Professional Documents

Culture Documents

API-620 NDE Test PDF

Uploaded by

jojo_323Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

API-620 NDE Test PDF

Uploaded by

jojo_323Copyright:

Available Formats

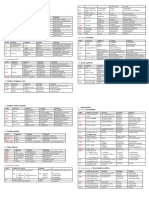

Appendix P

NDE and Testing Requirements Summary

Reference

Process Welds for which the Inspection and Testing is Required Section

Air Test Through tell-tale holes, all welds of nozzles with single thickness reinforcing plates, saddle 5.16.10, 7.18.2.3

flanges, or integral reinforcing pads. Does not include nozzles on the underside of tank

bottoms or reinforcements that are too narrow.

Air Test Completed tank 7.18.2.6

Air Test Roofs of tanks not designed for liquid loading. 7.18.3.1

Air Test Appendix R tanks: Shell-to-bottom welds which are not complete penetration. R8.2.3

Air Test Appendix R tanks: Completed tank. R.8.4

Air Test Appendix R tanks: Outer tank of a double wall refrigerated tank. R.9

Air Test Appendix Q: The shell-to-bottom welds that are not full penetration. Q.8.2.2

Air Test Appendix Q: Vapor space above hydrostatic test level when the tank is subjected to Q.8.5.1 &

pneumatic pressure. Q.8.5.4

Hydro Shell only if the roof is not designed for liquid loading. 7.18.3.1

Hydro Complete tank including the roof if so designed. 7.18.4.1

Hydro Appendix R tanks. R.8

Hydro Appendix Q. Q.8.1.1

MT Flush type shell connections: Nozzle-to-tank shell, Repad welds, shell-to-bottom reinforcing 5.27.11

pad welds on the root pass, every 1/2 in. of deposited weld, and completed weld.

MT Welds attaching nozzles, manways, and clean out openings unless given a liquid penetrant 7.18.2.2

test.

MT Appendix R carbon steel tanks: all butt welds not completely radiographed, cylindrical wall R.7.5

--```,`,,`,`,``````,,``,`,,`,`-`-`,,`,,`,`,,`---

to bottom annular plate weld, all welds of openings that are not completely radiographed

(includes progressive MT) attachment welds to primary components, and the second layer

of weld on joints with permanent backing strips.

MT Permanent and temporary attachments if not examined by PT. 7.16.3, R.7.8

PT Appendix R stainless steel tanks: all butt welds not completely radiographed, cylinder wall R.7.5

to bottom annular plate weld, all welds of openings that are not completely radiographed

(includes progressive PT) attachment welds to primary components, and the second layer

of weld on joints with permanent backing strips.

PT Welds attaching nozzles, manways, and clean out openings instead of MT if approved. Not 7.16.4

for Appendix Q tanks.

PT Appendix Q: All longitudinal and circumferential butt-welds not completely radiographed. Q.7.5.a

PT Appendix Q: Cylindrical wall-to-annular plate welds. Q.7.5.b

PT Appendix Q: Opening welds that are not radiographed. PT the root pass and every 1/2 in. of Q.7.5.c

deposited weld metal.

PT Appendix Q: Attachment welds of non-pressure parts to primary components. Q.7.5.d

PT Appendix Q: The second pass of joints on which backing strips are to remain. Q.7.5.e

PT Appendix Q: Base metal repairs for erection lug removal areas on primary components. Q.7.9

P-1

Copyright American Petroleum Institute

Provided by IHS under license with API Licensee=FMC Technologies /5914950002

No reproduction or networking permitted without license from IHS Not for Resale, 04/08/2009 20:53:15 MDT

P-2 API STANDARD 620

Reference

Process Welds for which the Inspection and Testing is Required Section

RT 100% butt welds of joints with plate thicker than 1.25 in. and tension stress greater than 0.1 5.26.2, 5.26.3

times the specified minimum tensile stress of the material and where required by joint

efficiency.

RT Spot examination for all butt-welded main joints that are not 100% radiographed except for 7.17.2.1

roof joints exempted by Table 5-2, tank bottoms fully supported, and components designed

for compressive stress only (5.26.4).

RT Flush-type shell connections. 5.27.11

RT Appendix Q: 100% of butt-welds with operating stress greater than 0.1 times plate tensile Q.7.6.1

strength.

RT Appendix Q: Spot RT butt-welds with operating stress less than or equal to 0.1 times the Q.7.6.2

plate tensile strength.

RT Appendix Q: 100% of butt-welds around thickened insert plates. Q.7.6.3

RT Appendix Q: All three plate butt joints except flat bottoms uniformly supported. Q.7.6.4

RT Appendix Q: 25% of butt-welded annular plate radial joints shall have 6-in. radiographs Q.7.6.5

taken at the outside of the selected joints.

RT Appendix Q: 25% of butt-welded compression bar radial joints shall have 6-in. radiographs Q.7.6.6

except as required by 5.26.3.3.

RT Appendix Q: 100% of longitudinal butt welds in pipes and pipe fittings containing liquids Q.7.7.2

within the limitations of 1.3.2 except for pipe 12 in. diameter or less that has been welded

without filler metal and has been hydrotested.

RT Appendix Q: 100% of longitudinal butt welds in pipes and pipe fittings containing vapor Q.7.7.3

within the limitations of 1.3.2 except for pipe 18 in. diameter or less that has been welded

without filler metal and has been hydrotested.

RT Appendix Q: 30% of all circumferential welded pipe joints. Q.7.7.4

RT Appendix Q: 100% of butt-welded joints used to fabricate tank fittings. Q.7.7.5

RT Appendix R tanks: Primary-component butt welds. R.7.6

RT Appendix R tanks: Butt welds in piping. R.7.7

VB Bottom Welds unless tested by tracer gas. 7.18.2.4

VB Appendix R tanks: all bottom welds, full penetration shell-to-bottom welds, and fillet welds R.8.2.1, R.8.2.2,

around bottom openings that do not receive repad pressure test. R.8.2.5

VB Appendix Q: All bottom welds and full penetration joints between the shell and bottom. Q.8.2.1

VB Appendix Q: Welds above hydro test level when the inner tank pneumatic pressure is Q.8.2.4

equalized on both sides.

VB Appendix Q: Attachment fillets around bottom openings that cannot be tested by air Q.8.2.5

pressure behind the repads.

VE Tack welds left in place. 6.9.1.4

VE All welds. 7.15.5

--```,`,,`,`,``````,,``,`,,`,`-`-`,,`,,`,`,,`---

VE Shell-plate butt welds. 7.16.1

VE Appendix Q: Base metal repairs for erection lug removal areas on secondary components. 7.16.1

Copyright American Petroleum Institute

Provided by IHS under license with API 标准分享网 www.bzfxw.com 免费下载

Licensee=FMC Technologies /5914950002

No reproduction or networking permitted without license from IHS Not for Resale, 04/08/2009 20:53:15 MDT

DESIGN AND CONSTRUCTION OF LARGE, WELDED, LOW-PRESSURE STORAGE TANKS P-3

Reference

Process Welds for which the Inspection and Testing is Required Section

VE Welds attaching nozzles, manways, and clean out openings. 7.16.4

--```,`,,`,`,``````,,``,`,,`,`-`-`,,`,,`,`,,`---

Definitions:

MT= Magnetic Particle Examination

PT = Liquid Penetrant Examination

Pen Oil = Penetrating Oil Test

RT = Radiographic Testing

VB = Vacuum Box Testing

VE = Visual Examination

Acceptance Standard:

MT: ASME Section VIII, Appendix 6, Paragraphs 6-3, 6-4, and 6-5

PT: ASME Section VIII, Appendix 8, Paragraphs 8-3, 8-4, and 8-5

VE: API 620, Sections 7.15.5.2 and 7.15.5.3

RT: ASME Section VIII, Paragraph UW-51(b)

Examiner Qualifications:

MT: API 620, Section 7.15.2.3

PT: API 620, Section 7.15.4.3

VE: None

VB: None

RT: ASNT Level II or III

Procedure Requirements:

MT: ASME Section V, Article 1, T-150

PT: ASME Section V, Article 6

VE: None

VB: None

RT: A procedure is not required. However, the examination method must comply with ASME

Section V, Article 2.

Copyright American Petroleum Institute

Provided by IHS under license with API Licensee=FMC Technologies /5914950002

No reproduction or networking permitted without license from IHS Not for Resale, 04/08/2009 20:53:15 MDT

You might also like

- Welding SymbolsDocument5 pagesWelding Symbolsjojo_323100% (3)

- API 650 12th - 2013Document4 pagesAPI 650 12th - 2013mohamedNo ratings yet

- Nde MapDocument8 pagesNde MapjorgekarlosprNo ratings yet

- Special Characters - Alt Keyboard SequencesDocument2 pagesSpecial Characters - Alt Keyboard Sequencesjojo_323No ratings yet

- Special Characters - Alt Keyboard SequencesDocument2 pagesSpecial Characters - Alt Keyboard Sequencesjojo_323No ratings yet

- Soil Bearing Capacity TableDocument1 pageSoil Bearing Capacity Tablejojo_323100% (1)

- PFI ES 16 - 2013 EditionDocument11 pagesPFI ES 16 - 2013 EditionArcadio Duran100% (1)

- Music GcseDocument45 pagesMusic GcseAimee DohertyNo ratings yet

- 2019 ASME Section VIII Division 1 SynopsisDocument58 pages2019 ASME Section VIII Division 1 SynopsisCristian Xavier Avendaño BelloNo ratings yet

- A Pi 650 TrainingDocument143 pagesA Pi 650 Trainingvaibhavd123No ratings yet

- TankInspectionTechniques3Document136 pagesTankInspectionTechniques3Zenon Kociuba100% (1)

- Live LoadsDocument1 pageLive Loadsjojo_323No ratings yet

- Oracle Data Integration - An Overview With Emphasis in DW AppDocument34 pagesOracle Data Integration - An Overview With Emphasis in DW Appkinan_kazuki104No ratings yet

- Qap HPCLDocument13 pagesQap HPCLdarshan100% (1)

- API-620 Nde TestDocument3 pagesAPI-620 Nde Testjojo_323No ratings yet

- F.sq-p.003 Rev. 0 Procedure For Repair, Alteration, and Modification Pressure VesselDocument7 pagesF.sq-p.003 Rev. 0 Procedure For Repair, Alteration, and Modification Pressure VesselIksan Adityo MulyoNo ratings yet

- MOUNDED BULLETS FOR LPG STORAGEDocument41 pagesMOUNDED BULLETS FOR LPG STORAGEMarco Dos Santos NevesNo ratings yet

- Coating or hydrotestingDocument4 pagesCoating or hydrotestinggigiphi1No ratings yet

- IOCL Refinery Project Tank Settlement Survey ReportDocument1 pageIOCL Refinery Project Tank Settlement Survey Reportarkaprava ghosh100% (1)

- Allowable Stress API-650Document1 pageAllowable Stress API-650jojo_323100% (2)

- 04.protection of 33KV Feeder.Document16 pages04.protection of 33KV Feeder.gnpr_10106080No ratings yet

- Rochor Station Pile Design CalculationsDocument15 pagesRochor Station Pile Design CalculationsDifa LiuNo ratings yet

- Bellin, E. H. (1984) - The Psychoanalytic Narrative On The Transformational Axis Between Writing and SpeechDocument15 pagesBellin, E. H. (1984) - The Psychoanalytic Narrative On The Transformational Axis Between Writing and SpeechofanimenochNo ratings yet

- RoundnessDocument35 pagesRoundnesssrinivasansscNo ratings yet

- Asme Sa-265 Specification For Nickel and Nickel-Base Alloy-Clad Steel PlateDocument7 pagesAsme Sa-265 Specification For Nickel and Nickel-Base Alloy-Clad Steel Platelucecita1902100% (1)

- Oil Chalk Test/Penetrating Oil TestDocument6 pagesOil Chalk Test/Penetrating Oil TestWeld ManiacNo ratings yet

- Beam Design Formulas With Shear and MomentDocument20 pagesBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- RT 2 Certification Scheme DetailDocument6 pagesRT 2 Certification Scheme DetailKatie RamirezNo ratings yet

- Edr 01 Dec 2018Document21 pagesEdr 01 Dec 2018AMALENDU PAULNo ratings yet

- STS Co. storage tank fabrication methodologyDocument15 pagesSTS Co. storage tank fabrication methodologypurshottam GHNo ratings yet

- Iqwq-ce1092-Mpere-00-0001 - 1 Static Equipement Installation Plan (Tank)Document17 pagesIqwq-ce1092-Mpere-00-0001 - 1 Static Equipement Installation Plan (Tank)Ali MajeedNo ratings yet

- Introduction To Oracle GroovyDocument53 pagesIntroduction To Oracle GroovyDeepak BhagatNo ratings yet

- API 1169 - Prep Test #3: Written by Dale Honn, P.E., P.L.SDocument45 pagesAPI 1169 - Prep Test #3: Written by Dale Honn, P.E., P.L.SHeartyscorpionNo ratings yet

- Evaluación requisitos código API 510 reparacionesDocument3 pagesEvaluación requisitos código API 510 reparacionesJuan Jose Espinoza BarandiaranNo ratings yet

- Leak Test Proce.-TankDocument7 pagesLeak Test Proce.-Tankpraveen 0064No ratings yet

- Sample RBI ReportDocument4 pagesSample RBI ReportSyed Mahmud Habibur RahmanNo ratings yet

- Astm A20Document1 pageAstm A20jojo_32367% (3)

- Api 653 Report-Hydrolic Test PDFDocument12 pagesApi 653 Report-Hydrolic Test PDFnaoufel1706No ratings yet

- API 510 - Day 1: G T Technical & Management Institute PVT - LTD.Document109 pagesAPI 510 - Day 1: G T Technical & Management Institute PVT - LTD.fathiNo ratings yet

- Reliance Industries Limited Line History Sheet For CS Piping Without PWHTDocument1 pageReliance Industries Limited Line History Sheet For CS Piping Without PWHTRavi ShankarNo ratings yet

- Global Projects Organisation: Material Specification For 316/316L and 6mo Austenitic Stainless SteelDocument33 pagesGlobal Projects Organisation: Material Specification For 316/316L and 6mo Austenitic Stainless SteelThiyagarajan JayaramenNo ratings yet

- Nādatanumanisham Shankaram Namami Me Manasa ShirasaDocument12 pagesNādatanumanisham Shankaram Namami Me Manasa Shirasaveena murthyNo ratings yet

- Verify scope acceptance of project deliverablesDocument5 pagesVerify scope acceptance of project deliverablesmypmpbooksNo ratings yet

- Pip Vefv1102Document1 pagePip Vefv1102ParkerNo ratings yet

- API 650 12th Edition 2013 - NDT RequirementDocument1 pageAPI 650 12th Edition 2013 - NDT Requirementfarjadulhaq100% (2)

- Solomons Organic Chemistry Solution Manual - Chapter 3Document12 pagesSolomons Organic Chemistry Solution Manual - Chapter 3Imanghh25% (4)

- Test API RP 1111Document2 pagesTest API RP 1111Nguyễn QuânNo ratings yet

- Pressure Vessel Dimension InspectionDocument3 pagesPressure Vessel Dimension InspectionAnas Sarkiah0% (1)

- Api 653Document3 pagesApi 653Mohammed IlliasuddinNo ratings yet

- F.O.B Cost Estimation of Shell and Tube Heat Exchangers: Surface Area Per ShellDocument9 pagesF.O.B Cost Estimation of Shell and Tube Heat Exchangers: Surface Area Per ShellVINOD KAMBLENo ratings yet

- Tank Settlement Report As Per API 653Document2 pagesTank Settlement Report As Per API 653Toñita Ramos0% (1)

- Astm Equivalent ListDocument1 pageAstm Equivalent Listjojo_323No ratings yet

- Operational Guidelines For VlsfoDocument2 pagesOperational Guidelines For VlsfoИгорьNo ratings yet

- Allowable Stress API 650Document1 pageAllowable Stress API 650jojo_323No ratings yet

- API Tank Settlement PDFDocument2 pagesAPI Tank Settlement PDFMuhammad BilalNo ratings yet

- SAIC-L-2074 Rev 0Document1 pageSAIC-L-2074 Rev 0philipyapNo ratings yet

- API 650 Technical Inquiries SummaryDocument28 pagesAPI 650 Technical Inquiries SummaryIgnatios Staboulis0% (1)

- UL-142 R912 Installation InstructionsDocument4 pagesUL-142 R912 Installation InstructionsRodrigoNo ratings yet

- Open Book Testing - API 653Document9 pagesOpen Book Testing - API 653EdisonCorderoNo ratings yet

- API 653 Effectivity SheetDocument1 pageAPI 653 Effectivity SheetIsmail MemonNo ratings yet

- Material Safety Data Sheet: Poly Cell AdhesiveDocument8 pagesMaterial Safety Data Sheet: Poly Cell AdhesiveMinh BảoNo ratings yet

- Vessel/S&T Heat Exchanger Standard Details (Metric Units)Document7 pagesVessel/S&T Heat Exchanger Standard Details (Metric Units)Jamil AhmadNo ratings yet

- WPS No. GT-SM-5B (F43) WPS No. GT-SM-5B (F43)Document4 pagesWPS No. GT-SM-5B (F43) WPS No. GT-SM-5B (F43)Amir Surya Hidayah100% (1)

- Asme Viii Pressure Vessels Full English 1Document5 pagesAsme Viii Pressure Vessels Full English 1Sterling100% (1)

- Vessel Cleaning ProcedureDocument6 pagesVessel Cleaning ProcedureZool HilmiNo ratings yet

- Inspection & Test Plan For Nozzle Replacement On VS ShellDocument1 pageInspection & Test Plan For Nozzle Replacement On VS ShellQC Taner 453100% (2)

- 2019-5 TechPresentation BeachDocument141 pages2019-5 TechPresentation Beachaneeshta100% (1)

- Procedure Demonstration RecordDocument5 pagesProcedure Demonstration RecordSantanu SahaNo ratings yet

- ASME U StampDocument2 pagesASME U StampAJAY1381No ratings yet

- Governing Thickness For Charpy Impact TestDocument1 pageGoverning Thickness For Charpy Impact TestAnonymous vnuWrIT7FWNo ratings yet

- Oil Gas Construction Factory L.L.CDocument2 pagesOil Gas Construction Factory L.L.CRenny DevassyNo ratings yet

- Procedure For Ferrit TestingDocument11 pagesProcedure For Ferrit TestingKarrar TalibNo ratings yet

- Uphill Versus Downhill Welding PDFDocument4 pagesUphill Versus Downhill Welding PDFPatrick DominguezNo ratings yet

- Standard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodDocument7 pagesStandard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodMauricio FernándezNo ratings yet

- Asme Sec X 2017Document3 pagesAsme Sec X 2017SARSAN NDTNo ratings yet

- API 510 Hydrostatic Head PressureDocument40 pagesAPI 510 Hydrostatic Head PressureHarmish mewadaNo ratings yet

- Floating Roof Sinking Failure ReportDocument17 pagesFloating Roof Sinking Failure ReportPablo Vladimir Millanao FuentesNo ratings yet

- Sa 672Document7 pagesSa 672lalitaliNo ratings yet

- Anexo T - API 650Document4 pagesAnexo T - API 650ChristiaanNo ratings yet

- API 650-2016 12th (Annex T)Document4 pagesAPI 650-2016 12th (Annex T)Farhan PutraNo ratings yet

- 650-781 Rev 0 - Update Appendix T NDE RequirementsDocument7 pages650-781 Rev 0 - Update Appendix T NDE RequirementsMohamed AtefNo ratings yet

- Mathcad Prime Keyboard ShortcutsDocument8 pagesMathcad Prime Keyboard Shortcutsjojo_323No ratings yet

- 01 Samss 005 PDFDocument5 pages01 Samss 005 PDFjojo_323No ratings yet

- Astm A36-A36m-2004 PDFDocument4 pagesAstm A36-A36m-2004 PDFmsalinasaguilarNo ratings yet

- Dome 1Document1 pageDome 1jojo_323No ratings yet

- Material Groups API 650Document2 pagesMaterial Groups API 650jojo_323100% (2)

- Dome Roof TableDocument1 pageDome Roof Tablejojo_323No ratings yet

- Bro Pocket GuideDocument8 pagesBro Pocket GuidepremNo ratings yet

- X-Enp (Metal Deck Nail)Document10 pagesX-Enp (Metal Deck Nail)jojo_323No ratings yet

- Min. Nozzles Spacing API-650Document1 pageMin. Nozzles Spacing API-650jojo_323No ratings yet

- SS FastenersDocument1 pageSS Fastenersjojo_323No ratings yet

- AWWA D100 Tension TableDocument1 pageAWWA D100 Tension Tablejojo_323No ratings yet

- Varec Pro093 Api2350 WhitepaperDocument18 pagesVarec Pro093 Api2350 WhitepaperFernando LoayzaNo ratings yet

- NG HeleDocument18 pagesNG Helejojo_323No ratings yet

- Thickness Limit AwwaDocument1 pageThickness Limit Awwajojo_323No ratings yet

- Wind Girder Table API 650Document2 pagesWind Girder Table API 650jojo_323No ratings yet

- Aramco Wind and Seismic Data (New)Document9 pagesAramco Wind and Seismic Data (New)jojo_323No ratings yet

- LET WVCST-Art Appreciation1Document5 pagesLET WVCST-Art Appreciation1jojo_323No ratings yet

- Let FoodsDocument7 pagesLet Foodsjojo_323No ratings yet

- DC Machines Chapter SummaryDocument14 pagesDC Machines Chapter SummaryMajad RazakNo ratings yet

- Affixation (Landscape)Document4 pagesAffixation (Landscape)difafalahudinNo ratings yet

- Home Automation Iot Bca Up (2ND SEMINAR PPT) RTDocument30 pagesHome Automation Iot Bca Up (2ND SEMINAR PPT) RTTejaswiniNo ratings yet

- RelativedensityipgDocument2 pagesRelativedensityipgapi-310625232No ratings yet

- Digital Logic Design - Switch Logic & Basic GatesDocument27 pagesDigital Logic Design - Switch Logic & Basic GatesTroon SoonNo ratings yet

- Pumps - IntroductionDocument31 pagesPumps - IntroductionSuresh Thangarajan100% (1)

- Impeller: REV Rev by Description PCN / Ecn Date CHK'D A JMM Released For Production N/A 18/11/2019 PDLDocument1 pageImpeller: REV Rev by Description PCN / Ecn Date CHK'D A JMM Released For Production N/A 18/11/2019 PDLSenthilkumar RamalingamNo ratings yet

- © Ncert Not To Be Republished: AlgebraDocument12 pages© Ncert Not To Be Republished: Algebrakritagyasharma29No ratings yet

- Excel Dynamic Arrays: Department Item Quantity Price Total $Document5 pagesExcel Dynamic Arrays: Department Item Quantity Price Total $Bilal Hussein SousNo ratings yet

- Sensors 22 09378 v2Document13 pagesSensors 22 09378 v2FahdNo ratings yet

- DbintfcDocument80 pagesDbintfchnr.uninstallNo ratings yet

- SIEMENS-7SA522 Setting CalculationDocument20 pagesSIEMENS-7SA522 Setting Calculationnaran19794735No ratings yet

- Network Layer: Computer Networking: A Top Down ApproachDocument83 pagesNetwork Layer: Computer Networking: A Top Down ApproachMuhammad Bin ShehzadNo ratings yet

- Module 4 - What Is The Required Rate of ReturnDocument2 pagesModule 4 - What Is The Required Rate of ReturnEthics BAENo ratings yet

- 2 To 12F SM UT Armoured OFC-2Steel Wire Design Sheet-7.5 MMDocument3 pages2 To 12F SM UT Armoured OFC-2Steel Wire Design Sheet-7.5 MMTropic BazarNo ratings yet

- Smart Dustbin using ArduinoDocument22 pagesSmart Dustbin using ArduinoEr Dinesh TambeNo ratings yet

- ChamSys Touchscreen SupportDocument2 pagesChamSys Touchscreen SupportKayla PadillaNo ratings yet

- Tips and Tricks I: Getting the Most Out of ArcGIS DesktopDocument108 pagesTips and Tricks I: Getting the Most Out of ArcGIS Desktoptanja222No ratings yet

- 3BSE079234 - en 800xa 6.0 ReleasedDocument7 pages3BSE079234 - en 800xa 6.0 ReleasedFormat_CNo ratings yet

- FDocument1 pageFDiego PorrasNo ratings yet