Professional Documents

Culture Documents

By @442" 774. (RZSWQ/J: O. D. Welsch 2,770,365

Uploaded by

Stajic Milan0 ratings0% found this document useful (0 votes)

9 views4 pagesThe document describes a vacuum flotation apparatus and process for purifying liquids such as industrial waste water or sewage. The process uses reduced pressure or vacuum to cause gases surrounding suspended solid particles in the liquid to expand, increasing the buoyancy of the solids and allowing them to float to the surface for removal. Atmospheric air is drawn into the apparatus to promote chemical reactions that form gas films on the solids. Agitation and circulation of the liquid-solid mixture enhances separation efficiency.

Original Description:

277

Original Title

9 US2770365

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document describes a vacuum flotation apparatus and process for purifying liquids such as industrial waste water or sewage. The process uses reduced pressure or vacuum to cause gases surrounding suspended solid particles in the liquid to expand, increasing the buoyancy of the solids and allowing them to float to the surface for removal. Atmospheric air is drawn into the apparatus to promote chemical reactions that form gas films on the solids. Agitation and circulation of the liquid-solid mixture enhances separation efficiency.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views4 pagesBy @442" 774. (RZSWQ/J: O. D. Welsch 2,770,365

Uploaded by

Stajic MilanThe document describes a vacuum flotation apparatus and process for purifying liquids such as industrial waste water or sewage. The process uses reduced pressure or vacuum to cause gases surrounding suspended solid particles in the liquid to expand, increasing the buoyancy of the solids and allowing them to float to the surface for removal. Atmospheric air is drawn into the apparatus to promote chemical reactions that form gas films on the solids. Agitation and circulation of the liquid-solid mixture enhances separation efficiency.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

NM’... 13, 1956 o. D.

WELSCH 2,770,365

VACUUM FLOTATION AND LIQUID PURIFICATION APPARATUS AND PROCESS

Filed Oct. 1, 1952

1N VENTOR

Wis Welsc?

BY @442“ 774. (RZswQ/J

ATTORNEY

United States Patent 0 2,770,365

Patented Nov. 13, 1956

Ira-3 2

mixture. Upon collision, the gas of the bubble coalesces

with the gas of the gaseous ?lmed solid and the solid be

comes attached to the colliding bubble. Increased buoy

2,770,365 ancy for the solid results. The greater the buoyancy

VACUUM FLOTATION AND LIQUID PURIFICA imparted to the solid, the better the chance of the solid

TION APPARATUS AND PROCESS being ?oated to the surface of the solid-liquid mixture.

In the present invention, this view of the basic con

Otis D. Welsch, Tonopah, Nev. dition of ?otation, wherein a gaseous ?lmed solid is

Application October 1, 1952, Serial No. 312,461 caused to rise to the surface, is considered of essential

10 importance, as under reduced pressure or vacuum gases

3 Claims. (Cl. 210—53) surrounding such particles expand and increase in vol

ume. This increase in the volume of the gaseous ?lm

results in a decrease of the speci?c gravity of the mass

represented by the combined solid and its gaseous ?lm.

This invention relates to the concentration, clari?ca 15 The resulting effect is that buoyancy is imparted to such

tion and puri?cation of waste Waters, such as industrial solid particles causing them to rise and ?oat upon the

waste waters or sewage, the process and apparatus be‘ surface of the mixture.

ing designed to function on a vacuum ?otation principle.

The gaseous ?lm surrounding each tiny particle, such

More particularly, the invention relates to an appara as described in the foregoing, may be one of the prod

tus and process which, in the ?otation of such waste, or 20 ucts of reaction between soluble compounds in the liquid

of minerals, contemplates the use of aeration in a man

and components on the surface of such solids. In the

ner whereby atmospheric air is drawn into the solid

case of sewage or industrial waste Waters, such soluble

liquid mixture by a vacuum or reduced pressure main

compounds may be considered as products of the decom

tained Within the reaction compartment. The invention position or digestion of organic material. Ordinarily,

contemplates separation of solids from liquid by a uni 25

organic acids are formed in decompositions of organic

form rising of such solids past a baffle structure, the lift materials and the chemical action of such acids upon the

ing being accomplished or induced by the imposition of solids of the mixture inevitably evolves gases of various

a vacuum in the upper portion of the reactor or vessel.

compositions. It is felt that in the practice of the pres

A principal object of my invention is the provision of

an apparatus and process which will create a more ef 30

ent invention, these gases ?lm or envelop the minute

?cient agitation and circulation of the solid-liquid mix suspended solids of the mixture, so that, under reduced

pressures or vacuum operation, their overall speci?c

ture than can be obtained in devices and processes here

gravities are‘ reduced to such an extent as ‘to render them

tofore known to the art under conditions of vacuum or buoyant in the described manner.

reduced pressure. Because of a continual upward move

ment of one phase of circulation of the solid-liquid mix 35 fulThere are‘ certain optimum conditions for the success

performance of the apparatus and process herein dis

ture from the feed inlet to the discharge outlet, the closed which should be observed.

agitation and circulation provided in my invention pro

motes a faster and more ef?cient ?otation and elimina

Firstly, to insure maximum development of gases of

tion of the ‘desired solids from the solid-liquid mixture. the type that will ?lm such solids, optimum pH condi

It is a further objective of my invention to accomplish 40

tions must be maintained in order that the proper gas

this high degree of agitation and circulation by means of eous reaction products will be formed. It has been found

atmospheric air drawn into the apparatus by the reduc— that a pH of approximately 7 of, for example, sewage

tion of pressure within the separator compartment. water promotes a condition for rapid chemical activity

Another objective of the invention is the provision of evolving gaseous reaction products which readily forms

means to continually cycle atmospheric air into solid 45 ?lms for the organic or other solids of the mixture.

Secondly, aeration of the mixture is vital as a means

liquid mixtures by an induced vacuum for the purpose

of creating a high degree of reactivity between the oxy— of introducing oxygen into the solution for promotion

gen drawn into the solid-liquid mixture and the solids and maintenance of such chemical activity. Aeration

is likewise important as a means to furnish the necessary

commonly found in such materials as industrial waste

waters or sewage. The process is thus particularly ap 50 gaseous medium which forms the bubbles necessary for

plicable to sewage treatment.

formation of the froth.

Another object of the invention is the provision of an Thirdly, constant agitation in the compartment is es

efficient, yet simple, apparatus and process which can sential to maintain the solids of the mixture in constant

be controlled easily by the operator and can be installed suspension and movement, thereby accelerating chemical

at very low cost. ‘ 55 reaction between the substances of the mixture. In the

My basic concept of a ?oatable solid is that the solid ‘ instant, invention, agitation is .accomplished by the con

particle be enveloped or ?lmed with a gaseous substance. joint effect of air introduction into the bottom of the

compartment and imposition of a vacuum at the top

This gaseous ?lmed solid is then in effect a weighted thereof.

bubble. Under conditions of vacuum this gaseous ?lm

expands, thereby imparting buoyancy to the solid par 60 Fourthly, circulation, as well as agitation, is essential

ticle. This buoyancy makes possible the rising of the to cause optimum separation between solids and liquid

solid particle to the surface of the pulp or sewage. The of the, mixture. In the instant invention, this circula

atmospheric air drawn into the solid-‘liquidl mixture is tion is obtained by utilizing a vacuum principle wherein

dispersed through the solid»liquid mixture in’ the form agitation is furnished by air bubbled into the mixture,

of bubbles. There bubbles tend to rise to the surface 65 the latter constantly being caused to rise within the

of‘ the solid-liquid mixture. Bubbles of gas are also compartment. Direction of movement of the solid-liq

formed when the dissolved gases of the liquid become in uid mixture is obtained by utilizing a suitable baffle and

soluble under conditions of a vacuum. Because of the the mixture is thereby caused to develop a helical course

agitation and circulation of the solid-liquid ‘mixture the from inlet to discharge outlet, thereby facilitating sep

gaseous ?lmed solids have many opportunities to collide 70 aration. The baffle also functions to break up or sep

with the countless gas bubbles created in the solid-liquid arate large bubbles of the froth into many smaller ones,

2,770,365

3 4

which are more effective in the ?otation procedure of solid-liquid mixture, ?nd an exit through this opening 22

this invention. to zone B of the apparatus. They then slide down the

Reference will now be made to a more particular de exterior of each of the plates 20 and 21 and are dis—

scription of my invention as disclosed in the drawings, charged from the compartment through appropriate dis

wherein: charge lines 42 and 44.

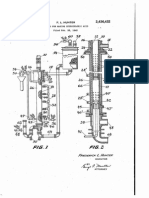

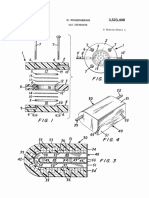

Figure l is a cross section of the apparatus used in An inlet for the solid-liquid mixture, ore and water

practicing the invention. mixture or other waste materials is provided on one side

Figure 2 is a section taken on the line 2-2 of Figure 1. of the compartment 1 and in the bottom of lower sepa

Figure 3 is a section taken on the line 3—3 of Figure 1. rating zone A, as indicated at 25. The outlet 26, for

Referring in more detail to these several views of the 10 residue after separation, is in line therewith and opposed

apparatus, it is seen that the closed compartment or re thereto upon the other side of the compartment.

actor is generally indicated at 1. As herein shown, it is A vacuum is induced as indicated in Figure 1 by a line

rectangular in shape, provided with sides 2 and 3 and 40 leading from a suitable vacuum source to the upper,

ends 4 and 5, all mounted on a base member 6. or separating zone B, of the compartment. As shown,

The top of the chamber 1 is comprised of two angularly 15 the vacuum line is directed to a point approximately over

disposed plates 7 and 8 which are interconnected at their the opening 22.

upper extremities by an additional transverse plate 9. In the practical use of the invention described in the

Obviously, these several walls of the compartment can 7 foregoing, a solid-liquid mixture of waste materials is

be fabricated in one piece or separately, as desired. introduced into the compartment through inlet 25 and a

The compartment 1 is divided into a lower separating 20 vacuum applied to line 40 in the upper part of the reac~

zone or chamber A and an upper separating zone or cham tor vessel. Lines 30 and 31 are opened to the desired ex

ber B by means to be hereinafter described. tent to permit atmospheric air to be admitted to the sepa

Located near the bottom of the compartment and in rating zone A through lines 30 and 31, which, as stated,

separating zone or chamber A is a well, or additional are located at desired distances throughout the length of

chamber, generally indicated at 11. It is open at top 25 the compartment. This air, under atmospheric pres

and bottom and formed of two longitudinal plates 10 sure and due to the vacuum induced in the upper portion

and 12, a?ixed at each of their opposite ends to the end of the compartment, is caused to bubble out the lower

plates 4 and 5 of the chamber 1. These members 10 ends of pipes 30 and 31 and rise between plates 10 and 12

and 12 are parallel to each other and positioned a rela and through chamber 11 of separating zone A. The

tively short distance above the base of the compartment operative effect of this rising column of bubbles is to cre

1 and extend approximately to the middle thereof. Such ate an air-lift of considerable force causing a rising of

plates also extend from the feed to the outlet end of the the solid-liquid mixture which impinges against the baffle

compartment. 15. The latter de?ects the whole mass of the mixture

Superimposed above and appreciably spaced from said toward the sides 2 and 3 of the compartment.

longitudinal plates is a ba?le 15 which, in this embodi Oxygen dissolved from the air so admitted to the solid

ment of the invention, has the shape of an inverted V, liquid mixture promotes and facilitates chemical activity

or with the sides thereof extending downwardly toward of the described type between the liquids and solids of the

the bottom of the compartment. As herein depicted, such mixture. Gaseous products of these reactions provide

ba?le 15 is located a short distance above the middle of gaseous ?lms for the solids in the mixture, reducing the

the compartment 1 and in the upper part of zone A. It 40 overall speci?c gravities of the ?lmed solids. When under

extends from end to end of the compartment. The pur reduced pressure the gas ?lms expand, thereby causing

pose of this baf?e is to de?ect the course of the rising them to also rise because of increased buoyancy in a

current of solid-liquid mixture in the lower part of the manner heretofore described.

separating chamber, or separating zone A thereof, pro Thus, the solid liquid mixture progresses toward the

moting agitation and separation of the solid-liquid mix opening 22 formed by plates 20 and 21 in an upward and

ture therein. 7 downward movement in a manner that can be described

A plurality of downwardly extending pipes, such as as helical.

those indicated at 30 and 31 are located on the center By coalescence and release of gas by the vacuum, a

line of the compartment 1. These pipes terminate in the foam or froth, low in gas and water content, is formed in

lower portion of the compartment and discharge at a the restricted opening 22. Such solids, which are not

point between the plates 10 and 12 of lower separating ?oated as a result of the ?rst air-lift, have countless op

zone A and appreciably above the bottom thereof. Al portunities for further ?otation as the solid-liquid mixture

though only two of such pipes are shown in the preferred is moved toward the discharge outlet 22. The vacuum

embodiment of the invention, it will be understood that lift then causes ?nal discharge of the largely solid material

any desired number may be employed depending upon which is emitted through this opening.

the particular conditions encountered, such as the length The circulation of the liquid-solid mixture through the

of the compartment, materials treated therein, etc. Such apparatus is best described as a helical movement through

pipes 30 and 31 are supplied for the purpose of leading zone A to discharge ?oated solids through 22 and out

air from the atmosphere, or oxygen, into the lower sepa lets 42 and 44. The un?oated solids and the liquid resi

rating zone of the compartment. Each of such pipes are 60 due is ultimately discharged through outlet 26.

provided with control valves 32 and 34 respectively The described continuous upward movement of the

utilized for the obvious purpose of controlling the amount solid-liquid mixture and its consequent impingement

of air admitted, so that admission thereof may be regu against the baffle 15 creates an et?cient agitation promot

lated to its optimum degree. ing maximum chemical activity further bene?cial to ?ota

The additional separation zone B in the upper portion 65 tion of the solids.

of the compartment is bounded by two angular plates The oxygen dissolved in the liquid as a result of aera

20 and 21, secured to the side walls 2 and 3 respectively tion provided by air drawn into the apparatus through

of the compartment. These plates divide the reactor into the pipes 30 and 31 causes and increases chemical activity,

the two separating zones A and B, heretofore referred producing gaseous end products and in sewage and waste

to. At their upper edges, each of these plates are ?anged water treatment transforms the suspended solids into

in a vertical direction to provide upwardly extending lips stable compounds with consequent puri?cation of such

forming a space or opening 22 therebetween. The ?oat waste waters. Such gaseous end products are suitable

able solid materials, because of buoyancy resulting from for forming gaseous ?lms upon the separate solid par

the expansion of their gaseous ?lms due to reduced pres ticles, as heretofore stated.

sure and/or attachment to bubbles created within the Furthermore, in sewage and waste water treatment

2,770,365

5 6

aerobic decomposition is continuously maintained as a above and adjacent said partitions, said lower chamber

result of the step of aeration through the introduction having opposed parallel plates disposed therein forming

of atmospheric air. Ordinarily, oxygen requirements in an air-lift compartment, a ba?'le with downwardly extend

activated sludge sewage treatment are high and cannot ing walls over said compartment and below said parti

generally be satis?ed by only the oxygen normally present tions, means to admit air under atmospheric pressure to

in the incoming sewage. For desirable and bene?cial re said compartment, said last-named means having control

sults, oxygen must be continuously supplied and replen valves to regulate the amount of air admitted7 means for

ished and the present apparatus and process is designed reducing pressure below atmospheric in said upper cham

to accomplish this function. ber, means on one side of said lower chamber to admit

It is emphasized that the importance and advantages of said materials, and exit means for the remainder of said

introducing atmospheric air into the reactor by the means materials on the other side of said lower chamber.

described are twofold: it enables ef?cient agitation and 3. A process for purifying a solid~liquid ?uid mixture

circulation to be easily accomplished and, secondly, as containing septic dissolved and suspended solids to render

outlined in the foregoing, it provide a source of oxygen said solids non-septic by partial decomposition due to

that is essential for ef?cient puri?cation of impure waters. 15 continuous aeration, agitation and circulation, said process

It will be further appreciated that my invention uniquely comprising the steps of charging said mixture to an initial

and advantageously combines two fundamental principles separating zone which is under constant vacuum pressure,

of operation: that of using a vacuum to induce constant de?ecting the upward ?ow of said mixture to provide a

upward ?ow of the solid-liquid mixture and introducing helical course through said zone, creating a condition of

oxygen or air through the same medium without the ne 20 turbulence through said zone by said de?ecting step and

cessity of employing superatmospheric pressures. Al~ the application of vacuum pressure, maintaining a vacuum

though processes and apparatus for the ?otation of min in a second separating zone, thereby to promote rising of

erals or for the treatment of waste waters have been both suspended and dissolved solids to said second zone,

devised heretofore, this combination of unique principles said second zone being in intercommunication with said

accomplishes simply and more etfectively the objectives 25 ?rst zone at the upper extremity thereof, admitting air

of previous processes. under atmospheric pressure to the lower portion of said

I claim: initial zone to additionally cause solid~d~issolving agitation,

1. An apparatus for scum ?otation of materials com circulation and oxidation of the solids of said mixture in

prising a vessel having two opposed and upwardly extend said initial zone, said oxidation resulting in partial dc‘

ing partitions therein forming upper and lower separatingr 30 composition of said solids in said initial zone, said oxida

chambers in said vessel, said partitions being spaced and tion causing said partially decomposed solids to ?oat to

terminating in vertical lips at their inner sides, thereby said second zone by reason of the buoyancy imparted

forming a passageway between said upper and lower thereto by adhering gases resulting from said decomposi

chambers, said lower chamber having opposed parallel tion, separating said ?oated solids by gravity ?ow from

plates disposed therein forming an air~lift compartment, said second zone, and discharging puri?ed liquid ‘from the

a ba?le with downwardly extending walls over said com‘ lower portion of said initial separating zone.

partment and below said partitions, means to admit air

under atmospheric pressure to said compartment, means References Cited in the ?le of this patent

for reducing pressure below atmosphere in said upper UNITED STATES PATENTS

chamber, means on one side of said lower chamber to 40

admit said materials, gravity exit means in said upper 1,253,653 Welsch ______________ __ Jan. 15, 1918

chamber for said materials, and exit means for the residue 1,312,754 Rowand _____________ __ Aug. 12, 1919

of said materials on the other side of said lower chamber. 1,706,281 Elmore ______________ __ Mar. 19, 1929

2. An apparatus for froth ?otation of materials com 2,158,976 Booth _______________ __ May 16, 1939

prising a vessel having two opposed and upwardly extend 45 2,307,154 Osuna ________________ __ Jan. 5, 1943

ing partitions therein forming upper and lower separating 2,324,400 Kelley et al. __________ __ July 13, 1943

chambers in said vessel, said partitions being spaced and 2,375,282 Clemens ______________ __ May 8, 1945

terminating in vertical lips at their inner sides, thereby FOREIGN PATENTS

forming a passageway between said upper and lower

510,125 Great Britain __________ __ July 27, 1939

chambers, gravity exit means for separated materials

You might also like

- US4767543Document6 pagesUS4767543Baba DookNo ratings yet

- Separation of Oil From Water by Dissolved Air FlotationDocument12 pagesSeparation of Oil From Water by Dissolved Air FlotationMarcosChaprãoNo ratings yet

- Lin 2003Document4 pagesLin 2003rospitauli24No ratings yet

- Drilling Fluids With AphronDocument7 pagesDrilling Fluids With Aphronsaa6383No ratings yet

- AWWA Article on Theoretical Principles of Water AerationDocument25 pagesAWWA Article on Theoretical Principles of Water AerationZafirahAhmadFauziNo ratings yet

- Bagan Dan Penjelasan PDFDocument3 pagesBagan Dan Penjelasan PDFYonatan AdiNo ratings yet

- Cavitation: For Other Uses, SeeDocument12 pagesCavitation: For Other Uses, SeepranavNo ratings yet

- Novel Hydrodynamic Cavitation Reactor Conceptual DesignDocument14 pagesNovel Hydrodynamic Cavitation Reactor Conceptual DesignSagarGuptaNo ratings yet

- A Report About Cavitation Phenomenon-By Murtadha Adil Tahir jassim - مرتضى عادل طاهر جاسمDocument15 pagesA Report About Cavitation Phenomenon-By Murtadha Adil Tahir jassim - مرتضى عادل طاهر جاسمAnmar HamidNo ratings yet

- CavitationDocument6 pagesCavitationPackianathan SarathNo ratings yet

- ABSORBERDocument7 pagesABSORBERDendy Wahyu RadityaNo ratings yet

- Reduce Water Vapor in Vacuum Systems with Dry Gas TechniquesDocument3 pagesReduce Water Vapor in Vacuum Systems with Dry Gas TechniquesEduardo LopesNo ratings yet

- Inertial Cavitation: Lord Rayleigh PressureDocument4 pagesInertial Cavitation: Lord Rayleigh PressureChemicalengineersaqiNo ratings yet

- Nitrogen oDocument36 pagesNitrogen oGabriel Ignacio SilvaNo ratings yet

- SupercavitationDocument31 pagesSupercavitationPankaj SattawatNo ratings yet

- Wet Column Pressure Drop LabDocument7 pagesWet Column Pressure Drop Labizarini taqwaNo ratings yet

- AAPG - Acoustic Well LoggingDocument129 pagesAAPG - Acoustic Well Loggingbalu10000No ratings yet

- ANEXO 8 US2436432 A Método para La Fabricación de Ácido Clorhídrico (18 de Mayo 1937)Document7 pagesANEXO 8 US2436432 A Método para La Fabricación de Ácido Clorhídrico (18 de Mayo 1937)CésarSánchezRosasNo ratings yet

- F4 Processes in FoamingDocument43 pagesF4 Processes in FoamingpadungekNo ratings yet

- PURPOSE OF AGITATION VESSELSDocument5 pagesPURPOSE OF AGITATION VESSELSMAHAD ZahidNo ratings yet

- Purpose of Agitation VesselDocument5 pagesPurpose of Agitation VesselMAHAD ZahidNo ratings yet

- ChemistryDocument33 pagesChemistryTakshak KhandelkarNo ratings yet

- Separation and Purification Technology: SciencedirectDocument10 pagesSeparation and Purification Technology: SciencedirectBelen TapiaNo ratings yet

- Effect of Frothers and Dodecylamine On Bubble Size and Gas Holdup in A Downflow Column PDFDocument7 pagesEffect of Frothers and Dodecylamine On Bubble Size and Gas Holdup in A Downflow Column PDFJose Luis Barrientos RiosNo ratings yet

- Recycle PTQDocument6 pagesRecycle PTQremsorNo ratings yet

- Fischer Tropsch ProcessDocument7 pagesFischer Tropsch ProcessNestor AquinoNo ratings yet

- Mechanical Separation TechDocument21 pagesMechanical Separation TechNkugwa Mark WilliamNo ratings yet

- Cavitation_WikipediaDocument21 pagesCavitation_WikipediaThommas HofmannNo ratings yet

- A Method For Particle Size Amplification by Water Condensation in A Laminar Thermally Diffusive FlowDocument10 pagesA Method For Particle Size Amplification by Water Condensation in A Laminar Thermally Diffusive FlowoksanaNo ratings yet

- CavitationDocument11 pagesCavitationphutd09No ratings yet

- EP0670178A2Document9 pagesEP0670178A2gta gtaNo ratings yet

- Us 3572375Document9 pagesUs 3572375Alex KattamisNo ratings yet

- United States Patent (191: StormoDocument18 pagesUnited States Patent (191: StormoPranav NakhateNo ratings yet

- The Votator Process for Chilling and Aerating Oils and FatsDocument3 pagesThe Votator Process for Chilling and Aerating Oils and FatsGrecia SuffoNo ratings yet

- Paraffinic Sludge Reduction Through Shearing and ResuspensionDocument5 pagesParaffinic Sludge Reduction Through Shearing and Resuspensionger80No ratings yet

- A Perspective On Flotation, A ReviewDocument24 pagesA Perspective On Flotation, A ReviewCarlos LopezNo ratings yet

- From Air Sparged Hydrocyclone To Gas Energy Mixing (GEM) Floration, Clean Water TechnologyDocument18 pagesFrom Air Sparged Hydrocyclone To Gas Energy Mixing (GEM) Floration, Clean Water TechnologyCamille Nunes LeiteNo ratings yet

- TugasDocument1 pageTugasDAVE DERALDYNo ratings yet

- A New Breakup Regime of Liquid Drops Identified in A Continuous and Uniform Air Jet Flow 2007Document7 pagesA New Breakup Regime of Liquid Drops Identified in A Continuous and Uniform Air Jet Flow 2007李海鹰No ratings yet

- Varas Et Al 2011Document7 pagesVaras Et Al 2011Gabriela Leal PinheiroNo ratings yet

- G - D B F: Ravity Riven Ubbly LowsDocument32 pagesG - D B F: Ravity Riven Ubbly LowsAnkitPatel90No ratings yet

- Dissolved Air Otation Model For Drinking Water Treatment: Canadian Journal of Civil Engineering February 2011Document11 pagesDissolved Air Otation Model For Drinking Water Treatment: Canadian Journal of Civil Engineering February 2011andrei_bertea7771No ratings yet

- The Production of Instant Foods by Jet AgglomerationDocument22 pagesThe Production of Instant Foods by Jet AgglomerationpraveenchinnaNo ratings yet

- Gas AbsorptionDocument8 pagesGas Absorptionfarah hannahNo ratings yet

- Effects of Dissolved Gas Supersaturation and Bubble Formation On Water Treatment Plant PerformanceDocument178 pagesEffects of Dissolved Gas Supersaturation and Bubble Formation On Water Treatment Plant PerformanceherybudiantoNo ratings yet

- A Novel Rapid Temperature Swing Adsorption Post Combustion CO2 - 2017 - Energy PDocument10 pagesA Novel Rapid Temperature Swing Adsorption Post Combustion CO2 - 2017 - Energy POjomopeterNo ratings yet

- Column Flotation Systems With Cavitation TubeDocument8 pagesColumn Flotation Systems With Cavitation TubeRogério Leonardo OliveiraNo ratings yet

- Processes: Analysis of Bubble Flow Mechanism and Characteristics in Gas-Liquid Cyclone SeparatorDocument14 pagesProcesses: Analysis of Bubble Flow Mechanism and Characteristics in Gas-Liquid Cyclone Separator43No ratings yet

- Breccias Volcanoes and MineralizationDocument5 pagesBreccias Volcanoes and MineralizationGeo Geo GeoNo ratings yet

- Pickell 1966Document7 pagesPickell 1966pavka789100% (1)

- Hamadi - IJRER - 2017Document21 pagesHamadi - IJRER - 2017Meli ChiambaNo ratings yet

- Spe 25758Document16 pagesSpe 25758Ariel CorredoresNo ratings yet

- Stoke's LawDocument6 pagesStoke's Lawjlcheefei9258No ratings yet

- Fluidisation stages and applicationsDocument6 pagesFluidisation stages and applicationsdevilturn70No ratings yet

- Bubble Size in Forced Circulation Loop Reactor (Ej) (FADAVI Et Al) (J of Chem Techn & BioTechn v83 2008) (4s) #PG (105-108)Document4 pagesBubble Size in Forced Circulation Loop Reactor (Ej) (FADAVI Et Al) (J of Chem Techn & BioTechn v83 2008) (4s) #PG (105-108)ScribdManíacoNo ratings yet

- Confined Fluid Phase Behavior and CO2 Sequestration in Shale ReservoirsFrom EverandConfined Fluid Phase Behavior and CO2 Sequestration in Shale ReservoirsNo ratings yet

- Nucleation of Water: From Fundamental Science to Atmospheric and Additional ApplicationsFrom EverandNucleation of Water: From Fundamental Science to Atmospheric and Additional ApplicationsNo ratings yet

- Blasting in Ground Excavations and Mines by B. Singh, P. Pal Roy, R. B. Singh, A. BagchiDocument94 pagesBlasting in Ground Excavations and Mines by B. Singh, P. Pal Roy, R. B. Singh, A. BagchiStajic MilanNo ratings yet

- Engineering Rock Blasting OperationsDocument195 pagesEngineering Rock Blasting OperationsCSTubarao95% (21)

- Underground Mine DesignDocument88 pagesUnderground Mine DesignStajic Milan100% (2)

- Block ModellingDocument118 pagesBlock ModellingStajic MilanNo ratings yet

- Explosive Principles - SicklerDocument62 pagesExplosive Principles - SicklerNicolas MafraNo ratings yet

- Geological DatabaseDocument145 pagesGeological DatabaseStajic MilanNo ratings yet

- Petrosjan, M. I - Rock Breakage by Blasting-Balkema (1994) PDFDocument156 pagesPetrosjan, M. I - Rock Breakage by Blasting-Balkema (1994) PDFahmedNo ratings yet

- (Agne - Rustan) Rock - Blasting - Terms - and - Symbols PDFDocument102 pages(Agne - Rustan) Rock - Blasting - Terms - and - Symbols PDFAnonymous ntE0hG2TPNo ratings yet

- Agne Rustan - Et Al-Rock Mechanics, Drilling and Blasting Desk Reference PDFDocument460 pagesAgne Rustan - Et Al-Rock Mechanics, Drilling and Blasting Desk Reference PDFMeša SelimovićNo ratings yet

- Underground Ring DesignDocument50 pagesUnderground Ring Designgeorgesar7No ratings yet

- Advanced Underground MassiveDocument70 pagesAdvanced Underground MassiveYuris EnfikNo ratings yet

- PlottingDocument167 pagesPlottingnine7tNo ratings yet

- Interpolador SurpacDocument19 pagesInterpolador Surpacgeorgesar7No ratings yet

- DTM SurfacesDocument67 pagesDTM Surfacesgeorgesar7No ratings yet

- SSILMDocument13 pagesSSILMStajic MilanNo ratings yet

- Pit DesignDocument96 pagesPit DesignStajic Milan100% (2)

- Road Design PDFDocument80 pagesRoad Design PDFM RamadanaNo ratings yet

- Surpac IntroductionDocument207 pagesSurpac IntroductionKrist Jan Jimenez Separa0% (1)

- LicenceManager User GuideDocument33 pagesLicenceManager User GuideStajic MilanNo ratings yet

- Licence ManagerDocument58 pagesLicence ManagerStajic MilanNo ratings yet

- Introduction To TCL SCLDocument89 pagesIntroduction To TCL SCLStajic Milan100% (4)

- Hub 1.7.1 ClientQuickStartGuideDocument3 pagesHub 1.7.1 ClientQuickStartGuideStajic MilanNo ratings yet

- Nie Haotian ThesisDocument72 pagesNie Haotian ThesisStajic MilanNo ratings yet

- SolidsDocument134 pagesSolidsStajic MilanNo ratings yet

- Tur 1Document180 pagesTur 1Stajic MilanNo ratings yet

- Sequentially Linear Continuum Model For Concrete FractureDocument9 pagesSequentially Linear Continuum Model For Concrete FractureStajic MilanNo ratings yet

- Streaming FilesDocument33 pagesStreaming FilesStajic MilanNo ratings yet

- Vertical Crater RetreatDocument30 pagesVertical Crater Retreatyorka25100% (2)

- Aegis - New Features - 2018-06 v1Document27 pagesAegis - New Features - 2018-06 v1Stajic MilanNo ratings yet

- DBS Drill & Blast ManagementDocument3 pagesDBS Drill & Blast ManagementStajic MilanNo ratings yet

- 2d MLN NozzleDocument86 pages2d MLN NozzleP K100% (1)

- Effect of Duty Cycle On Catalytic Thruster Degradation - ArchiveDocument6 pagesEffect of Duty Cycle On Catalytic Thruster Degradation - ArchiveHari PrasannaNo ratings yet

- General Chem Exam 1Document8 pagesGeneral Chem Exam 1emlfemNo ratings yet

- Laminating Techniques For Converters of Laminating AdhesivesDocument6 pagesLaminating Techniques For Converters of Laminating Adhesivescmmswim67No ratings yet

- D.V.S. MurthyDocument14 pagesD.V.S. Murthypusd_9040% (5)

- Rankine Theory PDFDocument23 pagesRankine Theory PDFHamza NadeemNo ratings yet

- GASES With Varying Path LengthDocument12 pagesGASES With Varying Path LengthKristine Ann VillanuevaNo ratings yet

- Thermo Lectures (Intro, Units & Properties)Document13 pagesThermo Lectures (Intro, Units & Properties)Basil BautistaNo ratings yet

- Classification of Tests:: Testing Procedures of A PumpDocument8 pagesClassification of Tests:: Testing Procedures of A PumpMohamad Izwan HussienNo ratings yet

- 2015 LectDocument78 pages2015 LectwantoknooNo ratings yet

- M.engineering - Piping SystemsDocument55 pagesM.engineering - Piping SystemsKordalhs KyriakosNo ratings yet

- Guide To The Use of en 1991-1-4 Wind ActionsDocument21 pagesGuide To The Use of en 1991-1-4 Wind ActionsmickmannersNo ratings yet

- 11 Fluids SDocument26 pages11 Fluids SapocalypticNo ratings yet

- Ultrasonic flowmeters for flexible measurementDocument39 pagesUltrasonic flowmeters for flexible measurementkatakliztmaNo ratings yet

- Introduction To PumpsDocument9 pagesIntroduction To PumpsJaydeep TrivediNo ratings yet

- Three Way Valve - Mixing & Diverting TypeDocument7 pagesThree Way Valve - Mixing & Diverting TypehorascanmanNo ratings yet

- Pdhs1a102 IclxDocument28 pagesPdhs1a102 IclxTân Phan VănNo ratings yet

- Pressure Vessel Accidents: Hazard Awareness and Precautions (WCE 2010Document4 pagesPressure Vessel Accidents: Hazard Awareness and Precautions (WCE 2010victorvikramNo ratings yet

- Marcet Boiler Lab Analyzes Steam PropertiesDocument14 pagesMarcet Boiler Lab Analyzes Steam PropertiesSims Gift ShibaNo ratings yet

- Basic Properties of Reservoir RockDocument102 pagesBasic Properties of Reservoir RockAli Al-Ali100% (4)

- Iptc 13784 MS PDocument9 pagesIptc 13784 MS PSergio Flores100% (1)

- Series R1E02 General Description Technical Information: Pressure Relief ValvesDocument3 pagesSeries R1E02 General Description Technical Information: Pressure Relief Valvesshahrol effendy rodziNo ratings yet

- C-15 Petroleum EnginesDocument64 pagesC-15 Petroleum Enginesmohammad hazbehzad100% (1)

- Maximizing Pressure PerformanceDocument2 pagesMaximizing Pressure PerformancePRAMOD KUMARNo ratings yet

- Chapter1&2 2023 - 2024Document85 pagesChapter1&2 2023 - 2024Sulaiman ObaidNo ratings yet

- Static and Modal Analysis ProceedureDocument7 pagesStatic and Modal Analysis ProceedureMukildev DevadasNo ratings yet

- Hydraulics Basic LevelDocument14 pagesHydraulics Basic LevelIndhusekaran NatarajanNo ratings yet

- Bernuili EquationDocument15 pagesBernuili EquationHaitham AliNo ratings yet

- Deadweight Testers&Gauges ManualDocument58 pagesDeadweight Testers&Gauges ManualReydale CachoNo ratings yet

- Valeport Midas CTDDocument67 pagesValeport Midas CTDXhuLE7oNo ratings yet