and one quarter inches or more in thick

ness and this ?at plate is cut or shaped so as to have ap a minimum. The water ?ow is such that the rudder 65

proximately the same outline when viewed in plan as is extremely effective and therefore the vessel is partic

the deck of thetug 10. Suitably secured to circumfer ularly easy to maneuver with the water flowing across

ential edge 18 of the plate 14, is an upstanding ?ange and over the conical stem section 32 to ensure a very

19 which encloses the underside of the deck structure short turning radius. Since the tug 10 has a low center

and which connects with the bulwarks of the vessel. of gravity due to the engine 60 being mounted in the

The bottom plate 14 is provided with an elongated main section 31, the vessel is exceptionally stable and

opening 20, see particularly FIG. 3, which opening is cannot readily be capsized.

formed in the center of the metal plate to extend rear A ships hull of the above described design is excep

wardly from a point close to bow end 21 of the plate to tionally easy to construct by a process which will now

a point spaced a suitable distance from stem end 22 of be described. Referring to FIG. 8,. a length of cylindri

cal tube 70 is used to form the sections 30 and 31. An

said plate. oblique cut is made across the tube 70 at an angle of

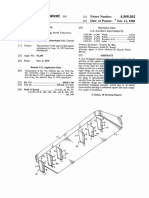

The hollow keel portion 16 comprises a bow section

30, a main section 31, and a stern section 32. As shown approximately 70 to the longitudinal axis of said tube,

in FIGS. 4 and 5, the metal bow section 30 is substan and this provides a short length 71 and a long length 72

tially triagnular when viewed from the side and is trans of tubing. The short length 71 is rotated 180 about its

versely curved in cross-section. Thus, section 30 has an longitudinal axis and the two out edges (35 and 40) are

upper edge 34 and a rear edge 35, the latter edge being then welded together. The rear edge 41 of the main

disposed at right angles to longitudinal axis 36 of said section and the front edge 47 of the stern section are

65

section. , A

also welded together and this completes the construc

Main section 31 is a metal cylinder, see particularly tion of the hull portion except'for the provision of the

FIGS. 4 and 6, with a portion cutaway to provide the top opening 50 which subsequently is formed by cut

3,822,661

' 3 4

ting away the surplus metal from the three sections. tion secured to said ?at bottom member rearwardly

The keel section 16 is then joined to the bottom plate of said bow section having substantially the same

14 and the marginal edges of the two openings 20 and radius of curvature as said bow section, having a

50 are welded together to provide the above described front end secured to the rear end of said bow sec

hull. tion, and having its longitudinal axis disposed at an

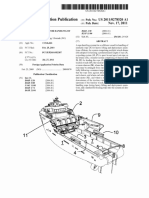

Referring to FIG. 9, the numeral 80 indicates gener obtuse angle with respect to the longitudinal axis of

ally another vessel having a hull 82 comprising a bot said bow section and downwardly rearwardly at an

tom plate 83 and two transversely spaced keel portions acute angle with respect to said ?at bottom mem

84. The portions 84 are constructed in the above de ber; and a conical stem section secured to said ?at

scribed manner to provide a hull having twin keels as bottom member rearwardly of said main section.

is desirable in some types of vessels. the forward end of said conical stern member hav

From the foregoing, it will be apparent I have pro ing substantially the same radius of curvature as the

vided a hull design which has the stability, water flow, rear end of said main section and being secured

and other characteristics which are desirable particu thereto; said keel portion forming with said ?at

larly in a vessel using for purposes of towing such as is bottom member a marginal edge, the marginal

shown in FIG. 1, or for a ferry such as is shown in FIG. edge of said bow section of said keel portion having

9. Construction costs are considerably reduced over a portion having a transverse dimension greater

those of conventional tug and ferry building methods than that of the remainder of said marginal edge.

due to the unique method of assembling the present

hull. 20 2. A boat according to claim 1 wherein said flat bot

I claim: tom member has a longitudinally extending elongated

1. A tug boat having a rounded, blunt, bow and in opening formed therein and having a marginal edge

cluding a hull comprising: and wherein said keel portion has a longitudinal open

a ?at bottom member extending across the full width ing having a marginal edge substantially conforming to

of the boat from one side to the other; 25 the marginal edge of said ?at bottom member, said

a keel portion depending from said flat bottom mem edges being in register.

ber extending longitudinally of the boat and com 3. A ships hull as claimed in claim 2, in which said

prising a plurality of edge welded tubular sections marginal edges of the elongated opening and the longi

each of which extends longitudinally of the boat in tudinal opening are welded together.

cluding: a substantially cylindrical tubular bow sec 4. A ships hull as claimed in claim 1, in which said

tion having a longitudinal axis sloping downwardly ?at bottom plate has a circumferential edge fitted with

rearwardly from said bow and secured to said bot an upstanding ?ange enclosing part of the deck struc

tom member in a manner presenting a blunt ture of the vessel.

* * * * *

rounded bow; a substantially cylindrical main sec

35

40

45

55

65

You might also like

- A Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderFrom EverandA Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderNo ratings yet

- United States Patent: (22l Fned' Lan' 14' 1974 Tivelyg' On Iopposite Sides Thereoftgare Disposezi Betvi/jeenDocument12 pagesUnited States Patent: (22l Fned' Lan' 14' 1974 Tivelyg' On Iopposite Sides Thereoftgare Disposezi Betvi/jeenاحمد عبدالكريمNo ratings yet

- Get. 31, 1944. I I G - Munro 2,361,409: Filed Dec. 2, 1943Document4 pagesGet. 31, 1944. I I G - Munro 2,361,409: Filed Dec. 2, 1943احمد عبدالكريمNo ratings yet

- Sept. 3, 1940.: Filed May 9, 1958Document7 pagesSept. 3, 1940.: Filed May 9, 1958احمد عبدالكريمNo ratings yet

- June 5, 1923. 1,457,961: Filed April 13, 1921 5 Sheets-Sheet 1Document17 pagesJune 5, 1923. 1,457,961: Filed April 13, 1921 5 Sheets-Sheet 1cll1968No ratings yet

- Browning Proto US1457961Document17 pagesBrowning Proto US1457961apoorva singhNo ratings yet

- Types of Propellers and Their ConstructionDocument4 pagesTypes of Propellers and Their ConstructionZhenyan ChenNo ratings yet

- Nomencleature of PropellerDocument2 pagesNomencleature of PropellerPavan KishoreNo ratings yet

- Design and Analysis of Propeller BladeDocument6 pagesDesign and Analysis of Propeller Bladechethan mahadevNo ratings yet

- 1978 ITTC Performance PredictionDocument31 pages1978 ITTC Performance PredictionqursenNo ratings yet

- Draft Survey - Bulk Vessels LoadingDocument5 pagesDraft Survey - Bulk Vessels LoadingSoubam Luxmibai100% (1)

- ITTC - Recommended Procedures: Performance, Propulsion 1978 ITTC Performance Prediction MethodDocument31 pagesITTC - Recommended Procedures: Performance, Propulsion 1978 ITTC Performance Prediction MethodAlfredoLopezNo ratings yet

- DNV CN41-5Document9 pagesDNV CN41-5Constantinos IvNo ratings yet

- Us 1001260Document5 pagesUs 1001260mehdi parsNo ratings yet

- Analysis and Design of Ship StructureDocument76 pagesAnalysis and Design of Ship StructureRicardo Pizá FernándezNo ratings yet

- Tanker stability report analysisDocument42 pagesTanker stability report analysisNikola DjordjevicNo ratings yet

- Lehm0028 00Document4 pagesLehm0028 00Aidel MustafaNo ratings yet

- RudderDocument33 pagesRuddertribleprinceNo ratings yet

- Stability Calculation - Immersing: Loadcase - Immersing Damage Case - IntactDocument6 pagesStability Calculation - Immersing: Loadcase - Immersing Damage Case - IntactfahmiNo ratings yet

- INDIAN MARITIME UNIVERSITY NSTL Lab reportDocument4 pagesINDIAN MARITIME UNIVERSITY NSTL Lab reportAnkit GhoshNo ratings yet

- Modelmaker Revision02Document43 pagesModelmaker Revision02AngelNo ratings yet

- 5 Papers MMD Ph2 Feb13Document6 pages5 Papers MMD Ph2 Feb13Rathinavel DassNo ratings yet

- Loadings Affecting On Boats and Small Craft: Markku Hentinen 2016Document12 pagesLoadings Affecting On Boats and Small Craft: Markku Hentinen 2016notengofffNo ratings yet

- WA2-1-Jurgens - Voith Schneider Propeller (VSP) - Investigations of TH PDFDocument11 pagesWA2-1-Jurgens - Voith Schneider Propeller (VSP) - Investigations of TH PDFAndre OliveiraNo ratings yet

- Self Propulsion Tests: Marine Engineering 2019Document23 pagesSelf Propulsion Tests: Marine Engineering 2019Yalqa RizqiNo ratings yet

- Design and Construction of High Speed, Hard Chine Planing HullDocument8 pagesDesign and Construction of High Speed, Hard Chine Planing Hullkhristc15No ratings yet

- 4 Blades PropellersDocument12 pages4 Blades PropellersFernando Raúl LADINONo ratings yet

- In-Service Performance of Aluminum Structural DetailsDocument114 pagesIn-Service Performance of Aluminum Structural DetailsMahdiNo ratings yet

- IMO2008 - MSC267 (85) - 2008 IS Code PDFDocument94 pagesIMO2008 - MSC267 (85) - 2008 IS Code PDFSrikanth ShivramNo ratings yet

- Hydrodynamic Support PresentationDocument108 pagesHydrodynamic Support PresentationAnonymous 95XksLBPZNo ratings yet

- Propeller Testing and Performance CurvesDocument6 pagesPropeller Testing and Performance CurvespothirajkalyanNo ratings yet

- Damen Stan Tender: General Deck Lay-OutDocument2 pagesDamen Stan Tender: General Deck Lay-Outvov1302No ratings yet

- ON APPLICATION OF PARAMETRIC METHOD FOR DESIGN OF PLANING CRAFTDocument11 pagesON APPLICATION OF PARAMETRIC METHOD FOR DESIGN OF PLANING CRAFTsowole olantunNo ratings yet

- Naval Architect Briefing on Ship Reference LinesDocument34 pagesNaval Architect Briefing on Ship Reference LinessufianNo ratings yet

- 2023 PSC CIC Presentation (English)Document36 pages2023 PSC CIC Presentation (English)manhcam78100% (1)

- Damaged StabilityDocument4 pagesDamaged StabilityUjjwal VermaNo ratings yet

- COLREG. Edición Refundida 2003. Español PDFDocument2 pagesCOLREG. Edición Refundida 2003. Español PDFJames PascualNo ratings yet

- Ship Geometry & Hull CharacteristicsDocument7 pagesShip Geometry & Hull CharacteristicsjishnusajiNo ratings yet

- P020213 Stability BookDocument115 pagesP020213 Stability BookPETERNo ratings yet

- Types of Rudders Used For ShipsDocument8 pagesTypes of Rudders Used For Shipsนัทเดช เรืองสวนNo ratings yet

- PREM For TenderDocument382 pagesPREM For Tenderthongchai_007100% (1)

- TA For Sea Chest Grating - SCI TKRDocument2 pagesTA For Sea Chest Grating - SCI TKRJay PatelNo ratings yet

- ResistanceManual PDFDocument71 pagesResistanceManual PDFJoe TahirNo ratings yet

- Guide For Power PredictionDocument11 pagesGuide For Power PredictionpagliasoNo ratings yet

- Project D1 - Ship Stability, Brem PavloDocument9 pagesProject D1 - Ship Stability, Brem PavloПавел БремNo ratings yet

- NES 106 Part 2 Requirements For Medical and Dental Organization in HM Surface Ships and SubmarinesDocument88 pagesNES 106 Part 2 Requirements For Medical and Dental Organization in HM Surface Ships and SubmarinesJEORJENo ratings yet

- Abs Rules Steel Vessels Under 90 MtsDocument254 pagesAbs Rules Steel Vessels Under 90 MtsDavid EgasNo ratings yet

- 14000 TEU container ship benchmark dataDocument15 pages14000 TEU container ship benchmark dataChahbi RamziNo ratings yet

- Tuning A Twin-Screw Rudder InstallationDocument6 pagesTuning A Twin-Screw Rudder Installationaeromexpower2009No ratings yet

- Design, Cavitation Performance, and Open-WaterDocument41 pagesDesign, Cavitation Performance, and Open-WateraminNo ratings yet

- Mesh ShipDocument7 pagesMesh ShipPranshu MalikNo ratings yet

- Saddle Wear Plate DesignDocument2 pagesSaddle Wear Plate DesignsterlingNo ratings yet

- Calculo de BotaduraDocument6 pagesCalculo de BotaduraJozé PaxtianNo ratings yet

- Nov. 9, 1965 G. C. Molotzak 3,216,390Document5 pagesNov. 9, 1965 G. C. Molotzak 3,216,390احمد عبدالكريمNo ratings yet

- United States Patent: (54) SailboatDocument5 pagesUnited States Patent: (54) Sailboat155No ratings yet

- Foldable Boat FlierDocument5 pagesFoldable Boat FlierRakeshNo ratings yet

- United States Patent (19) : (21) Appl. No.: 927,123Document7 pagesUnited States Patent (19) : (21) Appl. No.: 927,123155No ratings yet

- Jain. 1U, 1939. T.'4 Harris ': MW Gßz/:ÁwDocument4 pagesJain. 1U, 1939. T.'4 Harris ': MW Gßz/:Áwmoch rizki darmawanNo ratings yet

- Hs 509Document35 pagesHs 509احمد عبدالكريمNo ratings yet

- Waterjet Propelled Planing Hull with Stabilizing StrakesDocument7 pagesWaterjet Propelled Planing Hull with Stabilizing Strakesاحمد عبدالكريمNo ratings yet

- United States Patent (191: BulgariniDocument6 pagesUnited States Patent (191: Bulgariniاحمد عبدالكريمNo ratings yet

- Fé2T 3I° I1°I1$Veis 3I É I Ihie???Sfifi ?I T ?I?Fei?Ii: United States Patent (191 (11) Patent Number: 4,932,347Document9 pagesFé2T 3I° I1°I1$Veis 3I É I Ihie???Sfifi ?I T ?I?Fei?Ii: United States Patent (191 (11) Patent Number: 4,932,347احمد عبدالكريمNo ratings yet

- Patent for Hydro-Lift Boat Hull Offering Greater Stability and SpeedDocument8 pagesPatent for Hydro-Lift Boat Hull Offering Greater Stability and Speedاحمد عبدالكريمNo ratings yet

- Sept? 15, 1964: Filed Aug. 31, 1962Document5 pagesSept? 15, 1964: Filed Aug. 31, 1962احمد عبدالكريمNo ratings yet

- Sept. 2, 1.930. W. Wxlson 1,774,955: Filed De'C. 7, 1929 2 Sheets-Sheet L ADocument5 pagesSept. 2, 1.930. W. Wxlson 1,774,955: Filed De'C. 7, 1929 2 Sheets-Sheet L Aاحمد عبدالكريمNo ratings yet

- Us 6112687Document7 pagesUs 6112687احمد عبدالكريمNo ratings yet

- Unlted States Patent (191 (11) Patent Number: 4,722,294: Bruning (45) Date of Patent: Feb. 2, 1988Document9 pagesUnlted States Patent (191 (11) Patent Number: 4,722,294: Bruning (45) Date of Patent: Feb. 2, 1988احمد عبدالكريمNo ratings yet

- Us 20100211239Document36 pagesUs 20100211239احمد عبدالكريمNo ratings yet

- (Z5) 3.2%. 1:313111131311113111:11:13:11::iiifazayd'fi?lii/f? NestemonnehnnongihecenenneonhehnitheDocument10 pages(Z5) 3.2%. 1:313111131311113111:11:13:11::iiifazayd'fi?lii/f? Nestemonnehnnongihecenenneonhehnitheاحمد عبدالكريمNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2009/0282723 A1Document18 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2009/0282723 A1احمد عبدالكريمNo ratings yet

- Us 1202713Document5 pagesUs 1202713احمد عبدالكريمNo ratings yet

- Martin's Improved Boat Hull Design for Reduced Friction and Increased StabilityDocument5 pagesMartin's Improved Boat Hull Design for Reduced Friction and Increased Stabilityاحمد عبدالكريمNo ratings yet

- Us 4899679Document8 pagesUs 4899679احمد عبدالكريمNo ratings yet

- United States Patent (191 (11) Patent Number: 4,569,302Document6 pagesUnited States Patent (191 (11) Patent Number: 4,569,302احمد عبدالكريمNo ratings yet

- Malimsnmwnnn: .MWP MM& Mam ?RM PaaDocument10 pagesMalimsnmwnnn: .MWP MM& Mam ?RM Paaاحمد عبدالكريمNo ratings yet

- Tug Boat Cover Rolling Apparatus Optimized for SEODocument5 pagesTug Boat Cover Rolling Apparatus Optimized for SEOاحمد عبدالكريمNo ratings yet

- United States Patent: Pedersen Et A1. (45) Date of Patent: Jan. 23, 2007Document28 pagesUnited States Patent: Pedersen Et A1. (45) Date of Patent: Jan. 23, 2007احمد عبدالكريمNo ratings yet

- United States Patent (19) : Hammersland Et Al. (11) Patent NumberDocument9 pagesUnited States Patent (19) : Hammersland Et Al. (11) Patent Numberاحمد عبدالكريمNo ratings yet

- United States Patent 1191 - : (21) Appl - No.: 155,764Document13 pagesUnited States Patent 1191 - : (21) Appl - No.: 155,764احمد عبدالكريمNo ratings yet

- Us 7677532Document6 pagesUs 7677532احمد عبدالكريمNo ratings yet

- 9 Q /N - /ENTOR:: May 9, 1931 T. B. Modine 2,983,508Document3 pages9 Q /N - /ENTOR:: May 9, 1931 T. B. Modine 2,983,508احمد عبدالكريمNo ratings yet

- Us 20110278520Document11 pagesUs 20110278520احمد عبدالكريمNo ratings yet

- Us 5911190Document19 pagesUs 5911190احمد عبدالكريمNo ratings yet

- Nov. 9, 1965 G. C. Molotzak 3,216,390Document5 pagesNov. 9, 1965 G. C. Molotzak 3,216,390احمد عبدالكريمNo ratings yet

- Sample Cover Letter: No Work ExperienceDocument4 pagesSample Cover Letter: No Work ExperienceMaya ElvisaNo ratings yet

- MPTK Medium Pressure Pump Performance SpecsDocument2 pagesMPTK Medium Pressure Pump Performance SpecssaronandyNo ratings yet

- 176Document3 pages176Karthik AmigoNo ratings yet

- Rob Thomas Digital Booklet - Cradle SongDocument15 pagesRob Thomas Digital Booklet - Cradle SongAgnieszka ŁukowskaNo ratings yet

- Brake Pedals and ValveDocument4 pagesBrake Pedals and Valveala17No ratings yet

- PJ1117CM-2 5VDocument6 pagesPJ1117CM-2 5VАлексей ГомоновNo ratings yet

- Presentation On BAJAJDocument19 pagesPresentation On BAJAJVaibhav AgarwalNo ratings yet

- DS450 Shop Manual (Prelim)Document94 pagesDS450 Shop Manual (Prelim)GuruRacerNo ratings yet

- X-Span & Setting ToolsDocument18 pagesX-Span & Setting ToolsDenier RubianoNo ratings yet

- Eaton Tb09500001e PDFDocument62 pagesEaton Tb09500001e PDFJuan E Torres MNo ratings yet

- HTML Project RestaurantDocument8 pagesHTML Project RestaurantSandeep Chowdary0% (1)

- Process Thermodynamic Steam Trap PDFDocument9 pagesProcess Thermodynamic Steam Trap PDFhirenkumar patelNo ratings yet

- CISO Core Proficiency Prepared by Chintan GurjarDocument1 pageCISO Core Proficiency Prepared by Chintan GurjarDerpNo ratings yet

- 13-2021مواصفات الفنية لقطع غيار المكيفاتDocument4 pages13-2021مواصفات الفنية لقطع غيار المكيفاتTawfeeq Al-HababbiNo ratings yet

- LR Phono PreampsDocument44 pagesLR Phono PreampsMartin FernandezNo ratings yet

- Report On Corporate Communication Strategy Analysis ofDocument38 pagesReport On Corporate Communication Strategy Analysis ofNAFISA ISLAMNo ratings yet

- Prepositions-Of-place Worksheet Azucena SalasDocument3 pagesPrepositions-Of-place Worksheet Azucena SalasAndreia SimõesNo ratings yet

- BNF Syntax of Ruby - Less than 40 character title for Ruby BNF syntax documentDocument2 pagesBNF Syntax of Ruby - Less than 40 character title for Ruby BNF syntax documentChristian FerrazNo ratings yet

- Cheat SheetDocument50 pagesCheat SheetAnubhav ChaturvediNo ratings yet

- HEN SPF Roof Manual Spray Polyurethane FoamDocument77 pagesHEN SPF Roof Manual Spray Polyurethane FoamDavaakhuu ErdeneeNo ratings yet

- Touch Screen TechnologyDocument18 pagesTouch Screen TechnologySmîlērNo ratings yet

- Unit V DSS Development: Arun Mishra 9893686820Document17 pagesUnit V DSS Development: Arun Mishra 9893686820Arun MishraNo ratings yet

- List of Title-01Document30 pagesList of Title-01najwaNo ratings yet

- Grant Park Platform Bedroom Set Furniture RowDocument1 pageGrant Park Platform Bedroom Set Furniture Rowjyzjz6sr65No ratings yet

- Phase Locked LoopDocument4 pagesPhase Locked LoopsagarduttaNo ratings yet

- General Ledger Senior Accountant in Charlotte NC Resume Diana ShipeDocument1 pageGeneral Ledger Senior Accountant in Charlotte NC Resume Diana ShipeDianaShipeNo ratings yet

- A134 PDFDocument4 pagesA134 PDFJarbas MoraesNo ratings yet

- Pivot Part NumDocument2 pagesPivot Part Numrossini_danielNo ratings yet

- Engineering Data, Summary of Productivity 2022Document2 pagesEngineering Data, Summary of Productivity 2022Listya AnggrainiNo ratings yet

- Software Hardware Tech x86 VirtDocument9 pagesSoftware Hardware Tech x86 VirtwyfwongNo ratings yet