Professional Documents

Culture Documents

Chapter 4 Ribbed Slabs and Waffle Slabs

Uploaded by

Assefa NigussieOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 4 Ribbed Slabs and Waffle Slabs

Uploaded by

Assefa NigussieCopyright:

Available Formats

Chapter 4 Ribbed Slabs and Waffle Slabs

Ribbed slabs are used for long spans with relatively light loads. They are constructed in one

of the following ways as described in clause 30 of IS: 456-2000

1. As a series of concrete ribs with topping.

2. As a series of concrete ribs or solid blocks, between precast hollow as a solid blocks.

3. With continuous top and bottom but containing voids of rectangular, oval or other shapes.

These three types of constructions are shown in fig. 14.1.

(a) Series of concrete ribs with topping

(b) Concrete ribs or solid blocks, between precast hollow as a solid blocks

(c) Continuous top and bottom but containing voids

Fig. 4.1 Ribbed slab construction

Design of Reinforced Concrete & Post-Tensioned flat slab using software

1

Chapter 4 Ribbed Slabs And Waffle Slabs

4.1 PROPORTIONING THE DIMENSIONS OF RIB

The ribs may have rectangular, trapezoidal or any other appropriate shape. If trapezoidal (or

other shaped) rib is provided, the width of rib is calculated as an average width excluding

topping. The minimum width of the rib shall be determined in accordance with minimum

cover required to the reinforcement. The minimum width of the rib shall not be less than 65

mm. The depth of the rib excluding topping shall not be more than four times the width of

rib. Maximum spacing of the ribs shall be 1.5 m.

4.2 ANALYSIS AND DESIGN PROCEDURE OF RIBBED SLAB

Ribbed slab can be idealized as a solid slab replaced by a series of beams which are spaced at

smaller distances. Loading from the topping shall be transferred to the ribs simply by two-

way reinforced jail, usually formed by minimum reinforcement.

The ribs can be analyzed by the usual procedure applicable to the solid slabs. If the ribs are

continuous, they can be analyzed by one of the following ways.

(1) As continuous ribs, which may be analyzed by using coefficients applicable to continuous

beams or slabs if it has three or more than three uniformly loaded and approximately equal

spans; if not, these can be analyzed by moment distribution considering various live load

arrangement.

(2) If the ribs are not exposed to the weather or corrosive conditions, and if the support

cracks can be permitted, then continuous ribs are designed as a series of simply supported

ribs. In addition, few reinforcement at the support shall be provided to reduce the cracks at

the support.

The ribs are now designed as follows:

(a) Design for flexure

The ribs are designed as tee or ell beams. The width of the flange is usually the actual width

of the flange owing to the smaller spacing of the ribs. For example, a central tee beam has a

Design of Reinforced Concrete & Post-Tensioned flat slab using software.

2

Chapter 4 Ribbed Slabs And Waffle Slabs

flange width equal to the spacing of the ribs. For continuous ribs, support section is designed

as a rectangular section.Moment reinforcement consists of one bar or more than one bar at

the bottom or at the top as the case may be.If the continuous ribs are designed as simply

supported ribs, support reinforcement equal to 25 per cent of span reinforcement shall be

provided. These reinforcement shall extend at least one-tenth of clear span into adjoining

spans.Clear cover to the main reinforcement shall be as per the solid slabs. However, If the

ribbed slab Is provided with permanent hollow concrete blocks, the side cover may be 10

mm.The topping shall be usually provided with minimum reinforcement i.e. 0.12% with

HYSD bars and 0.15% with mild steel bars. The spacing of topping reinforcement shall not

be more than one-half the spacing of the ribs. If the ribs are widely spaced. the reinforcement

shall be designed.

(b) Design for shear

Ribs are designed for shear as follows:

(1) If τv < τc/2, shear reinforcement Is not required.

(2) If τc > τv > τc/2, minimum shear reinforcement as per beam design should be provided, if

the rib contains two or more bars. Top bars of diameter at least equal to the diameter of

stirrups, two in number, should be used to hold the shear reinforcement. If the rib contains

only one bar, shear reinforcement is not necessary.

(3) If τv > τc, shear reinforcement shall be designed as per beam design for shear.

(4) According to IS: 456, art. 30.3, where hollow blocks are used, for the purpose of

calculating shear stress, the rib width may be increased to take account of the wall thickness

of the block on one side of the rib; with narrow precast units, the width of the joining mortar

or concrete may be included.

(c) Development length, deflection and cracking

The rules to check development length, deflection and cracking shall be as per solid slab or

flanged beam design as the case may be.

Design of Reinforced Concrete & Post-Tensioned flat slab using software.

3

Chapter 4 Ribbed Slabs And Waffle Slabs

4.3 WAFFLE SLABS

Fig. 4.2 Waffle slab

4.3.1 TWO-WAY SPANNING RIBBED SLABS: WAFFLE SLABS

Ribbed slabs discussed in the previous articles are one-way spanning. We shall now discuss

two-way spanning ribbed slabs. Such slabs are also termed as waffle slabs. The analysis and

design set out for one-way spanning ribbed slabs in previous articles are applicable to waffle

slabs also. The moments in the ribs may be determined by using the coefficients for two-way,

solid slabs. Load transfer from waffle slabs to the supporting beams shall be assumed as per

two-way solid slabs.

Waffle slabs are usually made solid in some portion around the supporting beams

- to resist negative bending moment

- to resist torsion at the edges In the end spans

Design of Reinforced Concrete & Post-Tensioned flat slab using software.

4

Chapter 4 Ribbed Slabs And Waffle Slabs

- to provide flanges to the supporting beams and thus to

Increase the moment carrying capacity of supporting beams.

Introducing voids to the soffit reduces dead weight and these deeper, stiffer floors permit

longer spans which are economic for spans between 9 and 14 m. The saving of materials

tends to be offset by complication in site operations.

Standard moulds are 225, 325 and 425 mm deep and are used to make ribs 125 mm wide on a

1000 mm grid. Toppings are between 50 and 150 mm thick. The chart and data assume

surrounding and supporting downstand beams, which should be subject to separate

consideration, and solid margins. Both waffles and downstand beams complicate formwork.

4.3.2 ADVANTAGES

• Medium to long spans

• Lightweight

• Profiles may be expressed architecturally, or used for heat transfer.

4.3.3 DISADVANTAGES

Higher formwork costs than for other slab systems

Slightly deeper members result in greater floor heights

Construction work is slow, difficult to prefabricate reinforcement.

Design of Reinforced Concrete & Post-Tensioned flat slab using software.

5

Chapter 4 Ribbed Slabs And Waffle Slabs

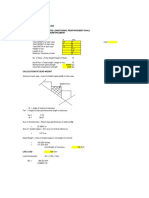

4.3.4 SPAN: DEPTH CHART FOR WAFFLE SLAB

Fig. 4.3 Span: Depth chart

Design of Reinforced Concrete & Post-Tensioned flat slab using software.

6

Chapter 4 Ribbed Slabs And Waffle Slabs

4.4 SAMPLE CALCULATION OF DESIGN OF REINFORCED

CONCRETE WAFFLE SLAB

Design of interior panel of a WAFFLE slab (Two-way slab)

Size of slab :- 8 m x 8 m

Concrete grade

:- M30

Steel grade :- Fe415

Conseder live load :- 4 kN/m2

Solution :

a) Proposed arrangement :-

total thickness of slab :- 300 mm

Thichness of topping :- 75 mm (Two-way ribbed slab)

1000

Spacing of ribs :- mm

width of waffle :- 125 mm

depth of waffle :- 225 mm

slab is made solid for 500 mm width at edges in all panels.

b) Loading :-

Topping :- self wt. 0.075 x 25 :- 1.875 kN/m2

floor finish :- 2 kN/m2

live load :- 4 kN/m2

Total :- 7.875 kN/m2

Rib :-

From topping :- 0.5 x 7.875 :- 3.9375 kN/m

self wt. :- 0.125 x 0.225 x 25 :- 0.703125 kN/m

Total :- 4.641 kN/m

Factored load :- 1.5 x 4.641 :- 6.96 kN/m

c) Shear and moments :-

shear at support (thickned slab) :- (w x l)/2 :- 27.84 kN

shear 1000

at mm from supp. (ribs) :-

0.5 x

:- 27.844 - 6.96 :- 24.36 kN

For two-way slab :-

l/b :- 1.000

Design of Reinforced Concrete & Post-Tensioned flat slab using software.

7

Chapter 4 Ribbed Slabs And Waffle Slabs

αx(+) :- αy(+) :- 0.024

αx(-) :- αy(-) :- 0.032

Mu(+) :- αx w lx2 :- 10.69 kNm

Mu(-) :- αy w ly2 :- 14.26 kNm

d) Flexure reinforcement :-

Assume 12 mm diameter bars dx :- 269 mm

dx :- 257 mm

Positive moment reinforcement :-

section is designed as a tee beam bf :- 1000 mm

bw :- 125 mm

Df :- 75 mm

(second layer is considered for symmetry) d :- 257 mm

Mu(+)

:- 11 kNm , bf / bw :- 8.00 Df / d :- 0.292

Mu,lim. T / (fck bw d2) :- 0.845 (Table 58, SP : 16)

Mu,lim. T :- 209.2928 kNm > 10.7 kNm

Ast :- 134.91 mm2 (Mu / (0.87 fy d))

provide 2 - 10 # :- 157 mm2

Negative moment reinforcement :-

14.3 1000

Mu(-) :- kNm b :- mm d :- 269 mm

Mu/bd2 :- 0.20

pt :- 0.055 pt = 50 { [1-(1-√(4.6Mu/fckbd2))] / (fy/fck) }

Ast :- 147.9833 mm2

provide 3 - 8 # between ribs + 2 - 8 #

:-

150.72 + 100.48 :- 251.2 mm2 (top bars of rib)

e) Shear :-

Shear in ribs at 500 mm from support

Vu :- 24.36 kN b :- 125 mm d :- 257 mm

τv :- 0.758 N/mm2 Vu /(b d)

100 As/(b d) :- 0.49

Design of Reinforced Concrete & Post-Tensioned flat slab using software.

8

Chapter 4 Ribbed Slabs And Waffle Slabs

τc :- 0.5 N/mm2 ( Page :- 73, IS : 456,2000)

τv > τc Shear design necessary.

16.06

vuc :- τc b d :- kN

vus :- vu - vuc :- 8.301 kN

use 6 mm dia two-legged stirrups with Asv :- 57 mm2

sv :- (0.87 fy Asv d) / vus :- 380.6 mm

spacing required for minimum shear reiforcement.

sv :- (0.87 fy Asv) / 0.4b :- 245.9 mm

193

maximum spacing permitted, sv,max :- 0.75 d :- mm

provide 6 mm dia @ 193 mm two-legged stirrups throught.

f) Development lenfth :-

177.2

Ld for negative moment bars :- mm

anchorage available :- 1000 mm ….ok

for positive moment bars

Mu1 :- 0.87 Fy Ast d :- 13.123 kN

24.3633

Vu :- kN

L0 :- 8 #

0.7002 +

1.3 Mu1/vu + L0 > Ld :- >

8# 177 mm

22.0684

8 # < # ….ok

g) Check for moment design at junction of solid slab and ribbed slab :-

x 300

negative moment reinforcement is designed considering the section 1000 mm mm

from support Mu(-)

1 m :- 10.11 kNm < Mu(-) ….ok

h) Deflection :-

basic span / d ratio :- 26

pt :- 100 As / (bf d) :- 0.05

modification factor :- 2.0 (page no. 38; IS 456-2000)

permissible span / d :- 52

actual span / d :- 31 < 52 ….ok

Design of Reinforced Concrete & Post-Tensioned flat slab using software.

9

Chapter 4 Ribbed Slabs And Waffle Slabs

i) Topping reinforcement :-

As :- 90 mm2/m.

d :- 56 assume 6.00 dia bar.

Maximum spacing :- 5 d :- 280 mm.

use 6 mm # wrapping mesh @ 200 mm c/c :- 141

mm2/m at the centre of topping.

steel quantity

along long span (+ve)steel :- 2 10 # (bottom steel of rib beam)

L :- 8 m

No. of bars :- 16 nos.

weight of steel :- 79 kg.

along short span (+ve) steel :- 2 10 # (bottom steel of rib beam)

L :- 8 m

No. of bars :- 16 nos.

weight of steel :- 79 kg.

along long span (-ve)steel :- 2 8 # (top steel of rib beam)

L :- 8 m

No. of bars :- 16 nos.

weight of steel :- 51 kg.

along short span (-ve) steel :- 2 8 # (top steel of rib beam)

L :- 8 m

No. of bars :- 16 nos.

weight of steel :- 51 kg.

along long span (-ve)steel :- 3 8 # (between ribs)

L :- 4 m

No. of bars :- 24 nos.

weight of steel :- 38 kg.

along short span (-ve)steel :- 3 8 # (between ribs)

L :- 4 m

No. of bars :- 24 nos.

weight of steel :- 38 kg.

topping reinforcement

along long span steel :- 6 # 200 mm c/c

L :- 1 m

Design of Reinforced Concrete & Post-Tensioned flat slab using software.

10

Chapter 4 Ribbed Slabs And Waffle Slabs

No. of bars :- 384 nos.

weight of steel :- 85 kg.

along short span steel :- 6 200 mm c/c

L :- 1 m

No. of bars :- 384 nos.

weight of steel :- 85 kg.

shear reinforcement :

along long span steel :- 6 # 193 mm c/c

L :- 0.85 m

No. of bars :- 332 nos.

weight of steel :- 63 kg.

along short span steel :- 6 # 193 mm c/c

L :- 0.85 m

No. of bars :- 332 nos.

weight of steel :- 63 kg.

total steel required for 3 span.

total steel required :- 12915 kg.

Total cost of steel :- 419724.3 Rs.

quantity of conc.in topping slab :- 43.20 m3

quantity of solid slab near mainbeam :- 86.40 m3

quantity of ribbed beams :- 28.35 m3

quantity of main beams :- 46.08 m3

total quantity of concrete :- 204.03 m3

quantity of steel in m3 :- 1.65 m3

% of steel :- 0.81 %

Total cost of slab :- 1431773 Rs.

interior panel bottom fibre stress :-M y / I :- 7.60E+00 N/mm2

Design of Reinforced Concrete & Post-Tensioned flat slab using software.

11

You might also like

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Waffle Slab DesignDocument12 pagesWaffle Slab DesigndrajkumarceNo ratings yet

- Waffle Slab Joint DetailsDocument6 pagesWaffle Slab Joint DetailsReymond Longtable100% (1)

- ACI 318-08 Rec Sec. MX - Q-Torsion DesignDocument16 pagesACI 318-08 Rec Sec. MX - Q-Torsion DesignSultana Jahan DipaNo ratings yet

- Your LOGO: Project Name Subject Element Number S1 Done byDocument11 pagesYour LOGO: Project Name Subject Element Number S1 Done byAamirShabbir100% (1)

- Design For Snow Loading On RoofsDocument4 pagesDesign For Snow Loading On Roofskkozak99No ratings yet

- ACI Design AidsDocument60 pagesACI Design AidsNabeel SheikhNo ratings yet

- Lecture 10 Analysis and Design of Waffle Slabs - 2011Document62 pagesLecture 10 Analysis and Design of Waffle Slabs - 2011José Pablo Rosales Sánchez100% (1)

- Baa2213 - Reinforced Concrete Design I 21516 PDFDocument7 pagesBaa2213 - Reinforced Concrete Design I 21516 PDFAizat HermanNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document8 pagesRCC92 Ribbed Slabs (Tables)lucianduNo ratings yet

- 2) Example 1 - Ribbed SlabDocument11 pages2) Example 1 - Ribbed SlabMohammadNajeeb0% (1)

- Truss DeflectionDocument2 pagesTruss DeflectionAb_AlizadehNo ratings yet

- Design of Waffle SlabDocument4 pagesDesign of Waffle SlabAriel Mayer100% (1)

- Strap Footing TheoryDocument4 pagesStrap Footing TheorySwopnilOjhaNo ratings yet

- Combined axial and bending strength of RC columnsDocument21 pagesCombined axial and bending strength of RC columnsMiski45No ratings yet

- Vicwest DiaphragmsDocument62 pagesVicwest Diaphragmsrmsa17No ratings yet

- Concrete Stair Design ACI318 PDFDocument4 pagesConcrete Stair Design ACI318 PDFMuhammad Dawood KhanNo ratings yet

- Article: Wide-Flange Beam To Hss Column Moment ConnectionsDocument3 pagesArticle: Wide-Flange Beam To Hss Column Moment ConnectionsBudi SimatupangNo ratings yet

- Purlin DESIGNDocument10 pagesPurlin DESIGNMohamed NkNo ratings yet

- Rules of Thumb - Structural Engineering Other Technical Topics FAQ - Eng-TipsDocument7 pagesRules of Thumb - Structural Engineering Other Technical Topics FAQ - Eng-Tipsnuwan01100% (1)

- Sizing slab reinforcementDocument5 pagesSizing slab reinforcementseljak_veseljak100% (1)

- Dhaka University of Engineering & TechnologyDocument25 pagesDhaka University of Engineering & TechnologyMozammel hoque100% (1)

- Quick-Connect Moment Connection For Portal Frame Buildings - An Introduction and Case StudiesDocument10 pagesQuick-Connect Moment Connection For Portal Frame Buildings - An Introduction and Case StudiesTuroyNo ratings yet

- RCC Design of Concrete Structures Nilson #S#Document783 pagesRCC Design of Concrete Structures Nilson #S#Tapu mojumder100% (2)

- Design and Analysis of Bolted ConnectionsDocument45 pagesDesign and Analysis of Bolted ConnectionskktttNo ratings yet

- Engr. Suñega - 2wayslab-DdmDocument31 pagesEngr. Suñega - 2wayslab-DdmJustinNo ratings yet

- Reinforced Concrete Design Theory P Bhatt Thomas Joseph MacGinleyDocument1 pageReinforced Concrete Design Theory P Bhatt Thomas Joseph MacGinleyjason_gernale2011No ratings yet

- Foundation Example 9.7Document14 pagesFoundation Example 9.7Deana WhiteNo ratings yet

- Cssbi 59 05 PDFDocument321 pagesCssbi 59 05 PDFcatalin2poppNo ratings yet

- Prepared BY Dr. Mohammed Kadhum FekheraldinDocument55 pagesPrepared BY Dr. Mohammed Kadhum Fekheraldinhemantkle2uNo ratings yet

- Footing Soil Pressure From Biaxial LoadingDocument18 pagesFooting Soil Pressure From Biaxial LoadingSon NguyenNo ratings yet

- DDA 3164 BEAM Shear Deflection and CrackDocument20 pagesDDA 3164 BEAM Shear Deflection and CrackZayyan RomjonNo ratings yet

- Development LengthDocument22 pagesDevelopment LengthAlok MamNo ratings yet

- مخططات بناية كونكريت و حديدDocument31 pagesمخططات بناية كونكريت و حديدalaa4altaieNo ratings yet

- Design Recommendations For Steel Deck Floor SlabsDocument32 pagesDesign Recommendations For Steel Deck Floor SlabsYannick PrattNo ratings yet

- Method of Producing Castellated Beams with Circular or Oval OpeningsDocument9 pagesMethod of Producing Castellated Beams with Circular or Oval OpeningsElango VijayasundaramNo ratings yet

- Checklist For Concrete Shear Wall (ACI 318-14)Document5 pagesChecklist For Concrete Shear Wall (ACI 318-14)renzo1221No ratings yet

- Steel beam design chart for grade S275Document294 pagesSteel beam design chart for grade S275azwanNo ratings yet

- Constructions: Load Bearing Constructions Using Wood-Concrete-Composite Technique With Glued-In - Shear ConnectorsDocument35 pagesConstructions: Load Bearing Constructions Using Wood-Concrete-Composite Technique With Glued-In - Shear ConnectorsPATRICIO SARAVIANo ratings yet

- Stair DesignDocument2 pagesStair DesignJimmyNo ratings yet

- Two Way Slab Design Analysis (8m x 7mDocument6 pagesTwo Way Slab Design Analysis (8m x 7mMuhammad Azeem KhanNo ratings yet

- Practical calculation formulae for parallel chord vierendeel trussesDocument25 pagesPractical calculation formulae for parallel chord vierendeel trussesRonald De GuzmanNo ratings yet

- Masonry Reinforcement Product SelectorDocument8 pagesMasonry Reinforcement Product Selectorkakarock79No ratings yet

- Memorial Hall ReportDocument19 pagesMemorial Hall ReportMike CarraggiNo ratings yet

- Wind Pressures Analysis by (NBCC) National Building Code of CanadaDocument9 pagesWind Pressures Analysis by (NBCC) National Building Code of CanadaAfzal Waseem100% (7)

- Academic Library Design-Waffle SlabDocument237 pagesAcademic Library Design-Waffle SlabAbdul HafeezNo ratings yet

- CSA Spec HILTI HIT 100 Technical SupplementDocument32 pagesCSA Spec HILTI HIT 100 Technical SupplementIsidro P. BuquironNo ratings yet

- Axially Loaded RC Column DesignDocument17 pagesAxially Loaded RC Column DesignBert EngNo ratings yet

- Concrete Slab Design DraftDocument13 pagesConcrete Slab Design DraftTom FallonNo ratings yet

- Steel Plate Shear Wall DesignDocument5 pagesSteel Plate Shear Wall DesignbuddychichiNo ratings yet

- Deltabeam Brochure EngDocument20 pagesDeltabeam Brochure EngymitevNo ratings yet

- Epoxy Connection TimberDocument6 pagesEpoxy Connection TimberJeffery RoweNo ratings yet

- Rebar Arrangement in SlabDocument12 pagesRebar Arrangement in Slableovorig100% (2)

- Chapter 4 Ribbed Slabs and Waffle SlabsDocument11 pagesChapter 4 Ribbed Slabs and Waffle SlabsSharan Bvp75% (4)

- RCI Hand Out Chapter 4 - PPT - 4.2 One Way Ribbed SlabDocument46 pagesRCI Hand Out Chapter 4 - PPT - 4.2 One Way Ribbed SlabNathnael Jia100% (3)

- CIV5304: Design of Structural Elements III: Engr DR Nuruddeen Muhammad MusaDocument30 pagesCIV5304: Design of Structural Elements III: Engr DR Nuruddeen Muhammad MusaNuruddeen MuhammadNo ratings yet

- Lecture 24 - Design of Two-Way Floor Slab SystemDocument72 pagesLecture 24 - Design of Two-Way Floor Slab SystemHeng KimsengNo ratings yet

- Design of SlabsDocument17 pagesDesign of SlabsAmay mishraNo ratings yet

- Behavior and Design of Spread Prestressed Concrete Slab Beam BridgesDocument406 pagesBehavior and Design of Spread Prestressed Concrete Slab Beam BridgesAssefa NigussieNo ratings yet

- Chapter - 3 Load On Bridge.Document13 pagesChapter - 3 Load On Bridge.Assefa NigussieNo ratings yet

- Slab Design Parameters and Load CalculationsDocument143 pagesSlab Design Parameters and Load CalculationsAssefa NigussieNo ratings yet

- Plastic Analysis PDFDocument69 pagesPlastic Analysis PDFShakeelNo ratings yet

- Thermal Energy Storage With Phase Change MaterialsDocument217 pagesThermal Energy Storage With Phase Change MaterialsAssefa NigussieNo ratings yet

- Slab Design Parameters and Load CalculationsDocument143 pagesSlab Design Parameters and Load CalculationsAssefa NigussieNo ratings yet

- Chapter Four. Roof DesignDocument85 pagesChapter Four. Roof DesignAssefa NigussieNo ratings yet

- Chapter Five Composite Structures (Concrete and Steel)Document15 pagesChapter Five Composite Structures (Concrete and Steel)Assefa Nigussie100% (1)

- Roof Design Wind Load AnalysisDocument65 pagesRoof Design Wind Load AnalysisAssefa NigussieNo ratings yet

- Slab DesignDocument15 pagesSlab DesignLawrence Arellano FernandezNo ratings yet

- Design of 6 Storey Building in EtabsDocument51 pagesDesign of 6 Storey Building in EtabsMisqal A Iqbal100% (2)

- Strip Method2Document42 pagesStrip Method2Assefa NigussieNo ratings yet

- 2009 Eesd Martinelli Filippou PDFDocument21 pages2009 Eesd Martinelli Filippou PDFAssefa NigussieNo ratings yet

- Moreno Fib SymposiumDocument16 pagesMoreno Fib SymposiumAssefa NigussieNo ratings yet

- Solution SD Test-1Document3 pagesSolution SD Test-1Assefa NigussieNo ratings yet

- Design and Analysis of Two-Way Reinforced Concrete SlabsDocument16 pagesDesign and Analysis of Two-Way Reinforced Concrete Slabsgullipalli75% (4)

- ICE Paper (Holistic Behaviour of Concrete Buildings in Fire) PDFDocument35 pagesICE Paper (Holistic Behaviour of Concrete Buildings in Fire) PDFAssefa NigussieNo ratings yet

- Faggella - Barbosa - Conte - Spacone - Restrepo - Probabilistic Seismic Response Analysis of A 3D RC Building - Struct-Safety - 2013Document17 pagesFaggella - Barbosa - Conte - Spacone - Restrepo - Probabilistic Seismic Response Analysis of A 3D RC Building - Struct-Safety - 2013Assefa NigussieNo ratings yet

- Stability Exam Fall-2014Document4 pagesStability Exam Fall-2014Assefa NigussieNo ratings yet

- 2007 SDTSB WallaceDocument18 pages2007 SDTSB WallaceChristian Alcedo SantiNo ratings yet

- Postgraduate Structural ProgrammesDocument5 pagesPostgraduate Structural Programmeskanishka_gunasekara7208No ratings yet

- Faggella - Barbosa - Conte - Spacone - Restrepo - Probabilistic Seismic Response Analysis of A 3D RC Building - Struct-Safety - 2013Document17 pagesFaggella - Barbosa - Conte - Spacone - Restrepo - Probabilistic Seismic Response Analysis of A 3D RC Building - Struct-Safety - 2013Assefa NigussieNo ratings yet

- PHD Baldock PDFDocument180 pagesPHD Baldock PDFSaurabh PednekarNo ratings yet

- Research Proposal for PhD in FieldDocument4 pagesResearch Proposal for PhD in FieldSyamil Ahamad SabkiNo ratings yet

- Hawiso DargeDocument83 pagesHawiso DargeAssefa NigussieNo ratings yet

- RC Design PDFDocument58 pagesRC Design PDFZerihun IbrahimNo ratings yet

- One Way SlabDocument12 pagesOne Way SlabJosé FerreiraNo ratings yet

- 2 Way SlabDocument28 pages2 Way SlabGautam PaulNo ratings yet

- Design of Waffle SlabDocument4 pagesDesign of Waffle SlabAriel Mayer100% (1)

- Ci3307scanlon 896 PDFDocument6 pagesCi3307scanlon 896 PDFAssefa Nigussie100% (1)

- The Disappointments Room PDFDocument129 pagesThe Disappointments Room PDFMufti Akhmad Shadiq Afnas0% (1)

- (D-303) Installation of Vessel Heat Exchanger - Rev.3 PDFDocument9 pages(D-303) Installation of Vessel Heat Exchanger - Rev.3 PDFmihir_jha2No ratings yet

- 1 Electrical SystemsDocument102 pages1 Electrical SystemsJhecca Cabillo100% (1)

- Architectural Project Forest VillaDocument9 pagesArchitectural Project Forest VillakapingaofficialNo ratings yet

- Sundance Supply®, LLC Framing GuideDocument15 pagesSundance Supply®, LLC Framing GuideHouariKouadriNo ratings yet

- Construction Cost Estimate: By: Engr. Erniel Dave A. GuyoDocument29 pagesConstruction Cost Estimate: By: Engr. Erniel Dave A. GuyoMica Joice FernandezNo ratings yet

- Quantity Takeoff: Dr. Ahmed ElyamanyDocument66 pagesQuantity Takeoff: Dr. Ahmed ElyamanysyampkNo ratings yet

- Building Codes SummaryDocument3 pagesBuilding Codes SummaryJoshua CimanesNo ratings yet

- Conservation Management Plan ST Briavels Castle, Gloucestershire, UKDocument130 pagesConservation Management Plan ST Briavels Castle, Gloucestershire, UKWin ScuttNo ratings yet

- Nova Scotia Home Finder Sept 2013Document120 pagesNova Scotia Home Finder Sept 2013Nancy BainNo ratings yet

- Basement Parking PDFDocument6 pagesBasement Parking PDFShameel PtNo ratings yet

- 18th-19th Century Family Houses Architectural FeaturesDocument3 pages18th-19th Century Family Houses Architectural FeaturesHustiuc RomeoNo ratings yet

- How To Build A Brick BBQDocument2 pagesHow To Build A Brick BBQnt01dannyNo ratings yet

- Bar BendingDocument142 pagesBar Bendingjaffna100% (4)

- Tableros MNSDocument18 pagesTableros MNSHector BarroetaNo ratings yet

- Le Corbusier's Five Points of ArchitectureDocument15 pagesLe Corbusier's Five Points of ArchitectureYash SethiNo ratings yet

- Cherry and Fir BookcaseDocument6 pagesCherry and Fir Bookcasecaballo_blanco_2100% (1)

- Standards VNA WarehouseDocument1 pageStandards VNA WarehouseAnonymous FZs3yBHh7No ratings yet

- Construction Methods and Structures As Expression of Architectural DesignDocument19 pagesConstruction Methods and Structures As Expression of Architectural DesignRen MariNo ratings yet

- Existing Building Dock Area PlanDocument1 pageExisting Building Dock Area PlanSudeshna Mahapdi - PawarNo ratings yet

- 2 - Creative and Innovative Use of TimberDocument85 pages2 - Creative and Innovative Use of TimberAbel GetachewNo ratings yet

- Hanson Waterproofing BrochureDocument7 pagesHanson Waterproofing BrochurePm889096No ratings yet

- Sankhamul Squatter SettlementDocument41 pagesSankhamul Squatter SettlementAshru SigdelNo ratings yet

- Find An NFPA Code or StandardDocument13 pagesFind An NFPA Code or StandardSalahuddin KhwajaNo ratings yet

- Construction Project Report for RV InfrastructureDocument31 pagesConstruction Project Report for RV InfrastructureMishra JiNo ratings yet

- Gaur Saundaryam Price List W.E.F. 01.07.2019 (PH-2)Document1 pageGaur Saundaryam Price List W.E.F. 01.07.2019 (PH-2)sishir mandalNo ratings yet

- Add A Wall Light PDFDocument5 pagesAdd A Wall Light PDFisland14No ratings yet

- Design Guidelines for Water Supply ProjectDocument5 pagesDesign Guidelines for Water Supply ProjectNyu123456No ratings yet

- Fine Schedule, Construction ViolationsDocument4 pagesFine Schedule, Construction Violationsf1propertyNo ratings yet