Professional Documents

Culture Documents

Lens Prism Grind MLG.147152050

Uploaded by

swami061009Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lens Prism Grind MLG.147152050

Uploaded by

swami061009Copyright:

Available Formats

SYLLABUS FOR THE TRADE

OF

MECHANIC LENS/PRISM GRINDING

(SEMESTER PATTERN)

UNDER

CRAFTSMEN TRAINING SCHEME (CTS)

Designed in: 2013

By

Government of India

CENTRAL STAFF TRAINING AND RESEARCH INSTITUTE

Directorate General of Employment & Training

Ministry of Labour & Employment

EN-Block, Sector-V, Salt Lake

Kolkata-700 091

MLG # double sem. 1 CSTARI

List of members of Trade Committee meeting for the trade of

“Mechanic Lens/Prism Grinding” held at ATI, Chennai

SL. REPRESENTING

NAME & DESIGNATION REMARK

NO. ORGANISATION

1 Shri. A.Mahendiran ATI,Chennai Chairman

2 Shri.S.Harinath Babu, Joint Director of Training ATI,Chennai Member

3 Shri.M.Thamizharasan,Dy.Director of Training ATI,Chennai Member

4 Shri.K.Srinivasa Rao, Dy.Director of Training ATI,Chennai Member

Grace & Noble,

5 Shri.Mustaq Ahmed Consultancy Member

Chennai-3

MSME-Development

6 Shri.K.V.Rao,Asst.Director Member

Institute, Chennai-32

7 Shri.Vyshakh Govt. ITI, Mala, Kerala Member

8 Shri. Bimal Govt. ITI, Mala, Kerala Member

Essilovi India Pvt. Ltd,

9 Smt.N.Anantha Lakshmi Member

Chennai

Lawrence & Mayo Ltd

10 Shri.Prem Sudhakar Member

Chennai

MLG # double sem. 2 CSTARI

List of members attended the Workshop to finalize the syllabi of existing CTS into Semester Pattern

held from 6th to 10th May’2013 at CSTARI, Kolkata.

Sl. No. Name & Designation Organisation Remarks

1. R.N. Bandyopadhyaya, Director CSTARI, Kolkata-91 Chairman

2. K. L. Kuli, Joint Director of Training CSTARI, Kolkata-91 Member

3. K. Srinivasa Rao, Joint Director of Training CSTARI, Kolkata-91 Member

4. L.K. Muhkerjee, Deputy Director of Training CSTARI, Kolkata-91 Member

5. Ashoke Rarhi, Deputy Director of Training ATI-EPI, Dehradun Member

6. N. Nath, Assistant Director of Training CSTARI, Kolkata-91 Member

7. S. Srinivasu, Assistant Director of Training ATI-EPI, Hyderabad-13 Member

8. Sharanappa, Assistant Director of Training ATI-EPI, Hyderabad-13 Member

9. Ramakrishne Gowda, Assistant Director of Training FTI, Bangalore Member

Goutam Das Modak,

10. RVTI, Kolkata-91 Member

Assistant Director of Trg./Principal

Govt. ITI, Dollygunj,

11. Venketesh. Ch. , Principal Member

Andaman & Nicobar Island

12. A.K. Ghate, Training Officer ATI, Mumbai Member

13. V.B. Zumbre, Training Officer ATI, Mumbai Member

P.M. Radhakrishna pillai,

14. CTI, Chennai-32 Member

Training Officer

15. A.Jayaraman, Training officer CTI Chennai-32, Member

16. S. Bandyopadhyay, Training Officer ATI, Kanpur Member

17. Suriya Kumari .K , Training Officer RVTI, Kolkata-91 Member

18. R.K. Bhattacharyya, Training Officer RVTI, Trivandrum Member

19. Vijay Kumar, Training Officer ATI, Ludhiana Member

20. Anil Kumar, Training Officer ATI, Ludhiana Member

21. Sunil M.K. Training Officer ATI, Kolkata Member

22. Devender, Training Officer ATI, Kolkata Member

23. R. N. Manna, Training Officer CSTARI, Kolkata-91 Member

24. Mrs. S. Das, Training Officer CSTARI, Kolkata-91 Member

25. Jyoti Balwani, Training Officer RVTI, Kolkata-91 Member

26. Pragna H. Ravat, Training Officer RVTI, Kolkata-91 Member

27. Sarbojit Neogi, Vocational Instructor RVTI, Kolkata-91 Member

I.T.I., Berhampore,

28. Nilotpal Saha, Vocational Instructor Member

Murshidabad, (W.B.)

29. Vijay Kumar, Data Entry Operator RVTI, Kolkata-91 Member

MLG # double sem. 3 CSTARI

GENERAL INFORMATION

1. Name of the Trade : Mechanic Lens/Prism Grinding.

2. N.C.O. Code No. :

3. Duration : One year

4. Power norms : 7.5 KW

5. Space norms : Workshop: 100 Sqr meter.

6. Entry Qualification : Passed 10th class examination.

7. Unit size (No. of Student) : 12

8. Instructor’s/ Trainer’s : (A) Degree in Mechanical Engineering from

Qualification recognized engg. college/university with one year

experience in the relevant field.

OR

Diploma in Mechanical Engg from recognized

board of technical education with two years

experience in the relevant field

OR

10th/Madhyamic pass + NTC/NAC in the relevant

Trade with 3 years post qualification experience

in the relevant field.

(B) Desirable qualification :

Preference will be given to a candidate with

Craft Instructor’s Certificate.

* Note: At least one Instructor must have Degree/Diploma in Mechanical Engineering.

MLG # double sem. 4 CSTARI

Syllabus for the Trade of “MECHANIC LENS/PRISM GRINDING” under C.T.S.

Duration: Six Month

First Semester Code: MLG – Sem - I

Week Workshop calculation

Trade practical Trade Theory Engg.Drawing

No. & science

1 -Familiarization with the Institute -Importance of safety and general INTRODUCTION INTRODUCTION

-Importance of Trade training --Different precautions observed in the Institute Important of Importants of science and

skills involved in the trade. -Safety codes and standards Engineering drawing calculation to the trade

-Observing safety precautions in the job & applicable to glass and mirror and its knowledge skill and fundamental

precision/critical aspects in the job. workers arithmetical operations

-Care and handling of glasses addition subtraction,

-Safety appliance such as goggles, multiplication and division

face mask hand gloves etc.

2 BASIC FITTING GRINDING & -Description of hand tools, uses, care -Use of Drawing GENERAL

BENCH WORKING: maintenance. Instruments. T-square SIMPLIFICATIONS

-Identification of different hand tools -Description of chisels and its Drawing Board etc -Fraction, Addition,

related to the trade and handling application Subtraction, Multiplication

and Division problems

Grinding of chisel

3 -Marking and sawing practice on M.S flats -Description of Hacksaw &Grinding - Letters, Numbers - Fraction, Addition,

6 mm thick Wheels,Diamond cutter and and Alphabets as per Subtraction and

Trepanning Tools. IS 696-1972 Multiplication problems

Hacksaw frame, blade types and

application

4 -Filing practice, simple fitting works, -Files specification, description, uses , -Letters, Numbers -Decimal - Addition,

marking practice with steel rule, dividers measuring standards (English, Metric and Alphabets as per Subtraction,

and callipers (circles, areas, parallel lines). units) Description of dividers, IS 696-1972 Multiplication, Division

Use of Vernier calipers and Micrometer and calipers, vernier calipers and problems

Depth gauge Micrometer, Depth gauge uses and

care & maintenance

MLG # double sem. 5 CSTARI

5 -Drilling different sizes of holes by hand -Familiarization of Drilling machine -Free hand sketching -Fraction and decimals

and Machine and uses of straight lines, conversion

-Drills types and operations rectangles, circles -Fraction to Decimal and

and polygons vice versa

6 -Trepanning (format cutting) -Different types of Trepanning Tools -Use of different -Decimal - Addition,

& Tool Holder. types of lines and Subtraction,

symbols for drawing. Multiplication, division –

Importants of putting problems

dimension on the

drawing as per IS

696-1972

7 -Use of screw drivers, spanners, pliers, etc. -Description of screw drivers, pliers -Free hand sketching -Decimal - Addition,

-Use of Electric heater for heating glasses. and spanners. with dimension scale Subtraction,

-Use of various types of Tongs -Description of Tongs, size, types and and proportionate Multiplication and

uses. sketching Division problems

-Glass cutting tools – Description of

Diamond tipped cutter and wheel type

cutter.

8 MAKING OF GLASS MIRRORS -Types of glasses and commercial -Reading of simple METALS:

FROM SHEET GLASS forms of glasses and glass materials blue print -Properties and uses of

-Identification & Demonstration of ( sheet glass and plate glass) and cast iron ,wrought iron,

materials of different Glasses such as soda their uses plain carbon steel and

lime glass, potash lime glass, potash led -Important of glasses in Engineering alloy steels

glass and common glass field

-Glass materials and its composition

-Cleaning, Marking and cutting of glasses to 1. Idea about ‘refractive index’ & ‘V

different shapes such as square, rectangle, on value”

3 mm and 5.5 mm thick glasses 2. Types and major classification of

glass such as soda lime glass, potash

lime glass, potash led glass, common

glass

3. Use of glass/optic in different fields.

MLG # double sem. 6 CSTARI

9 -Cleaning, Marking and cutting of glasses to -Defects in Glass materials & -Isometric views and -Properties and uses of

different shapes such as step cutting and detection oblique views with cast iron, wrought iron,

circular cutting on 3 mm and 5.5 mm thick of defects dimensions of such plain carbon steel and

glasses 1. Nature of defects (i.e. air bubbles, as Cube, alloy steels

veins, in- homogeneity etc.) Rectangular block,

2. Adverse effects on products Cylinder etc.

for these defects.

3.Instruments/ Equipments used

to detect these defects.

10 -Drilling on plain glasses 3mm, 5 mm and 10 -Types of glasses such as coloured -Explanation of -Properties and uses of

mm thick glass, bullet proof glass, fiber glass, simple Orthographic Copper, Zinc, Lead, Tin

foam glass, float glass, glass blocks, projection - I st and Alluminium

heat excluding glass, obscured angle projection as

glass, safety glass, shielding glass, per IS 696 - 1972

ultra violet ray glass, wired -glass,

11 -Forming of glass for making concave mirror Types of mirrors such as plain or -Explanation of -Properties and uses of

straight mirror, spherical or curved simple Orthographic Brass, Bronze, Rubber

mirror (concave and convex) projection - 3 rd and Timber

angle projection as

per IS 696 - 1972

12 -Forming of glass for making convex mirror -Glass moulding process. -Sketching the UNITS:

views of solid -Systems of units-

bodies when viewed British, metric and SI

perpendicular to units for Length, Mass,

their surfaces and Area, Volume, Capacity

axes and Time

13 -Grinding of glasses to different profiles -Glass mould components -Sketching the -Conversion between

1. Nick ring views of solid British and Metric system

2. Bottle mould bodies when viewed

3. Bottle plate perpendicular to

their surfaces and

axes

MLG # double sem. 7 CSTARI

14 -Sensitizing of glasses -Indian standard quality -Free hand sketching SQUARE ROOTS

specification for silvered glass of plan and elevation -The Square and Square

mirror for general purpose and of simple objects roots of whole number

furniture mirror like Hexagonal bar, and decimal, shop

Circular bar, tapered problems

bar and Hallow bar -Pythagoras theorem

etc.

15 -Polishing of glasses -Surface preparation of glasses – -Reading of simple HEAT AND

polishing compounds and polishing blue print TEMPERATURE:

procedure -Definition of Heat and

Temperature

-Effect of Heat,

Thermometric scales such

as Celsius, Fahrenheit and

Kelvin. Temperature

measuring instruments

16 -Surface preparation and Silvering of Glass -Silvering of glass mirrors -Views of simple -Conversion between the

mirrors Hallow and solid above Scales of

Bodies with Temperature

Dimensions -Units of Heat-Calorie,

B.Th.U.,C.H.U. Specific

Heat, Latent Heat, Heat

Loss and Heat Gain -

simple problem

17 -Coppering of Glass mirrors -Coppering of glass mirrors -Views of simple PERCENTAG

Hallow and solid -Changing percentage in

Bodies with to Decimal and Fraction

Dimensions and vice versa- problem

on percentage related

trade

18 -Painting on glasses -Types of paints used for painting -Construction of -Percentage-Changing

glasses and painting procedure Orthographic percentage in to Decimal

MLG # double sem. 8 CSTARI

Projection from the and Fraction and vice

given isometric view versa- problem on

of shaped Blocks in percentage related trade

First angle method

19 -Inspection and testing of Glasses and Glass -Inspection and testing of glasses -Construction of -SPEED AND

mirrors and Glass mirrors Orthographic VELOCITY:

Projection from the Definition, difference

given isometric view between speed ,velocity

of shaped Blocks in and acceleration.

First angle method -MASS AND WEIGHT:

Definition, difference

between Mass and Weight

20 -Project work - manufacturing of furniture -Project work - manufacturing -Construction of -Newton’s Law of motion

mirror of furniture mirror Orthographic -Definition of Force, unit

Projection from the of force in MKS system

given isometric view and S.I Unit of Force

of shaped Blocks in

3rd angle method

21 Project work - manufacturing of concave Project work - manufacturing of -Construction of RATIOS AND

and convex mirror concave and convex mirror Orthographic PROPORTIONS:

Projection from the -Ratio-Simple problems

given isometric view in Ratios

of shaped Blocks in

3rd angle method

22 -Project work - manufacturing of dentist -Project work - manufacturing -Construction of -Proportions-direct and

mirror of dentist mirror Orthographic inverse

Projection from the -Proportions – shop

given isometric view problems

of shaped Blocks in

3rd angle method

MLG # double sem. 9 CSTARI

23 -Project work - manufacturing of periscope -Project work - manufacturing do do

of periscope

24 -Project work - manufacturing of periscope -Project work - manufacturing

of periscope

25 (i) Project work,

(ii) Industrial visit (Optional)

26 Examination.

MLG # double sem. 10 CSTARI

Syllabus for the Trade of “MECHANIC LENS/PRISM GRINDING” under C.T.S.

Duration : Six Month

Second Semester Code : MLG – Sem - II

Week Trade practical Trade Theory Engg. Drawing Workshop calculation &

No. science

1. -Familiarization with the Institute Importance of safety and general -Print reading related WORK POWER

Importance of Trade training precautions to missing lines and ENERGY:

Different skills involved in the observed in the Institute missing views -Units of work in M.K.S

trade. Observing safety precautions Safety codes and standards applicable to -Exercise on blue print system and SI unit of

in the job & precision/critical glass and mirror workers work

aspects in the job. Care and handling of glasses -Simple problems of Power

Safety appliance such as goggles, face mask

hand gloves etc.

2. Identification & Demonstration of A) Optical materials and its composition -Drawing simple Laws of reflection,

materials of different Lenses 1. Types of lens (glass, CR 39, poly Isometric views from refraction and dispersion

carbonate etc.) Ortho graphic views

2. Use of optical lens in different -Drawing views of

fields lenses and Prisms

B) Defects in Optical lens materials &

detection of defects

1. Nature of defects (i.e. air bubbles, veins,

In homogeneity etc.)

2. Adverse effects on products for these

defects.

3.Instruments/Equipments used to detect

these defects.

MLG # double sem. 11 CSTARI

3. PARAMETERS OF LENSES Uses of lenses and prism -Free hand sketching -Practical units of power

Determination of Radius of Reflection, Refraction Refractive of spectacles such as Watt and Horse

curvature & Focal length of Index, and Dispersion Power

different lenses and determination -Definition of I.H.P, BHP

of power by different methods and Efficiency

4. MAKING OF LENSES , Concept & understanding of the lens -Free hand sketching -Definition of Energy,

& PRISMS. maker’s formula, different types of lenses of riveted joints Potential Energy and

Practice on use of spherical block focal length Vs radius of curvature, linear -Exercise on Blue print Kinetic Energy

60 mm dia. & angular magnification. reading related to - Simple problems related to

Lens setting on spherical block Power of different lenses. Unit of Power missing dimensions Potential Energy and

setting of lens (Dioptre). and missing Kinetic Energy

dimensions and

missing sections

5. Heating pitch, placing on block Different terminology related to optical -Free hand sketching -Laws of Conservation of

with power glass (Bio-Focal) , lens. Defects of Lenses/images Spherical of Nuts and bolts with Energy, S.I. Units of Energy

setting axis. Lens setting on aberrations, Chromatic aberrations, dimensions from - Problems related to

cylindrical block Working Astigmatism,Coma ctc. samples Potential Energy and

process: (Trepanning) -Free hand sketching Kinetic Energy

of hand tools of the

trade

6. Shaping, Rubbing, finishing, and Methods of overcome aberration. -Free hand sketching ALGEBRA:

Polishing by Cerium oxide and Different applications of Lenses. of hand tools of the -Algebraic symbols and

White oxide. Concept of ‘A spherical Lens’ for trade Fundamentals, Addition,

corrections spherical aberration and idea Subtraction, Multiplication

of ‘Extra Dispersion Lens (ED)’ and and Division

Polarize Glass -Algebra – Simple equation

problems

7. Setting Cylindrical die (Tool) Manufacture of optical components -Free hand sketching of -Algebra- Simultaneous

Operate cylindrical m/c. /spherical from material available in market hand tools of the trade Equation Problems

m/c. 1. Material in the form of glass slab/glass -Algebra - Quadratic

mould Equation problems

MLG # double sem. 12 CSTARI

2. Machines used in manufacture of

optics (i.e. slicing, Trepanning, Milling,

Curve generating, Grinding, Smoothing

Polishing, Centering & edging etc.

8. Practice on different Manufacture of optical components -Free hand sketching of -Levers: Types of Levers

operations involved in from material available in market keys and cotters with with their examples

manufacturing of (continued) their dimensions from

Lenses. 3. Tools & Cutters used for samples as per IS

1 Curve generation. manufacture of Optics. standard

2 Grinding 4. Abrasives and its grades used for

3 Smoothing grinding & polishing of optics.

4 Polishing & Hand Polishing 5. Process for manufacture of lenses,

prisms & other types of optical

components.

9. Practice on different Description of Gala (Dammar) -Free hand sketching of -Simple problems on

operations involved in Types & uses in grinding of screw threads with their straight and ball cranked

manufacturing of Lenses. Lenses dimensions from levers

5. Centering &Edging Method of Heating pitch for fixing agents samples as per IS -DENSITY & SPECIFIC

6. Inspection of various Familiarization with cylindrical block standard GRAVITY:

parameters -Mass, weight and

7. Cementing of lenses Archimedes principles &

8. Fusion of Lenses related problems

9. Anti reflection coatings

10. SPECTACLES LENSES Method of finishing and polishing and -Geometrical -MENSURATION:

1. Selection of glass moulds use of cerium oxide and white oxide. development of Prism, - Area square rectangle,

2. Polishing & Profiling to Use of different abrasives of different Pyramid and Equilateral Triangle,

suit in frame grades Isometrics Isosceles Triangle, Right

3. Measurement of power and angled Triangle, Scalene

axis Triangle problems

MLG # double sem. 13 CSTARI

11. SPECTACLES LENSES Description of dies (optical Exercise on blue print - Area square rectangle,

4. manufacturing of Bi-focal glass) Types of die, sizes and reading related to Equilateral Triangle,

lenses their uses surface symbols Isosceles Triangle, Right

5. Transmission measurement Uses of cylindrical and spherical m/c angled Triangle, Scalene

Triangle problems

Lens fitting: 1. Familiarization of edging machine and uses -Triangular prism and -Areas- Hexagon, Circle,

12. Lens fitting on frame by grinding, of different types of glass moulds in hexagonal prism- Circular ring, Sector and

edging and sizing according to accordance with polishing and profiling projection and Ellipse - problems

the required frame. development

Mounting of lens in frame

13. Inspection & Quality Control Defects of eye and correction using -Cylinder projection - Areas of Prism, cone,

1. Use of test plates /proof plates lenses. and development cylinder, hallow cylinder-

2. Measurement of curvature Different parameters of spectacles. -Cone projection and shop problems

& use of instruments (optical development

spherometer) -Examples based on

Right cones

14. 1 Inspection & Quality Control Methods of testing of parameters of -Cylinder projection - Volume and Weight of

4 3. Measurement of Focal Length spectacles. and development simple solid bodies such as

for +Ve & -Ve Lenses & Mirrors -Cone projection and Cube, Square, Prism

4. Use of optical measuring devices development Rectangular Prism, and

such as ‘Angle Dekkor’, -Examples based on Hexagonal Prism

Lensometer, Refractometer, Right cones

Spherometer, Interferometer, Strain

viewer etc.

Idea about optical aberrations.

15 Making Prism & other flat Types of prism such as right angle -Views of simple solid -Volume and weight of

surfaces prism, dispersing prism, penta prism, bodies cut by section simple solid bodies such as

Practice on different operations rhomboid prism and their applications plane on drawing Cube, Square Prism,

For manufacturing of prisms methods (Full and Half Rectangular Prism,

and other flat surfaces Sections) I.S. 696/1972 Hexagonal Prism,

1. Profiling Triangular Prism, Cone and

2. Blocking Cylinder shaped Vessels

MLG # double sem. 14 CSTARI

3. Grinding

4. Smoothing

5. Polishing

16 Making Prism & other flat Principle of manufacturing of prisms -Views of hollow - Finding the capacity of in

surfaces - continued & other flat surfaces bodies with litres of Square,

1. Removal from block Parts of lens and prism dimensions Rectangular, Hexagonal,

2. Cleaning Conical and Cylindrical

3. Measurement of parameters shaped Vessels

4. Anti-reflection coating

5. Cementing (if applicable)

17 Surface finish on optical Different applications of prism -Exercise on Blue print Finding the lateral surface

components reading area and Total surface

1. Manufacture of front surface & Blocking materials for prism making -Sketching of finished Area of Square,

back surface mirrors. articles from drawings Rectangular, Hexagonal,

2. Chemical silvering on optics preparation of sequence Cone and Cylinder Shaped

3. Vacuum deposition of different Vassals, Further practice of

materials on optics Mensuration problems

18 Surface finish on optical Basic Idea about special types of -Free hand sketching of PROPERTIES OF

components – continued optical components simple objects related MATERIALS :

Anti-reflection coatings on optics 1. Graticules/Raticles to the trade and -Elastic limit, Ultimate

Cementing of optical components 2. Cylindrical Lenses preparation of simple tensile strength, Toughness,

3. Bi-Prism working drawing from Brittleness, Ductility,

4. Refraction Gratings the sketches Malleability, Creep etc

19 Silvering of Lenses and Application of silvered lenses and Drawing different Different types of optical

Prisms prism Silvering procedure types of Lenses with material their properties and

dimensions use

20 Optical instruments & devices Tools and machines used in -Conventional STRESS & STRAIN:

Demonstration & practice on manufacturing of optical instruments representation of -Definition of Stress, Strain,

application of different optical Materials by B.I.S Modulus of elasticity and

instruments and devices Factor of safety

-Simple problems related to

Stress &Strain

MLG # double sem. 15 CSTARI

21 Optical instruments & devices Optical instruments & its basic functions -Method of indicating BASIC ELECTRICITY:

Demonstration & practice on 1. Telescope surface roughness by -Electric current, Voltage,

application of different optical 2. Microscope B.I.S Power, resistance ,

instruments and devices 3. Binoculars conductors and insulators

1. Telescope 4. Periscope -Ohms law, Faraday’s laws

2. Microscope 5. Range Finder of Electromagnetic

3. Binoculars 6. Theodolites Induction, Types of current

4. Periscope 7. Night Vision devices effects of Current and

5. Range Finder related problems

6. Theodolites

7. Night Vision devices

22 Use of Refraction equipments and Refraction equipments and its basic -Method of indicating BASIC ELECTRICITY:

its basic functions functions surface roughness by -Electric current, Voltage,

1. Lensometer, 1. Lensometer, B.I.S Power, resistance ,

2.Auto Refractometer, 2.Auto Refractometer, conductors and insulators

3.Slit lamp, 3.Slit lamp, -Ohms law, Faraday’s laws

4.Lens tray, 4.Lens tray, of Electromagnetic

5.Lens frame 5.Lens frame Induction, Types of current

6. optical refraction unit, 6. optical refraction unit, effects of Current and

7. Phoropter 7. Phoropter related problems

8. Retinoscope. 8. Retinoscope.

Idea about optical aberrations

23 Project work Project work do do

1. Making of spectacles 1. Making of spectacles

2. Making of prism & magnifying 2. Making of prism & magnifying

glasses lanses

24 Project work Project work do do

1. Making of spectacles 1. Making of spectacles

2. Making of prism & 2. Making of prism & magnifying

magnifying glasses lenses

25 Revision

26 Examination

MLG # double sem. 16 CSTARI

MECHANIC LENS/PRISM GRINDING

List of tools & equipments for 12 trainees + one

A. Trainees Kit – (As per the below table)

Sl.No. Name of the Items Quantity

1, Steel rule 150 mm (Graduated both English and metric) 13 Nos.

2. Outside calipers 13 Nos.

3. Inside Calipers 13 Nos.

4. Odd leg caliper 150 mm 13 Nos.

5. Scriber 150x3 mm 13 Nos.

6. Combination Pliers 150 mm 13 Nos.

7. Goggles (fiber plastic cup) safety glasses 13 Nos.

8. Hammer ball pein ½ lb. 13 Nos.

9 Hand gloves leather 13 Nos.

10 Face mask 13 Nos.

11 Try square 13 Nos.

B. General Machinery Shop Outfit (as per the table)

Sl No. Name & Description of the Tools Quantity

1. Hammer copper 0.50 kg 06 nos.

2. Oil cane 06 nos.

3. Drill Chuck 12 mm cap. Taper shanks 06 nos.

4. Diamond wheel dressing (single stone mounted) 12 nos.

5. Files, Hand flat 200 mm smooth 12 nos.

6. Files 150 mm Half round 12 nos.

7. Files- Triangular, Dead smooth 200 mm and 150 mm 06 nos.

8. Hacksaw frame 200 to 300 mm adjustable 06 nos.

9. Oil stone carborandum, coarse on one side and fine on the other 12 nos.

200x50x25 mm

10. Screw Driver 200 mm 06 nos.

11. Screw Driver 300 mm 06 nos.

12. Spanner D.E. ( both Metric & English) 03 sets each

13. Fitter vice 4” Jaw (100 mm)-2 nos. 06 nos.

14. Center punch 150x6 mm dia-2 nos. 06 nos.

15. Chisel cold flat 12 mm –2 nos 02 nos.

18. Hand drill 6 mm-capacity 2 nos

19. Drill Twist 1 mm to 12 mm, in step of 1 mm 2 nos.

20. Set of Morse sockets (0-1), (1-2) and (2-3) 1 no

21. Fire Extinguisher 2 nos.

22. Fire Buckets with stand 2 nos.

23. Adjustable wrench 250 mm size 4 nos.

24. Grease Gun 1 no

25 Vernier caliper 200 mm, inside and outside (graduated in inches 6 nos.

and millimeters) least count 0.020 mm as per IS 3651

26 Wooden foldable scale metric 12 nos.

27 Universal bevel protractor – blade range 150 and 300 mm, dial 1 6 nos

degree, Vernier 5’ with head, acute angle attachment

28 Micro meter outside 0 to 25 mm, least count 0.01 mm 2nos

29 Micro meter outside ball type 0 to 25 mm, least count 0.01 mm 1no

30 Depth Micrometer range 0 to 150 mm with 6 depth rods, least 1 no

count 0.010 mm

31 Glass drill bit Diamond drilling bits size 5mm, 6 mm,8mm and 12 each

10 mm (consumable)

MLG # double sem. 17 CSTARI

32 Glass cutter (consumable) 12 nos

33 Diamond cutter 12 nos

34 Circular cutter for glass cutting 6 nos

35 Electric heater for heating glasses. 3 nos

36 Glass plain 3 mm,5mm, 10 mm thick As required

37 Granite Surface Plate, grade 0, 630 x 630 x 100mm with 1 no

adjustable stand

38 Glass Tray 4 nos.

39 Wash basin, Measuring Jars, Jelt Brushes and balance 1 set

40 Glass sheet 3 mm As required

41 Glass sheet 5.5 mm As required

42 Chemical paints and Varnish As required

C. GENERAL MACHINERY / EQUIPMENT

1. Drilling Machine Pillar type 0-12 capacity with motorized 1 no.

2* Automatic beveling machine 1 no

3* Surface polishing machine 1 no

4* Bevel polishing machine 1 no

5* Spray gun with air compressor with 3 HP Motor 1 no

* one machine for four units

(I) For Glass Spherical

1. Bench Grinder 250 mm dia. (Lighter type) 1 no.

2. Spherical Generator 1no.

2. Two Spindle Spherical Smoother & Polisher 2 nos.

4. Single Spindle Hand Operator Machine 1 no.

5. Spherical Tools (C.I.Casting) 150 nos.

6. Spherical Aluminum Runner 40 nos.

7. Thickness Glass 1 nos.

8. Spherometer Set (+ & -) 1 nos.

9 Rim less nose plier 12 nos

10 Nose plier 12 nos

11 Bold Nut Nose Plier 12 nos

12 CR Lens Cutter 12 nos

13 Lens Drilling machine, Piller type 12 mm Capacity 1 no

14 Lens Grooving machine 2 nos

15 Lens Format cutting machine 2 nos

16 Lens Axis Marking Chart machine 2 nos

17 Lens Grinding machine Opto lab 2 nos

18 Spectacle Frames - metal 24 nos

19 Spectacle Frames-supra 24 nos

20 Spectacle Frames-rim less 24 nos

21 Spectacle Frames-shell frame 24 nos

22 UV Rays detection machine 1 no

23 Photo chromatic detection 1 no

24 Polarization detection picture 1 no

MLG # double sem. 18 CSTARI

(II) For Cylindrical

1. Toric Generator 1 no.

2. Pneumatic Auto System Cylindrical Smoother & Polisher 2 nos.

3. Alloy Blocker 1no.

4. Cylinder Tools (Aluminium) 800 nos.

5. Cylindrical Aluminium Block 50 nos.

6. Torometer 1 no.

7. Evalue Gauge (0 – 25 ) 1 no.

8. Diameter Reducer 1 no.

9. Tap Applicator 1 no.

10. Tool Rack 1 no.

11. Chiller Unit (with Chiller Tank) 1 no.

12. Thickness Gauge 1 no.

13. Fabrication Items -

14. Alloy for CR 2 Kgs.

15. Diamond for CR 1 no.

(III) Measuring / Checking Devices

1 Optical Spherometer 1 no.

3. Lenso Meter 1 no.

2. Auto Refractro Meter 1 no.

3 Binacular 1no

4 Retinoscope 1 no

5 Telescope 1no

6 Periscope 1no

7 Microscope 1no

8 Range Finder 1no

9 Theodolites 1no

10 Night Vision devices 1no

11 Slit lamp, 1no

12 Lens frame 5 nos.

13 Optical refraction unit (Chair unit) 1 set

14 Phoropter 1no

15 Lens Tray (plain to -20 and plain to + 20 1set

(IV) For Spectacle Fittings

1 Auto edge M/C 1 no

2 Hand edge M/C 1 no

D. WORKSHOP FURNITURE

SL.NO NAMES & DESCRIPTION OF FURNITURE QUANTITY

1. Wooden Work bench 340x120x75 cm 4

2. Locker with 6 drawers ( standard size ) 2

3. Metal Rack 180x150x45cm 2

4. Steel almirah 1

5. Black board and easel 1

6. Instructor’s Desk or table & Chair 1set

7. Stool 4

MLG # double sem. 19 CSTARI

You might also like

- Mechanic Mechatronic.148161529Document60 pagesMechanic Mechatronic.148161529swami061009No ratings yet

- Mechanic Machine Tool Maintenance.148161504Document37 pagesMechanic Machine Tool Maintenance.148161504swami061009No ratings yet

- Mechanic Repair Maintenance of Light Vehicles.163153836Document23 pagesMechanic Repair Maintenance of Light Vehicles.163153836swami061009No ratings yet

- Syllabus for Instrument Mechanic (Chemical PlantDocument35 pagesSyllabus for Instrument Mechanic (Chemical Plantviero widyantoNo ratings yet

- Maint Mech Chem Plant.150164641Document29 pagesMaint Mech Chem Plant.150164641swami061009No ratings yet

- Excavator Operator EOM.147152035Document7 pagesExcavator Operator EOM.147152035swami061009No ratings yet

- Mechanic Mining Machinery: Syllabus For The Trade OFDocument58 pagesMechanic Mining Machinery: Syllabus For The Trade OFswami061009No ratings yet

- Laboratory Asstt Chem Plant.150164539Document27 pagesLaboratory Asstt Chem Plant.150164539swami061009No ratings yet

- Mechanic Repair Maintenance of Heavy Vehicles.157115932Document22 pagesMechanic Repair Maintenance of Heavy Vehicles.157115932swami061009No ratings yet

- Mechanic (Refrigeration & Air-Conditioner) (Semester Pattern)Document33 pagesMechanic (Refrigeration & Air-Conditioner) (Semester Pattern)swami061009No ratings yet

- Painter General.150164702Document21 pagesPainter General.150164702swami061009No ratings yet

- Old Age Care: Central Staff Training and Research InstituteDocument8 pagesOld Age Care: Central Staff Training and Research InstituteKARMAVEERNo ratings yet

- Syllabus for Plastic Processing Operator TradeDocument13 pagesSyllabus for Plastic Processing Operator Tradeswami061009No ratings yet

- Syllabus for Lift Mechanic TradeDocument24 pagesSyllabus for Lift Mechanic Tradeswami061009No ratings yet

- Instrument Mechanic.146180122Document32 pagesInstrument Mechanic.146180122swami061009No ratings yet

- Pump Operator Cum Mechanic .156171802Document18 pagesPump Operator Cum Mechanic .156171802swami061009100% (1)

- Mechanic Industrial Electronics.150171925Document28 pagesMechanic Industrial Electronics.150171925swami061009No ratings yet

- Mechanic Medical Electronics.146180428Document37 pagesMechanic Medical Electronics.146180428swami061009No ratings yet

- Stone Mining Machine Operator SMO.147152544Document13 pagesStone Mining Machine Operator SMO.147152544swami061009No ratings yet

- Building Maintenance: Central Staff Training and Research InstituteDocument11 pagesBuilding Maintenance: Central Staff Training and Research Instituteswami061009No ratings yet

- 7 Dental Laboratory TechnicianDocument14 pages7 Dental Laboratory TechnicianOsama Fadel ahmedNo ratings yet

- Mech Motor Vech.157172612Document50 pagesMech Motor Vech.157172612swami061009100% (1)

- Interior Design Syllabus GuideDocument15 pagesInterior Design Syllabus Guideswami061009No ratings yet

- Data Entry Operator: Syllabus For The Trade OFDocument10 pagesData Entry Operator: Syllabus For The Trade OFMusaib MuzaffarNo ratings yet

- Domestic Painter: Central Staff Training and Research InstituteDocument20 pagesDomestic Painter: Central Staff Training and Research Instituteswami061009No ratings yet

- Mechanic Computer Hardware.150164904Document32 pagesMechanic Computer Hardware.150164904swami061009No ratings yet

- CTS Leather Goods MakerDocument47 pagesCTS Leather Goods MakerFaizan AhmedNo ratings yet

- Information Technology & Electronics System MaintenanceDocument21 pagesInformation Technology & Electronics System Maintenanceswami061009No ratings yet

- Curriculum - Leather Goods MakerDocument47 pagesCurriculum - Leather Goods MakerPH KRISHNA100% (1)

- Finance ExecutiveDocument18 pagesFinance ExecutiveSam ONiNo ratings yet

- SYLLABUS FOR MARKETING EXECUTIVE CRAFTSMEN TRAINING SCHEMEDocument13 pagesSYLLABUS FOR MARKETING EXECUTIVE CRAFTSMEN TRAINING SCHEMESam ONiNo ratings yet

- Curriculum - Footwear MakerDocument48 pagesCurriculum - Footwear MakerShahriar H DiptoNo ratings yet

- Syllabus For The Trade Of: Machinist (Grinder)Document27 pagesSyllabus For The Trade Of: Machinist (Grinder)swami061009No ratings yet

- Stone Processing Machine Operator SPO.147152600Document14 pagesStone Processing Machine Operator SPO.147152600swami061009No ratings yet

- Sanitary Hardware Fitter.161173142Document14 pagesSanitary Hardware Fitter.161173142swami061009No ratings yet

- Electronics Mechanic (Semester Pattern) : Syllabus For The Trade ofDocument41 pagesElectronics Mechanic (Semester Pattern) : Syllabus For The Trade ofMohamed SalamNo ratings yet

- Mechanic Agricultural Machinery.164170839Document41 pagesMechanic Agricultural Machinery.164170839swami061009No ratings yet

- Gold Smith.148161552Document16 pagesGold Smith.148161552swami061009No ratings yet

- Mech Auto Elec Electrnx.170160916Document14 pagesMech Auto Elec Electrnx.170160916swami061009No ratings yet

- Fitter SyllabusDocument29 pagesFitter SyllabusNand Kishore DubeyNo ratings yet

- Electrician: Sector - ElectricalDocument73 pagesElectrician: Sector - ElectricalAbdul AjisNo ratings yet

- Electrician 156165842Document31 pagesElectrician 156165842swami061009No ratings yet

- CTS Lift and Escalator Mechanic - CTS - NSQF-5 PDFDocument68 pagesCTS Lift and Escalator Mechanic - CTS - NSQF-5 PDFVISHALNo ratings yet

- Electrician (Semester Pattern) : Syllabus For The Trade OFDocument30 pagesElectrician (Semester Pattern) : Syllabus For The Trade OFNand Kishore DubeyNo ratings yet

- CTS Electrician 2017Document73 pagesCTS Electrician 2017Narasimharao75% (4)

- Electrician (Semester Pattern) : Syllabus For The Trade OFDocument28 pagesElectrician (Semester Pattern) : Syllabus For The Trade OFV.c. MunjaniNo ratings yet

- Cts Driver Cum Mech (LMV) - Cts - nsqf-3Document37 pagesCts Driver Cum Mech (LMV) - Cts - nsqf-3Rohit RumadeNo ratings yet

- CTS Electroplator CTS 2017Document68 pagesCTS Electroplator CTS 2017sudhirNo ratings yet

- Course Curricula Under Skill Development Initiative Scheme (Sdis) Based On Modular Employable Skills (MES)Document20 pagesCourse Curricula Under Skill Development Initiative Scheme (Sdis) Based On Modular Employable Skills (MES)Charu JainNo ratings yet

- CTS Fitter 2017Document78 pagesCTS Fitter 2017ITI SHAHPURA DINDORI0% (1)

- Electrician Career GuideDocument68 pagesElectrician Career GuideSantosh Vishwakarma100% (1)

- Syllabus for Mechanic Radio and Television TradeDocument17 pagesSyllabus for Mechanic Radio and Television Tradeswami061009No ratings yet

- CTS Plumber - CompressedDocument53 pagesCTS Plumber - CompressedKrishNo ratings yet

- NSQF Level - 6Document43 pagesNSQF Level - 6Nitin B maskeNo ratings yet

- NSQF Level - 6: Electrician (Cits)Document56 pagesNSQF Level - 6: Electrician (Cits)prasadum23210% (2)

- Mechanic Auto Body Painting GuideDocument58 pagesMechanic Auto Body Painting GuideMirkamotors ethiopiaNo ratings yet

- CTSMech - MiningMachinery CTS NSQF-5Document96 pagesCTSMech - MiningMachinery CTS NSQF-5Vinod GuptaNo ratings yet

- CTS Turner 2017 PDFDocument74 pagesCTS Turner 2017 PDFgiti kalpiNo ratings yet

- Syllabus CTS WIREMAN 2017Document64 pagesSyllabus CTS WIREMAN 2017Rudraksha PatleNo ratings yet

- Polity & Eco. (VICS) Quick BookletDocument23 pagesPolity & Eco. (VICS) Quick Bookletswami061009No ratings yet

- History Quick Digest (VICS)Document36 pagesHistory Quick Digest (VICS)swami061009No ratings yet

- 42 Etudes PDFDocument72 pages42 Etudes PDFtrikaa2000No ratings yet

- 367 ErpBookDocument13 pages367 ErpBooksravankumar248No ratings yet

- eNovaCNC Operating ManualDocument43 pageseNovaCNC Operating Manualswami061009No ratings yet

- Lathe Ofd PDFDocument25 pagesLathe Ofd PDFswami061009No ratings yet

- Best Science Notes PDFDocument94 pagesBest Science Notes PDFRajesh Kar100% (1)

- O Metoda de Vioara PDFDocument241 pagesO Metoda de Vioara PDFCatalin PaunNo ratings yet

- Syllabus 2014 Lecturer MechDocument2 pagesSyllabus 2014 Lecturer Mechswami061009No ratings yet

- Kanban Vs KaizenDocument28 pagesKanban Vs KaizenSimon KohNo ratings yet

- Technology Manual EnovaDocument119 pagesTechnology Manual Enovaswami061009No ratings yet

- Operating Manual for EDM Machine and Paper Filtration UnitDocument58 pagesOperating Manual for EDM Machine and Paper Filtration Unitswami061009No ratings yet

- 6 PokaYokeDocument22 pages6 PokaYokeChandru NatarajanNo ratings yet

- The Hindu Review September 2017Document21 pagesThe Hindu Review September 2017rajanNo ratings yet

- Energy and LightDocument206 pagesEnergy and Lightswami061009No ratings yet

- MSME Technology Center Bhopal Recruitment Advertisement-2020Document3 pagesMSME Technology Center Bhopal Recruitment Advertisement-2020sankalp maheshwariNo ratings yet

- ELCAM ManualDocument67 pagesELCAM Manualswami06100990% (10)

- A-18-05867 WID All-Star Catalog 2019 LR PDFDocument158 pagesA-18-05867 WID All-Star Catalog 2019 LR PDFKALLU GuptaNo ratings yet

- WIDIA 2017 Master Catalog MetricDocument1,815 pagesWIDIA 2017 Master Catalog Metricswami061009No ratings yet

- Widia - Advances 2018 - Metric - LR PDFDocument84 pagesWidia - Advances 2018 - Metric - LR PDFswami061009No ratings yet

- T01Document24 pagesT01swami061009No ratings yet

- Sinumerik840D Programming ManualDocument199 pagesSinumerik840D Programming ManualtblazekaNo ratings yet

- U DrillDocument3 pagesU Drillswami061009No ratings yet

- GD KT Pro-0731-0418 Sus Abs V1Document6 pagesGD KT Pro-0731-0418 Sus Abs V1swami061009No ratings yet

- GD KT Pro-0716-Us-0118 Sus Abs V1 PDFDocument100 pagesGD KT Pro-0716-Us-0118 Sus Abs V1 PDFswami061009No ratings yet

- MetrologiaIndustrial2016 DMIS PDFDocument700 pagesMetrologiaIndustrial2016 DMIS PDFLokesh100% (2)

- GD KT PRO-Plansee-Facts-and-Figures SEN ABS V1 PDFDocument19 pagesGD KT PRO-Plansee-Facts-and-Figures SEN ABS V1 PDFswami061009No ratings yet

- 2.problems On Leibnitz TheoremDocument17 pages2.problems On Leibnitz TheoremShubham80% (20)

- SPE-AIME, Exxon Production Research Co. Hoyer, Spbaime, Exxon Production Research CoDocument11 pagesSPE-AIME, Exxon Production Research Co. Hoyer, Spbaime, Exxon Production Research CoAbie WinathamaNo ratings yet

- Mathematics of Cryptography: Algebraic StructuresDocument68 pagesMathematics of Cryptography: Algebraic StructuresSrivathsala Suresh TangiralaNo ratings yet

- PSPP TutorialDocument24 pagesPSPP Tutorialyarrha100% (1)

- Practice Problem Solutions CIDocument3 pagesPractice Problem Solutions CIatiq mengalNo ratings yet

- Y6 Autumn Block 1 WO7 Round Any Integer 2022Document2 pagesY6 Autumn Block 1 WO7 Round Any Integer 2022M alfyNo ratings yet

- Introduction To AnglesDocument9 pagesIntroduction To Anglesapi-344095596No ratings yet

- Statistics and Probability Concepts ExplainedDocument31 pagesStatistics and Probability Concepts ExplainedSiva Kumar ArumughamNo ratings yet

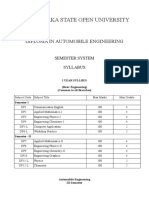

- Distance Automobile Engineering Diploma KSOU, Syllabus Automobile Engineering Distance ModeDocument56 pagesDistance Automobile Engineering Diploma KSOU, Syllabus Automobile Engineering Distance ModeSunil JhaNo ratings yet

- 2.9 Reteach Algebra 2Document3 pages2.9 Reteach Algebra 2Ari KatsavNo ratings yet

- DSP Lab Expt 3 EECE GITAM-19-23Document5 pagesDSP Lab Expt 3 EECE GITAM-19-23gowri thumburNo ratings yet

- Program To Multiply Two Sparse Matrices Using C Language: Course Code:-Mcs 021 Course Name:-Ds Q.1 AnsDocument17 pagesProgram To Multiply Two Sparse Matrices Using C Language: Course Code:-Mcs 021 Course Name:-Ds Q.1 AnsAbinash MishraNo ratings yet

- Rule #1 Explained: 2.7.1 Variations of Form (Rule #1: Envelope Principle)Document6 pagesRule #1 Explained: 2.7.1 Variations of Form (Rule #1: Envelope Principle)Anonymous 7ZTcBnNo ratings yet

- 7SR242 - Duobias Technical Manual Chapter 07 Applications GuideDocument56 pages7SR242 - Duobias Technical Manual Chapter 07 Applications GuideVishwanath TodurkarNo ratings yet

- Ib Academy Math Studies Study GuideDocument64 pagesIb Academy Math Studies Study GuideSuuz de Bruijn100% (11)

- Thermodynamics Lecture 1Document15 pagesThermodynamics Lecture 1Shahla GondalNo ratings yet

- Mathematical MethodsDocument13 pagesMathematical MethodsphooolNo ratings yet

- Arm Exercises For LabDocument3 pagesArm Exercises For Labnizamhaider123No ratings yet

- Thermal Analysis of A at Plate Collector With Solidworks and Determination of Heat Convection Coefficient Between Water and AbsorberDocument14 pagesThermal Analysis of A at Plate Collector With Solidworks and Determination of Heat Convection Coefficient Between Water and AbsorberAntonio FIFANo ratings yet

- Hanouts Sta304Document191 pagesHanouts Sta304silence queenNo ratings yet

- Unit 1E Equation of LocusDocument16 pagesUnit 1E Equation of LocusAnn Pamila SantosNo ratings yet

- Ca PDFDocument27 pagesCa PDFYousef MohamedNo ratings yet

- A-Level Math & Logic Challenge 2010Document9 pagesA-Level Math & Logic Challenge 2010Faith HoNo ratings yet

- Syllabus STAB52 F20 LEC01Document4 pagesSyllabus STAB52 F20 LEC01rickyangnwNo ratings yet

- Coventor Tutorial: Bi-Stable Mechanical Beam SimulationDocument49 pagesCoventor Tutorial: Bi-Stable Mechanical Beam Simulationmadhas100% (1)

- ML 2 (Mainly KNN)Document12 pagesML 2 (Mainly KNN)utpal100% (1)

- STEM - BC11LC IIIc 1Document5 pagesSTEM - BC11LC IIIc 1ALJON TABUADANo ratings yet

- Imprtant Problems EE339Document28 pagesImprtant Problems EE339sultanNo ratings yet

- Generator Answers 3Document6 pagesGenerator Answers 3Ahmad SwandiNo ratings yet

- Ap Biology Equations and Formulas SheetDocument2 pagesAp Biology Equations and Formulas Sheetapi-286357921No ratings yet