Professional Documents

Culture Documents

JMC PDF

Uploaded by

nurlianaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JMC PDF

Uploaded by

nurlianaCopyright:

Available Formats

Precious Metal Recovery from Spent Catalysts

By Piers Grumett

Johnson Matthey Catalysts, Jeffreys Road, Enfield, Middlesex EN3 7PW, U.K.

A new process called AquaCat® for the recovery of precious metals from spent heterogeneous

and homogeneous catalysts is described. The process has two stages, the first stage is to

determine the precious metal content of a spent heterogeneous catalyst using new direct

sampling technology. The second stage involves supercritical water oxidation, during which

the carbonaceous material is converted into less noxious compounds, leaving the precious

metals as their oxides.

Spent organic-based catalysts which contain This was followed by filtration and treatment via

precious metals have traditionally been treated by the traditional incineration route. Figure 2 shows a

incineration to recover the precious metal content. graph of the quantity of precious metals found by

Incineration destroys the organic content of the direct sampling compared to incineration. Samples

catalyst and leaves an ash which, before chemical are monitored against expectations for each batch.

recovery is started, is sampled to determine the Computational fluid dynamics was used to

precious metal content. However, a new more model the production-scale process. Output from

environmentally-friendly process, AquaCat®, joint- the modelling is shown as a deviation from the

ly developed and patented (1, 2) by Johnson average concentration in the vessel and is less than

Matthey (3) and Chematur Engineering AB (4), 0.5% throughout most of the mixing vessel, see

takes a different approach, see Figure 1.

Direct Sampling

AquaCat® allows a spent heterogeneous cata-

lyst, such as palladium or platinum on a carbon

support, to have the metal content evaluated prior

to treatment, directly from the as-received samples.

The spent catalyst is received as a wet filter cake

with a particle size distribution between 5 and 500

µm. This is added to water and surfactant in a ves-

sel and mixed by agitation and by using a pumped

recirculation loop in order to create a homoge-

neous dispersion. A series of small representative

samples of the mixture are then removed from the

recirculation loop by automated extraction. These

are collected together to form a sample which is

sub-sampled in the laboratory and analysed for its

precious metal content using standard analytical

techniques.

The sampling procedure was extensively vali-

dated on a pilot scale before being scaled up for

use in production. Over fifty samples of materials

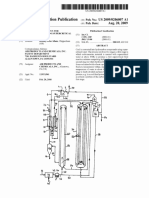

Fig. 1 Part of AquaCat® at the Enfield site. The direct

representative of typical as-received spent catalyst sampling equipment is on the left. The feed tank and high

were evaluated using the direct sampling process. pressure pump for the SCWO process are on the right

Platinum Metals Rev., 2003, 47, (4), 163166 163

Figure 3. The concentration of material at the out-

let and thus in the recirculation loop is equal to the

average of the concentrations in the vessel. This

ensures that the sample taken from the recircula-

tion loop is representative.

Supercritical Water Oxidation

The water-based slurry is then pumped into the

feed tank for the next step in the process: super-

critical water oxidation (SCWO). Water becomes

supercritical at a temperature above 374ºC and

pressure above 221 bar, when its viscosity is close

to that of the gas phase but with higher density. In

this process organic materials become soluble in

the supercritical water, which is thus used as a sol- Fig. 2 Pilot scale validation graph of the amounts of

vent for the oxidation. Inorganic materials, precious metal found by direct sampling compared with

traditional incineration. Most points fall on or close to

however, become insoluble. If feed materials con- line y = x, showing that the two evaluation procedures

tain high levels of salts the SCWO process is not are equivalent. In fact they are statistically equivalent

suitable.

A flow diagram of the SCWO process is shown the sites steam main). The product is cooled to

in Figure 4. The SCWO process is based on ambient temperature and pressure prior to the

Chematur Engineerings supercritical water oxida- combustion gases being separated off. The pre-

tion process, Aqua Critox®. Water is pressurised to cious metal oxides along with any other trace

approximately 240 bar using a high-pressure elements, such as base metal oxides and silica, are

pump, then heated to about 385°C to be in its sent on for further refining.

supercritical phase. In the SCWO plant heteroge-

neous (solid) catalysts are fed in a slurry form from

the feed tank whereas homogeneous (liquid) cata-

lysts are fed directly into the reactor.

Processing Heterogeneous Catalysts

The slurry containing ~ 5% of spent catalyst is

pumped up to a pressure of ~ 240 bar then passed

through the economiser (heat-exchanger) into the

heater to raise its temperature to 385ºC. The mate-

rial then enters the reactor where sufficient high-

pressure oxygen is injected to allow the heat of

reaction to raise the temperature to ~ 600ºC. Next,

quench water is injected to reduce the temperature

before a second oxygen injection, which allows the

reaction to go to completion. The organic compo-

nents are converted to carbon dioxide, water and

nitrogen and the metals form their oxides.

The product from the reactor next passes Fig. 3 A computational fluid dynamics model of the

through the economiser to preheat the incoming sampling vessel is presented. The output from the

modelling is shown as the deviation from the average

feed and then to a steam boiler (where up to one concentration in the vessel and it is less than 0.5%

tonne per hour of steam is generated and fed into relative throughout most of the mixing vessel

Platinum Metals Rev., 2003, 47, (4) 164

Fig. 4 Flow diagram of the supercritical water oxidation process, based on Chematur Engineerings supercritical

water oxidation process, Aqua Critox®. Water is pressurised to ~ 240 bar using a high-pressure pump and then heated

to ~ 385ºC so that it is in the supercritical phase. Heterogeneous (solid) catalysts are fed in a slurry form from the

feed tank. In contrast, homogeneous (liquid) catalysts are fed directly into the reactor

Processing Homogeneous Catalysts No SOx emissions because sulfur remains in

Homogeneous catalysts are processed similarly the liquid effluent, and is treated off site as sulfate.

to heterogeneous catalysts except that only high- No dioxins or furans due to effective oxidation.

pressure water is fed into the economiser. The The process is also more energy efficient as the

homogeneous catalyst is injected directly into the energy from the exothermic reaction is used to

reactor after the oxygen injection points because it preheat the incoming feed and generate steam.

is not miscible with subcritical water and it often The process is continuous giving a greater degree

contains phosphorus which would pyrolyse in the of control than in batch incineration. SCWO can

preheating equipment when oxygen is not present. oxidise the organics in metal-organic composi-

tions, particularly heterogeneous or homogen-

The Benefits of AquaCat® eous precious metals catalysts, and produce metal

Several environmental benefits result from oxides with few byproducts and low loss of pre-

using the SCWO process instead of traditional cious metals. Catalysts containing higher levels of

incineration. In part these are because the process residual organics can thus be treated more safely.

is totally enclosed and so prevents the release of Benefits from direct sampling include the

any harmful substances and metal loss. As such it acceptance of material in intermediate bulk con-

achieves efficiencies for organic destruction close tainers, as well as drums, thus hazardous materials

to 100%. Additional benefits include: are handled less. Incoming residues are check-

Lower CO2 emissions less fuel is required. weighed and sampled before any processing

No CO emissions the reaction goes to com- demonstrating confidence in the process efficacy.

pletion. The prior sampling also gives earlier evaluation

No NOx emissions lower reaction temperature. than in traditional processing.

Platinum Metals Rev., 2003, 47, (4) 165

References The Author

1 S. Collard, A. Gidner, B. Harrison and L. Stenmark, ®

Piers Grumett is the Production Manager for Aquacat , Johnson

World Appl. 01/83,834 Matthey Catalysts, at the Enfield site, U.K. He has managed

2 Filtration & Separation, June 2003, 40, (5) , 16 and ref- ®

Aquacat from its initial stages, through installation, to current day-

erences therein to-day operations. His interests include continuous improvement

3 http://www.chemicals.matthey.com/ of process operations and implementing operational changes.

4 http://www.chematur.se/ Other interests are environmentally-friendly procedures and safety.

Hydrogen Economy Forum in Russia

SECOND INTERNATIONAL SYMPOSIUM ON SAFETY AND ECONOMY OF HYDROGEN TRANSPORT

IFSSEHT-2003 was held from 18th to 22nd August State Physics, Chernogolovka) who looked at the phase

at Sarov, Russia, where about 250 delegates from 12 equilibria at high pressures.

countries attended a range of presentations on various The influence of H and vacancies on the evolution of

aspects of hydrogen (H). The symposium also commem- structure in thermodynamically open Pd-based alloys

orated the 60th anniversary of pioneering H utilisation was discussed by A. A. Katsnelson, V. M. Avdyukhina,

by Boris Shelishch who, during the Siege of Leningrad, A. A. Anishchenko and G. P. Revkevich (Moscow State

devised H-powered vehicles. Selected papers, some relat- University). B. A. Spiridonov and V. N. Ermilin

ing to the platinum metals, are reported here. (Voronezh State Technical University, Russia) described

Papers looked at atomic H energy, nuclear ways to chemical deposition of a catalytic Pd layer for a H sen-

produce H from water, the H economy, and the Kyoto sor. Generation of a colloidal layer of Pd was involved.

agreement effects on Russia. Safe ways to process H Mechanical instability in concentrated non-homoge-

from the H2S trapped in the Black Sea were described by neous M-H media, M = Pd, Nb, V, was examined by L.

V. G. Kashiya (Sukhumi Physical-Technical Institute, V. Spivak and N. E. Skryabina (Perm State University,

Tbilisi, Georgia). More traditional H production using Russia). Equilibrium deuterium pressure over Pd and its

electrolysers in fuelling stations for various projects in alloys was described by S. V. Dyomina, M. V. Glagolev

Europe (ECTOS, CUTE and CEP) was examined by A. and A. I. Vedeneev (Russian Federal Nuclear Centre,

Cloumann and K. Sollid (Norsk Hydro Electrolysers, Sarov). An analysis of stationary isotherms of H perme-

Norway). Modules to extract pure H from industrial gas ability in Pd alloy membranes was described by L. L.

mixtures, using palladium (Pd) alloy (Pd-In-Ru, Pd-Cu Muravyov, A. B. Vandyshev and M. Sh. Gadelshin

and Pd-Y) thin foil membranes, diameter 50150 mm, (Institute of Engineering Science, Ekaterinburg, Russia).

were evaluated by D. I. Slovetsky, E. M. Chistov and N. A. L. Gusev (Russian Federal Nuclear Centre, Sarov)

R. Roshan (A. V. Topchiev Institute, Moscow). described research underway on low-temperature H

Micro- and nano-patterning of silicon (Si) wafer sub- detectors and absorbers, including one based on pal-

strates by sputtering Pd and platinum (Pt) for H ladised manganese (Mn) dioxide with a protective anti-

separation membranes in reformers for fuel cells were oxidant membrane of thin-walled quartz shells. He fur-

discussed by H. Presting and colleagues from Daimler- ther described work with Voronezh State University into

Chrysler, Germany, and the Institute of Microelectronics the effect of H on the electrical properties of metal oxide

Technology, Chernogolovka, Russia. films alloyed with Si. Lastly, work with the Institute of

Work on H in metals and alloys began with a survey Problems of Chemical Physics, Chernogolovka, on the

of H diffusion coefficients in Pt, Pd and their alloys, pre- production of palladised films of Mn and Co oxides,

v

sented by J. Cermák (Institute of Physics, Prague) and F. which can serve as the basis of H sensors, was mentioned.

A. Lewis (Queens University, Belfast). Problems with Abstracts of the proceedings have been published in

residual stress in hollow cylinders related to diffusion English and Russian as an International Scientific Journal for

problems were described by N. M. Vlasov and I. I. Fedik Alternative Energy and Ecology (ISJAEE) Special Issue,

(Louch Research Institute, Russia), while the role of ISSN 1608-8298, http://isjaee.hydrogen.ru/, available

segregation at dislocations and grain boundaries in Pd from the Scientific Technical Centre TATA, PO Box

and some other metals was discussed by Yu. S. Nechaev 787, Sarov, Nizhni Novgorod Region, 607183 Russia;

and G. V. Filippov (Bardin Central Research Institute of Fax: +7 (83130) 63107; E-mail: gusev@hydrogen.ru.

Ferrous Metallurgy, Moscow). F. A. LEWIS

Stable and unstable equilibria in metal-H systems, Fred Lewis is retired from Queen’s University, Belfast, after many

such as rhodium-H, were examined by V. E. Antonov, I. years of research into hydrogen diffusion in palladium and

O. Bashkin and E. G. Ponyatovsky (Institute of Solid- palladium alloys. These are still his main interests.

Platinum Metals Rev., 2003, 47, (4) 166

You might also like

- Aqua CatDocument4 pagesAqua Catlonely3No ratings yet

- Ruthenium Catalyst For Treatment of Water Containing Concentrated Organic WasteDocument7 pagesRuthenium Catalyst For Treatment of Water Containing Concentrated Organic WastesunliasNo ratings yet

- Aqueous-Phase Hydrodeoxygenation of Sorbitol With PT SiO2 Al2O3Document12 pagesAqueous-Phase Hydrodeoxygenation of Sorbitol With PT SiO2 Al2O3Paulo CésarNo ratings yet

- Ref 3 Lu2012Document9 pagesRef 3 Lu2012erlan rosyadiNo ratings yet

- Kinetics and Mechanism of Cyclohexanol Dehydration PDFDocument10 pagesKinetics and Mechanism of Cyclohexanol Dehydration PDFAlberto_Varela0014No ratings yet

- Zhang 2014Document5 pagesZhang 2014oviabeautyNo ratings yet

- Continuous Hydrogen Production by SequenDocument10 pagesContinuous Hydrogen Production by SequenwameathNo ratings yet

- Catalytic Wet Air OxidationDocument10 pagesCatalytic Wet Air OxidationAman PrasadNo ratings yet

- Kinetics and Mechanism of Cyclohexanol Dehydration in High-Temperature WaterDocument10 pagesKinetics and Mechanism of Cyclohexanol Dehydration in High-Temperature WaterChuck ÜbermenschNo ratings yet

- Diseño de Reactores 2Document17 pagesDiseño de Reactores 2Luz Idalia Ibarra RodriguezNo ratings yet

- Chemical Engineering Journal: Bholu Ram Yadav, Anurag GargDocument9 pagesChemical Engineering Journal: Bholu Ram Yadav, Anurag GargGaneshbhoiteNo ratings yet

- Sinterizacion Del Cu en WGSRDocument5 pagesSinterizacion Del Cu en WGSRsayonara_3No ratings yet

- Fouling and Scale Control 2009Document31 pagesFouling and Scale Control 2009kikokalazo0% (1)

- Bioreactor Design Studies For A Novel Hydrogen-Producing BacteriumDocument12 pagesBioreactor Design Studies For A Novel Hydrogen-Producing BacteriumDan CretuNo ratings yet

- Oxidation of Cu (II) - EDTA in Supercritical Water-Experimental Results and ModelingDocument10 pagesOxidation of Cu (II) - EDTA in Supercritical Water-Experimental Results and ModelingPeter KozlikhinNo ratings yet

- 1.1 AbstractDocument25 pages1.1 AbstractZati TarhiziNo ratings yet

- Energy: Peiqin Sun, Mingxing Heng, Shaohui Sun, Junwu ChenDocument9 pagesEnergy: Peiqin Sun, Mingxing Heng, Shaohui Sun, Junwu ChenyemresimsekNo ratings yet

- Lin 2001Document8 pagesLin 2001Navid AhadiNo ratings yet

- 42 JMES 486 2013 BerradiDocument6 pages42 JMES 486 2013 BerradiAhmed AliNo ratings yet

- 2021 CH 274Document23 pages2021 CH 274Ali Raza MeharNo ratings yet

- AltacusxewDocument23 pagesAltacusxewГаанби Н'ШиефNo ratings yet

- Non-Catalytic Liquefaction of Microalgae in Sub and Supercritical AcetoneDocument28 pagesNon-Catalytic Liquefaction of Microalgae in Sub and Supercritical Acetonejosè CarhuapomaNo ratings yet

- Mitigation of Heat Exchanger FoulingDocument5 pagesMitigation of Heat Exchanger Foulingbabak mirNo ratings yet

- PDFDocument5 pagesPDFOmar ReyesNo ratings yet

- 1-PbSO4 Leaching in Citric Acid Sodium Citrate Solution and Subsequent ...Document10 pages1-PbSO4 Leaching in Citric Acid Sodium Citrate Solution and Subsequent ...Gregorio Antonio Valero VerdeNo ratings yet

- Ethanol Plant Research2Document5 pagesEthanol Plant Research2Tosin AwonusiNo ratings yet

- A Novel Nickel/carbon Catalyst For CH and H Production From Organic Compounds Dissolved in Wastewater by Catalytic Hydrothermal GasificationDocument6 pagesA Novel Nickel/carbon Catalyst For CH and H Production From Organic Compounds Dissolved in Wastewater by Catalytic Hydrothermal GasificationAnonymous sVheFhq9PNo ratings yet

- C. C. C. C. S S S S.... Okoli Okoli Okoli Okoli and and and and P. C. P. C. P. C. P. C. Okonkwo Okonkwo Okonkwo OkonkwoDocument6 pagesC. C. C. C. S S S S.... Okoli Okoli Okoli Okoli and and and and P. C. P. C. P. C. P. C. Okonkwo Okonkwo Okonkwo OkonkwoHemaNo ratings yet

- Wei Li, Shan Tan, Yun Shi, Sujing Li: SciencedirectDocument8 pagesWei Li, Shan Tan, Yun Shi, Sujing Li: SciencedirectAnindita IndrianaNo ratings yet

- Reforming and IsomerizationDocument17 pagesReforming and Isomerizationhala mrayanNo ratings yet

- Grupo 07B Barner1992Document17 pagesGrupo 07B Barner1992Roberto Eduardo Quispe MamaniNo ratings yet

- Topic: Catalytic Wet Air Oxidation: Dept. of Chemical Engineering IIT DelhiDocument26 pagesTopic: Catalytic Wet Air Oxidation: Dept. of Chemical Engineering IIT DelhiAmit GuptaNo ratings yet

- 10 1016@j Jece 2013 04 0171Document6 pages10 1016@j Jece 2013 04 0171Violeta GarciaNo ratings yet

- Treatment of Poultry Slaughterhouse Wastewaters by ElectrocoagulationDocument5 pagesTreatment of Poultry Slaughterhouse Wastewaters by ElectrocoagulationGrinder Hernan Rojas UrcohuarangaNo ratings yet

- D6721-Standard Test Method For Determination of Chlorine in Coal by Oxidative Hydrolysis MicrocoulometryDocument4 pagesD6721-Standard Test Method For Determination of Chlorine in Coal by Oxidative Hydrolysis MicrocoulometryAyaNo ratings yet

- Effect of Operating Conditions On CSTR Performance: An Experimental StudyDocument5 pagesEffect of Operating Conditions On CSTR Performance: An Experimental Studyahmed nawazNo ratings yet

- Visual Encyclopedia of Chemical Engineering Catalysts: General InformationDocument7 pagesVisual Encyclopedia of Chemical Engineering Catalysts: General InformationVanNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2009/0206007 A1Document13 pagesPatent Application Publication (10) Pub. No.: US 2009/0206007 A1Tree SilviaNo ratings yet

- Acetone ProductionDocument2 pagesAcetone ProductionpehweihaoNo ratings yet

- The Invention: Zadgaonkars' ProcessDocument3 pagesThe Invention: Zadgaonkars' ProcessHimanshu SukhadwalaNo ratings yet

- 1 s2.0 S1876610217314078 MainDocument10 pages1 s2.0 S1876610217314078 Maingen.elang.0505No ratings yet

- HPU/06 - Hydrogen Production from Fossil and Biomass FuelsDocument4 pagesHPU/06 - Hydrogen Production from Fossil and Biomass FuelsMazen OthmanNo ratings yet

- Yan 2010Document4 pagesYan 2010Karen MaryNo ratings yet

- 1 s2.0 S1226086X12001566 MainDocument7 pages1 s2.0 S1226086X12001566 Mainrizanda93No ratings yet

- A New Multifunctional Corrosion and Scale Inhibitor - 2008Document13 pagesA New Multifunctional Corrosion and Scale Inhibitor - 2008Benoit EmoNo ratings yet

- Effects of Different Parameters On Photocatalytic Oxidation of Slaughterhouse Wastewater Using Tio and Silver-Doped Tio NanoparticlesDocument10 pagesEffects of Different Parameters On Photocatalytic Oxidation of Slaughterhouse Wastewater Using Tio and Silver-Doped Tio NanoparticlesNicholas YeohNo ratings yet

- (2019-11p) IOP MSE - Subcritical Water...Document7 pages(2019-11p) IOP MSE - Subcritical Water...ClearyNo ratings yet

- Acrylic Acid ProductionDocument10 pagesAcrylic Acid Productionstavros7No ratings yet

- ) Pergamon: Energy Com, Ers. MGMTDocument6 pages) Pergamon: Energy Com, Ers. MGMTyemresimsekNo ratings yet

- Group 3 - Acetone Production Via The Dehydrogenation of IPADocument7 pagesGroup 3 - Acetone Production Via The Dehydrogenation of IPAQuỳnh Như PhạmNo ratings yet

- Investigation of IsobutaneDocument17 pagesInvestigation of IsobutanedafinaNo ratings yet

- Effect of Operating Conditions On CSTR Performance: An Experimental StudyDocument6 pagesEffect of Operating Conditions On CSTR Performance: An Experimental StudyYu HuiNo ratings yet

- New Treatment of The Black Liquor Produced From Pulping of Rice StrawDocument8 pagesNew Treatment of The Black Liquor Produced From Pulping of Rice StrawDrWael ElheleceNo ratings yet

- Effect of Organic and Inorganic Compounds On Dissolution Kinetics of Chalcopyrite in Hydrogen Peroxide - Hydrochloric Acid SystemDocument9 pagesEffect of Organic and Inorganic Compounds On Dissolution Kinetics of Chalcopyrite in Hydrogen Peroxide - Hydrochloric Acid SystemlolisfrairegNo ratings yet

- Bioprocess Lab Manual GuideDocument27 pagesBioprocess Lab Manual GuideFatih RushdiNo ratings yet

- 1 s2.0 S0255270107000451 MainDocument6 pages1 s2.0 S0255270107000451 Mainttugce29No ratings yet

- Water Gas Shift Reaction: Research Developments and ApplicationsFrom EverandWater Gas Shift Reaction: Research Developments and ApplicationsNo ratings yet

- Transition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesFrom EverandTransition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesNo ratings yet

- Production of Clean Hydrogen by Electrochemical Reforming of Oxygenated Organic CompoundsFrom EverandProduction of Clean Hydrogen by Electrochemical Reforming of Oxygenated Organic CompoundsNo ratings yet

- q4 18 PTQ PDFDocument140 pagesq4 18 PTQ PDFnurlianaNo ratings yet

- 2017 Catalysis PDFDocument68 pages2017 Catalysis PDFnurlianaNo ratings yet

- Chemical Cleaning MethodsDocument71 pagesChemical Cleaning MethodsDonatas Bertasius100% (1)

- Astm d445 1965 PDFDocument8 pagesAstm d445 1965 PDFnurlianaNo ratings yet

- 2017 Catalysis PDFDocument68 pages2017 Catalysis PDFnurlianaNo ratings yet

- Control Valve Calculation SpreadsheetDocument3 pagesControl Valve Calculation SpreadsheetnurlianaNo ratings yet

- Control Valve Calculation SpreadsheetDocument3 pagesControl Valve Calculation SpreadsheetnurlianaNo ratings yet

- Testing Methods For Fertilizers 2013Document370 pagesTesting Methods For Fertilizers 2013Azote85No ratings yet

- Control Valve Calculation SpreadsheetDocument3 pagesControl Valve Calculation Spreadsheetweimar solizNo ratings yet

- Fuego y Explosiones de Materiales Quimicos PRMDDocument61 pagesFuego y Explosiones de Materiales Quimicos PRMDPedro Reynaldo Marin DominguezNo ratings yet

- pressureProcedTest PDFDocument7 pagespressureProcedTest PDFfaizal azizNo ratings yet

- Process Simulation in Refineries Sampler 1Document34 pagesProcess Simulation in Refineries Sampler 1surefooted1100% (1)

- Recycling Precious Metal Catalysts for Oil Refining and Petrochemical ProcessesDocument4 pagesRecycling Precious Metal Catalysts for Oil Refining and Petrochemical ProcessesnurlianaNo ratings yet

- JMC PDFDocument4 pagesJMC PDFnurlianaNo ratings yet

- DynaWave SuperClausDocument2 pagesDynaWave SuperClausNKNo ratings yet

- Foam and AntifoamDocument10 pagesFoam and AntifoamGanesh GanyNo ratings yet

- DynaWave SuperClausDocument2 pagesDynaWave SuperClausNKNo ratings yet

- Guide To The London Metal Exchange: Setting The Global StandardDocument11 pagesGuide To The London Metal Exchange: Setting The Global StandardnurlianaNo ratings yet

- Eat That Frog! by Brian Tracy: Presented by Mary T. CastañuelaDocument32 pagesEat That Frog! by Brian Tracy: Presented by Mary T. Castañuelanurliana100% (1)

- Draft Clean Air Regulation NotesDocument34 pagesDraft Clean Air Regulation NotesLean Seey TanNo ratings yet

- HP2 2015Document4 pagesHP2 2015nurlianaNo ratings yet

- pressureProcedTest PDFDocument7 pagespressureProcedTest PDFfaizal azizNo ratings yet

- Readme PDFDocument6 pagesReadme PDFnurlianaNo ratings yet

- InstallfontDocument1 pageInstallfontnurlianaNo ratings yet

- Soft Uni SolutionsDocument8 pagesSoft Uni Solutionsnrobastos1451No ratings yet

- Dramatic Nuclear Winter Concept Art WorkshopDocument5 pagesDramatic Nuclear Winter Concept Art WorkshopArc AngleNo ratings yet

- Theoryt. PR.: of Birth H-GHRDocument1 pageTheoryt. PR.: of Birth H-GHRSanjay TripathiNo ratings yet

- KEY - Unit 12 Test ReviewDocument4 pagesKEY - Unit 12 Test ReviewHayden MulnixNo ratings yet

- Crime Prevention and Security Management in Museums - En+itDocument218 pagesCrime Prevention and Security Management in Museums - En+itPaul Dan OctavianNo ratings yet

- DLL Mtb-Mle3 Q2 W2Document6 pagesDLL Mtb-Mle3 Q2 W2MAUREEN GARCIANo ratings yet

- Lab 4.5.1 Observing TCP and UDP Using Netstat (Instructor Version)Document7 pagesLab 4.5.1 Observing TCP and UDP Using Netstat (Instructor Version)Rifqi Imaduddin IrfanNo ratings yet

- Beer Lambert LawDocument2 pagesBeer Lambert LawMuhammad ZubairNo ratings yet

- Ophthalmology CurriculumDocument71 pagesOphthalmology CurriculumEdoga Chima EmmanuelNo ratings yet

- SAP Inventory Module ProcessDocument37 pagesSAP Inventory Module ProcessRajesh ChalkeNo ratings yet

- TOK Essay - Does Language Play Roles of Equal Importance in Different Areas of KnowledgeDocument3 pagesTOK Essay - Does Language Play Roles of Equal Importance in Different Areas of KnowledgeTenisha Castillo100% (2)

- QC Story TRAINING SLIDEDocument47 pagesQC Story TRAINING SLIDEDIPAK VINAYAK SHIRBHATE83% (6)

- ManualDocument572 pagesManualjoejunkisNo ratings yet

- Elitmus Test: (Register On Site To See Answers)Document4 pagesElitmus Test: (Register On Site To See Answers)SaideepChembuliNo ratings yet

- ISO - 8041.2005 - Human - Response - To - Vibrations - Measuring - Instrumentation PDFDocument98 pagesISO - 8041.2005 - Human - Response - To - Vibrations - Measuring - Instrumentation PDFraffacapNo ratings yet

- Recruitment Needs Are of Three Types: PlannedDocument7 pagesRecruitment Needs Are of Three Types: PlannedShraddha MomayaNo ratings yet

- SAR ADC TutorialDocument48 pagesSAR ADC TutorialPing-Liang Chen100% (1)

- Identifying VariablesDocument25 pagesIdentifying Variablesapi-236248022No ratings yet

- wk8 Activity PresentationDocument13 pageswk8 Activity Presentationapi-280934506No ratings yet

- The Historic 7Th March Speech of Bangabandhu Sheikh Mujibur RahmanDocument31 pagesThe Historic 7Th March Speech of Bangabandhu Sheikh Mujibur RahmanSanzid Ahmed ShaqqibNo ratings yet

- Heritage Theme Resort: Thesis ReportDocument8 pagesHeritage Theme Resort: Thesis ReportNipun ShahiNo ratings yet

- Sem-1 Drama: Do You Consider It As A Tragic Play? Submit Your Review. (Document20 pagesSem-1 Drama: Do You Consider It As A Tragic Play? Submit Your Review. (Debasis ChakrabortyNo ratings yet

- Apsa StyleDocument4 pagesApsa StyleLincoln DerNo ratings yet

- For HARDBOUNDDocument89 pagesFor HARDBOUNDdelcar vidal100% (1)

- Complete Note Books of Leonardo Da VinciDocument510 pagesComplete Note Books of Leonardo Da VinciDanish MerajNo ratings yet

- FreePBX Installation GuideDocument6 pagesFreePBX Installation Guidetinhs2cop0% (1)

- 1 ECI 2015 Final ProgramDocument122 pages1 ECI 2015 Final ProgramDenada Florencia LeonaNo ratings yet

- Bethesda Softworks LLC v. Behaviour Interactive, Inc. and Warner Bros. Entertainment Inc.Document34 pagesBethesda Softworks LLC v. Behaviour Interactive, Inc. and Warner Bros. Entertainment Inc.Polygondotcom100% (1)

- NLP - The Satanic Warlock - NLP and The Science of SeductionDocument18 pagesNLP - The Satanic Warlock - NLP and The Science of SeductionnegreanNo ratings yet

- Cluster Sampling: ProcedureDocument12 pagesCluster Sampling: ProcedureAahil RazaNo ratings yet