Professional Documents

Culture Documents

Synthetic Slag For Secondary Steelmaking

Uploaded by

Waqas Ahmed100%(2)100% found this document useful (2 votes)

117 views6 pagesSteel

Original Title

Synthetic Slag for Secondary Steelmaking

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSteel

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

100%(2)100% found this document useful (2 votes)

117 views6 pagesSynthetic Slag For Secondary Steelmaking

Uploaded by

Waqas AhmedSteel

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 6

SYNTHETIC SLAG FOR SECONDARY

STEELMAKING

Synthetic Slag for Secondary Steelmaking

Synthetic slag consists of prepared mixture of several individual oxides

which is used during secondary steelmaking to assist the steel treatment in

the ladle from the viewpoint of effective refinement. Synthetic slag practice

is normally used to obtain clean steels and also for the desulphurization of

the liquid steel.

Secondary steelmaking is a critical quality control step between the primary

steelmaking and the continuous casting of the liquid steel. A key feature for

success with the secondary steelmaking processes is the slag control. Use

of synthetic slag which is specifically designed to have the required

chemical composition and physical properties helps in the slag control.

The desirable properties of the synthetic slag include (i) slag is to have

high sulphide capacity, (ii) it is to be basic in nature, (iii) it is to be fluid to

obtain faster reaction rates, and (iv) it is not to cause excessive refractory

wear.

The secondary steelmaking slag is in liquid form in the ladle and floats on

the surface of liquid steel which is usually at temperature of 1,600 deg or

higher. It acts like a sponge to absorb the impurities consisting mainly of

sulphur and non-metallic inclusions. The design of the slag is a critical step

impacting the efficiency of the steel refining processes during the

secondary steelmaking.

Slag regime in secondary steelmaking significantly influences the final

quality of the produced steel, particularly with respect to the achieved

desulphurization of steel. One of the possibilities for influencing the slag

regime is the application of synthetic slags to the ladle slag, formed from

slag-making additions during the liquid steel tapping.

Synthetic slag practice during secondary steelmaking maximizes the

efficiency of the steel refining process by (i) improving steel quality, (ii)

improving productivity, (iii) reducing costs, and (iv) protecting the

environment (since it removes the need of addition of fluorspar also called

fluorite). The other objectives of use of the synthetic slag during secondary

steelmaking are as follows.

To cover the liquid steel with an insulating layer to reduce heat losses which

otherwise takes place due to heat radiation.

To remove the possibility of reoxidation of steel from atmospheric oxygen.

To absorb inclusions present in the liquid steel.

To desulphurize liquid steel. Using synthetic slag of desired basicity and

sulphide capacity, deoxidized steel can be desulphurized to as low as 0.005 %

of sulphur.

The use of the synthetic slag practice is to be attractive especially when there

is low capital cost of equipment associated with the application of this

practice.

Synthetic slag is used during the secondary steelmaking because of the

following.

Synthetic slag greatly influences deoxidation and desulphurization of the

liquid steel.

It greatly shortens the steelmaking time, efficiently remove impurities and

improve the steel quality.

It is a required additive for production of special steels such as bearing

quality steel.

It reduces dust float pollution effectively.

It lowers melting temperature of slag.

It helps in increasing the slag fluidity.

It helps in absorbing inclusions and impurities, thus producing cleaner steel.

Synthetic slag is stable and nearly dust-free and hence easy to handle and

there is no pollution during its handling.

The basic task of the synthetic slags, which are normally added to ladle

slags, is to increase the quality of liquid steel by forming an active slag for

an improvement of the kinetic conditions in the ladle for the refining

processes. Added synthetic slags influence the properties of the ladle slag

not only with its chemical and phase compositions, but also with the

manner of their preparation and the granularity of the used raw materials.

The aim of applying synthetic slags is to create a fluid, sufficiently basic,

and liquid slag with a low melting temperature, which contributes to an

acceleration of the physical and chemical processes at the slag-metal

interface, thus influencing the efficiency of the secondary steelmaking.

Synthetic slag modifies the composition of ladle slag and physically,

thermally and chemically protects the liquid steel during ladle refinement

and casting. Synthetic slag products are specifically formulated to specific

conditions existing in a steel melting shop for appropriate desulphurization

and non-metallic inclusion absorption without adversely affecting ladle

refractory.

Treating the liquid steel with synthetic slag in the ladle is an efficient and

relatively cheap method of reducing the non-metal inclusion content by

reducing the sulphur and oxygen content. The principle of the process of

using synthetic slag consists in making a contact on a large surface

between the liquid steel and a slag having a composition selected to

ensure an advanced steel deoxidation and desulphurization.

Design of synthetic slag

Slag design in secondary metallurgy is crucial for the performance in

steelmaking. It guarantees the quality and cleanliness of the steel and the

consistency of its performance. It is critical since it impacts the efficiency of

the steel refining process during the secondary steelmaking. The slag is to

have necessary physical and chemical properties. It is to have low melting

temperature, low viscosity of liquid slag, and optimum fluidity.

Main components of synthetic slag are CaO, Al2O3 and a small amount of

SiO2. Synthetic slag having these components is also known as calcium

aluminate (CA) flux.

When the ladles are lined with magnesia carbon or dolomite refractories

then MgO forms an important component of the synthetic slag. This

synthetic slag is also called calcium magnesium aluminate (CMA) flux.

CMA slag allows a quick formation of a homogeneous and liquid slag with a

high capacity to absorb sulphur and oxide inclusions from the steel bath,

very similar to CA slag. CMA synthetic slag brings the MgO-content in the

slag, right after tapping, close to the saturation concentration and

minimizes the dissolution of magnesia carbon or dolomite refractories in the

slag.

Earlier CaF2 was also used to be a component of the synthetic slag since

fluorite was added during the production of synthetic slag. CaF2 helps in

increasing the slag fluidity as well as sulphide capacity of slag but it attacks

the refractories and has environmental issues because of formation of

gaseous compound SiF4 due to interaction of CaF2 with SiO2 in the slag.

Use of fluorite in the preparation of synthetic slag is generally no more

done these days.

Sometimes aluminum (Al) is added in the synthetic slag to deoxidize the

liquid steel since transfer of sulphur from liuid steel to slag is followed by

transfer of oxygen from slag to steel. Therefore deoxidation of steel is

essential for efficient desulphurization.

The synthetic slag is to be designed for each application. The CaO and

Al2O3 contents in calcium aluminates is varied in large ranges mainly to

suit local conditions of secondary steelmaking in the steel melting shop of

the plant. Synthetic slag has CaO content usually in the ranges from 25 %

to over 55 %, Al2O3 content in the ranges from 30 % to over 55 %. The

slag is normally low in SiO2, Fe2O3, and TiO2. MgO percentage in CMA

synthetic slag ranges from 3 % to 6 %. In case aluminum is added in

synthetic slag then usually itis in the range of 5 % to 16 %.

The melting point of the slag is generally in the range of 1350 deg C to

1400 deg C. Bulk density of the synthetic slag usually ranges from 2.85

tons/cum to 3.0 tons/cum. Product size of the synthetic slag is to facilitate

its quick melting in the ladle as well its easy handling. Size distribution is

normally tailored as per requirement. Usually synthetic slags are supplied

in three size ranges consisting of 1 mm to 50 mm, 3 mm to 30 mm, and 10

mm to 100 mm.

Generally synthetic slag is basic in nature. However, special synthetic slag

can be designed for a specific purpose. For removal of oxide inclusions, a

neutral slag with CaO/SiO2=1 or 1.2 can be used especially when no

desulphurization is needed.

Calcium aluminate system

Synthetic slag basically consists of calcium aluminates which are the salts

of aluminic acid and calcium hydroxide. The composition of various

minerals is obtained by heating calcium oxide (lime) and aluminum oxide

(bauxite) together at high temperatures (around 1600 deg C). The phase

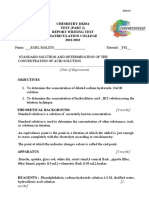

diagram of calcium aluminate system is given at Fig 1.

Fig 1 Phase diagram of calcium aluminate system

The phase diagram of the CaO-Al2O3 system shows that there are several

calcium aluminates appear in the system out of which few are stable.

Calcium aluminate for synthetic slag is made of select raw materials of

calcium and aluminum, blended at a proper proportion, ground to powder,

pelletized after churning, sintered or melted in kiln. The mineral

composition of calcium aluminate for synthetic slag is to be CA, CA2, C3A

and C12A7. The phase diagram shows that there are several calcium

aluminates appear in the system out of which few are stable at atmospheric

pressure under an atmosphere of normal humidity. The stable phases

shown in the phase diagram (formed at atmospheric pressure under an

atmosphere of normal humidity) are as follows.

Tricalcium aluminate, 3CaOAl2O3 (C3A) It is the most basic of the calcium

aluminates. Melting point is 1,542 deg C and density of 3.064 g/cc.

Dodeca calcium hepta-aluminate, 12CaO7Al2O3 (C12A7) (Mayenite) -Its

composition and properties have been the subject of much debate, because

of variations in composition that can arise during its high-temperature

formation. Melting point is 1400 deg C and density of 2.68 g/cc.

Monocalcium aluminate, CaOAl2O3 (CA) It is formed when the appropriate

proportions of calcium carbonate and aluminum oxide are heated together

until the mixture melts. It melts incongruently at 1390 deg C. Density is 2.945

g/cc.

Monocalcium di aluminate, CaO2Al2O3 (CA2).

Monocalcium hexa-aluminate, CaO6Al2O3 (CA6).

In the steel industry during secondary steelmaking, a number of synthetic

slags based on Al2O3 are used which are produced from natural or

secondary raw materials in different forms. However, the use of synthetic

slags is influenced by the choice of manufacturing process being used.

Based on the manufacturing process, there are two types of calcium

aluminates which are used. These are sintered calcium aluminate and

fused calcium aluminate. The first type is sintered in rotary kiln and the

second type is fused in electric arc furnace. Sintered calcium aluminate is

produced by sintering of high purity alumina and low silica limestone.

Fused calcium aluminate is produced by melting of high grade bauxite and

low silica limestone and then solidifying and crushing the molten material.

In both the process of manufacturing selection of raw materials is an

important aspect. The objective during manufacture of calcium aluminate

flux is to have the mineral composition of CA, CA2, C3A and C12A7. Since

bauxite is a material which is mined, it is always associated with certain

impurities and hence the composition wise, fused calcium aluminate flux is

inferior to the sintered calcium aluminate flux provided pure alumina is used

for sintering.

The specific consumption of calcium aluminate varies from 6 kg/ton to 12

kg/ton depending on the process condition, steels initial and final chemistry,

and composition of the calcium aluminate flux. It is advisable to add 1/3rd

to 1/2 at the ladle bottom and balance on the top for better performance of

the calcium aluminate flux.

The advantages associated with the use of secondary slag during the

secondary steelmaking include the following.

Protection of the ladle and tundish refractories.

Savings of energy at the ladle furnaces.

Consistent chemistry of the secondary steelmaking slag.

Faster steel refining times during the secondary steelmaking.

Sulphur and inclusion removal from the steel making the steel cleaner.

Greater yields during the continuous casting through improved castability.

A good cover slag for the prevention of gaseous pick-up from the atmosphere.

An effective fluid sink that absorbs inclusions from steel.

Synthetic slag generally contains no fluorine compounds, thus avoids

refractory attack and atmospheric pollution.

Synthetic slag practice during secondary steelmaking is quite simple and

not much capital investment is needed for it. Certain issues are associated

with this practice are given below.

Desulphurization need may vary from one heat to other heat, if slag carry-

over from primary steelmaking furnace is not controlled. Oxygen content of

steel from primary steelmaking furnace may also vary. If these two aspects

are not controlled then consistent results from synthetic slag practice may not

be achieved.

CaO is one of the major components of the synthetic slag. It is hygroscopic

and leads to hydrogen pick up.

Argon rinsing is necessary with the use of synthetic slag to stir the bath.

The slag attacks the ladle refractory. In case there is Ca F2 in the synthetic

slag then the refractory wear is higher.

Heat is necessary for melting the synthetic slag.

You might also like

- Inclusion Sulphur ControlDocument5 pagesInclusion Sulphur ControlDeepak Patel100% (1)

- InclusionsDocument40 pagesInclusionsricha_msmeNo ratings yet

- Lecture 42Document5 pagesLecture 42Abhijeet BhagavatulaNo ratings yet

- Steel CleanlinessDocument22 pagesSteel Cleanlinessdrbeyer100% (1)

- STS BLOOM CASTER FOR SPECIAL STEELS AT IZHSTALDocument21 pagesSTS BLOOM CASTER FOR SPECIAL STEELS AT IZHSTALkalaiNo ratings yet

- Inclusion in Cast SteelDocument42 pagesInclusion in Cast SteelAnonymous w6v7JWfr5100% (1)

- Effective Filtration of Steel CastingsDocument40 pagesEffective Filtration of Steel CastingsWalter Hartwell WhiteNo ratings yet

- CONTINUOUS CASTING ColloquiumDocument18 pagesCONTINUOUS CASTING ColloquiumakritiNo ratings yet

- The Effect of Slag Modeling To Improve Steelmaking Processes PDFDocument12 pagesThe Effect of Slag Modeling To Improve Steelmaking Processes PDFPaulo J. C. EstevesNo ratings yet

- Strollberg LEO WorkshopDocument54 pagesStrollberg LEO WorkshopBinod Kumar PadhiNo ratings yet

- Dieless Wire DrawingDocument8 pagesDieless Wire DrawingRohit GothwalNo ratings yet

- Understanding The Properties of Oxide Scales On Hot Rolled Steel StripDocument6 pagesUnderstanding The Properties of Oxide Scales On Hot Rolled Steel Stripradinasr100% (1)

- Tempcore ProcessDocument23 pagesTempcore ProcessKumaran 1987No ratings yet

- Retained Austenite and PittingDocument6 pagesRetained Austenite and PittingSuhaib AshrafNo ratings yet

- The TEMPCORE ProcessDocument15 pagesThe TEMPCORE ProcessShanna Lee100% (1)

- Continuous Casting Solidification PhenomenaDocument20 pagesContinuous Casting Solidification PhenomenaSyed HasniNo ratings yet

- Electric Arc Furnace Steelmaking by Jeremy A. T. Jones, Nupro CorporationDocument9 pagesElectric Arc Furnace Steelmaking by Jeremy A. T. Jones, Nupro CorporationGilson JuniorNo ratings yet

- Effect of Basic Chemical Element in Sgi Ductile Iron IJERTV1IS7135Document7 pagesEffect of Basic Chemical Element in Sgi Ductile Iron IJERTV1IS7135Uma KoduriNo ratings yet

- Rates of Dissolution of Magnesite and Dolomite in EAF SlagsDocument14 pagesRates of Dissolution of Magnesite and Dolomite in EAF SlagsAgustine SetiawanNo ratings yet

- Scale Nippon SteelDocument5 pagesScale Nippon SteelsankhadipNo ratings yet

- Improvement of Surface Quality of Continuously Cast Steel Control PDFDocument130 pagesImprovement of Surface Quality of Continuously Cast Steel Control PDFChrist ChristiNo ratings yet

- Casting: "Net Shape" or "Near-Net Shape" Process AdvantagesDocument27 pagesCasting: "Net Shape" or "Near-Net Shape" Process AdvantagesnsbaruaoleNo ratings yet

- Stainless Steel 2008Document25 pagesStainless Steel 2008hawktripNo ratings yet

- Binders ComparisionDocument8 pagesBinders Comparisionavutu_kunduruNo ratings yet

- PRODUCTION OF STEEL-Lecture 2Document68 pagesPRODUCTION OF STEEL-Lecture 2Nyanda MalashiNo ratings yet

- Steel Processing in Energy Optimizing Furnace: 4.1 Preparation of EofDocument8 pagesSteel Processing in Energy Optimizing Furnace: 4.1 Preparation of EofRitesh KumarNo ratings yet

- Conducting MaterialsDocument8 pagesConducting MaterialsVihang DholakiyaNo ratings yet

- Computer Modeling of Refractory/Slag/Metal InteractionsDocument8 pagesComputer Modeling of Refractory/Slag/Metal InteractionsAbderrahim AmchtahrirNo ratings yet

- STEEL TITLEDocument23 pagesSTEEL TITLEMahadi HasanNo ratings yet

- Development of a new hydraulic mold oscillator model for continuous casting processesDocument5 pagesDevelopment of a new hydraulic mold oscillator model for continuous casting processesM M HossainNo ratings yet

- Thermomechanical Processing and Constitutive Strength of Hot Rolled Mild SteelDocument104 pagesThermomechanical Processing and Constitutive Strength of Hot Rolled Mild SteelvishwanathanskNo ratings yet

- EAF GeneralDocument60 pagesEAF GeneralFaisal SalehNo ratings yet

- Development of Ductile Iron Over Fifty YearsDocument36 pagesDevelopment of Ductile Iron Over Fifty YearsDenis Yasmin AlineNo ratings yet

- THE EFFECT OF FOAMY SLAG IN THE ELECTRIC ARC FURNACES ON ELECTRIC Energy Consumption PDFDocument10 pagesTHE EFFECT OF FOAMY SLAG IN THE ELECTRIC ARC FURNACES ON ELECTRIC Energy Consumption PDFManojlovic VasoNo ratings yet

- Ingot StructureDocument5 pagesIngot StructureklawsisNo ratings yet

- Lecture 04-CCT and TemperingDocument17 pagesLecture 04-CCT and TemperingRudy Dwi PrasetyoNo ratings yet

- Rr411802 Steel MakingDocument4 pagesRr411802 Steel MakingSrinivasa Rao GNo ratings yet

- State of The Art in The Control of Inclusions During Steel Ingot CastingDocument29 pagesState of The Art in The Control of Inclusions During Steel Ingot Castinggaurav vermaNo ratings yet

- Metallic Materials Sessional Microstructure StudyDocument39 pagesMetallic Materials Sessional Microstructure StudyMuhammedNayeemNo ratings yet

- Tramp Elements and Billet CarckingDocument7 pagesTramp Elements and Billet CarckingOmar TahaNo ratings yet

- Progress and Perspective of Refractory Technology in SteelmakingDocument5 pagesProgress and Perspective of Refractory Technology in SteelmakingemregnesNo ratings yet

- Billet Defects: Pin-Hole and Blow-Hole Formation, Prevention and EvolutionDocument11 pagesBillet Defects: Pin-Hole and Blow-Hole Formation, Prevention and EvolutionBoujemaa DrifNo ratings yet

- Melting and Holding October 08Document10 pagesMelting and Holding October 08Aragaw MuluNo ratings yet

- Billet Defects: Pinhole and Blowhole Formation, Prevention and EvolutionDocument11 pagesBillet Defects: Pinhole and Blowhole Formation, Prevention and EvolutionAbdelraouf ZaidNo ratings yet

- Effects of MN Content and Heat TreatmentDocument5 pagesEffects of MN Content and Heat TreatmentTrần Xuân VịnhNo ratings yet

- Metallurgy of Continuous Casting TechnologyDocument20 pagesMetallurgy of Continuous Casting Technologyahmed ebraheemNo ratings yet

- Heat TreatmentDocument21 pagesHeat TreatmentChernet MerknehNo ratings yet

- A Review of Defects in Beam Blank Casting and The Measures Proposed For Their EliminationDocument35 pagesA Review of Defects in Beam Blank Casting and The Measures Proposed For Their EliminationJorge Madias100% (1)

- Contineous CastingDocument3 pagesContineous CastingMuhammad ImranNo ratings yet

- Indian Steel Making ProcessesDocument10 pagesIndian Steel Making ProcessesSarbajitManna100% (1)

- O HC HCDocument101 pagesO HC HCIndustrial Infra Jobs100% (1)

- Mould Fluxes in The Steel Continuous Casting ProcessDocument30 pagesMould Fluxes in The Steel Continuous Casting ProcessUgur KayaNo ratings yet

- Inclusions in Steel by Calcium TreatmentDocument89 pagesInclusions in Steel by Calcium TreatmentSuleyman HaliciogluNo ratings yet

- Steel Dynamics Bar Book Rev 2 New CoverDocument194 pagesSteel Dynamics Bar Book Rev 2 New CoverNina LazuardiNo ratings yet

- The Iron Puddler My life in the rolling mills and what came of itFrom EverandThe Iron Puddler My life in the rolling mills and what came of itNo ratings yet

- Lead 68: Edited Proceedings, Third International Conference on Lead, VeniceFrom EverandLead 68: Edited Proceedings, Third International Conference on Lead, VeniceNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- V4i12 Ijertv4is120090Document6 pagesV4i12 Ijertv4is120090Waqas AhmedNo ratings yet

- Full ThesisDocument93 pagesFull ThesisWaqas AhmedNo ratings yet

- s11665 997 0098 9Document2 pagess11665 997 0098 9Waqas AhmedNo ratings yet

- Paper Information: Performance Enhancement of TMT Rebar in Accelerated CorrosionDocument7 pagesPaper Information: Performance Enhancement of TMT Rebar in Accelerated CorrosionWaqas AhmedNo ratings yet

- Image Capture & Analysis GuideDocument35 pagesImage Capture & Analysis GuideWaqas AhmedNo ratings yet

- 7steel CorrosionDocument30 pages7steel CorrosionbaluNo ratings yet

- Deformedbar KSD3504 Gudie1Document4 pagesDeformedbar KSD3504 Gudie1Waqas AhmedNo ratings yet

- Australian/New Zealand StandardDocument2 pagesAustralian/New Zealand StandardWaqas AhmedNo ratings yet

- Presentation 1111Document1 pagePresentation 1111Waqas AhmedNo ratings yet

- Gs BrochureDocument20 pagesGs BrochureKatherine StuartNo ratings yet

- 132 KV Grid StationDocument14 pages132 KV Grid StationWaqas AhmedNo ratings yet

- 132 KV Grid StationDocument14 pages132 KV Grid StationWaqas AhmedNo ratings yet

- Bond Characteristics of Reinforced TMT Bars in Self Compacting Concrete and Normal Cement Concrete - ScienceDirectDocument14 pagesBond Characteristics of Reinforced TMT Bars in Self Compacting Concrete and Normal Cement Concrete - ScienceDirectWaqas AhmedNo ratings yet

- 1-2lecture Ceramic Engineering MEDocument45 pages1-2lecture Ceramic Engineering MEWaqas AhmedNo ratings yet

- Corrosion of Stainless SteelDocument19 pagesCorrosion of Stainless SteelWaqas AhmedNo ratings yet

- IJETR032311Document6 pagesIJETR032311erpublicationNo ratings yet

- Irfan Ali Corrosion in ConcreteDocument29 pagesIrfan Ali Corrosion in ConcreteWaqas AhmedNo ratings yet

- Critical Analysis On Characterization Techniques and TestingDocument25 pagesCritical Analysis On Characterization Techniques and TestingWaqas AhmedNo ratings yet

- IJETR032311Document6 pagesIJETR032311erpublicationNo ratings yet

- Paper Information: Performance Enhancement of TMT Rebar in Accelerated CorrosionDocument7 pagesPaper Information: Performance Enhancement of TMT Rebar in Accelerated CorrosionWaqas AhmedNo ratings yet

- Buildings Ductile For Good Seismic PerformanceDocument2 pagesBuildings Ductile For Good Seismic PerformanceWaqas AhmedNo ratings yet

- Ductility Requirements of Earthquake Res PDFDocument6 pagesDuctility Requirements of Earthquake Res PDFAbdullah SimpsonNo ratings yet

- Earl's Practical Test Part 2 (Lab Report Template) - Dk014Document5 pagesEarl's Practical Test Part 2 (Lab Report Template) - Dk014MALIUS BIN SUNGGI MoeNo ratings yet

- Aisi 1045Document1 pageAisi 1045edraelmx100% (1)

- Dog ShampooDocument2 pagesDog ShampooTrần Văn LộcNo ratings yet

- Experiment 15 - UrineDocument3 pagesExperiment 15 - UrineJesette KhoNo ratings yet

- Bronze: LG2 - Leaded GunmetalDocument3 pagesBronze: LG2 - Leaded GunmetalDodi SuhendraNo ratings yet

- Fees Indo-Minerals 2010Document26 pagesFees Indo-Minerals 2010BambangNo ratings yet

- Fringe LinksDocument6 pagesFringe Linksdhana210No ratings yet

- Note CHP 3 Material Science 281 Uitm Em110Document40 pagesNote CHP 3 Material Science 281 Uitm Em110bino_ryeNo ratings yet

- Rearrangement ReactionsDocument7 pagesRearrangement ReactionssantiisantNo ratings yet

- Gulf Precast GRCDocument12 pagesGulf Precast GRCmujeebscribdNo ratings yet

- Technip Germany Coke Calcining ExpertiseDocument17 pagesTechnip Germany Coke Calcining ExpertiseSimin Coke Co.No ratings yet

- Mass Balance Examples4Document8 pagesMass Balance Examples4Darel Williams100% (2)

- India's Sponge Iron Industry and the Scope for Clean TechnologyDocument38 pagesIndia's Sponge Iron Industry and the Scope for Clean TechnologydekanitaesriepaksiNo ratings yet

- The Role of Bismuth in The SOHIO ProcessDocument39 pagesThe Role of Bismuth in The SOHIO ProcessMarnel Roy MayorNo ratings yet

- AMMONIUM SULPHATE, TECHNICAL SpecificationDocument10 pagesAMMONIUM SULPHATE, TECHNICAL Specificationbabji dudekulaNo ratings yet

- Common Casting Defects - Sand Mold, Metal CastingDocument10 pagesCommon Casting Defects - Sand Mold, Metal CastingAbhinav Pratap MauryaNo ratings yet

- 17 Inspissator FinthfhgDocument6 pages17 Inspissator FinthfhgArchieDuqueNo ratings yet

- Notes Unit 9 KEYDocument28 pagesNotes Unit 9 KEYJovan Nikodinovski100% (1)

- Assignment 3 MemoDocument4 pagesAssignment 3 MemoporschaveNo ratings yet

- Degreasers Program Eng 0 PDFDocument8 pagesDegreasers Program Eng 0 PDFtopguitarNo ratings yet

- Water-Based Non-Ionic Polymeric Surfactants As Oil Spill Dispersants PDFDocument7 pagesWater-Based Non-Ionic Polymeric Surfactants As Oil Spill Dispersants PDFAfzal AktharNo ratings yet

- Unit 1 Metals and Melting Practices: StructureDocument45 pagesUnit 1 Metals and Melting Practices: StructureTapas BanerjeeNo ratings yet

- LABSA ProposalDocument10 pagesLABSA ProposalMichelle MendozaNo ratings yet

- 2,3,4,5 TetraphenylcyclopentadienoneDocument6 pages2,3,4,5 TetraphenylcyclopentadienoneDenisse Watt Cuarteros100% (2)

- ESI and APCI IonizersDocument14 pagesESI and APCI IonizersJessica JimenezNo ratings yet

- FePO4 Raman SpectraDocument14 pagesFePO4 Raman SpectraPaola FarfanNo ratings yet

- Urine Crystals (Crystalluria)Document17 pagesUrine Crystals (Crystalluria)John AsamaohNo ratings yet

- Final Report 3Document10 pagesFinal Report 3TOBIRAMA SenkuNo ratings yet

- Royalene 301T TDSDocument1 pageRoyalene 301T TDSMohamed BendoudouchNo ratings yet

- CHEL04A - Transes in BiochemistryDocument7 pagesCHEL04A - Transes in BiochemistryMikhaella GwenckyNo ratings yet