Professional Documents

Culture Documents

Bottle Filling Devices

Uploaded by

alguna540 ratings0% found this document useful (0 votes)

8 views5 pagesGROSBOIS - US2822830A

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentGROSBOIS - US2822830A

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views5 pagesBottle Filling Devices

Uploaded by

alguna54GROSBOIS - US2822830A

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

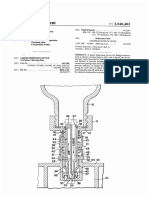

Feb. 11, 1958 L. GROSBOIS 2,822,830

‘BOPTLE FILLING DEVICES

Filed Jan. 26, 1954 2 Sheots-Shoot 1

L INVENTOR.

w Oe Graben.

Maulage

Feb. 11, 1958 L. GRosBoIs 2,822,830

BOTTLE FILLING DEVICES

Filed Jan. 26, 1954 2 Sheets-Sheot 2

WJ

acearees,

United States Patent Office

1

2,822,830

‘BOTTLE FILLING DEVICES

Lucien Grosbols, Lyon, France, assignor to Société Nou-

elle des Anciens Etablissements TF, Wenger, Paris

France, a limited liability company of France

Application January 26, 1954, Serial No. 406,210

$ Claims. (Cl, 141—59)

‘This invention refers to bottle filing devices wherein a

partial vacuum created in the storage tank prevents the

quid trom flowing from the filing nozzle when the latios

is not in engagement with a bottle. When the nozzle is

engayed with a bole the liquid may on the contrary

flow freely from the nozzle into the bottle wheh is thus

progressively filled. When the bottle thus filled is re.

moved trom the nozzle, air from the outer atmosphere

flows through the nozzle towards the storage tank where

by the liquid still within the nozale is expelled into tho

tank,

A ‘rst abject of this invention is to provide a bottle

filing device of the kind above referred to wherein the

‘height of liguid within the filled bottles may be determined

by stopping the flow of liguid from the taak into the

bottles being filled when the level within the latter hse

reached predctermined point, without having to rely

fon additional means or on the return of am excess of

Liquid from the bot into the tank,

‘Still another object of this invention is to limit the

‘quantity of air sucked into the storage tank, to reduce the

‘minimum value of the negative pressure required in the

tank for satisfactory operetion and to avoid aeration of the

liguid within the tank by air bubbles from the filling nozzle

oF nozzles associated therewith,

According to this invention a bottle fling device com-

prises a constant level storage tank within whieh there 1s

‘ainisined a substantially constant negative pressure, fil.

ing nozzles connected with this tank by the ascendiag

branch of passageways in the form of a syphon tube and

‘an air exhaust tube associated to each filing nozzle, the

said tube having its lower end so arranged that it is en

‘gaged into the neck of the bottle being filed, while its up.

‘per end opens in the sir space of the storage tank.

twill be apprecisted that with such an arrangement the

negative pressure within the tank may be 40 adjusted that

when no bottle is engaged with a given nozzle the Liquid

in the syphon passageway may be located. below the

"uppermost point of the latter, whereby no flow of laud

through the nozzle caa take place. “When on the conttary

the nozzle is in engagement with the neck of a bots,

the pressure within the Iatter becomes equal to the re. °

duced pressure prevailing within che tank and liquid may

freely flow through the passageway and through the

nozzle, the air from the latter escaping progressively

through the air exhaust tube, When the level in the bottle

reaches the lower end of the ait exhaust tube the air sill

present in the upper portion of the botlle neck may 00

‘more escape and the flow of liquid is stopped. ‘The air

therefore raises towards the uppermost point of the

syphon passageway where itis so to speak entrapped and

therefore prevents any further flow of liquid iato the

bottle, When the bottle is removed air from the outer

atmosphere flows into the nozale and thus re-establishes

the level of liquid in the passageway to its original height,

Air also flows into the storage tank through the aif ex:

hhaust tube end the small quantity of liqutd present in this

tube is thus expelled into the tank,

0

16

20

0

0

50

70

2,822,830

Patented Fek. 11, 1958

2

In the annexed drawings:

Fig. 1 is a diggrammatical vertical section of a filing

device according to the first embodiment ofthis invention,

Figs. 2 to 4 are partial views similar to Fi

ing the successive steps of a filling operation,

Fig. 3 is a longitudinal section of a filing head ac-

cording to the diagrammatical represeatation of Fig. I,

Figs. 6 to 10 are views respectively corresponding 6

Figs. 1 to 5, bur illustrating a second embodiment of this

inveation,

‘The device diagrammatically illustrate

prises a storage tank 1 connected by a tube 2 with a

blower or like machine adapted to create within Yank £

{constant negative pressure of relatively small value, for

instance corresponding to somo centimetres of water,

‘The tank 1 contains the liquid with which the bottles sve

to be filled. | This liquid may be of any kind provided

it is not Hable to evolve gas under the action of the Te-

duced pressure (partial vacuum) to which itis submitted,

‘The level A—A of this liquid within the tank remains

onstaat and in the example illustrated this is oblained

by supplying liguid to the tank by means of a pipe 3

closed by a needle valve controlled by a float 5. To the

Sotiom of tank 1 there is fixed a downwardly opening

hhead adapted to receive the neck of the bottle to be

filled, such head being formed with a passageway in the

form of @ syphon extending between the task and the

portion of the head where the neck of the bottle is to be

received. In the example illustrated the head comprises

a lower sleeve 6 and an upper sleeve 7 of smaller diam.

eter forming an upward extension of the former, these

sleeves being connected with each other by a shoulder x.

bellshaped body 8 is disposed over the sleeves thus ar.

Tanged, its lower edge being at a small distance above the

bottom of tank 1. The filing head also comprises an

axial air exhaust tubo 9 with its lower end well below

the shoulder connecting sleeves 6 and 7 while its upsoe

{end opens within tank I above the liquid level A—-A in the

The height of the liquid level A—A within the tank

and the negative pressure prevailing in the ait space of

the same are so determined that when no bottle sen

gaged into the heed described the level of liquid within

the bell-shaped body $ is situated at B—B above the

lower edge of body 8 but below the upper edge of sleeve

7, Xt will be appreciated that the difterence a between

levels A—A and B—B corresponds to the nepative pre

sure in the air space of the tank with respect to the outer

atmospheric pressure. At this position of rest ait com

tinuously flows into the tank through the sir exhaust fate

9, but the blower which creates the negative pressure suche

this air and maintains the reduced pressure required,

Tube 9 may be of relatively small diameter.

When the neck of a bottle is engaged into the sleeve 6

(Fig. 2) and is tightly pressed against the shoulder which

gonnects the sleeves 6 and 7, the inner space of the fling

head is isolated from the outer atmosphere. Due to the

presence of the air exhaust tube 9 the pressure within the

bottle becomes equal to the reduced pressure prevailing

jn the air space of the tank 4 and the difference w of

Fig. I no more prevents liquid from risiag within the

bell-shaped body 8. ‘The liquid therefore flows over the

edge of sleeve 7 into the neck 10 of the botle while the

air from the latter escapes axially through the air exhaust

tube 9. ‘The syphon is thus started.

‘When the bottle is filled to the desired degree the

liquid level reaches the lower end of tube 9 (Fig. 3) and

the exhaust of air through the latter is no more pos-

sible.” The normal flow of liquid is thus stopped. ‘The

small quantity of liquid in the upper portion of the head

flows down gently into the bottle along the walls of the

neck while the air from the upper portion of the bottle

Fig. 1 com.

2,822,880

neck rises towards the upper end of the sleeve 7. When

‘the liquid level in the bell-shaped body 8 has reached

the edge of sleeve 7, tis residual flow cesses. The level

in the bottle neck 10 is now at C=C-slightly. above the

Tower end of the air exhaust tube 9 and in the latter it

has raised to D—D. ‘The difference b between the levels,

CC and D—D is of course equal to the difference

between the level A—A and the level EE of the upper

end of sleeve 7.

‘When the botile is removed (Fig. 4) te atmospheric

pressure is re-established within body 8 aud within the

heck 20 of the bottle, The level of liquid in body 8 is

thus returned to the horizontal plane B—B of Fig 1

fand the small quantity of liquid which was in tube 9 is

‘expelled into the storage tank 1

Tt is to be remarked that doring-the whole fing op-

eration no air has been allowed to bubble through the

Figuid. The latter is not therefore unduly aerated. The

fiaal level of liquid in the bottle neck is exactly deter-

snined by the lower end of the air exttaust tube 9. The

ead comprises no liquid nozzle dipping into the bottle

whereby the cross-section of the bottle neck may be fully

tsed, which is of importance with bottles provided with

necks of small diameter.

Fig. 5 shows the preferred construction of the head

described. In this construction the sleeve 6 is welded

to the bottom of the storage tank 4, although it could be

fxed by any other means. A lower tubular guide 11

fs slidably arranged in sleeve 6, the said guide having a

flaring lower end to recsive the bottle neck. ‘The outer

periphery of guide 11 is provided with a. longitudinal

Broove 1a into which projects the end of a screw 6a

Strowed in the sleeve wall. The upper end of sleeve 6

receives an annular member 12 made of a plastic max

ferial such as rubber and on member 42 fits another an-

fnular member 13 which plays the role of the sleeve 7 of

Fig. 1. The annular member 13 is covered by the body

8 in the form of a conical bell having a cylindrical lower

portion which strrounds the sleeve 6 with a substantial

Fnermediate annular space, Ribs 14 maintain the cone

fal portion of body 8 spaced from the annular member

$B. "The lower edge 82 of the lower cylindrical portion

Gf body 8 is of smaller diameter and it fis on the sleeve

6 wherein it is Hxed by a bayonet joint. Openings 8

fre provided in the wall of body 8 immediately above

the fower edge 8a to permit inlet of liquid into the said

ody. The air exhatst tube 9 is passed through the

luppermost portion of body 8 where it is screwed. The

Tower portion of tube 9 carries a conical deflector 15

Iocated below the annular member 13 to prevent liquid

from running along the tube.

TE will be observed that the construction described

permits of readily removing the parts for cleaning pur

poses.

"in the modification of Fis.

‘does not extend downwardly as in Fig. 1, but it is cov-

Gred by a eylindro-conical cap 16 which extends below

‘ho said body and terminates at a small distance above

{he bottom of the tank. This eap also extends upwardly

fn the form of a cylindrical sleeve 17 which surrounds

fhe air exhaust tube 9 and terminates above the Tiquid

fevel AA in the tank, its upper end forming a cali

‘brated annular office around tube 9.

‘In the absence of any bottle the liquid Tevel within

cap 16 is at FF, that is between the lover edge of

Saly $ and the lower edge of cap 16. Air from the

pore atmosphere may therefore low into the nk through

‘he annular passage between the cylindrical extension 17

the Mike tube 9 as well as through the tube 9 itself. But

ating to the restricted cross-section of the annular pas- 7

Stes the pressure within the cap 16 is substantially higher

than the pressure in the air space of the tank. This dit-

ference of pressure is represented by the difference ©

foween the levels A—A and FF.

‘When the neck of the bottle to be filled is engeged

6 the bellshaped body 8 5

10

6

20

2

20

40

into sleeve 6 (Fig. 7) the pressure decreases in the body

8 and in the bottle, The liquid therefore rises in the

head and the syphon is started as in the preceding case.

“Tho botile is progressively filled while air escapes chroush

‘the axial tube 9 into the storage tank 1. It will be noted

that owing to the pressure drop resulting from the flow

‘of liquid into the bottle the liquid level in the cylindrical

extension 17 is at G—G slightly below the level A—A

fn the tank. When the level in the bottle reaches the

lower end ofthe air exhaust tube 9, the flow of liquid is

Hopped and tie level ia the tube 9 rises to a height d

(Fig, 8) equal to the difference between the level A—A.

in the tank and the level E—E of the upper edge of the

upper sleeve 7.

"ven the bottle is removed (Fig. 9) the outer air

‘ows into the bottle aeck and into body 8. ‘The small

quantity of liquid present in tube 9 is expelled into the

fank 1, ~The liquid which was in the upper portion of

the cap 46 flows down while air bubbles up through this

owing liquid and escapes through the upper end of the

extension 17. ‘The liquid level within cap 16 then re-

turns to the position F—F of Fig. 6.

Tt will be appreciated that the operation of the modi

fication described is substantially the same as in the frst

embodiment illustriaed in Figs. 1 to 4. The negative

[pressure required i however higher since the liquid level

In the filing head must be brought lower than in the

‘fist case. The bubbling of air through the liquid when

the bottle is removed is sometimes undesirable, ‘The

How of air into the storage tenk in the absence of a bot-

fle is more important. This modified embodiment may

however be of advantage in some cases, for instance

then itis desired to feed the storage tank from sn open

Texerveir without any pump or the like, which requires

i substantial negative pressure ia the tank.

Fig, 10 illustrates the preferred construction of the

filing head of Fig, 6. The sleeve 6, the slidable guide

TH aad the annular member 12 of rubber or other plas:

fie material are those already described with reference

fo Fig, 5. The anmular member 12 supports a conical

body 19 provided with a downward cylindrical exten-

Zion which fits en sleeve 6 whereon it is fixed by a bayo-

et joint. This body 19 is formed with a contral cavity

20 opening downwardly and with passages 24 in the form.

of syphon tubes extending from this central cavity to the

Serighery. of the said body. Body 39 in turn carries

Pas puter cap 16 of eylindro-conical shape which is spaced

therefrom by aibs 16a, The lowermost ribs 162 coop-

waste with coasse pitch threads provided on the periphery

Gf body 19. Cap 16 extends upwardly in the form of

She cplindrical extension or sleeve 17 and the calibrated

Gtince of passage is obtained by leaving a sufficiently

Shall annular space between extension 47 and the ait

SMhaust tube 9 serewed through body 19. Here also the

Satious parts are readily removable for cleaning or other

purposes. .

“The body 19 may be made into two parts disposed one

above the other with an intermediate space forming pe

sages 24

T claim:

1A filing device for bottles comprising » constant

evel storage tank in the sir space of which there is main-

{ined a substantially constant negative pressure: a filing

vate disposed below the level of liquid within said

Reratant level storage tank and connected with said storage

tank by a passage in the form of a syphon duct having an

Eavendiag branch opening in said tank, the height of the

jigoid within the tank above the horizontal plane of the

Hover end of said ascending branch being greater than

The fective height of said ascending branch and then

{he hydraulic head corresponding to the negative pres:

rae eyeintsined in the air space of said tank, but smaller

thus said hydraulic head plus the effective heisht of said

ther ing branch; and an air exhaust tube associated to

aid fling nozzle, said air-exhaust tube having its lower

2,822,880

5

fend so disposed with respect to said nozzle that it is en-

gaged into the neck of the bottle being filled while its

‘upper end opens in the air space of said tank.

2. A filing device for bottles comprising a constant

level storage tank in the air space of which there is main-

tained a substantially constant negative pressure; a sleeve

vertically fixed to the bottom of said tank and opening

through said bottom below the level of the liquid within

Said tank, said sleeve being adapted to receive the neck.

of a bottle to be filled; a sealing washer of plastic material

Aisposed at the upper end of said sleeve, sald washer

having a lower inner diameter than said sleeve in such

44 manner that the upper end of the neck of the bottle

being filled may bear tightly against sald washer; a body

mounted at the upper end of said sleeve on said washer,

said body having a central cavity opening downwardly,

above the central hole of said washer to form # filing

nozzle therewith, and ssid body being provided with pas:

sages opening on the one side in this cavity and on the

other side on the periphery of said body at & lower level

than in the cavity so as to form the ascending branches

‘of syphon duct between said tank and said slewve: the

height of the liquid within the tank above the horizontal

plane of the lower end of said ascending branches being

sreater than tne effective height of said ascending branches

‘and than the hydraulic head corresponding to the nega.

tive pressure maintained in the air space of said task,

Dut smaller than said hydraulic head plus the effective

hicight of said ascending branches; and an axial air ex

hhaust tube passed vertically through said body with its

‘epper end opening in the air space of said tank and with

its lower end so disposed below said washer that itis ex

‘aged into the neck of the bottle being filled substantially

at the filling height desired for said bottle,

3. A filling device for bottles comprising @ constant

lovel storage tank in the air space of which there is main

tained 2 substantially constant negative pressure; a sleeve

vertically fixed to the bottom of said tank and opening

through said bottom below the level of the liguid within

said tank, said sleeve being adapted to receive the neck

‘of a bottle to be filled; a sealing washer of plastic material

disposed at the upper end of said sleeve, said washer

having a lower inner diameter than said sleeve in such

4 manner that the upper end of the neck of the bottle

being filed may bear tightly against said washer; a body

‘mounted at the upper end of said sleeve on said washer,

said body having a central cavity opening downwardly,

above the central hole of said washer to form a filling

fozzle therewith, and ssid body being provided with pas:

sages opening on the one side in this cavity and on the

‘other side on the periphery of said body at a lower level

than in the cavity so as to form the ascending branches

of a syphon duct between said tank and said sleeve, the

height of the liquid within the tank above the horizontal

plane of the lower end of said ascending branches being

‘eater than the effective height of said ascending branches

‘and than the hydraulic head corresponding to the negn-

tive pressure maintained in the air space of said tank. but

smaller than said hydraulic head plus the effective height

Of said ascending branches; a covering cap disposed oa

said body with its lower edge below the openings of said

passages on the periphery of suid body, said cep communi

cating with the air space of said storage tank through a

calibrated orifice; and an axial air exhaust tube passed

vertically though said body with its upper end opening

in the air space of said tank and with its lower end so

6

disposed below said washer that it is engaged into the

neck of the botle being filled substantially at the Ailing

height desired for said bottle.

4. A filling device for bottles comprising a constant

‘5 level storage tank in the air space of which there is main.

tained a substantially constant negative pressure; « sleeve

Vertically fixed to the bottom of said tank and opening

through said bottom below the level of the liquid withia

said tank, said sleeve being adapted to receive the neck

of a bottle to be filled; a sealing washer of plastic material

isposed at the upper end of said sleeve, said washer

having a lower inner diameter than said sleeve in such

‘@ manner that the upper end of the neck of the bottle

being filled may bear tightly against said wasber; a body

‘mounted at the upper end of said sleeve on said washer,

said body having a central cavity opening dowawardly,

above the central hole of said washer to form a filling

nozzle therewith, and said body being provided with pase

sages opening on the one side in this cavity and on'the

20 other side on the periphery of said body at a lawer level

tan in the cavity so as to form the ascending branches of

syphon duct between said tank and said sleeve, the

height of the liquid within the tank above the horizontal

plane of the lower end of said ascending branches being

‘greater than the effective height of said ascending branches

and than the hydraulic head corresponding to the negalive

Pressure maintained in the air space of said tani but

smaller than said hydraulic head plus the eflecive height

of said ascending branches; a covering cap disposed ‘on

said body with its lower edge below the openings of sald

passages on the periphery of said body, said cap being of

evlindro-conical shape and being formed with an upward

axial tubular extension opening in the air space of said

tanks and an axial air exhaust tube pasied vertically

38 through said body and extending through said tubular ex.

tension with a restricted clearance, the upper end of said

‘ube opening in the air space of said tank above

tubular extension, while the lower end of said tube is so

disposed below said washer that it is engaged into the

neck of the bottle being filed substantially at the filling

height desired for said bottle.

5. A filling device for bottles comprising & constant

lovel storage tank in the air space of which there is maint

tained a substantially constant negative pressure; a filling

nozzle connected with said storage tank by 2 passage in

the form of a syphon duct having an ascending branch

‘opening in said tank, the level ofthe liquid within the tank

being substantially above the upper bend of said syphon

ddact, and said filing nozzle opening downwardly below

the lower end of the ascending branch of said syphon

duct within said tank; and an air exhaust tube associated

to said filing nozzle, said air exhaust tube having it

lower end so disposed with respect to said nozzle tha

is received within the neck of the bottle being filled while

its. upper end opens in the air space of said tank,

0

1s

25

30

“0

45

50

55

References Cited in the file of this patent

UNITED STATES PATENTS

eo 1,929,736 Oct. 10, 1933

2,364,400 Dee. 5, 1944

2,533,109 Hannover Dec. 5, 1950

2(607,521 Broadhurst — “Aug. 19, 1952

0s FOREIGN PATENTS

105,733 Australia ~ Nov. 3, 1938

You might also like

- Aiset N 5000Document2 pagesAiset N 5000alguna54No ratings yet

- Abb Nema Explosion Proof Ac & DCDocument56 pagesAbb Nema Explosion Proof Ac & DCCarlos Alvarez L.No ratings yet

- Agilent - ICP MS 7500Document659 pagesAgilent - ICP MS 7500alguna54No ratings yet

- Liquid Dispensing DeviceDocument4 pagesLiquid Dispensing Devicealguna54No ratings yet

- Pressureless Multi-Lane Dividing ApparatusDocument11 pagesPressureless Multi-Lane Dividing Apparatusalguna54No ratings yet

- Clamp Gripper For Container Transport SystemDocument16 pagesClamp Gripper For Container Transport Systemalguna54No ratings yet

- Weight Control Filling ApparatusDocument11 pagesWeight Control Filling Apparatusalguna54No ratings yet

- 7500ceICP MShardwaremanualenDocument334 pages7500ceICP MShardwaremanualenbahram adimiNo ratings yet

- Filling ValveDocument4 pagesFilling Valvealguna54No ratings yet

- Bottle Filling Machine + US 4 967 813 ADocument15 pagesBottle Filling Machine + US 4 967 813 Aalguna54No ratings yet

- Vehicle fuse and relay guideDocument17 pagesVehicle fuse and relay guidealguna54No ratings yet

- 2SC2655 Y (F) ToshibaDocument2 pages2SC2655 Y (F) Toshibaalguna54No ratings yet

- Weight Measuring Type Filling MachineDocument19 pagesWeight Measuring Type Filling Machinealguna54No ratings yet

- Filling Valve + US 4 794 959 ADocument4 pagesFilling Valve + US 4 794 959 Aalguna54No ratings yet

- Apparatus For Widening and Slowing Down A Stream of Upright BottlesDocument6 pagesApparatus For Widening and Slowing Down A Stream of Upright Bottlesalguna54No ratings yet

- Aquence LG 75-EnDocument1 pageAquence LG 75-Enalguna54No ratings yet

- Sell Sheet Optal XP en FinalDocument2 pagesSell Sheet Optal XP en Finalalguna54No ratings yet

- Aquence LG 75S-EnDocument1 pageAquence LG 75S-Enalguna54No ratings yet

- MRM Elgin SMPP135v2 Filler ManualDocument90 pagesMRM Elgin SMPP135v2 Filler Manualalguna54No ratings yet

- 00 05manual PDFDocument129 pages00 05manual PDFNevsaint MartinezNo ratings yet

- 00 05manual PDFDocument129 pages00 05manual PDFNevsaint MartinezNo ratings yet

- Accumax Va Fa Instruction ManualDocument2 pagesAccumax Va Fa Instruction Manualalguna54No ratings yet

- HYPRO, Pocket Guide 2010 Nozzle TablesDocument8 pagesHYPRO, Pocket Guide 2010 Nozzle Tablesalguna54No ratings yet

- 5BH TiDocument16 pages5BH Tialguna54No ratings yet

- Science Direct + Biochemical System A Tics and Ecology - A Comparative Study of Flavonoids in Some Members of The PapaveraceaeDocument3 pagesScience Direct + Biochemical System A Tics and Ecology - A Comparative Study of Flavonoids in Some Members of The Papaveraceaealguna54No ratings yet

- AlloyingElements enDocument24 pagesAlloyingElements enhsemargNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)