Professional Documents

Culture Documents

Design and Sizing Calculation: Based On Api 521 Fourth Edition, March 1997 Horizontal Knockout Drum Data Input

Uploaded by

Chitu Ionut LaurentiuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Sizing Calculation: Based On Api 521 Fourth Edition, March 1997 Horizontal Knockout Drum Data Input

Uploaded by

Chitu Ionut LaurentiuCopyright:

Available Formats

Heading area

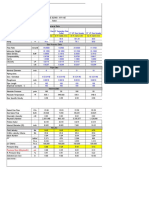

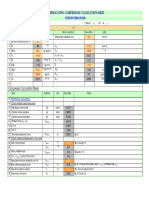

DESIGN AND SIZING CALCULATION

BASED ON API 521 FOURTH EDITION, MARCH 1997

HORIZONTAL KNOCKOUT DRUM

DATA INPUT

Ml liquid flow rate 24.64 kg/s

Mv gas flow rate 58.79 kg/s

dl liquid density 816.14 kg/m3

dv gas density 1.916 kg/m3

p operating pressure 100 kPag

T operating temperature -20 C

vg gas viscosity 0.009 cP

cs drain volume 1.89 m3

t liquid holdup 10 min

D droplet size 300 µm

g filling degree 25 %

vmax maximum allowed velocity 0.5Mach m/s

CALCULATIONS

The drag coefficient is determined as follows: The dropout velocity is : The vapour rate is:

C(Re)2= 6760.23 Uc = 1.02 m/s Qv= 30.68 m3/s

From API 521, figure 20 is determined C=f(C(Re)2)

On this diagram we are reading: C= 1.1

A horizontal vessel with an inside diameter Di and a cylindrical length L should be assumed:

Di= 4.8 m

L= 12 m

The total cross-sectional area is:

At= 18.09 m2

The liquid holdup required is determined as follows:

AL1= 0.16 m2

The cross sectional segment for liquid is determined as follows:

AL2= 1.51 m2

The cross sectional segment for vapor is determined as follows:

Av= 16.42 m2

The vertical depths of the liquid and vapor spaces are determined using standard geometry:

hv= 4.7002 m

hL1= 0.0009 m which means that: ht= hv+hL1+hL2

hL2= 0.0989 m

Total ht= 4.8 m correct depth calculation

The adequacy of the vapor space is verified as follows:

The vertical drop available for liquid dropout is equal to hv in centimeters.

The liquid dropout time is determined as follows:

θ= 4.6 seconds

The velocity of N vapor passes is determined as follows:

N= 1

Uv= 1.87 m/s

The drum length required is determined as follows: Lmin= 8.599 m Acceptable

Lmin must be less than or equal to the above assumed cylindrical drum length, L;

Otherwise the calculation must be repeated with a newly assumed cylindrical drum length.

You might also like

- PSV Capacity ConversionDocument4 pagesPSV Capacity Conversionaw_aeNo ratings yet

- Vessel Sizing SpreadsheetDocument28 pagesVessel Sizing SpreadsheetEmamokeNo ratings yet

- Relief Load Calculation For Fire Case - As Per API 521Document1 pageRelief Load Calculation For Fire Case - As Per API 521ktejankarNo ratings yet

- Thermal Relief Rate Calculation for Jet A1 in 20Document1 pageThermal Relief Rate Calculation for Jet A1 in 20Ascend032100% (1)

- Breather Valves DatasheetDocument4 pagesBreather Valves Datasheetmilton1987No ratings yet

- PVV Cal Sheet LabixDocument45 pagesPVV Cal Sheet LabixPranpath Narupantawart50% (2)

- Sizing of The Feed Nozzles For Gas-Liquid Separator - Industrial Professionals - CheresourcesDocument5 pagesSizing of The Feed Nozzles For Gas-Liquid Separator - Industrial Professionals - CheresourcesJavierNo ratings yet

- PSV Sizing Report (Fire Case)Document7 pagesPSV Sizing Report (Fire Case)Elias EliasNo ratings yet

- Normal Design: Depressurize From Design Pressure To 50% in 15 MinutesDocument2 pagesNormal Design: Depressurize From Design Pressure To 50% in 15 Minutesmatteo2009No ratings yet

- Blowdown Orifice Sizing CalculationDocument2 pagesBlowdown Orifice Sizing CalculationOmprakaash MokideNo ratings yet

- CALCULATING THE BLEEDER VENT SIZE FOR AN AIR VENTING SYSTEMDocument2 pagesCALCULATING THE BLEEDER VENT SIZE FOR AN AIR VENTING SYSTEMmassive85No ratings yet

- Shell K.O.drum SeparatorDocument11 pagesShell K.O.drum SeparatorChitu Ionut LaurentiuNo ratings yet

- Spreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2Document33 pagesSpreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2MaheshNo ratings yet

- Tank Venting Requirements (API 2000) 2Document3 pagesTank Venting Requirements (API 2000) 2RubensBoerngenNo ratings yet

- PSV Scenario and CalculationDocument35 pagesPSV Scenario and CalculationBaba Johneh0% (1)

- Gas Line Sizing by API 14E Method Revision #: ??: Pressure Drop (Fittings Etc) Elbows, Tees Elbows, Tees Elbows, TeesDocument4 pagesGas Line Sizing by API 14E Method Revision #: ??: Pressure Drop (Fittings Etc) Elbows, Tees Elbows, Tees Elbows, Teesusaid saifullahNo ratings yet

- Spreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2Document26 pagesSpreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2venkatesh801No ratings yet

- TBE Inlet Separator V 2100 FLNG2Document6 pagesTBE Inlet Separator V 2100 FLNG2halipzramlyzNo ratings yet

- Guide For Vessel Sizing PDFDocument24 pagesGuide For Vessel Sizing PDFManish542No ratings yet

- Gas Line Sizing - Api 14E Input Description Unit: General DataDocument13 pagesGas Line Sizing - Api 14E Input Description Unit: General DataSamuel OnyewuenyiNo ratings yet

- Volume Calculation For Pressure Vessel TankDocument2 pagesVolume Calculation For Pressure Vessel Tanksai srikarNo ratings yet

- Atmospheric Storage Tanks Venting Required API 2000 (6th ED 2009)Document18 pagesAtmospheric Storage Tanks Venting Required API 2000 (6th ED 2009)ganeshdhageNo ratings yet

- Ejercicio 246 PSV438 RESUELTODocument2 pagesEjercicio 246 PSV438 RESUELTOHumberto Ivan Gonzales TapiaNo ratings yet

- Three Phase Separator Sizing - No InternalDocument2 pagesThree Phase Separator Sizing - No InternalSaeid Rahimi MofradNo ratings yet

- PVRV Sizing Calculation for 10% Overpressure TankDocument2 pagesPVRV Sizing Calculation for 10% Overpressure Tankkarthipetro100% (7)

- Line Sizing Criteria As Per Different International StandardsDocument4 pagesLine Sizing Criteria As Per Different International StandardsTiano BaLajadia100% (1)

- Flare Ko Drum SizingDocument5 pagesFlare Ko Drum SizingSujith Sekar100% (2)

- PSV Sizing Psv-402 Update PsetDocument7 pagesPSV Sizing Psv-402 Update PsetBui Khoi NguyenNo ratings yet

- Atmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)Document1 pageAtmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)Mohammed AttiaNo ratings yet

- 5639-72-PP-031 - RB-PSV Sizing Report-PSV203A&BDocument9 pages5639-72-PP-031 - RB-PSV Sizing Report-PSV203A&BpavanNo ratings yet

- Pipeline Pressurisation & de Pressurisation CalculationDocument4 pagesPipeline Pressurisation & de Pressurisation Calculationhatakerobot50% (2)

- Pressure Vessel Data Sheet for TEG ContactorDocument2 pagesPressure Vessel Data Sheet for TEG ContactorElias EliasNo ratings yet

- Orifice Sizing PrinciplesDocument12 pagesOrifice Sizing Principlesjlcheefei9258100% (1)

- Condensate Line SizingDocument2 pagesCondensate Line SizingAnonymous oVRvsdWzfBNo ratings yet

- Pump (English) TemplateDocument1 pagePump (English) TemplateMichael HaiseNo ratings yet

- Depressurization Calculation..Document12 pagesDepressurization Calculation..Faber TrujilloNo ratings yet

- PSV SizingDocument3 pagesPSV SizingpavanNo ratings yet

- Gas Line SizingDocument11 pagesGas Line SizingEbby OnyekweNo ratings yet

- Fire Relief Dynamic StudyDocument2 pagesFire Relief Dynamic StudyImtinan MohsinNo ratings yet

- Line Sizing ReportDocument7 pagesLine Sizing Reportmichael chiwuezeNo ratings yet

- Gas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetDocument5 pagesGas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetNaqqash Sajid0% (2)

- 2 Phase Flow Pressure Drop Calc Suresh1Document6 pages2 Phase Flow Pressure Drop Calc Suresh1NKNo ratings yet

- Kg-Tower ManualDocument5 pagesKg-Tower ManualJohnny50% (2)

- Nozzle Load As Per MegyesyDocument3 pagesNozzle Load As Per MegyesyamaNo ratings yet

- PSV SIZING CALCULATIONSDocument3 pagesPSV SIZING CALCULATIONSAthiphap SrisupareerathNo ratings yet

- Flare Knock Out Drum Sizing SheetDocument2 pagesFlare Knock Out Drum Sizing Sheetsanjay100% (4)

- Section 7Document51 pagesSection 7Asad Khan0% (1)

- Blowdown of A Gas VolumeDocument41 pagesBlowdown of A Gas VolumeJames R. Lawrence Sr.20% (5)

- Ssags PSV SizingDocument5 pagesSsags PSV SizingEkundayo JohnNo ratings yet

- Air Consumption Rev 1Document1 pageAir Consumption Rev 1Cahyadi YadiNo ratings yet

- E3 Field Development Production Separator DesignDocument5 pagesE3 Field Development Production Separator DesignhaiderNo ratings yet

- Fuel gas filter sizing calculationDocument1 pageFuel gas filter sizing calculationIndraharja FerryNo ratings yet

- C 4Document52 pagesC 4saur1No ratings yet

- 1A 2021 End Sem TP CML 352 FinalDocument4 pages1A 2021 End Sem TP CML 352 FinalJason RoyNo ratings yet

- Flowmeter Apparatus (Venturi, Orifice, Rotameter)Document10 pagesFlowmeter Apparatus (Venturi, Orifice, Rotameter)meghaparinNo ratings yet

- Example (1) :: SolutionDocument12 pagesExample (1) :: Solutionياسر فاضلNo ratings yet

- CHE 111P Seatwork 1Document3 pagesCHE 111P Seatwork 1Dodjie MaestrecampoNo ratings yet

- Chimney Functions and DesignDocument6 pagesChimney Functions and DesignReydin CampoamorNo ratings yet

- Lab 4 Gas Permeability MeasurementDocument6 pagesLab 4 Gas Permeability MeasurementRichard OwusuNo ratings yet

- Design of Distillation Column EquipmentDocument41 pagesDesign of Distillation Column EquipmentHardik Gandhi100% (1)

- Process Calculations 2nd Ed. - V. Venkataramani, N. Anantharaman & K.M. Meera Sheriffa Begum 2011 PDFDocument260 pagesProcess Calculations 2nd Ed. - V. Venkataramani, N. Anantharaman & K.M. Meera Sheriffa Begum 2011 PDFantonino69100% (6)

- AspenHYSYSDynModelV7 1 RefDocument229 pagesAspenHYSYSDynModelV7 1 RefHarold GuittuNo ratings yet

- Fire Fighting NoteDocument125 pagesFire Fighting NotepolamNo ratings yet

- AspenHYSYSDynModelV7 1 RefDocument229 pagesAspenHYSYSDynModelV7 1 RefHarold GuittuNo ratings yet

- 11-4080 HYSYS Relief Valve Sizing Demo Guide FinalDocument18 pages11-4080 HYSYS Relief Valve Sizing Demo Guide FinalNoman Abu-FarhaNo ratings yet

- Ghid BarcelonaDocument149 pagesGhid BarcelonaChitu Ionut LaurentiuNo ratings yet

- Mixed Refrigerants Efficient Liquids RecoveryDocument5 pagesMixed Refrigerants Efficient Liquids RecoveryChitu Ionut LaurentiuNo ratings yet

- Extractive Distillation Separates Benzene and CyclohexaneDocument12 pagesExtractive Distillation Separates Benzene and CyclohexaneROHAN PATILNo ratings yet

- Conduct of Operations Field Handbook PDFDocument213 pagesConduct of Operations Field Handbook PDFChitu Ionut LaurentiuNo ratings yet

- Flare Calc Sheet API - RP 521Document13 pagesFlare Calc Sheet API - RP 521ionutlaur86100% (1)

- Deepakchopra Viatadupamoarte 140930102417 Phpapp02Document275 pagesDeepakchopra Viatadupamoarte 140930102417 Phpapp02victoriaNo ratings yet

- Shell K.O.drum SeparatorDocument11 pagesShell K.O.drum SeparatorChitu Ionut LaurentiuNo ratings yet

- Cutting Conics AsDocument3 pagesCutting Conics Asbabe09No ratings yet

- Aspire Manual PDFDocument356 pagesAspire Manual PDFkisslevente007No ratings yet

- Cara Menghitung Dimensi Runner Turbin AirDocument24 pagesCara Menghitung Dimensi Runner Turbin AirPasbon Da SilvaNo ratings yet

- EFX Framework Assembly DesignDocument78 pagesEFX Framework Assembly DesignFareedMohmedNo ratings yet

- ENGINEERING SURVEYS (Route Surveying)Document8 pagesENGINEERING SURVEYS (Route Surveying)Verlyn Kate Pang-ayNo ratings yet

- Rural Road Construction Project ReportDocument33 pagesRural Road Construction Project ReportNandu KingsNo ratings yet

- Digital Learning Week 7 8 Agenda Entire Set 7th GradeDocument12 pagesDigital Learning Week 7 8 Agenda Entire Set 7th GradeRoss HamiltonNo ratings yet

- Introduction To CAD 3DDocument3 pagesIntroduction To CAD 3DFitowinNo ratings yet

- Desk Lamp DFM Analysis and RedesignDocument125 pagesDesk Lamp DFM Analysis and RedesignNur' AyuniNo ratings yet

- Civil Engineering Surveying I Course: Practical Content GuideDocument21 pagesCivil Engineering Surveying I Course: Practical Content GuideArinze samuel100% (1)

- Finnwood HelpDocument137 pagesFinnwood HelpAl GaleNo ratings yet

- Aqua 1Document329 pagesAqua 1AshutoshAparajNo ratings yet

- Eagle PointDocument24 pagesEagle Pointsurafela minaleNo ratings yet

- 7.3.6.4 Bending Moments - Load Cases: Prestress EffectsDocument16 pages7.3.6.4 Bending Moments - Load Cases: Prestress Effectstailieuxaydung2019No ratings yet

- RM E Getting Started DINDocument73 pagesRM E Getting Started DINRam NepaliNo ratings yet

- Electrical Resistivity of Manufactured Carbon and Graphite Articles at Room TemperatureDocument5 pagesElectrical Resistivity of Manufactured Carbon and Graphite Articles at Room TemperatureLabeed ShamilNo ratings yet

- Practical Guild Airflow MeasurementDocument20 pagesPractical Guild Airflow MeasurementJason NguyenNo ratings yet

- AutoCAD 3D NotesDocument16 pagesAutoCAD 3D Notesryanavincent0% (1)

- 252 Map Exercises 2016Document46 pages252 Map Exercises 2016Adept Titu Eki100% (2)

- CAIE IGCSE Geography Notes, Paper 2Document4 pagesCAIE IGCSE Geography Notes, Paper 2Muhammad Ahmad NoorNo ratings yet

- 2022-13-Johnson 1994 Grain Size From Thin SectionsDocument15 pages2022-13-Johnson 1994 Grain Size From Thin SectionsIan Yain BonavittaNo ratings yet

- Calculation of Wing Loads PDFDocument55 pagesCalculation of Wing Loads PDFJony Oliver Lazo RamosNo ratings yet

- Output Analysis Workshop Solution Problem # 1: Figure 1. Profile Plot of Problem # 1Document22 pagesOutput Analysis Workshop Solution Problem # 1: Figure 1. Profile Plot of Problem # 1suman subediNo ratings yet

- Catálogo MitutoyoDocument20 pagesCatálogo MitutoyoFelipe SchiehllNo ratings yet

- Sms Tuflow 1dDocument32 pagesSms Tuflow 1dmostafa aboelkhearNo ratings yet

- COMPARISON OF BASE ISOLATOR AND ORDINARY BUILDING BEHAVIORDocument51 pagesCOMPARISON OF BASE ISOLATOR AND ORDINARY BUILDING BEHAVIORJody SetiawanNo ratings yet

- How Do I Calculate The Surface Area of An Elbow - QuoraDocument3 pagesHow Do I Calculate The Surface Area of An Elbow - QuoraAVINASHRAJNo ratings yet

- Offsets at Irregular IntervalsDocument16 pagesOffsets at Irregular IntervalsRenjith S AnandNo ratings yet

- Hyperview 13 0 SectioncutDocument6 pagesHyperview 13 0 SectioncutĐức Phạm NgọcNo ratings yet

- BV NI621-Guidelines For Moonpool AssessmentDocument8 pagesBV NI621-Guidelines For Moonpool AssessmentRobin GuNo ratings yet