Professional Documents

Culture Documents

Marlex K307

Uploaded by

Santiago Jorge Toledo ToledoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Marlex K307

Uploaded by

Santiago Jorge Toledo ToledoCopyright:

Available Formats

For more information and technical

assistance contact:

Chevron Phillips Chemical Company LP

P.O. Box 4910

The Woodlands, TX 77387-4910

800.231.1212

PREMIUM EXTRUSION AND RIGID PACKAGING RESINS

®

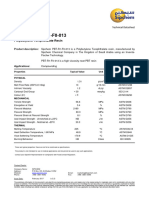

Marlex K307

MEDIUM DENSITY POLYETHYLENE

This medium density, high molecular weight hexene This resin meets these specifications:

copolymer is tailored for geomembrane applications that ASTM D4976 - PE 225

require: GRI-GM13 except carbon black requirements

Outstanding ESCR FDA 21 CFR 177.1520(c) 3.1a, use conditions C through G

Broad fusion range per 21 CFR 176.170(c). Volume of food contacting article

Excellent melt strength must be equal to or greater than 5 gallons.

Good processability

Typical geomembrane applications for K307 include:

Landfill liners

Gasoline and chemical tank containment liners

Tunnel moisture barriers

Mine tailing collection projects

(1)

NOMINAL PHYSICAL PROPERTIES English SI Method

3

Density --- 0.937 g/cm ASTM D1505

Flow Rate (HLMI, 190/21.6) --- 21.0 g/10 min ASTM D1238

Tensile Strength at Yield, 2 in/min, Type IV bar 2,900 psi 20 MPa ASTM D638

Elongation at Break, 2 in/min, Type IV bar 800% 800% ASTM D638

Flexural Modulus, Tangent - 16:1 span:depth, 0.5 in/min 120,000 psi 830 MPa ASTM D790

ESCR, Condition B (10% Igepal), F 50 >1,500 h >1,500 h ASTM D1693

ESCR, Condition C (100% Igepal), F50 >1,500 h >1,500 h ASTM D1693

ASTM D5397

SP-NCTL >900 h >900 h

(Appendix)

Durometer Hardness, Type D (Shore D) 57 57 ASTM D2240

Vicat Softening Temperature, Loading 1, Rate A 221°F 105°C ASTM D1525

Heat Deflection Temperature, 66 psi, Method A 137°F 58°C ASTM D648

Brittleness Temperature, Type A, Type I specimen <-103°F <-75°C ASTM D746

2 2

Tensile Impact, Type S bar 190 ft•lb/in 400 kJ/m ASTM D1822

1. The nominal properties reported herein are typical of the product, but do not reflect normal testing variance and therefore should not be used for

specification purposes. Values are rounded. The physical properties were determined on compression molded specimens that were prepared in

accordance with Procedure C of ASTM D4703, Annex A1.

Revision Date July, 2004

Before using this product, the user is advised and cautioned to make its own determination and assessment of the safety and

suitability of the product for the specific use in question and is further advised against relying on the information contained

herein as it may relate to any specific use or application. It is the ultimate responsibility of the user to ensure that the product is

suited and the information is applicable to the user's specific application. Chevron Phillips Chemical Company LP does not

make, and expressly disclaims, all warranties, including warranties of merchantability or fitness for a particular purpose,

regardless of whether oral or written, express or implied, or allegedly arising from any usage of any trade or from any course of

dealing in connection with the use of the information contained herein or the product itself. The user expressly assumes all risk

and liability, whether based in contract, tort or otherwise, in connection with the use of the information contained herein or the

product itself. Further, information contained herein is given without reference to any intellectual property issues, as well as

federal, state or local laws which may be encountered in the use thereof. Such questions should be investigated by the user.

Page 1 of 1

You might also like

- TDS - Marlex® K306 PolyethyleneDocument1 pageTDS - Marlex® K306 PolyethyleneMauricio Alejandro Castillo SorianoNo ratings yet

- Specification Sheet 5502 50100 and TR 571Document3 pagesSpecification Sheet 5502 50100 and TR 571MZY Commercial EnterprisesNo ratings yet

- Driscoplex 6500 Pe2708 / (Pe2406) Pipe: Pipe & Fittings Data SheetDocument2 pagesDriscoplex 6500 Pe2708 / (Pe2406) Pipe: Pipe & Fittings Data SheetmariannyNo ratings yet

- Mpact D143: Metallocene Linear Low Density PolyethyleneDocument1 pageMpact D143: Metallocene Linear Low Density PolyethyleneJulio GarcíaNo ratings yet

- Driscoplex 5300 Series Pe3608 / (Pe3408) : Geothermal Systems Data SheetDocument2 pagesDriscoplex 5300 Series Pe3608 / (Pe3408) : Geothermal Systems Data SheetmariannyNo ratings yet

- Mdpe 3305MQDocument2 pagesMdpe 3305MQHữu LộcNo ratings yet

- Specification Sheets 50100 5202BN TR571Document3 pagesSpecification Sheets 50100 5202BN TR571MZY Commercial EnterprisesNo ratings yet

- Specification Sheet 50100 and TR 571Document2 pagesSpecification Sheet 50100 and TR 571MZY Commercial EnterprisesNo ratings yet

- Sabic Hdpe Bm1052: High Density PolyethyleneDocument2 pagesSabic Hdpe Bm1052: High Density PolyethyleneifahNo ratings yet

- Driscoplex 3100 Series Pipe Data Sheet: Property Unit Test Procedure Typical ValueDocument2 pagesDriscoplex 3100 Series Pipe Data Sheet: Property Unit Test Procedure Typical ValuemariannyNo ratings yet

- HXM 50100Document1 pageHXM 50100MZY Commercial EnterprisesNo ratings yet

- D139FKDocument1 pageD139FKsonhungdoanNo ratings yet

- Sabic Hdpe B5429: High Density PolyethyleneDocument2 pagesSabic Hdpe B5429: High Density Polyethylenegetasew altasebNo ratings yet

- 3 Property H7900 EngDocument1 page3 Property H7900 EngMohit MohataNo ratings yet

- K-Resin Styrene-Butadiene Copolymers (SBC) : Customer Benefits Typical ApplicationsDocument1 pageK-Resin Styrene-Butadiene Copolymers (SBC) : Customer Benefits Typical ApplicationsPatricio Bravo CastilloNo ratings yet

- Marlex TRB-115 PolyethyleneDocument1 pageMarlex TRB-115 PolyethyleneSeyfullah Akan KarapaçaNo ratings yet

- TDS LC670 Eng 220216Document1 pageTDS LC670 Eng 220216AthonioMourinhoNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- Description and Use: WWW - Muntajat.qaDocument2 pagesDescription and Use: WWW - Muntajat.qaEleannys GarciasNo ratings yet

- SABIC® HDPE - M80064S - Global - Technical - Data - SheetDocument2 pagesSABIC® HDPE - M80064S - Global - Technical - Data - Sheets0n1907No ratings yet

- LG Chem TDS SP988 EnglishDocument1 pageLG Chem TDS SP988 EnglishSérgio BarbosaNo ratings yet

- HHM 5202 BNDocument1 pageHHM 5202 BNMZY Commercial EnterprisesNo ratings yet

- Lldpe 20100326-165732-Tds-02-Uf1810t-1Document1 pageLldpe 20100326-165732-Tds-02-Uf1810t-1Addison FregilNo ratings yet

- Exceed™ S 9333 Series: Performance PolymerDocument2 pagesExceed™ S 9333 Series: Performance PolymerMaram YasserNo ratings yet

- PP PP9074MED DatasheetDocument1 pagePP PP9074MED DatasheetDiogo SouzaNo ratings yet

- SABIC® HDPE - M200056 - Global - Technical - Data - SheetDocument2 pagesSABIC® HDPE - M200056 - Global - Technical - Data - SheetAhmed Elgazar100% (1)

- Tds Hp450j EnglishDocument1 pageTds Hp450j EnglishMd Abdul SalamNo ratings yet

- Sipchem PBT-R1-F0-013: Polybutylene Terephthalate ResinDocument1 pageSipchem PBT-R1-F0-013: Polybutylene Terephthalate ResinTahir IqbalNo ratings yet

- 3 Property R3450 EngDocument1 page3 Property R3450 EngMohit MohataNo ratings yet

- Duraline - Ficha Técnica Tubería PEAD 4710 (Gas Natural)Document4 pagesDuraline - Ficha Técnica Tubería PEAD 4710 (Gas Natural)FrancoNo ratings yet

- 3812 ExceedDocument2 pages3812 ExceedJimmys GothiqueNo ratings yet

- SABICs P6006NDocument2 pagesSABICs P6006NroybharggavNo ratings yet

- HD Blow - Q 5502 BNDocument1 pageHD Blow - Q 5502 BNNaren RawatNo ratings yet

- Chevron_Phillips_Marlex_D139Document1 pageChevron_Phillips_Marlex_D139AthonioMourinhoNo ratings yet

- Hdpe Data Sheet - TR571Document1 pageHdpe Data Sheet - TR571Gopi Kokkiligadda / Sr. Quality Engineer/Medchal Fastening PlantNo ratings yet

- Sipchem PBT-R1-G0-011: Polybutylene Terephthalate ResinDocument1 pageSipchem PBT-R1-G0-011: Polybutylene Terephthalate ResinTahir IqbalNo ratings yet

- HDPE 2035 Bapolene PDFDocument1 pageHDPE 2035 Bapolene PDFAleexis FunezNo ratings yet

- Sabic BM 1052Document2 pagesSabic BM 1052ifahNo ratings yet

- PEADM5372Document2 pagesPEADM5372nicolas yoris marcoglieseNo ratings yet

- Exceed™ XP 8318MJ: Performance PolymerDocument2 pagesExceed™ XP 8318MJ: Performance PolymerMaram YasserNo ratings yet

- Marlex D139 Polyethylene: Nominal Resin Properties English SI MethodDocument1 pageMarlex D139 Polyethylene: Nominal Resin Properties English SI MethodGabriela Lopez MunozNo ratings yet

- Nylatron® 4.6 - BoedekerDocument6 pagesNylatron® 4.6 - BoedekerMas ZuhadNo ratings yet

- High Density Film Grade Excellent StrengthDocument1 pageHigh Density Film Grade Excellent StrengthRPM28XINo ratings yet

- High Density Polyethylene Grade Used in Injection Molding Melt Index: 62 Density: 0.942Document2 pagesHigh Density Polyethylene Grade Used in Injection Molding Melt Index: 62 Density: 0.942Phung LucNo ratings yet

- Exceed S 9243MLDocument2 pagesExceed S 9243MLzhen liuNo ratings yet

- TDS HP740T DaelimDocument1 pageTDS HP740T Daelimbrandon abella gutierrezNo ratings yet

- LLDPE-218BJ_edit (1)Document3 pagesLLDPE-218BJ_edit (1)Chu ChuNo ratings yet

- DK 3.0mm HDPE Geomembrane Mill CertificateDocument2 pagesDK 3.0mm HDPE Geomembrane Mill CertificatemikeNo ratings yet

- Upp Tds Ep548s EnglishDocument1 pageUpp Tds Ep548s EnglishRula SiuNo ratings yet

- TDS Pe 202 SP4808Document2 pagesTDS Pe 202 SP4808Desri AkbarNo ratings yet

- 02 Bab IiDocument2 pages02 Bab IiariefNo ratings yet

- Exceed™ XP 8358 Series: Performance PolymerDocument2 pagesExceed™ XP 8358 Series: Performance PolymerMaram YasserNo ratings yet

- Exceed™ XP 6026 Series: Performance PolymerDocument2 pagesExceed™ XP 6026 Series: Performance PolymerMaram YasserNo ratings yet

- K-Resin Styrene-Butadiene Copolymers (SBC) : Customer Benefits Typical ApplicationsDocument1 pageK-Resin Styrene-Butadiene Copolymers (SBC) : Customer Benefits Typical ApplicationssumherilNo ratings yet

- Pead - Chevron Phillips - HHM 5502 BN PDFDocument1 pagePead - Chevron Phillips - HHM 5502 BN PDFAdemilson Alves Dos SantosNo ratings yet

- Estane Skythane S185A TPU: TypeDocument1 pageEstane Skythane S185A TPU: Typejuliushasan2No ratings yet

- TDS - Marlex® HHM 5502BN PolyethyleneDocument1 pageTDS - Marlex® HHM 5502BN PolyethyleneindahNo ratings yet

- Product 06931 HOMO PT331MDocument1 pageProduct 06931 HOMO PT331MKan Sang MokNo ratings yet

- Lldpe - LL7410D PDSDocument1 pageLldpe - LL7410D PDSchinchotarngNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Paper tube adhesive composition increases strengthDocument4 pagesPaper tube adhesive composition increases strengthProduction SHVPMNo ratings yet

- Company Profile & ProductsDocument40 pagesCompany Profile & ProductsMohit Agarwal100% (1)

- Gas Sensors A ReviewDocument15 pagesGas Sensors A ReviewThành Nhân ĐặngNo ratings yet

- Determination of Enzyme Activity Through Glucose Using Picric Acid Method, PH and Temperature (2EMT - Group 1, 2010)Document6 pagesDetermination of Enzyme Activity Through Glucose Using Picric Acid Method, PH and Temperature (2EMT - Group 1, 2010)Mary ChristelleNo ratings yet

- Synthesis and Spectrophotometric Study of Some New Azo Dyes Derived From MetoclopramideDocument9 pagesSynthesis and Spectrophotometric Study of Some New Azo Dyes Derived From MetoclopramideDarian HerascuNo ratings yet

- Osmotic DrugDocument14 pagesOsmotic DrugUbaid ShabirNo ratings yet

- Bioremediation of Heavy MetalsDocument9 pagesBioremediation of Heavy MetalsshwetaNo ratings yet

- Organic Synthesis TutorialDocument2 pagesOrganic Synthesis TutorialPrabash Rathnayaka100% (1)

- Bokaro Steel PlantDocument43 pagesBokaro Steel PlantRishita PanjwaniNo ratings yet

- Bonding in complexes explained by Crystal Field TheoryDocument22 pagesBonding in complexes explained by Crystal Field TheoryMahendra Pratap SinghNo ratings yet

- 1.1, 1.2, 1.3 Carbohydrates PDFDocument4 pages1.1, 1.2, 1.3 Carbohydrates PDFshahbazhu006No ratings yet

- Paper Organic Chemistry "Soap": Arranged By: Andi Ria Indahsari Asik 1913442004Document11 pagesPaper Organic Chemistry "Soap": Arranged By: Andi Ria Indahsari Asik 1913442004Andi RiaNo ratings yet

- Chemistry - Extra Edge Topics For NEET 2020 PDFDocument4 pagesChemistry - Extra Edge Topics For NEET 2020 PDFalishNo ratings yet

- Department of Chemistry Memorial University of Newfoundland Chemistry 1050Document11 pagesDepartment of Chemistry Memorial University of Newfoundland Chemistry 1050Abdo BedirNo ratings yet

- Chemistry 2000 Paper 2+ansDocument17 pagesChemistry 2000 Paper 2+ansapi-3824003No ratings yet

- Tonsil Supreme 118ffDocument2 pagesTonsil Supreme 118ffmuhammadnainNo ratings yet

- DOC316.53.01173 8ed PDFDocument8 pagesDOC316.53.01173 8ed PDFcarlososorio_184664No ratings yet

- El Suelo, Regulador Fisicoquímico de Elementos Traza para Las PlantasDocument14 pagesEl Suelo, Regulador Fisicoquímico de Elementos Traza para Las PlantasKelly Marian BautistaNo ratings yet

- Hydrometallurgy NotesDocument96 pagesHydrometallurgy NotesTatenda SibandaNo ratings yet

- Decalcification: Mark Lester B. Cauan, RMTDocument59 pagesDecalcification: Mark Lester B. Cauan, RMTMarissa Cordova100% (2)

- Test Bank For Microbiology A Systems Approach 6th Edition Marjorie Kelly Cowan Heidi SmithDocument31 pagesTest Bank For Microbiology A Systems Approach 6th Edition Marjorie Kelly Cowan Heidi SmithAmandaReynoldsagfcy100% (23)

- Synthesis and Charecterization of Alfecrni Four Component High Entropy Alloy by Mechanical AlloyingDocument5 pagesSynthesis and Charecterization of Alfecrni Four Component High Entropy Alloy by Mechanical Alloyingvsraju2No ratings yet

- Jobs Plot Experiment Lab ManualDocument6 pagesJobs Plot Experiment Lab ManualGourav DasNo ratings yet

- Pharmaceutical 3-A (P3-A) P3A - 2 - 2008Document23 pagesPharmaceutical 3-A (P3-A) P3A - 2 - 2008CHRISTIAN ZAVALANo ratings yet

- Sample Questions - Chapter 11Document7 pagesSample Questions - Chapter 11Rasel IslamNo ratings yet

- 2B. Translokasi Di FloemDocument13 pages2B. Translokasi Di FloemTimahRasyidi SNo ratings yet

- Organic Chemistry Reactions of AlkenesDocument12 pagesOrganic Chemistry Reactions of Alkenesrakeshtrikha8668No ratings yet

- Preparation of OintmentsDocument27 pagesPreparation of OintmentsHisham AlhirereNo ratings yet

- Determining Heavy Metal Levels in Natural Water by DPASVDocument29 pagesDetermining Heavy Metal Levels in Natural Water by DPASVSandraNo ratings yet

- ToxicologyDocument194 pagesToxicologyAnkitaNo ratings yet