Professional Documents

Culture Documents

V2i11 Ijertv2is111089

Uploaded by

sagarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

V2i11 Ijertv2is111089

Uploaded by

sagarCopyright:

Available Formats

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 11, November - 2013

CFD Analysis And Performance Of Parallel And Counter Flow In

Concentric Tube Heat Exchangers

D.Bhanuchandrarao1, M.Ashok chakravarthy2, Dr. Y. Krishna3, Dr. V .V. Subba Rao4, T.Hari Krishna1

1

M.Tech Student, Thermal engineering, V.R Siddhartha Engineering College, JNTU

2

Assistant Professor, Mechanical Engineering, V.R Siddhartha Engineering College, JNTU

Vijayawada, Andhra Pradesh, India

3

Scientist ‗G‘, Structures & Materials Test Centre, Defence R&D Laboratory, Hyderabad-500058

4

Associate Professor, Jawaharlal Nehru Technological University Kakinada, Department of Mechanical Engineering

Kakinada - 533003

Abstract is estimated by using the best design of this type of heat

exchanger.

A Heat Exchanger is a device built for the efficient heat

transfer from one fluid to another, whether the fluids 1.2 LITERATURE SURVEY

are separated by a solid wall so that they never mix, or

the fluids are directly in contact. Every year research The development of fluid flow and temperature profiles

in Heat exchanger technology is growing to develop of a fluid after undergoing a sudden change in wall

efficient, compact and economical heat exchangers, all temperature is dependent on the fluid properties as well

over the world. Updating the community for this as the temperature of the wall. This thermal entrance

development needs an interaction. In last five years problem is well known as the Graetz Problem. From

Concentric tube heat exchangers utilize forced reference [1] for incompressible Newtonian fluid flow

convection to lower the temperature of a working fluid with constant ρ and k,

while raising the temperature of the cooling medium. The velocity profile can also be developing and can be

The purpose of this paper is to use ANSYS used for any Prandtl number material assuming the

RT

FLUENT12.1 software and hand calculations to velocity and temperature profiles are starting at the

analyze the temperature drops as a function of both same point [2]. For the original Graetz problem,

inlet velocity and inlet temperature and how each Poiseuille flow was assumed and equation was used to

varies with the other. Each heat exchanger model was describe the fully developed velocity field of the fluid

IJE

built in steps and analyzed along the way until both flowing through the constant wall temperature tubing.

parallel flow and counter flow heat exchanger models Analyzing the paper from Sellars [3] where he extends

were developed. The results were compared between the Graetz problem, this equation for velocity is also

each model and between parallel and counter flow with used. For the purposes of this paper and the use of the

fouled piping. Turbulent flow was also analyzed during finite element program, a constant value for the inlet

the development of the heat exchangers to determine its velocity was used. This means a modified Graetz

effect on heat transfer. While as expected the fouled problem was introduced and analyzed.

heat exchanger had a lower performance and therefore In the cases studied, engine oil was assumed to be

cooled the working fluid less, the performance of the flowing through the inner pipe which was made of

counter heat exchanger unexpectedly of the parallel copper and cooled by the outer concentric pipe in

heat exchanger. which water was flowing. Material properties such as

dynamic viscosity, density, Prandtl number, and

1 INTRODUCTION thermal conductivity were obtained from reference [4].

Graetz found a solution in the form of an infinite series

1.1 PROJECT BACKGROUND

in which the eigenvalues and functions satisfied the

Sturm-Louiville system. While Graetz himself only

The heat exchanger is a device which transferred the

determined the first two terms, Sellars, Tribus, and

heat from hot medium to cold medium without mixed

Klein [5] were able to extend the problem and

both of medium since both mediums are separated with

determine the first ten eigenvalues in 1956. Even

a solid wall generally. There are many types of heat

though this further developed the original solution, at

exchanger that used based on the application. For

the entrance of the tubing the series solution had

example, double pipe heat exchanger is used in

extremely poor convergence where up to 121 terms

chemical process like condensing the vapor to the

would Mnot make the series converge.

liquid. When to construct this type of heat exchanger,

Schmidt and Zeldin[6] in 1970 extended the Graetz

the size of material that want to uses must be

problem to include axial heat conduction and found that

considered since it affected the overall heat transfer

for very high Peclet numbers (Reynolds number

coefficient. For this type of heat exchanger, the outlet

temperature for both hot and cold fluids that produced

IJERTV2IS111089 www.ijert.org 2782

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 11, November - 2013

multiplied by the Prandtl number) the problem solution exchanger. By using CFD simulation software, it can

is essentially the original Graetz problem. reduces the time and operation cost compared by

Hwang et al [7] measured pressure drop and heat Analytical calculations in order to measure the

transfer coefficient in fully developed laminar pipe optimum parameter and the behaviour of this type of

flow using constant heat flux conditions. Based on the heat exchanger.

experimental results they showed that the experimental

friction factor was in good agreement with the 2.1 OBJECTIVES OF RESEARCH:

theoretical predictions using the Darcy equation.

Bianco et al [8] observed only amaximum of 11% The objective of the present study is to provide more

difference between single and two phase results for the complete understanding Flow maldistribution in tubular

laminar regime. heat exchanger by studying area weighted and mass

Akbari et al [9] for the first time compared three weighted temperature profiles for maldistribution

different two phase models and the single phase model without back flow and maldistribution with back flow.

in the laminar regime. Single and two phase models And comparison of average temperature profiles of

were found to be predicting identical hydrodynamic flow maldistribution with the average temperature

fields but very different thermal ones. profiles of uniform mass flow distribution.

The expression defining the velocity distribution in a This numerical investigation was carried out for the

pipe flow across turbulent flow is derived and concentric tube arrangement with different diameter of

demonstrated in Bejan, “Convective heat transfer tubes. A finite volume numerical scheme is used to

coefficient”,1994 . Hydro dynamically developed flow predict the conjugate heat transfer and fluid flow

is achieved in a pipe after a certain length i.e. entrance characteristics with the aid of the computational fluid

length Le , where the effect of viscosity reaches the dynamics (CFD) commercial code, FLUENT. The

centre of pipe. At this point the velocity assumes some governing equations for the energy and momentum

average profile across the pipe which is no longer conservation were solved numerically with the

influenced by any edge effects arising from the

RT

assumption of three-dimensional steady flow. An

entrance region. The flow of real fluids exhibit viscous effective model, the standard based k-ε turbulence

effects in pipe flow. Here this effect is identified for model was applied in this investigation.

turbulent flow conditions. As described in the section 1.2, the available relevant

IJE

A closer look at all the experimental and numerical literature is quite limited With respect to the analytical

works reveals that most of the forced convective heat and it is still difficult to predict the physics of the flow

transfer studies in pipe flow have been done with maldistribution within the circular tube banks.

constant wall flux boundary condition. So in this work, Therefore, temperature distributions within the bundle

a systematic computational fluid dynamic investigation were studied numerically. The objective of this study is

with constant wall temperature Boundary condition has to develop a CFD simulation to predict heat Transfer in

been carried out adopting the single phase approach in concentric tube heat exchanger by using different fluids.

the turbulent regime and the results are compared with

the analytical and numerical results available in the

2.2 SCOPES OF RESEARCH:

literature.

The scopes of this research are as follows:

i. Study on heat transfer for heat exchanger

specific to double pipe heat exchanger types.

2 PROBLEM STATEMENT ii. Design the double pipe heat exchanger by

using ANSYS WORKBENCH.

The double pipe heat exchanger is used in industry iii. Simulation in double pipe heat exchanger by

such as condenser for Chemical process and cooling using FLUENT software.

fluid process. This double pipe heat exchanger is iv. Analysis the heat exchanger specific to flow

designed in a large size for large application in industry. rate of hot and cold fluid.

To make this small double pipe heat exchanger type v. To simulate heat transfer in concentric tube

become practicality, the best design for this small heat exchanger by using CFD-Fluent software.

double pipe heat exchanger is choose. vi. To analyze the heat transfer in concentric tube

Heat transfer is considered as transfer of thermal heat exchanger by comparing the simulation

energy from physical body to another. Heat transfer is result to the Analytical calculations. Validate

the most important parameter to be measured as the simulation results to the Analytical

performance and efficiency of the concentric tube heat calculations within 5% error.

IJERTV2IS111089 www.ijert.org 2783

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 11, November - 2013

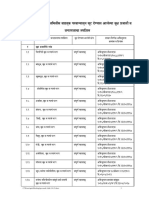

Thermal Specifi Dynamic

2.3 Problem description and modelling: Different Density

conducti c heat viscosity

fluids (ρ) Pr

Geometry Modelling: vity(K) CP (μ)

properties kg/m3

The geometry made in ANSYS workbench. This W/mk j/kgK kg/m-s

geometry imported to ansys fluent and repairs the Transformer

826 159 0.134 2328 0.0091

oil

geometry. The geometry consists of a length of 1m.

Concentric tube of inner tube inner diameter 0.1m and Toluene 866 6.5 0.151 1675 0.0005

outer tube inner diameter 0.24m. Benzene 875 6.51 0.159 1759 0.00058

Gas oil 830 50.4 0.135 2050 0.00332

Ethylene

1111.4 150.4 0.252 2415 0.0157

glycol

Glycerin 1259.9 6780.3 0.286 2427 0.799

Water 998.2 6.99 0.6 4182 0.001003

Different Thermal Specific

Density

material conductivity(K) heat CP

(ρ) kg/m3 W/mk

properties j/kgK

For this project, fully developed laminar and turbulent

incompressible fluid flow will be analyzed in three heat Copper 8978 387.6 381

exchanger cases: parallel flow, counter flow, and flow

in a fouled heat exchanger. The resulting temperature Aluminum 2719 203.2 871

difference will be compared and be determined as a

function of the inlet velocity and inlet temperatures. 3 SIMULATION

The overall objective is to determine the max

RT

temperature difference in these cases for both laminar

3.1 FINITE VOLUME METHOD:

and turbulent flow for a variety of flow rates and inlet

temperatures. To simplify the number of variables, The mass, momentum, and scalar

water and oil will be chosen as the fluids to maintain transport equations are integrated over all the fluid

IJE

viscosities and densities of the fluids constant. The type elements in a computational domain using CFD. The

of heat exchanger used will be of concentric tube finite volume method is a particular finite differencing

design. Water will be the cooling medium and oil the numerical technique, and is the most common method

working fluid. for calculating flow in CFD codes. This section

describes the basic procedures involved in finite

2.4 Defining Material Properties: volume calculations.

Water was used as the base fluid flowing through The finite volume method involves first

tubing or piping. Its material properties were derived creating a system of algebraic equations through the

from tables based on the temperature which was being process of discretising the governing equations for

calculated in the model. The material was defined in mass, momentum, and scalar transport. To account for

FLUENT using its material browser. For the different flow fluctuations due to turbulence in this project, the

flow arrangement problem model certain properties RANS equations are discretised instead when the cases

were defined by the user prior to computing the model, are run using the k-epsilon turbulence model. When

these properties were: thermal conductivity, density, the equations have been discretised using the

heat capacity at constant pressure, ratio of specific appropriate differencing scheme for expressing the

heats, and dynamic viscosity. For the modified Graetz differential expressions in the integral equation (i.e.

problem with pipe wall conduction as well as for the central, upwind, hybrid, or power-law, or other higher-

heat exchanger models the material library properties in order differencing schemes), the resulting algebraic

FLUENT were used. equations are solved at each node of each cell.

3.2 Numerical procedure and computational

methodology:

The governing differential transport equations were

converted to algebraic equations before being solved

numerically. After the specification of the boundary

condition, the solution control and the initialization of

IJERTV2IS111089 www.ijert.org 2784

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 11, November - 2013

the solution have to be given before the iteration starts.

The solution controls like the pressure velocity

coupling and the discrimination of the different

variables and the relaxation factors have to be specified.

The solutions sequential algorithm (called the

segregated solver) used in the numerical computation

requires less memory that the coupled solver. Since we

are using the segregated solver for our problem, the

default under relaxation factors are used and the

SIMPLE scheme for the pressure velocity coupling is

used and the second discrimination is used for the Turbulence Flow temperature and velocity profile

momentum and the standard scheme is used for the of single pipe with Constant Wall Temperature:

pressure.

4 RESULT AND DISCUSSIONS

The observations of CFD simulation results are

discussed below for the given boundary conditions. To

determine the best design for double pipe heat

exchanger type.

i. Results will be analysed using ANSYS

FLUENT.

ii. Hand calculations will be done to use as a

cross check

iii. ANSYS FLUENT is a useful tool for

RT

modelling laminar flow heat transfer.

The modified gratez problem ANSYS workbench

model:

IJE

Graetz problem calculations:

4.1 The Modified Graetz Problem Results: At velocity V=0.0001m/s

Laminar Flow temperature and velocity profile of

single pipe with Constant Wall Temperature: Reynolds number

Re = ρvD/ μ

= (988x0.0001x0.1) / (5.47x10-4) =18.062

Now Pr = Cp μ/K

= (4181X5.47X10-4)/0.64 = 3.57

Dimensionless length value

L* =L/DRePr

= 1/ (0.1x18.062x3.57) = 0.1556

Nusselt number

Num = 3.66 + {(0.075/ L*)/ (1+ (0.05/ (L*) ^ (2/3)}

= 4.072

Num = (-1/4 L*) x (ln (Tm*(L)

Tm*(L) = e-4 L* Num =0.0793

Tm (L) = Tw-(Tw-To) X Tm*(L)

= 30-(30-50) x0.0793

=31.6oc =304.67 k

IJERTV2IS111089 www.ijert.org 2785

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 11, November - 2013

Modified Graetz Problem Centreline Temperature

for single pipe: Laminar Flow in a parallel Heat Exchanger:

Temperature Velocity Profile for parallel Heat

Exchanger:

Different velocity vs. out let temperature of single

pi[e:

Turbulent Flow in a parallel Heat Exchanger:

Temperature and Velocity Profile for a

turbulent parallel Flow Heat Exchanger:

RT

I

FLUEN

inlet Expected

Inlet Wall T

IJE

Velocit value by % Error

temp. temp. VALUE

y calculation

(K) (K) (K)

(m/s) (K)

0.0001 50 30 304.67 305.142 0.1572

0.001 50 30 316.49 321.151 1.4510

0.01 50 30 317.39 323.165 1.7836

The Modified Graetz Problem Calculations:

Comparison of fluent value vs. expected value:

4.2 Concentric Tube parallel Flow Heat Exchanger:

Concentric tube Heat Exchanger ansys12.1

workbench Model:

ANSYS12.1 workbench Mesh model:

Laminar Flow in parallel Heat Exchanger

Problem Calculations:

At velocity V=0.0001m/s

DO = 0.14m Di = 0.1m

AO = 0.4398 m2 Ai =0.3142 m2

Cross sectional area of each fluid flow

Aoil = πr2 = 0.00785m2

Awater = π (ro2-ri2) = 0.02985 m2

Mass flow rate

IJERTV2IS111089 www.ijert.org 2786

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 11, November - 2013

Moil= ρAv= (826). (0.007854).(0.0001)=0.0006487 kg/s Laminar parallel Flow Heat Exchanger

Mwater= ρAv= (998.2). (0.02984).(0.0001)=0.00297 kg/s Temperature Change:

Heat capacity rates.

Coil = Cpoil × Moil = 2328×0.0006487=1.51W/K

Cwater=Cp, water× Mwater =4182×0.002979 =12.45 W/K

Ratio of heat capacity:

Cr=Cmin/Cmax= Coil/ Cwater=0.1212

Reynolds number

Re = ρvD/ μ

= (4 x Moil)/ (π Di μoil)

= (4x0.0006487)/ (π x 0.1 x0.00915) = 0.902 Turbulent parallel Flow Heat Exchanger

Temperature Change:

Nusselt Number

Nu = 3.66 + (0.0668A/ (1+ (0.4 X A0.667))

= 4.435

A = Re Pr (Di/L) =14.35 m2

Heat transfer coefficient

The inner pipe wall is:

hi = Koil x Nu/ Di

= (0.134 x 4.435)/0.1 =5.942 w/m2k

Cooling Water Flow Rate Effect on Oil Outlet

Design overall heat transfer coefficient Temperature for laminar flow:

RT

UA = 1/{(1/ hi Ai)+(1/ ho Ao)+( ln(DO/ Di)/2 πLKcopper)}

= 0.7687 w/k

IJE

Number of transfer units

NTU = UA/Cmin = 0.7687/1.5102 = 0.509

Effectiveness

έ = 1- e {-NTU (1+Cr)}/ (1+Cr)

= 1- e {-0.59 (1+0.12121)}/ (1+0.12121) Cooling water velocity vs. the log mean temperature

= 0.3879 Difference:

Heat capacity

q = έ x Cmin x (Thi-Tci)

= 61.507 watts

Cold and hot fluid out let temperatures

Tco = Tci + (q/ Cmax) = 293.15 + (61.507/12.45)

=298.09 k

Tho = Thi - (q/ Cmin) =398.15 – (61.507/1.510)

= 357.42 k Cooling water velocity vs. Change in oil

temperature Difference:

Log mean temperature difference

q = UA∆TLM

∆TLM=61.507/0.7687=80.017 k

∆TLM = (∆T2 - ∆T1)/ ln (∆T2/∆T1)

=(357.42-298.08)-(398.15-293.15)/ln((357.42-

298.08)/(398.15-293.15))

∆TLM =80.17k

IJERTV2IS111089 www.ijert.org 2787

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 11, November - 2013

Cooling water velocity vs. the outlet temperature of

Different fluids for copper tube material:

Laminar Flow in Counter Heat Exchanger Problem

Calculations:

Cooling water velocity vs. the outlet temperature of

Different fluids for aluminium tube material: Effectiveness

έ = 1- e {-NTU (1-Cr)}/ {1- Cr e {-NTU (1-Cr)}}

= 1- e {-0.59 (1+0.12121)}/ 1- 0.12121 x e {-0.59 (1+0.12121)}

= 0.391

Heat capacity

q = έ x C min x (Thi-Tci) = 61.988 watts

Cold and hot fluid out let temperatures

T co = T ci + (q/ C max) = 293.15 + (61.507/12.45)

4.3 Concentric Tube Counter Flow Heat Exchanger: =298.09 k

Laminar Flow in a Counter Heat Exchanger: T ho = T hi + (q/ C min) =398.15 – (61.507/1.510)

Temperature and Velocity Profile for Counter Heat = 357.42 k

RT

Exchanger:

Log mean temperature difference

q = UA∆TLM

∆TLM = 61.998/0.7687 = 80.645 k

IJE

∆TLM = (Tho- Tci) - (Thi- Tco)/ ln (Tho -Tci/Thi - Tco)

=(357.09-293.15)-(398.15-298.15)/ln((357.09-

293.15)/(398.15-298.12))

∆TLM =80.64k

Laminar Counter- Flow Heat Exchanger

Temperature Change:

Turbulent Flow in a Counter Heat Exchanger:

Temperature and Velocity Profile for a Turbulent

Counter Flow Heat Exchanger: Turbulent Counter- Flow Heat Exchanger

Temperature Change:

IJERTV2IS111089 www.ijert.org 2788

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 11, November - 2013

Cooling Water Flow Rate Effect on Oil Outlet Cooling water velocity vs. the outlet temperature of

Temperature for laminar flow: Different fluids for copper tube material:

Cooling water velocity vs. the log mean temperature Cooling water velocity vs. the outlet temperature of

Difference: Different fluids for aluminium tube material:

Laminar parallel flow heat exchanger for copper

material:

RT

Expected value for calculations Fluent value

IJE

Heat Overall Log

Cold Hot Log Cold Hot

transfer heat mean

Heat fluid fluid mean fluid fluid

Different Velocity Reynolds co-efficient transfer temp.

capacity out let outlet temp. out let outlet

fluids (m/s) number of inner co- differen

(watts) temp temp Differen temp temp

pipe efficient ce

(k). (k). ce (k). (k). (k).

(w/m2k) (w/k) (k).

Transfor 0.0001 0.902 5.492 0.7687 61.507 298.09 357.42 80.17 304.12 342.2 65.92

mer 0.001 9.0273 11.02 1.426 142.07 294.29 388.74 99.63 302.94 373.1 88.83

oil 0.01 90.17 25.56 3.3062 342.91 293.42 395.08 103.70 302.21 381.24 90.96

0.0001 14.77 3.85 0.756 56.47 297.68 348.52 80.32 302.56 341.3 66.46

toulene 0.001 147.78 6.59 1.172 116.92 294.68 387.55 99.29 301.96 371.24 85.90

0.01 1477.8 7.94 0.976 123.92 293.29 397.06 126.94 301.12 380.31 91.9

0.0001 14.85 6.184 0.797 59.6 297.73 348.79 79.69 303.41 339.2 64.82

benzene 0.001 148.55 6.96 0.91 91.30 293.89 390.57 97.57 302.11 375.61 88.31

0.01 1488.5 8.38 1.08 112.36 293.25 397.21 104.23 301.82 380.92 91.43

0.0001 2.5 5.373 0.693 55.28 297.58 356.87 79.76 302.71 335.4 62.01

Gas oil 0.001 25 5.967 0.774 78.64 293.71 392.34 101.46 302.21 377.31 89.25

0.01 250 7.317 0.946 99.51 293.22 397.38 105.12 301.56 384.21 93.37

0.0001 0.7078 9.83 1.275 95.9 300.8 352.57 75.4 305.61 334.1 59.06

Ethylene

glycol 0.001 7.078 11.01 1.432 143.1 294.24 391.33 99.86 303.11 376.32 88.14

0.01 70.78 13.42 1.72 180.8 293.29 397.32 105.21 303.12 381.56 91.07

0.0001 0.0158 11.15 1.44 107.86 301.76 353.12 74.93 308.14 339.2 60.64

glycerine 0.001 0.158 12.49 1.625 163.41 294.81 391.32 101.48 303.82 373.14 85.92

0.01 1.58 15.23 1.96 204.69 293.31 397.12 104.43 304.61 382.12 90.56

0.0001 37.816 9.015 1.034 115.93 299.56 351.83 76.53 306.32 337.2 60.68

water 0.001 378.16 9.69 1.235 136.26 294.29 387.24 97.68 303.12 374.42 87.12

0.01 3781.6 11.56 1.486 198.26 293.46 390.98 104.82 303.56 381.92 91.03

IJERTV2IS111089 www.ijert.org 2789

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 11, November - 2013

Laminar flow Counter heat exchanger for copper

material:

Expected value for calculations Fluent value

Overall Log

Heat Hot Log Hot

heat Cold Cold mean

transfer co- Heat fluid mean fluid

Different Velocity Reynolds transfer fluid out fluid out temp.

efficient of capacity outlet temp. outlet

fluids (m/s) number co- let temp let temp differen

inner pipe (watts) temp differen temp

efficient( (k). (k). ce

(w/m2k) (k). ce(k). (k).

w/k) (k).

Transfor 0.0001 0.902 5.492 0.7687 61.507 298.12 357.09 80.64 300.51 338.56 68.25

mer 0.001 9.0273 11.02 1.426 142.07 294.42 387.64 99.03 298.24 378.25 92.32

oil

0.01 90.17 25.56 3.3062 342.91 293.42 395.82 104.23 297.24 386.34 96.9

0.0001 14.77 3.85 0.756 56.47 297.72 347.95 77.32 300.14 335.11 66.06

toulene 0.001 147.78 6.59 1.172 116.92 294.03 387.8 99.27 298.01 380.22 93.45

0.01 1477.8 7.94 0.976 123.92 293.25 397.31 104.5 297.11 390.62 99.24

0.0001 14.85 6.184 0.797 59.6 297.96 348.46 75.19 300.24 338.24 68.12

benzene 0.001 148.55 6.96 0.91 91.30 293.88 390.51 101.6 297.52 382.56 94.9

0.01 1488.5 8.38 1.08 112.36 293.23 397.13 104.51 296.91 390.81 102.24

0.0001 2.5 5.373 0.693 55.28 297.60 356.55 80.56 301.02 339.21 69.104

Gas oil 0.001 25 5.967 0.774 78.64 293.7 392.31 102.12 297.12 383.21 92.81

0.01 250 7.317 0.946 99.51 293.29 397.4 104.76 297.01 390.42 99.14

0.0001 0.7078 9.83 1.275 95.9 301.42 351.42 80.98 303.12 336.24 65.64

RT

Ethylene

glycol 0.001 7.078 11.01 1.432 143.1 294.3 391.28 101.29 299.41 386.24 96.01

0.01 70.78 13.42 1.72 180.8 293.29 398.01 104.39 298.12 391.24 99.05

0.0001 0.0158 11.15 1.44 107.86 301.94 352.43 76.12 303.56 337.21 66.138

IJE

glycerine 0.001 0.158 12.49 1.625 163.41 294.46 391.34 100.8 300.16 381.24 99.67

0.01 1.58 15.23 1.96 204.69 294.04 397.98 104.36 299.24 391.21 98.49

0.0001 37.816 9.015 1.034 115.93 301.56 357.76 78.79 302.22 338.12 67.24

water 0.001 378.16 9.69 1.235 136.26 294.38 391.21 100.85 299.31 383.92 94.74

0.01 3781.6 11.56 1.486 198.26 293.56 398.21 104.82 298.32 391.56 99.11

Turbulent parallel and counter flow heat exchanger

for copper material:

Parallel flow Counter flow

Cold

Hot Log Cold Hot Log

fluid

Velocit fluid mean fluid fluid mean

out

y (m/s) outlet temp. out let outlet temp.

Different let

temp. differe temp. temp. differenc

fluids temp.

(K) nce(K) (K) (K) e(K)

(K)

Transforme

0.56 294.2 396.52 103.65 294.01 395.92 103.45

r oil

toulene 0.035 294.1 397.21 104.04 293.91 396.21 103.919

benzene 0.56 294.3 397.56 104.21 293.61 396.56 103.97

Gas oil 0.22 293.2 396.92 104.35 294.12 396.32 103.59

Ethylene

0.72 293.5 397.21 104.32 294.32 397.11 103.89

glycol

glycerine 0.56 294.1 396.32 103.57 294.92 396.56 103.319

water 0.002 104.2 397.11 104.23 294.21 397.12 103.95

IJERTV2IS111089 www.ijert.org 2790

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 11, November - 2013

Laminar parallel and counter flow heat exchanger

for Aluminium material:

Parallel flow Counter flow

Cold Hot Cold Hot Log

Velocity Log mean

fluid fluid fluid fluid mean

(m/s) temp.

Different out let outlet out let outlet temp.

difference

fluids temp. temp. temp. temp. differenc

(K)

(K) (K) (K) (K) e(K)

0.0001 303.16 332.1 57.78 300.21 336.26 66.78

Transformer 0.001 302.56 384.16 92.8 298.12 372.16 89.24

oil

0.01 298.18 391.26 98.94 297.22 390.56 99.204

0.0001 302.16 334.21 61.47 300.56 335.61 66.24

toulene 0.001 301.62 381.01 91.59 298.01 378.56 92.59

0.01 297.61 390.56 98.85 297.12 390.96 99.04

0.0001 302.56 336.21 62.71 300.42 333.21 64.66

benzene 0.001 301.86 381.26 91.63 297.68 380.26 93.94

0.01 297.41 392.56 100.82 297.56 392.52 99.78

0.0001 302.18 337.21 63.73 300.12 336.79 67.206

Gas oil 0.001 300.92 382.42 92.75 297.42 382.56 94.95

0.01 297.01 393.42 100.64 297.42 391.56 99.56

0.0001 303.86 334.18 60.12 300.92 336.12 66.48

Ethylene

0.001 302.14 385.1 93.41 298.56 383.21 94.74

glycol

0.01 298.24 391.56 99.04 298.02 391.92 99.44

0.0001 304.16 338.21 63.03 302.25 337.21 66.704

RT

glycerine 0.001 303.56 384.56 92.48 299.19 381.56 93.58

0.01 299.36 391.92 98.64 298.82 392.56 99.36

0.0001 303.75 337.42 62.71 301.02 336.81 66.79

water 0.001 302.96 383.21 92.07 298.92 383.41 94.62

IJE

0.01 298.56 391.02 98.59 298.32 391.56 98.71

Turbulent parallel and counter flow heat exchanger

for Aluminium material:

Parallel flow Counter flow

Log Log

Cold Hot Cold Hot

Different Velocit mean mean

fluid fluid fluid fluid

fluids y (m/s) temp. temp.

outlet outlet out let outlet

Differen Differen

temp. temp. temp. temp.

ce ce

(K) (K) (K) (K)

(K) (K)

Transforme

r 0.56 294.12 397.01 103.94 294.01 396.21 103.86

oil

toulene 0.035 294.04 392.31 101.59 293.86 394.87 102.98

benzene 0.56 294.36 389.25 99.85 293.61 396.21 102.96

Gas oil 0.22 293.96 394.56 102.78 294.01 394.24 102.45

Ethylene

0.72 294.12 397.12 98.403 294.12 397.56 104.21

glycol

glycerine 0.56 294.93 397.61 103.83 294.56 397.21 103.62

water 0.002 294.23 396.13 103.58 294.12 397.45 104.06

IJERTV2IS111089 www.ijert.org 2791

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 11, November - 2013

5. Conclusions The fouled heat exchangers performance was

The performance, CFD analysis of different fluids much lower than the non-fouled heat

and different pipe materials were investigated on exchanger. There was an approximate 2 K rise

parallel and counter flow in concentric tube heat in outlet temperature for a fouled concurrent

exchanger. The conclusions of this investigating at are heat exchanger and an approximate 1 K rise in

as follows. outlet temperature for a fouled countercurrent

The main objective of this project was to heat exchanger vice a fraction of a Kelvin

analyse the fluid flow in double pipe heat change between the concurrent and

exchangers and the subsequent performance of countercurrent heat exchangers.

these heat exchangers. This finding proves it is more important for

To facilitate this analysis, the ANSYS engineers and developers to focus on the

FLUENT 12.1 finite volume analysis program method of preventing damage to the heat

was used to perform the modelling and transfer surfaces and the type of material

calculations. In order to verify the chosen than it is to focus on the type of flow.

development of each model, the models were The more time that is spent researching how a

built in stages and each stage analysed and material will perform over time and the type

verified. of corrosion that occurs with the material or

The first stage was a modified Graetz problem ways to prevent corrosion and deterioration in

model where velocity and temperature profiles the system will be more efficient.

were analysed for fluid flow in a tube of 1.0 m 6. References

in length. This basic model was verified by

hand calculations and the percent difference [1] Concentric tube heat exchanger: operating principle with

was seen to be less than 2%. parallel flow. Art.

[2] White, Frank. Viscous Fluid Flow. 3rd ed. New York: The

It should be noted, that for the lower velocity McGraw-HillCompanies, Inc., 2006.

RT

of .0001 m/s, the laminar model actually [3] Conley, Nancy, Adeniyi Lawal, and Arun B. Mujumdar. ―An

cooled the outlet flow to 305.148 K in the Assessment of the Accuracy of Numerical Solutions to the

modified Gratez problem while the turbulent Graetz Problem.‖ Int. Comm. Heat Mass Transfer. Vol.12.

Pergamon Press Ltd. 1985.

model only cooled the flow to 322.25503 K. It

IJE

[4] Kays, William, Michael Crawford, and Bernhard Weigand.

was also discovered that the centreline Convective Heat and Mass Transfer. 4th ed. New York: The

temperature from start to finish (0 to 1 m) had McGraw-Hill Companies, Inc.,2005.

a more parabolic, gradual slope lowering from [5] Sellars J., M. Tribus, and J. Klein. ―Heat Transfer to Laminar

Flow in a Round Tube or Flat Conduit—The Graetz Problem

the inlet temperature of 323.15 K to Extended.‖ The American Society of Mechanical Engineers.

305.93648 K while the turbulent flow had an Paper No. 55-SA-66 AD-A280 848. New York. 1955.

almost linear relationship with the centreline [6] Subramanian, Shankar R. ―The Graetz Problem.‖ Web. 12

temperature against the arc length. Apr. 2012.

[7] K.S.Hwang, S.K.Jang, S.U.S.Chio, Flow and convective heat

The parallel and counter flow models first transfer characteristics of water-based Al2O3 nanofluids in

were verified to be providing the same cooling fully developed laminar flow regime, International Journal of

relationship as expected from these types of Heat and Mass Transfer, 52 (2009) 193-199.

heat exchangers. All models with and without [8] V. Bianco, F. Chiacchio, O. Manca, S. Nardini, Numerical

investigationof nanofluids forced convection in circular tubes,

fouling showed that as the cooling water flow Applied Thermal Engineering, 29 (2009) 3632 – 3642.

increased, so did the amount of heat transfer [9] M. Akbari, N. Galanis, A. Behzadmehr, Comparative analysis

by a decreasing oil outlet temperature and of singleand two-phase models for CFD studies of nanofluid

increasing oil temperature difference. heat transfer, International Journal of Thermal Sciences, 50

(2011) 1343 – 1354.

The ANSYS FLUENT results were found to [10] Valko, Peter P. ―Solution of the Graetz-Brinkman Problem

be fairly consistent with hand calculations with the Laplace Transform Galerkin Method.‖ International

with most of the values within 5% of each Journal of Heat and Mass Transfer 48. 2005.

other. [11] Blackwell, B.F. ―Numerical Results for the Solution of the

Graetz Problem for a Bingham Plastic in Laminar Tube Flow

The material properties which were with Constant Wall Temperature.‖ Sandia Report. Aug. 1984.

temperature dependent were considered Encyclopædia Britannica Online. Web. 12 Apr. 2012.

constant based on the inlet temperature of the [12] White, F.M., Fluid Mechanics, 3rd edition. Mc- Graw Hill,

fluid flow for the hand calculations instead of 1994

using the average temperature whereas the

ANSYS FLUENT values were from the

material library.

IJERTV2IS111089 www.ijert.org 2792

You might also like

- 325C Excavator Hydraulic System SchematicDocument2 pages325C Excavator Hydraulic System SchematicMgc Elektronik86% (7)

- Review of Experimental Analysis of Parallel and Counter Flow Heat Exchanger IJERTV5IS020385Document3 pagesReview of Experimental Analysis of Parallel and Counter Flow Heat Exchanger IJERTV5IS020385hyugkyu LeeNo ratings yet

- 1.parallel Flow Heat ExchangersDocument8 pages1.parallel Flow Heat ExchangerssanthoshNo ratings yet

- Numerical Modeling and Simulation of A Double Tube Heat Exchanger Adopting A Black Box ApproachDocument8 pagesNumerical Modeling and Simulation of A Double Tube Heat Exchanger Adopting A Black Box ApproachSanika TalathiNo ratings yet

- AnushaDocument6 pagesAnushaElemental Hero GaiaNo ratings yet

- Thermal Modeling of Heat Exchanger: A Review: January 2017Document7 pagesThermal Modeling of Heat Exchanger: A Review: January 2017Preciously OmnesNo ratings yet

- Effect of Non-Newtonian Fluids On The Performance of Plate Type Heat ExchangerDocument4 pagesEffect of Non-Newtonian Fluids On The Performance of Plate Type Heat Exchangerdeepika snehiNo ratings yet

- CFD Analysis of Shell and Tube Heat Exchanger PerformanceDocument6 pagesCFD Analysis of Shell and Tube Heat Exchanger PerformanceSrijan VermaNo ratings yet

- IRJET Spiral CoilDocument10 pagesIRJET Spiral CoilRithwik pawarNo ratings yet

- 1 s2.0 S0017931016303982 MainDocument15 pages1 s2.0 S0017931016303982 MainasalazarhNo ratings yet

- Study On Effect of Twisted Tape Insert Geometry in Heat ExchangerDocument4 pagesStudy On Effect of Twisted Tape Insert Geometry in Heat ExchangerEditor IJTSRDNo ratings yet

- Articulo Evaporación ExpoDocument9 pagesArticulo Evaporación ExpoCamila RodriguezNo ratings yet

- Mushtaq 2014Document11 pagesMushtaq 2014boilingenhanceNo ratings yet

- Thermal Analysis of Hot Wall Condenser For Domestic RefrigeratorDocument6 pagesThermal Analysis of Hot Wall Condenser For Domestic RefrigeratorHimanshuNo ratings yet

- Irjet V4i6236 PDFDocument6 pagesIrjet V4i6236 PDFArih FadiNo ratings yet

- Study The Performance of Different Packing in Open Cooling TowersDocument19 pagesStudy The Performance of Different Packing in Open Cooling TowersfiNo ratings yet

- Analysis of Overall Heat Transfer Coefficient and Effectiveness in Split Flow Heat Exchanger Using Nano FluidsDocument13 pagesAnalysis of Overall Heat Transfer Coefficient and Effectiveness in Split Flow Heat Exchanger Using Nano Fluidsananthakanna2010No ratings yet

- Finite Element and Temperature Distribution Analysis Over The Heat Pipe BoundaryDocument6 pagesFinite Element and Temperature Distribution Analysis Over The Heat Pipe BoundaryIJRASETPublicationsNo ratings yet

- Theoretical Analysis On Heat and Mass Transfer in A Direct Evaporative CoolerDocument5 pagesTheoretical Analysis On Heat and Mass Transfer in A Direct Evaporative CoolermariemNo ratings yet

- CFD Simulation of A Double Pipe Heat by Baru, Ibsa and Dr. VDocument10 pagesCFD Simulation of A Double Pipe Heat by Baru, Ibsa and Dr. VIbsa NemeNo ratings yet

- Cooling Fin OptimizationDocument8 pagesCooling Fin OptimizationKamer YıldızNo ratings yet

- Thermal Analysis of The Heat Exchanger Tubes Using Ansys PDFDocument4 pagesThermal Analysis of The Heat Exchanger Tubes Using Ansys PDFMuhammadBarrylAnggriawanNo ratings yet

- CFD Analysis On Hdpe Double Pipe Heat ExchangerDocument8 pagesCFD Analysis On Hdpe Double Pipe Heat ExchangerSai Krishna SKNo ratings yet

- Design Procedure of Shell and Tube Heat Exchanger: Alok Shukla, Prakash Kumar, Dr. Deo. Raj TiwariDocument4 pagesDesign Procedure of Shell and Tube Heat Exchanger: Alok Shukla, Prakash Kumar, Dr. Deo. Raj TiwarierpublicationNo ratings yet

- CFD Heat SinkDocument60 pagesCFD Heat SinkSandeep RimzaNo ratings yet

- Evaluation of Recuperative Tube-In-Tube Heat Exchanger Operating in Cryogenic Refrigeration Process: Simulation-Based Transient StudyDocument12 pagesEvaluation of Recuperative Tube-In-Tube Heat Exchanger Operating in Cryogenic Refrigeration Process: Simulation-Based Transient StudyZoraida CarrasqueroNo ratings yet

- IJERT CFD Analysis of Double Pipe Counte (Lab 11)Document13 pagesIJERT CFD Analysis of Double Pipe Counte (Lab 11)bjuanlunabNo ratings yet

- 2 67 1581919845 4ijmperdapr20204Document12 pages2 67 1581919845 4ijmperdapr20204TJPRC PublicationsNo ratings yet

- Imulation and Modeling of Heat Pipe: International Journal of Technical Research (IJTR) Vol. 5, Issue 1, Mar-Apr 2016Document5 pagesImulation and Modeling of Heat Pipe: International Journal of Technical Research (IJTR) Vol. 5, Issue 1, Mar-Apr 2016pouriyaNo ratings yet

- Yadav 2021Document12 pagesYadav 2021moontree1990No ratings yet

- Faculty of Engineering and Technology Department of Chemical EngineeringDocument10 pagesFaculty of Engineering and Technology Department of Chemical Engineeringmasedi malatjiNo ratings yet

- 1 s2.0 S0735193309002188 Main PDFDocument7 pages1 s2.0 S0735193309002188 Main PDFbooyemahemehrNo ratings yet

- Developing Empirical Nusselt Number Correlations For Single Phase Flow Through A Plate Heat ExchangerDocument31 pagesDeveloping Empirical Nusselt Number Correlations For Single Phase Flow Through A Plate Heat ExchangerAli Hashmi100% (1)

- Comparison of Circular & Elliptical Tubes For Heat ExchangerDocument3 pagesComparison of Circular & Elliptical Tubes For Heat ExchangerdeepakS1990No ratings yet

- Thermal Analysis of Hollow Pipe Using Altair Hyperworks IJERTV1IS6265Document13 pagesThermal Analysis of Hollow Pipe Using Altair Hyperworks IJERTV1IS6265ADVOKASI PPI MALAYSIANo ratings yet

- Investigation and Experimental Analysis of Gasketed Plate Type Heat ExchangerDocument6 pagesInvestigation and Experimental Analysis of Gasketed Plate Type Heat ExchangerFurkan YildirimNo ratings yet

- Sant Longowal Institute of EngineeringDocument41 pagesSant Longowal Institute of EngineeringPANKAJ KUMARNo ratings yet

- Design and Performance Analysis of Double Pipe Heat Exchanger in Counter FlowDocument6 pagesDesign and Performance Analysis of Double Pipe Heat Exchanger in Counter FlowSolooloo Kebede NemomsaNo ratings yet

- FGFGHDocument11 pagesFGFGHLiviu BadeaNo ratings yet

- Cryogenics: R.M. Damle, M.D. AtreyDocument10 pagesCryogenics: R.M. Damle, M.D. AtreyNavin DNo ratings yet

- Numerical Simulation of A Cylindrical Heat Pipe and Performance StudyDocument7 pagesNumerical Simulation of A Cylindrical Heat Pipe and Performance StudypouriyaNo ratings yet

- 1 s2.0 S1359431122011401 MainDocument14 pages1 s2.0 S1359431122011401 MainTanti ArdiyatiNo ratings yet

- Mathematical Modeling of Spiral Heat ExcDocument4 pagesMathematical Modeling of Spiral Heat ExcKaleem UllahNo ratings yet

- Asis GiriDocument14 pagesAsis Giriait hssainNo ratings yet

- Effect of Fouling On Thermal and Hydraulic Parameter of Shell and Tube Heat ExchangerDocument10 pagesEffect of Fouling On Thermal and Hydraulic Parameter of Shell and Tube Heat ExchangerJoão Paulo VissottoNo ratings yet

- CFD Analysis of Tube in Tube Helical Coil Heat ExchangerDocument6 pagesCFD Analysis of Tube in Tube Helical Coil Heat ExchangerMohsen SalehiNo ratings yet

- 2017 - Review of Nature-Inspired Heat Exchanger TechnologyDocument17 pages2017 - Review of Nature-Inspired Heat Exchanger TechnologyCarlos Fernando Rojas TovarNo ratings yet

- Final ReportDocument70 pagesFinal ReportSudarshan KulandhaivelNo ratings yet

- Project ReportDocument23 pagesProject Reportbabulsethi1567No ratings yet

- Study of Flow and Heat Transfer Analysis in Shell and Tube Heat Exchanger Using CFDDocument8 pagesStudy of Flow and Heat Transfer Analysis in Shell and Tube Heat Exchanger Using CFDBigNo ratings yet

- Experimental Studies On Heat Transfer and Pressure Drop Characteristics For New Arrangements of Corrugated Tubes in A Double Pipe Heat ExchangerDocument10 pagesExperimental Studies On Heat Transfer and Pressure Drop Characteristics For New Arrangements of Corrugated Tubes in A Double Pipe Heat ExchangerkumarNo ratings yet

- Heat ExchangerDocument7 pagesHeat ExchangerShekinah HartNo ratings yet

- Transient Heat Transfer by Free Convection in A Packed Bed of Spheres: Comparison Between Two Modelling Approaches and Experimental ResultsDocument40 pagesTransient Heat Transfer by Free Convection in A Packed Bed of Spheres: Comparison Between Two Modelling Approaches and Experimental ResultsAlcalá LucianoNo ratings yet

- Giani Zail Singh Campus College of Eng. & Technology Maharaja Ranjit Singh State Technical University Bathinda (Punjab)Document22 pagesGiani Zail Singh Campus College of Eng. & Technology Maharaja Ranjit Singh State Technical University Bathinda (Punjab)vaibhav bothraNo ratings yet

- Numerical Studies of A Double-Pipe Helical Heat Exchanger: Timothy J. Rennie, Vijaya G.S. RaghavanDocument8 pagesNumerical Studies of A Double-Pipe Helical Heat Exchanger: Timothy J. Rennie, Vijaya G.S. Raghavan1AdityaPathania1No ratings yet

- Applied Thermal Engineering: P.M. Ardhapurkar, Arunkumar Sridharan, M.D. AtreyDocument10 pagesApplied Thermal Engineering: P.M. Ardhapurkar, Arunkumar Sridharan, M.D. Atreybagiyo condroNo ratings yet

- Design and Analysis of Shell and Tube Heat ExchangerDocument8 pagesDesign and Analysis of Shell and Tube Heat ExchangerawusomNo ratings yet

- Numerical investigation of convective heat transfer and pressure loss in a round tube fitted with circular-ring turbulatorsDocument6 pagesNumerical investigation of convective heat transfer and pressure loss in a round tube fitted with circular-ring turbulatorsGanesh BodakheNo ratings yet

- Numerical Investigation of Laminar Heat Transfer Performance of Various Cooling Channel DesignsDocument12 pagesNumerical Investigation of Laminar Heat Transfer Performance of Various Cooling Channel DesignsZahid MaqboolNo ratings yet

- Experimental Thermal and Fluid Science: M.R. SalimpourDocument5 pagesExperimental Thermal and Fluid Science: M.R. Salimpourmartin sabusNo ratings yet

- ServicePlus - ISSUANCE OF PASSES TO GOODS VEHICLE - Krishnat - Hanumant - Sutar PDFDocument1 pageServicePlus - ISSUANCE OF PASSES TO GOODS VEHICLE - Krishnat - Hanumant - Sutar PDFsagarNo ratings yet

- Trip ListDocument1 pageTrip ListsagarNo ratings yet

- Tom Sum 2019 PDFDocument4 pagesTom Sum 2019 PDFParkar UmerNo ratings yet

- GR Wood TransportDocument2 pagesGR Wood TransportsagarNo ratings yet

- Attachment M - John Fowler - AnnexXRevBDocument5 pagesAttachment M - John Fowler - AnnexXRevBBùi Văn HợpNo ratings yet

- Ijesrt: International Journal of Engineering Sciences & Research TechnologyDocument6 pagesIjesrt: International Journal of Engineering Sciences & Research TechnologymonikaNo ratings yet

- Chemical Bonding and Molecular Structure ExplainedDocument36 pagesChemical Bonding and Molecular Structure Explainedmanish365No ratings yet

- Maharashtra Motor Vehicles Department Government of MaharashtraDocument1 pageMaharashtra Motor Vehicles Department Government of MaharashtrasagarNo ratings yet

- W4 PD MRu 6 CF MG QUNEDocument1 pageW4 PD MRu 6 CF MG QUNEsagarNo ratings yet

- Ijesrt: International Journal of Engineering Sciences & Research TechnologyDocument6 pagesIjesrt: International Journal of Engineering Sciences & Research TechnologymonikaNo ratings yet

- CPU Thermal Analysis July 10Document11 pagesCPU Thermal Analysis July 10sagarNo ratings yet

- A Review On Kinematics of Hydraulic Excavators Ba PDFDocument9 pagesA Review On Kinematics of Hydraulic Excavators Ba PDFsagarNo ratings yet

- Attachment M - John Fowler - AnnexXRevBDocument52 pagesAttachment M - John Fowler - AnnexXRevBsagarNo ratings yet

- CookieDocument1 pageCookiesagarNo ratings yet

- Fishing Rod NonLienar AnalysisDocument7 pagesFishing Rod NonLienar Analysissagar0% (1)

- Large Deformation Analysis - ManualDocument2 pagesLarge Deformation Analysis - ManualsagarNo ratings yet

- Maharashtratil Kille Ani ItihasDocument101 pagesMaharashtratil Kille Ani Itihasalpatil250% (2)

- Ent. 110 (50 Bit) (E)Document12 pagesEnt. 110 (50 Bit) (E)sagarNo ratings yet

- 7913433154revised Central Sector Scheme For Conservation PDFDocument126 pages7913433154revised Central Sector Scheme For Conservation PDFNazeer AhmadNo ratings yet

- Gjxpfib 1Document2 pagesGjxpfib 1sagarNo ratings yet

- Whatsnew PDFDocument234 pagesWhatsnew PDFsagarNo ratings yet

- ISO 23210 2009 Calculation Program EDocument9 pagesISO 23210 2009 Calculation Program ETri SulyonoNo ratings yet

- F2 2I UpdatedddDocument17 pagesF2 2I UpdatedddMohd Nik Harith FawwazNo ratings yet

- The Surface Roughness Effect On The Performance of Supersonic EjectorsDocument9 pagesThe Surface Roughness Effect On The Performance of Supersonic EjectorsmyskyshepherdNo ratings yet

- D07012 EID Parry Vendor ListDocument2 pagesD07012 EID Parry Vendor ListNegama ThullahNo ratings yet

- Fluid KinematicsDocument109 pagesFluid KinematicsLorence Gabayan100% (1)

- UmmuSaiyidahNajihah SKMO ThesisReportDocument113 pagesUmmuSaiyidahNajihah SKMO ThesisReportAUTVPDPPB1022 Ummu Saiyidah Najihah Binti ZainudinNo ratings yet

- Manometer Fluid Flow CalculationsDocument6 pagesManometer Fluid Flow Calculationsmonkey manNo ratings yet

- KS4 Physics IG 2022Document127 pagesKS4 Physics IG 2022Lungten PhuentshoNo ratings yet

- MEBS6008 Environmental Services II Fluid Network AnalysisDocument60 pagesMEBS6008 Environmental Services II Fluid Network Analysisahtin618No ratings yet

- Effect of Gurney Flaps On A NACA 0011 Airfoil: Roy MyoseDocument13 pagesEffect of Gurney Flaps On A NACA 0011 Airfoil: Roy MyoseMarcos SoarNo ratings yet

- Fluid Mechanics: Imam Muhammad Bin Saud Islamic University, Riyadh, Saudi ArabiaDocument24 pagesFluid Mechanics: Imam Muhammad Bin Saud Islamic University, Riyadh, Saudi ArabiaMohamed ElgamalNo ratings yet

- Printing WPA108C11Document1 pagePrinting WPA108C11BM ThaísNo ratings yet

- Solenoid Valves for High Pressure Applications 1/4”-2Document1 pageSolenoid Valves for High Pressure Applications 1/4”-2Nguyễn KhoaNo ratings yet

- THF Lecture 02Document52 pagesTHF Lecture 02aNo ratings yet

- Review of Wind TunnelsDocument15 pagesReview of Wind TunnelsFahad AliNo ratings yet

- Ce 343L - Fluid Mechanics Final ExamDocument3 pagesCe 343L - Fluid Mechanics Final ExamMichelle DaarolNo ratings yet

- FMP-401 2021-Ag-8243Document4 pagesFMP-401 2021-Ag-8243ABdullah ButtNo ratings yet

- Simulation of Accumulator Influence On Hydraulic Shock in Long PipeDocument4 pagesSimulation of Accumulator Influence On Hydraulic Shock in Long PipeGkkNo ratings yet

- Free Conv Porous - Ppt+free Conv Porous - Ppt+.ppt+free Conv Porous - PPT+Document13 pagesFree Conv Porous - Ppt+free Conv Porous - Ppt+.ppt+free Conv Porous - PPT+Sunil SainiNo ratings yet

- Formulae BookDocument74 pagesFormulae Bookimran khanNo ratings yet

- A3-MEDIUM-DUTY-FIX-MOTOR - MAM v1.3Document40 pagesA3-MEDIUM-DUTY-FIX-MOTOR - MAM v1.3martinuskaNo ratings yet

- Old Exam 4307Document6 pagesOld Exam 4307rizwan ghafoorNo ratings yet

- Deeply Dimpled TubeDocument13 pagesDeeply Dimpled Tubemh.cheraghi.1989No ratings yet

- Fluid PropertiesDocument56 pagesFluid PropertiesABU SALEH MD. NASIMNo ratings yet

- AIROTM Nozzles Atomize Heavy FuelsDocument4 pagesAIROTM Nozzles Atomize Heavy Fuelsmadeup jonesNo ratings yet

- Compressible Equations Gas PDFDocument7 pagesCompressible Equations Gas PDFsoesonesNo ratings yet

- Pump CalculationDocument7 pagesPump CalculationPiping_SpecialistNo ratings yet

- UNIVERSITI TENAGA NASIONA1.docx 2Document16 pagesUNIVERSITI TENAGA NASIONA1.docx 2Dinesh RaviNo ratings yet