Professional Documents

Culture Documents

Material Data Sheet - Stainless Steel 1.4404 (316L)

Uploaded by

Ratnasari PudenaliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material Data Sheet - Stainless Steel 1.4404 (316L)

Uploaded by

Ratnasari PudenaliCopyright:

Available Formats

Design. Material. 3D Printing.

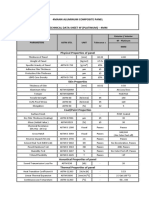

Material Data Sheet - Stainless steel 1.4404 (316L)

Material Description

The 1.4404 steel from AIRBUS APWORKS belongs to the group of stainless steels and is a corrosion

resistant, fully austenitic, chromium, nickel, molybdenum, and iron based alloy. Parts built from Airbus

APWorks’ 1.4404 steel have a chemical composition corresponding to ASTM F138 “Standard

Specification for Wrought 18Cr-14Ni-2.5Mo Stainless Steel Bar and Wire for Surgical Implants (UNS

S31673).”

This material is ideal for the automotive industry and shipbuilding industry for welding components, for

aerospace for fastening components, for equipment for the food industry with regard to corrosion

resistant pipes and containers, chemical/pharmaceutical industry, as well as the oil and gas industry.

Built parts can be machined, shot peened, and polished in as built or stress relieved (AMS2759) states

if required.

General Properties

Properties Values

Density (g/cm3) 7.9

Typical tolerance (μm) ± 100

Smallest wall thickness (mm) 1.0

Surface roughness, as built (μm) * Ra 15 / Rz 90 *

Mechanical Properties

Properties Values

Young’s Modulus (GPa) 180

Yield Strength (MPa) 470

Ultimate Tensile Strength (MPa) 540

Elongation at Break (%) 40

Hardness (HRC) 15

Values stated in the datasheet refer to the minimum properties that are reached using Additive Layer

Manufacturing in the least strong direction of the material.

The values of the mechanical properties are generated from tests conducted at room temperature,

according to DIN EN 2002-001 standards, from specimens that have been machined.

* The surface roughness values depend on the measurement method used and the orientation of the

surface. The values quoted here give an indication of what can be achieved for certain surfaces.

AIRBUS APWORKS GmbH I Willy Messerschmitt Str. 1 I 82024 Taufkirchen I Germany

Tel.: +49 (0) 89 954738762 I info@apworks.de

REV 0006 – 20170517

You might also like

- Engineering Material Specification: Printed Copies Are UncontrolledDocument8 pagesEngineering Material Specification: Printed Copies Are UncontrolledaldairlopesNo ratings yet

- ABS-M30i: Production-Grade Thermoplastic For Fortus 3D PrintersDocument2 pagesABS-M30i: Production-Grade Thermoplastic For Fortus 3D PrinterskaledioskoppNo ratings yet

- Th-130 Universal Hardness TesterDocument2 pagesTh-130 Universal Hardness TesterJuan CarlosNo ratings yet

- Results in EngineeringDocument9 pagesResults in EngineeringEgehan ÜnalNo ratings yet

- Machining Performance Enhancement of Brass C360 Alloy Using Taguchi Based Grey Relational Analysis MethodDocument10 pagesMachining Performance Enhancement of Brass C360 Alloy Using Taguchi Based Grey Relational Analysis MethodTJPRC PublicationsNo ratings yet

- Precidur C45/C45E: Heat Treatable and Spring SteelDocument3 pagesPrecidur C45/C45E: Heat Treatable and Spring SteelAsad EjazNo ratings yet

- PC Abs Spec SheetDocument2 pagesPC Abs Spec SheetAli YudiNo ratings yet

- Katalog Umformtechnik 293628 (2011) - EN-GBDocument84 pagesKatalog Umformtechnik 293628 (2011) - EN-GBDaivison CamposNo ratings yet

- Filament Specifications Unit ValueDocument4 pagesFilament Specifications Unit ValueRoberto Gonzalo PelazNo ratings yet

- Determination of Optimum Cutting Parameters For Multiperformance Characteristics in CNC End Milling of Al-Si7Mg Aluminum AlloyDocument7 pagesDetermination of Optimum Cutting Parameters For Multiperformance Characteristics in CNC End Milling of Al-Si7Mg Aluminum AlloyerpublicationNo ratings yet

- SAE E-BAJA Team VORTEXDocument12 pagesSAE E-BAJA Team VORTEXPrakash kumarNo ratings yet

- Precidur 16Mncr5: Case Hardening SteelDocument3 pagesPrecidur 16Mncr5: Case Hardening SteelShubhangi ShindeNo ratings yet

- Thyssenkrupp dd12 Product Information Precision Steel enDocument3 pagesThyssenkrupp dd12 Product Information Precision Steel entablicafiskalNo ratings yet

- Duraform Pa Plastic: General Properties FeaturesDocument2 pagesDuraform Pa Plastic: General Properties FeaturesMarouane MbarkiNo ratings yet

- Polymax PC Tds v4Document2 pagesPolymax PC Tds v4Hector GarciaNo ratings yet

- Manual RugosimetroDocument6 pagesManual RugosimetroFabian Kmilo de GomezNo ratings yet

- TPU 95A Technical Data SheetDocument3 pagesTPU 95A Technical Data SheetSteven DonosoNo ratings yet

- Engineering Material Specification: Controlled Document at Page 1 of 7Document7 pagesEngineering Material Specification: Controlled Document at Page 1 of 7Reginaldo SantosNo ratings yet

- Hoist Chains: For Manual and Motor-Driven HoistsDocument12 pagesHoist Chains: For Manual and Motor-Driven HoistsjoosuasinagaNo ratings yet

- Tata Steel Engineering Ympress s355mc High Strength Steel Datasheet enDocument2 pagesTata Steel Engineering Ympress s355mc High Strength Steel Datasheet enSachin UgalmugaleNo ratings yet

- ASNZS 3679 - 2 400 (L15) Welded Beam and Columns Datasheet Apr 2020Document2 pagesASNZS 3679 - 2 400 (L15) Welded Beam and Columns Datasheet Apr 2020aries andhikaNo ratings yet

- Table Dismantled Type CNC PlasmaDocument10 pagesTable Dismantled Type CNC Plasmajairo eduardoNo ratings yet

- 303 Stainless Steel Material Data SheetDocument3 pages303 Stainless Steel Material Data SheetBlack LotusNo ratings yet

- SS GP1 M270 - 04 09 - enDocument5 pagesSS GP1 M270 - 04 09 - enPiotr PawłowskiNo ratings yet

- Filament Specifications Unit Value: All 3D Printed Parts Printed at 100% Infill and Annealed at 110ºC/20 MinDocument4 pagesFilament Specifications Unit Value: All 3D Printed Parts Printed at 100% Infill and Annealed at 110ºC/20 MinRoberto Gonzalo PelazNo ratings yet

- PolyCast TDS V3Document2 pagesPolyCast TDS V3jerome.luganNo ratings yet

- DS-DuraForm Flex Plastic USDocument2 pagesDS-DuraForm Flex Plastic USBahadır UysalNo ratings yet

- Ultimaker PC Technical Data SheetDocument3 pagesUltimaker PC Technical Data SheetFelipe TeixeiraNo ratings yet

- Powdermet Brochure BodycoteDocument6 pagesPowdermet Brochure BodycoteAngel LagrañaNo ratings yet

- Parametric Optimization of CNC Drilling Machine For Mild Steel Using Taguchi Design and Single To Noise Ratio Analysis - Y Tyagi (2012)Document9 pagesParametric Optimization of CNC Drilling Machine For Mild Steel Using Taguchi Design and Single To Noise Ratio Analysis - Y Tyagi (2012)TAUFIQ ARIEF NUGRAHANo ratings yet

- Precidur DD11: Mild, Unalloyed SteelDocument3 pagesPrecidur DD11: Mild, Unalloyed SteelMada TetoNo ratings yet

- Teslin: Quick OverviewDocument3 pagesTeslin: Quick OverviewDewiNo ratings yet

- Tata Steel - YMPRESS S500MC - Data SheetDocument2 pagesTata Steel - YMPRESS S500MC - Data SheetpnagarajjNo ratings yet

- Aluminium ADC12Document3 pagesAluminium ADC12Harish Kalme100% (1)

- International Journal of Chemtech Research: Pravin Pawar, Raj Ballav, Amaresh KumarDocument6 pagesInternational Journal of Chemtech Research: Pravin Pawar, Raj Ballav, Amaresh KumarMuhamad BaharudiantoNo ratings yet

- Jsir 69 (8) 606-612Document7 pagesJsir 69 (8) 606-612Vijay KumarNo ratings yet

- Data Sheet 173 Armox 440T 2016-04-22 34 371857150 enDocument3 pagesData Sheet 173 Armox 440T 2016-04-22 34 371857150 enJose ManuelNo ratings yet

- 03 - Surface Roughness Analysis in Finishing End-Milling of Duplex Stainless Steel UNS S32205Document10 pages03 - Surface Roughness Analysis in Finishing End-Milling of Duplex Stainless Steel UNS S32205Gustavo Rocha de QueirozNo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrintersDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrinterskaledioskoppNo ratings yet

- 316LVM Stainless Steel Ideal for ImplantsDocument2 pages316LVM Stainless Steel Ideal for ImplantsRaj RajeshNo ratings yet

- Ultimaker ABS (TDS)Document3 pagesUltimaker ABS (TDS)reinaldolubeNo ratings yet

- SIEMENS - Ingenieria Mecanica 2012 08 - CENITEC 1Document141 pagesSIEMENS - Ingenieria Mecanica 2012 08 - CENITEC 1Nestor IglesiasNo ratings yet

- Thyssenkrupp hsm-380 Product Information Precision Steel enDocument3 pagesThyssenkrupp hsm-380 Product Information Precision Steel enParthi NatarajNo ratings yet

- Track Adjuster-MeraDocument1 pageTrack Adjuster-MeraSame TrầnNo ratings yet

- PolyMax PLA TDS V4Document2 pagesPolyMax PLA TDS V4fNo ratings yet

- Dimensional and Surface Texture Characterization in Fused Deposition Modelling (FDM) With ABS PlusDocument8 pagesDimensional and Surface Texture Characterization in Fused Deposition Modelling (FDM) With ABS PlusChris BurgerNo ratings yet

- Colorbond Ultra Datasheet New V8Document2 pagesColorbond Ultra Datasheet New V8Gireesh Krishna KadimiNo ratings yet

- Datasheets E FDMDocument5 pagesDatasheets E FDMAlireza YaghoubiNo ratings yet

- 18crnimo7-6: Steel GradeDocument4 pages18crnimo7-6: Steel GradeFINNING CATNo ratings yet

- ULTEM 9085: Production-Grade Thermoplastic For Fortus 3D PrintersDocument3 pagesULTEM 9085: Production-Grade Thermoplastic For Fortus 3D PrintersRui MatiasNo ratings yet

- P430 ABSplus 3D Printing Material Properties SummaryDocument1 pageP430 ABSplus 3D Printing Material Properties SummaryuarkgolfNo ratings yet

- GMW14672 ProfileID - 000070128Document15 pagesGMW14672 ProfileID - 000070128Muthu Ganesh100% (1)

- Technical Data Sheet PC: Filament SpecificationsDocument3 pagesTechnical Data Sheet PC: Filament SpecificationsVladimir SarmientoNo ratings yet

- 7ME63105KK136AA2-ZDocument2 pages7ME63105KK136AA2-ZElvis AlvarezNo ratings yet

- Colorbond XRW Datasheet New V8Document2 pagesColorbond XRW Datasheet New V8Gireesh Krishna KadimiNo ratings yet

- Engineering Material SpecificationDocument10 pagesEngineering Material SpecificationMike FiorenNo ratings yet

- 4mann Aluminum Composite Panel Technical Data Sheet 4F (Platinum) - 4MmDocument1 page4mann Aluminum Composite Panel Technical Data Sheet 4F (Platinum) - 4MmSTRUCTURAL ENGG DEPT TDLCCSNo ratings yet

- Charla Ing. Andreas Hunger - Nuevas Tendencias en El ProcesoDocument39 pagesCharla Ing. Andreas Hunger - Nuevas Tendencias en El ProcesoWalter-uniNo ratings yet

- Ultimaker TPU 95A: Technical Data SheetDocument3 pagesUltimaker TPU 95A: Technical Data SheetFelipe TeixeiraNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Caesar II BrochureDocument2 pagesCaesar II BrochurePrakhar KulshreshthaNo ratings yet

- GS Butter Production 07 12 GB WebDocument8 pagesGS Butter Production 07 12 GB WebIzudin OkicNo ratings yet

- Life Cycle Assessment of Sewer System: Comparison of Pipe MaterialsDocument13 pagesLife Cycle Assessment of Sewer System: Comparison of Pipe MaterialsRatnasari PudenaliNo ratings yet

- Static & Dynamic Analysis of Piping SystemDocument105 pagesStatic & Dynamic Analysis of Piping Systemkarthikeashwar100% (4)

- Reliability Analysis Applied On Centrifugal PumpsDocument9 pagesReliability Analysis Applied On Centrifugal PumpsJose Rodriguez Sanchez100% (2)

- Tables - TechnicalProperties - EN 10088 PDFDocument24 pagesTables - TechnicalProperties - EN 10088 PDFeugenio.gutenbertNo ratings yet

- GS Shortening General Information 07 12 GB Web PDFDocument7 pagesGS Shortening General Information 07 12 GB Web PDFRatnasari PudenaliNo ratings yet

- Stainless Steel: Users GuideDocument35 pagesStainless Steel: Users GuideRatnasari PudenaliNo ratings yet

- Aci 351 3R PDFDocument26 pagesAci 351 3R PDFLakshmi PrabhaNo ratings yet

- Preparing, Cleaning, and Evaluating Corrosion Test SpecimensDocument8 pagesPreparing, Cleaning, and Evaluating Corrosion Test SpecimensLê CôngNo ratings yet

- ASM Architecture ASM Disk Group AdministrationDocument135 pagesASM Architecture ASM Disk Group AdministrationVamsi ChowdaryNo ratings yet

- Borneo United Sawmills SDN BHD V Mui Continental Insurance Berhad (2006) 1 LNS 372Document6 pagesBorneo United Sawmills SDN BHD V Mui Continental Insurance Berhad (2006) 1 LNS 372Cheng LeongNo ratings yet

- The Causes of Cyber Crime PDFDocument3 pagesThe Causes of Cyber Crime PDFInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- cp2021 Inf03p02Document242 pagescp2021 Inf03p02bahbaguruNo ratings yet

- Troubleshooting Edge Quality: Mild SteelDocument14 pagesTroubleshooting Edge Quality: Mild SteelAnonymous U6yVe8YYCNo ratings yet

- (EMERSON) Loop CheckingDocument29 pages(EMERSON) Loop CheckingDavid Chagas80% (5)

- Syllabus - Mech 3rd YearDocument130 pagesSyllabus - Mech 3rd YearAbhishek AmarNo ratings yet

- Dubai Healthcare Providers DirectoryDocument30 pagesDubai Healthcare Providers DirectoryBrave Ali KhatriNo ratings yet

- Lead Magnet 43 Foolproof Strategies To Get More Leads, Win A Ton of New Customers and Double Your Profits in Record Time... (RDocument189 pagesLead Magnet 43 Foolproof Strategies To Get More Leads, Win A Ton of New Customers and Double Your Profits in Record Time... (RluizdasilvaazevedoNo ratings yet

- GE Supplier Add Refresh FormDocument1 pageGE Supplier Add Refresh FormromauligouNo ratings yet

- Nammo Bulletin 2014Document13 pagesNammo Bulletin 2014Dmitry Karpov0% (1)

- Trustees Under IndenturesDocument233 pagesTrustees Under IndenturesPaul9268100% (6)

- User-Centered Website Development: A Human-Computer Interaction ApproachDocument24 pagesUser-Centered Website Development: A Human-Computer Interaction ApproachKulis KreuznachNo ratings yet

- Proprietar Utilizator Nr. Crt. Numar Inmatriculare Functie Utilizator Categorie AutovehiculDocument3 pagesProprietar Utilizator Nr. Crt. Numar Inmatriculare Functie Utilizator Categorie Autovehicultranspol2023No ratings yet

- Factors Affecting Employee Turnover and Job Satisfaction A Case Study of Amari Hotels and Resorts Boondarig Ronra and Assoc. Prof. Manat ChaisawatDocument26 pagesFactors Affecting Employee Turnover and Job Satisfaction A Case Study of Amari Hotels and Resorts Boondarig Ronra and Assoc. Prof. Manat ChaisawathumeragillNo ratings yet

- Converting An XML File With Many Hierarchy Levels To ABAP FormatDocument8 pagesConverting An XML File With Many Hierarchy Levels To ABAP FormatGisele Cristina Betencourt de OliveiraNo ratings yet

- "Corbel" - Concrete Corbel Analysis: Program DescriptionDocument4 pages"Corbel" - Concrete Corbel Analysis: Program DescriptioniuliandurdureanuNo ratings yet

- Bid Document PDFDocument125 pagesBid Document PDFAzharudin ZoechnyNo ratings yet

- AB InBev Code of Business Conduct PDFDocument10 pagesAB InBev Code of Business Conduct PDFcristian quelmis vilca huarachiNo ratings yet

- BCM Risk Management and Compliance Training in JakartaDocument2 pagesBCM Risk Management and Compliance Training in Jakartaindra gNo ratings yet

- City Gas Distribution ReportDocument22 pagesCity Gas Distribution Reportdimple1101100% (9)

- Difference Between Knowledge and SkillDocument2 pagesDifference Between Knowledge and SkilljmNo ratings yet

- Software Engineering Modern ApproachesDocument775 pagesSoftware Engineering Modern ApproachesErico Antonio TeixeiraNo ratings yet

- Broschuere Unternehmen Screen PDFDocument16 pagesBroschuere Unternehmen Screen PDFAnonymous rAFSAGDAEJNo ratings yet

- Building A Computer AssignmentDocument3 pagesBuilding A Computer AssignmentRajaughn GunterNo ratings yet

- Central BankDocument65 pagesCentral BankFarazNaseer100% (1)

- InvoiceDocument1 pageInvoiceAnurag SharmaNo ratings yet

- How To: Create A Clickable Table of Contents (TOC)Document10 pagesHow To: Create A Clickable Table of Contents (TOC)Xuan Mai Nguyen ThiNo ratings yet

- Iqvia PDFDocument1 pageIqvia PDFSaksham DabasNo ratings yet

- C J L F S: Vinod TiwariDocument21 pagesC J L F S: Vinod TiwariVinod TiwariNo ratings yet