Professional Documents

Culture Documents

P1 A C LH

Uploaded by

Mohamed Reda HusseinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P1 A C LH

Uploaded by

Mohamed Reda HusseinCopyright:

Available Formats

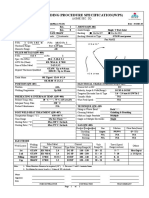

KAHROMIKA WELDING PROCEDURE SPECIFICATION ( WPS ) WPS : S/18

Page 1 of 2

(P1-A-C-Lh ) Date / : 29/12/003

Company Name: Misr Co.For Mechanical & Electrical Projects ( KAHROMIKA ) Prepared by : Eng. Samir Yakout

Supporting PQR No.( s) : 001

WPS.Rev.No.: P1-A-C-Lh ( S/18 ) Rev.0

QW 410.25 :

Date : 29/12/003

Type: Manual

Welding Process (es) : SMAW ( E-6010 -- E-7018 )

Joints ( QW-402) QW - ( 402.1 - 402.10 )

o

Joint Design : V– 75 Joint Detail 37.5ْ

Backing Material : NO

Root spacing : 2 – 3 mm

Retainers : NO

Root face : 1- 3 mm

Base Metals ( QW –403)

P-No.: 1 Group No. : Any to P-NO. 1 Group No. : Any

Specification type and grade : SA 106 GR B. t0 Specification type and grade : SA 106 - GR. B

T/t limits <8" : N /A

N0 pass > ½"

P.No 5 / 9 /10 : N/A

Thickness Range ( mm)

Base Metal Thick. : Groove 1/6" (2.0 mm) up to 3/8" ( 10.0 mm )

T Qualified : 1/6" ( 2.0mm) ------- 2 T ( 16.36 mm)

Deposited Weld Metal Thick . : 2.0 mm- (E-6010) - 6.0 mm (E-7018) ---- Max. Thk’s Qualified : 4.0mm (E-6010) --12.36mm( E-7018)

Pipe Dia . range : over 2 7/8" ( OD . 12 3/4 --" sch .120) --- Range Qualified : ALL

Filler Metals (QW –4 04)

AWS / SFA : 5.1 ( E-6010 ) 5.1 (E-7018)

Class : E-6010 , E- 7018

F-No : 3 4

A-No. : 1 1

Size of Filler metals : 3.25 mm 2.5 , 3.25 ,4 mm

Name of Flux : N/A N/A

Production Form : ---------- --------------

Consumable insert : NO NO

Trade Name : N/A N/A

KAHROMIKA WPS Back WPS: S/18

Page 2 of 2

Date / 29/12/003

Positions (QW-405) Post weld heat treatment (QW-407)

Heating Rate: N/A Cْ / h

Position (s) of Groove: Any

Temperature Range: N/A Cْ / h

Welding Progression: Up: X Down: X Holding Time: N/A h

Position (s) of Fillet: Any Cooling Rate: N/A Cْ / h

Postweld Heat Treat. ( Fْ ) : NO

Preheat (QW-406) Gas ( QW-408)

Shielding Gas(es) : NO

Preheat Temp. Min. : 10 Cْ (50 Fْ ( Percent Composition ( mixt.) : NO

Interposes Temp.Max : None Flow Rate: NO

Preheat Maintenance : NO Gas Backing : NO

Trailing Shielding Gas Comp.: NO

Temperature Control : NO

Other : NO

Electrical Characteristics ( QW-409)

Current AC or DC : DC ( E-6010 ) , DC ( E-7018 )

Polarity : DCRP ( electrode + ) E-6010 -------- DCRP (electrode + ) E-7018

Amps (Range) : ( 40 –120 ) E-6010 --- (70-200) , ( 140-200) E-7018

Tungsten Electrode Size and Type : NO

ode of Metal Transfer for GMAW : NO

Pulsing of current : NO

Technique ( QW-410)

String or Weave Bead : Both

Orifice or Gas cup Size : NO

Initial and Interpass Cleaning : Brushing & Grinding

Method of backing Gouging : NO

Contact Tube to work Distance : N/A

Multiple or single Pass ( per side ) : Multiple

Multiple or single Electrodes : Single

Travel Speed ( Range) : NO

Penning : NO

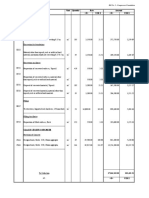

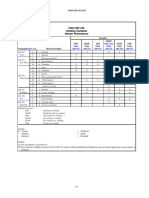

Table Welding Parameters :

Welding – Number of Process (es) Pos. Filler metal Current Voltage Travel

sequence Beads Range Speed

Range

Weld Class Dia Current Current (Volt)

-Layer AWS mm Type Range

Polarity (Amp.)

1 1 SMAW ALL E-6010 3.25 DCRP 40-120 18-28

2(note 1) 1 SMAW ALL E-6010 3.25 DCRP 40-120 18-28

3 1 SMAW ALL E 7018 3.25 DCRP 70-200 19-24

4 1 SMAW ALL E 7018 3.25 DCRP 140-200 20-24

n 1 SMAW ALL E 7018 4 DCRP 140-200 20-24

Note :

( 1 ) The second pass with E- 6010 is optional

------------------------- -------------------------

Date Signed

You might also like

- StudentDocument7 pagesStudentKartik AryanNo ratings yet

- WPS MCC 001 PDFDocument1 pageWPS MCC 001 PDFNuwan RanaweeraNo ratings yet

- QW-451 Welding THK - June5Document17 pagesQW-451 Welding THK - June5Raj SNo ratings yet

- Handbook MetrodeDocument371 pagesHandbook Metrodejf2587No ratings yet

- The Feasibility of Eliminating Flood Problems in The Philippines Through Pervious ConcreteDocument24 pagesThe Feasibility of Eliminating Flood Problems in The Philippines Through Pervious ConcreteClarisse DuenasNo ratings yet

- Mivan Shuttering - QuotationDocument5 pagesMivan Shuttering - Quotationmahesh pandeyNo ratings yet

- Jetty BOQDocument5 pagesJetty BOQLawal Abdul-Rasheed Ayinde100% (1)

- Cswip 3.1Document2 pagesCswip 3.1Anna PariniNo ratings yet

- PWPS Eksperimen Super DuplexDocument33 pagesPWPS Eksperimen Super Duplexryan.sNo ratings yet

- Colour Coding As Per BHELDocument7 pagesColour Coding As Per BHELKedar Choksi0% (1)

- Sa 672Document7 pagesSa 672lalitaliNo ratings yet

- 175 019900Document2 pages175 019900Abu Anas M.SalaheldinNo ratings yet

- Test Pack ProcedureDocument10 pagesTest Pack ProcedureDaengkulle Firmansyah PuteraNo ratings yet

- SAIC-W-2078 Review PWHT Proc For TankDocument5 pagesSAIC-W-2078 Review PWHT Proc For Tankkarioke mohaNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- WPS, PQR, WPQDocument2 pagesWPS, PQR, WPQESL100% (1)

- NCR AG I 055 With Vendors ReplyDocument12 pagesNCR AG I 055 With Vendors ReplymuhammedemraanNo ratings yet

- PWHT TableDocument1 pagePWHT TableSumner TingNo ratings yet

- Asset Integrity Daily ReportDocument1 pageAsset Integrity Daily Reportعصمت ضيف اللهNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- GMCo - WPSDocument8 pagesGMCo - WPSMohamed AtefNo ratings yet

- 9.19 - P-101 - Positive Material IdentificationDocument13 pages9.19 - P-101 - Positive Material IdentificationRays TioNo ratings yet

- TDC QapDocument69 pagesTDC QapKuppuraj ParamsivamNo ratings yet

- WPS, PQR, WQT, WPQ: BBW30103 Teknologi Kimpalan BerautomasiDocument12 pagesWPS, PQR, WQT, WPQ: BBW30103 Teknologi Kimpalan BerautomasiNazrin GLNo ratings yet

- Office: Printout Sample - ASME WPSDocument2 pagesOffice: Printout Sample - ASME WPSDanem HalasNo ratings yet

- Asm Products & Education Catalog: Celebrating Our First 100 Years of Materials InnovationDocument52 pagesAsm Products & Education Catalog: Celebrating Our First 100 Years of Materials InnovationVinit AhluwaliaNo ratings yet

- Oxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupsDocument6 pagesOxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupssanketNo ratings yet

- Astm 890Document3 pagesAstm 890bsnegi111No ratings yet

- Welder Qualification Record: CODE: AS/NZS 1554.5-2014 WMS-WPS-30Document2 pagesWelder Qualification Record: CODE: AS/NZS 1554.5-2014 WMS-WPS-30Ali TalebiNo ratings yet

- Table - Qw-416 Welding Variables For Welder PerformanceDocument1 pageTable - Qw-416 Welding Variables For Welder PerformanceAnonymous VohpMtUSN100% (1)

- Part2 Notice 1Document21 pagesPart2 Notice 1Danem Halas100% (1)

- GS 30-1-7 - MainbodyDocument16 pagesGS 30-1-7 - MainbodySubash ChandraboseNo ratings yet

- Wps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Document4 pagesWps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Nilotpal Kumar RaiNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Steel Properties Material Grade Comparison ChartDocument1 pageSteel Properties Material Grade Comparison Chartgk80823No ratings yet

- Pressure Vessel Plate InspectionDocument5 pagesPressure Vessel Plate InspectionSadashiw PatilNo ratings yet

- Cathodic Protection BOMDocument4 pagesCathodic Protection BOManonymous542No ratings yet

- Severin FinalDocument26 pagesSeverin Finalcristasocum_trans1758No ratings yet

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Document15 pagesFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaNo ratings yet

- Barcol ProcedureDocument1 pageBarcol ProcedureseetharamannNo ratings yet

- TDC 003 - SS Pipes - r0Document1 pageTDC 003 - SS Pipes - r0samkarthik47No ratings yet

- API 653 Above Ground Storage Tank InspectorDocument2 pagesAPI 653 Above Ground Storage Tank InspectorMohamed Hichem Guesmi0% (1)

- 57 PQRDocument13 pages57 PQRAbdul Tri Hamdani HamdaniNo ratings yet

- Seamless Steel Line Pipe Seamless Steel Line Pipe: Pipes & Tubes Pipes & TubesDocument8 pagesSeamless Steel Line Pipe Seamless Steel Line Pipe: Pipes & Tubes Pipes & TubesMoh'd MansourNo ratings yet

- WTIA TN 11 Commentary On The Standard ASNZS 1554 Structural Steel WeldingDocument99 pagesWTIA TN 11 Commentary On The Standard ASNZS 1554 Structural Steel WeldingZac NastNo ratings yet

- PWHTDocument1 pagePWHTMohdBadruddinKarimNo ratings yet

- SAW Presentation - SSDocument62 pagesSAW Presentation - SSRishabh KumarNo ratings yet

- WPS-PQR ListDocument1 pageWPS-PQR ListSandra SandersNo ratings yet

- Grade Point Average CalculatorDocument1 pageGrade Point Average CalculatorRaquelNo ratings yet

- Procedure Demonstration RecordDocument5 pagesProcedure Demonstration RecordSantanu SahaNo ratings yet

- Nozzle Fit-Up Inspection Report: Inspected & Prepared byDocument9 pagesNozzle Fit-Up Inspection Report: Inspected & Prepared byDaison PaulNo ratings yet

- Sample Forms WPS PQRDocument22 pagesSample Forms WPS PQRGMNo ratings yet

- Ucs 56Document1 pageUcs 56enemesio_85100% (1)

- ISO - TR - 20173 - 2009 - EN - PDF For Material GroupingDocument11 pagesISO - TR - 20173 - 2009 - EN - PDF For Material GroupingS.K.AGRAWALNo ratings yet

- Acceptance Criteria Asme B31.3 PDFDocument1 pageAcceptance Criteria Asme B31.3 PDFAhmad Rizki100% (1)

- Din 54109-2-89 PDFDocument2 pagesDin 54109-2-89 PDFAndres Afanador MuñozNo ratings yet

- 202 1sp 0 Saw Cs CsDocument8 pages202 1sp 0 Saw Cs CskrishimaNo ratings yet

- Astm A516 Grade 70Document1 pageAstm A516 Grade 70Javier Caamaño VillafañeNo ratings yet

- Schematic Diagram For Hydrotest.Document1 pageSchematic Diagram For Hydrotest.vsNo ratings yet

- Rererence - PIM-SC-2505-N - CS PIPING FABRICATIONDocument14 pagesRererence - PIM-SC-2505-N - CS PIPING FABRICATIONaslam.ambNo ratings yet

- Api 1104 VT TestDocument2 pagesApi 1104 VT TestKali AbdennourNo ratings yet

- Rapid p0030 CPP U0030 Qac Mom 0024 Quality MeetingDocument13 pagesRapid p0030 CPP U0030 Qac Mom 0024 Quality MeetingAtuk Safiz100% (1)

- The Complete Guide to Telephone Interview Questions and AnswersFrom EverandThe Complete Guide to Telephone Interview Questions and AnswersNo ratings yet

- IqamaDocument1 pageIqamaMohamed Reda HusseinNo ratings yet

- Copy of PassportDocument2 pagesCopy of PassportMohamed Reda HusseinNo ratings yet

- Privacy Notice and ConsentDocument2 pagesPrivacy Notice and ConsentMohamed Reda HusseinNo ratings yet

- SAP Number DataDocument5 pagesSAP Number DataMohamed Reda HusseinNo ratings yet

- Satip-Log Satip Title Nesma Transmittal Sa Aramco TransmittalDocument2 pagesSatip-Log Satip Title Nesma Transmittal Sa Aramco TransmittalMohamed Reda HusseinNo ratings yet

- Non-Conformance Details:: Dept./Discipline: Issue Date: Raised by LocationDocument1 pageNon-Conformance Details:: Dept./Discipline: Issue Date: Raised by LocationMohamed Reda HusseinNo ratings yet

- Project-Mip-14: Procedure For Material Equipments Receiving, Handling, Storage & PreservationDocument34 pagesProject-Mip-14: Procedure For Material Equipments Receiving, Handling, Storage & PreservationMohamed Reda HusseinNo ratings yet

- Installation Manual FPIDocument60 pagesInstallation Manual FPIMohamed Reda HusseinNo ratings yet

- Internal NCR LogDocument7 pagesInternal NCR LogMohamed Reda HusseinNo ratings yet

- Test Procedure NFPA 705Document3 pagesTest Procedure NFPA 705Mohamed Reda HusseinNo ratings yet

- 157-RD-12-17 Saudi Perlite CompanyDocument4 pages157-RD-12-17 Saudi Perlite CompanyMohamed Reda HusseinNo ratings yet

- 09-SAMSS-097 - Ready-Mixed Concrete PDFDocument9 pages09-SAMSS-097 - Ready-Mixed Concrete PDFMohamed Reda HusseinNo ratings yet

- Agap WPSDocument181 pagesAgap WPSMohamed Reda Hussein100% (1)

- As-Built Drawing Process GuidelineDocument1 pageAs-Built Drawing Process GuidelineMohamed Reda Hussein100% (1)

- SR. # Client Name Insp Cash/Credit AmountDocument15 pagesSR. # Client Name Insp Cash/Credit AmountMohamed Reda HusseinNo ratings yet

- WP056P Rev0Document12 pagesWP056P Rev0Mohamed Reda HusseinNo ratings yet

- ASME U StampingDocument1 pageASME U StampingMohamed Reda HusseinNo ratings yet

- Hardness: Minimum Thickness Requirements For Various Testing MethodsDocument1 pageHardness: Minimum Thickness Requirements For Various Testing MethodsMohamed Reda HusseinNo ratings yet

- WPQR SMAW EN-2 - 30mm (Under Modification)Document2 pagesWPQR SMAW EN-2 - 30mm (Under Modification)Mohamed Reda HusseinNo ratings yet

- RNCS 039 Allegato1 FG 1 & 2Document2 pagesRNCS 039 Allegato1 FG 1 & 2Mohamed Reda HusseinNo ratings yet

- Surface PreparationDocument3 pagesSurface PreparationMohamed Reda Hussein80% (5)

- Pictures Related To NCR NO.100: Picture 1 (B667) Picture 2 (B642)Document2 pagesPictures Related To NCR NO.100: Picture 1 (B667) Picture 2 (B642)Mohamed Reda HusseinNo ratings yet

- RCC Curtainwall QuantityDocument2 pagesRCC Curtainwall QuantityHeerendra SharmaNo ratings yet

- ICE Check Certificate RegisterDocument10 pagesICE Check Certificate RegisterKam LauNo ratings yet

- Weldablity of MetalsDocument15 pagesWeldablity of MetalspchakrNo ratings yet

- REFRACTICA - The Refractory Maintenance NewsletterDocument8 pagesREFRACTICA - The Refractory Maintenance Newslettersumay banerjeeNo ratings yet

- Seismic Base Coe. NBC 105-2016Document11 pagesSeismic Base Coe. NBC 105-2016Aditya JoshiNo ratings yet

- API-510 QuestionsDocument21 pagesAPI-510 Questionssjois_hs100% (1)

- Basics of GrindingDocument15 pagesBasics of Grindingmaulikgadara100% (1)

- Bolt A Band - 2Document6 pagesBolt A Band - 2Oscar YudistiraNo ratings yet

- ASTM Standards: Range of Products & Material GradeDocument1 pageASTM Standards: Range of Products & Material Gradeeko kusumoNo ratings yet

- Inspection Checklist For Installation of Interlocking Precast Concrete Pavers and KerbstonesDocument1 pageInspection Checklist For Installation of Interlocking Precast Concrete Pavers and KerbstonesDipin Nediya Parambath100% (3)

- AVR 1500 Audio/Video Receiver: Service ManualDocument74 pagesAVR 1500 Audio/Video Receiver: Service ManualMartel QuirozNo ratings yet

- Setting of CementDocument18 pagesSetting of CementRajat GuptaNo ratings yet

- Ses KP2 Sleeve Expander ToolDocument2 pagesSes KP2 Sleeve Expander ToolSpqdNo ratings yet

- Composite Steel Formwork System: Outline of Live-End Anchorage PocketDocument30 pagesComposite Steel Formwork System: Outline of Live-End Anchorage PocketJames MizziNo ratings yet

- Revision of IS 456 & IS 1343 - SummaryDocument3 pagesRevision of IS 456 & IS 1343 - Summaryshiv paa0% (1)

- CG-2016284-02 CHEMGUARD Pre-Piped Vertical Bladder TanksDocument6 pagesCG-2016284-02 CHEMGUARD Pre-Piped Vertical Bladder TanksAnonymous S9qBDVkyNo ratings yet

- Aquapel PDFDocument1 pageAquapel PDFKS LeeNo ratings yet

- Grey Iron CastingsDocument7 pagesGrey Iron Castingssivakumar990No ratings yet

- Haldia Petrochemicals LTD LLDPEDocument6 pagesHaldia Petrochemicals LTD LLDPEsenthilkumar santhanamNo ratings yet

- Precast SectionsDocument16 pagesPrecast SectionsRigid JointNo ratings yet

- LSI Cypress LPS Low Pressure Sodium Series Brochure 1987Document6 pagesLSI Cypress LPS Low Pressure Sodium Series Brochure 1987Alan MastersNo ratings yet

- LIGMANDocument1 pageLIGMANDessouki SamakNo ratings yet

- Assab Steels 705M Machinery Steel: Metal, Ferrous Metal, Alloy SteelDocument2 pagesAssab Steels 705M Machinery Steel: Metal, Ferrous Metal, Alloy SteelMuhammad FikriNo ratings yet

- B466 PDFDocument6 pagesB466 PDFKikin K. Permata100% (1)

- Metal Panels CatalogueDocument30 pagesMetal Panels Cataloguefacade vietnamNo ratings yet

- D B B D: General NotesDocument1 pageD B B D: General NotessamiabdulwahabNo ratings yet