Professional Documents

Culture Documents

Your guide to safer boiler operation

Uploaded by

Ronald KahoraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Your guide to safer boiler operation

Uploaded by

Ronald KahoraCopyright:

Available Formats

Your guide to safer boiler operation

Your guide to safer boiler operation

Your guide to safer boiler operation BOILER CHEMICAL INFORMATION

CLICK ANYWHERE to RETURN to

A at InspectApedia.com

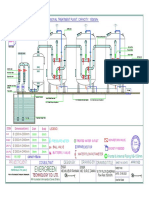

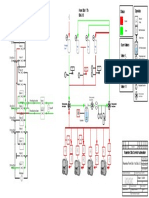

4 1

8 C

5 Supply main D

2 E

ASME

B Relief valve

Check

valve

City water

supply

8

6 Fill valve

normally

used

3 7

Hot water boiler

Pump

Return main

Steam boiler Hot-water boiler

1. Safety valve Steam boiler A. Expansion tank

Hot-water boiler

2. Safety

1. Low-water valvecutoffSteam boiler B.A.Low-water

Expansion cutoff

Hot-water

tank boiler

3.Safety

1.2. Water column

valve

Low-water cutoff blow-down valve C.A.

B. Combination

Expansion

Low-water temperature/pressure

tank

cutoff

4.Low-water

2.3. Pressuretrols

Water column (one

cutoff is high-limit

blow-down valvesafety) gauge

C. or altitude/temperature

B. Combination

Low-water cutoff gauge

temperature/pressure

5. Steam

3.4.Water pressure-gauge

column(one

Pressuretrols blow-down valvesafety)

is high-limit D. Operating

C. Combination

gauge aquastattemperature/pressure

or altitude/temperature gauge

6.Pressuretrols

4.5. Water column

Steam clean-out

pressure-gauge

(one (cross tee)

is high-limit safety) E.D.High-limit

Operating

gauge safety

aquastataquastat

or altitude/temperature gauge

7.

6. Bottom

Water blow-off

column

5. Steam pressure-gauge and

clean-out drain valve

(cross tee) E. High-limit

D. Operating aquastatsafety aquastat

8.Water

6.7. Low-water

Bottom column cutoff/blow-off

blow-off and drain

clean-out valve

(crossvalve

tee) E. High-limit safety aquastat

Note:

7.8. Second

Low-water

Bottom low-water-cutoff

cutoff/blow-off

blow-off and drain valve not shown in diagram

valve

8.Note:

Low-waterSecondcutoff/blow-off

low-water-cutoff not shown in diagram

valve

Boiler water-level – The first duty when taking over a boiler-room shift is to make certain the pipe, fittings and valves

betweenNote: the water Second

glasslow-water-cutoff

and boiler are free notandshownopeninbydiagram

blowing down the water column and water glass and noting the

Boiler water-level – The first duty when taking over a boiler-room shift is to make certain the pipe, fittings and valves

promptness of the return of water to the glass.

betweenwater-level

Boiler the water glass and first

– The boiler are when

duty free and takingopen by ablowing

over downshift

boiler-room the water column

is to make and water

certain glass

the pipe, and noting

fittings the

and valves

promptness

between of the return of water toare

thefreeglass.

The most important rule – The most important rule for the safe operation of boilers is to maintain the proper water- the

the water glass and boiler and open by blowing down the water column and water glass and noting

promptness

level at all of the return

times, and as of water to

constant the glass.

a level as conditions will permit. If water is not visible in the water glass, shut the boiler

The most important rule – The most important rule for the safe operation of boilers is to maintain the proper water-

off immediately until a safe water-level has been determined.

levelmost

The at all times,

important and as constant

rule – The a level

most as important

conditionsrule willforpermit. If water

the safe is notof

operation visible

boilers in is

thetowater glass,the

maintain shut the boiler

proper water-

off

level immediately

at all times, until

and a

as safe water-level

constant a level has

as been determined.

conditions will permit. If water

Low-water and feedwater controls – The low-water cutoff is the most important electrical/mechanical device on is not visible in the water glass, shut the boiler

offyour

immediately until a safeawater-level

boiler for maintaining safe water-level. has been determined.

If a low-water condition develops, it could very well result in an overheating and

Low-water

explosion of your and feedwater

boiler. The low-water controls – The low-water

cutoff should be tested atcutoff is the most important electrical/mechanical device on

least weekly.

your boiler for maintaining a safe water-level.

Low-water and feedwater controls – The low-water cutoff is the most If a low-water condition develops, it could very well

important result in an overheating

electrical/mechanical andon

device

explosion

your of your

boiler for maintaining

Low-water boiler. The low-water

a safe water-level.

cutoff, evaporation cutoff should

test If(steam be

a low-water tested at least

– While

condition

boiler) weekly.

the boiler

develops, is invery

it could operation, shut in

well result offanthe feedwater and

overheating

pump and

explosion ofmonitor

your boiler.the boiler water-level.

The low-water Theshould

cutoff low-water cutoffatshould

be tested shut down the burner before the water level goes

least weekly.

Low-water

out of sight low; cutoff, evaporation

if the burner does not shut testoff,(steam

restart theboiler)

feedwater – While the boiler

pump before is in operation,

the water level goes shut

out ofoffsight

the low

feedwater

and

pump and

immediately monitor the

troubleshoot boiler

the water-level.

low-water The

cutoff to low-water

determine cutoff

the causeshould

of shut

failure.

Low-water cutoff, evaporation test (steam boiler) – While the boiler is in operation, shut off the feedwater

down

The the

boiler burner

must be before

under the water

constant level

attendancegoes

out

by ofproperly

a sight low; if the burner

licensed engineer doesat nottimes

all shutduring

off, restart

this the feedwater pump before the water level goes out of sight low and

test.

pump and monitor the boiler water-level. The low-water cutoff should shut down the burner before the water level goes

immediately troubleshoot the low-water cutoff to determine the cause of failure. The boiler must be under constant attendance

out of sight low; if the burner does not shut off, restart the feedwater pump before the water level goes out of sight low and

by a properly licensed

Low-water cutoff,engineer

slow drain at alltest

times(steam

during this test. – While the boiler is in operation, shut off the feedwater pump

boiler)

immediately troubleshoot the low-water cutoff to determine the cause of failure. The boiler must be under constant attendance

byand slowly open the bottom blow valve to drain the water from the boiler. The low-water cutoff should shut down the burner

a properly licensed engineer at all times during this test.

Low-water

before the water cutoff,

level goesslow outdrain

of sighttestlow;(steam

if the burner boiler)

does not– While the restart

shut off, boiler the

is infeedwater

operation,pump shut before

off thethefeedwater pump

water level

and

goesslowly

out ofopensightthelowbottom blow valvetroubleshoot

and immediately to drain the water from thecutoff

the low-water boiler.toThe low-water

determine the cutoff

cause should shutThe

of failure. down themust

boiler burner

Low-water cutoff, slow drain test (steam boiler) – While the boiler is in operation, shut off the feedwater pump

before

be under theconstant

water level goes outbyofasight

attendance low;licensed

properly if the burner doesatnot

engineer allshut

timesoff, restart

during thetest.

this feedwater pump before the water level

and slowly open the bottom blow valve to drain the water from the boiler. The low-water cutoff should shut down the burner

goes out of sight low and immediately troubleshoot the low-water cutoff to determine the cause of failure. The boiler must

before the water level goes out of sight low; if the burner does not shut off, restart the feedwater pump before the water level

be under constant attendance by a properly licensed engineer at all times during this test.

goes out of sight low and immediately troubleshoot the low-water cutoff to determine the cause of failure. The boiler must

be under constant attendance by a properly licensed engineer at all times during this test.

Firing – Aside from the standpoint of economy, maintain the fire as uniformly as possible to avoid an excessive rate of

combustion, undesirable variations in temperature and possible explosions. The destructive force in a boiler explosion is

caused by the instant release of energy stored in the water as heat.

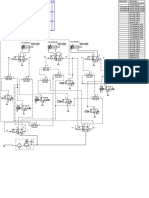

Water gauges – Keep all connections and valves clear. Test by blowing down the water glass and water column regularly.

Gauge cocks or tri-cocks should also be blown regularly.

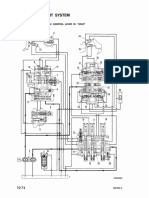

Safety valves – The safety valve is the most important valve on the boiler. Safety valves prevent dangerous over

pressurization of the boiler. Safety valves are installed in case there is failure of pressure controls or other devices designed

to control the firing rate. All safety valves should be kept free of debris by testing the safety valve regularly. This should be

done when the steam pressure is at approximately 75 percent of the safety-valve set pressure. Safety and safety-relief valves

on low-pressure boilers should be tested at least quarterly, this is in accordance with the National Board Inspection Code.

Blow-down valves – The concentration of solids in the boiler should be measured and the boiler blown-down at such

intervals as necessary to maintain established limits. Blow-down valves are placed at the lowest point of the boiler for the

purpose of blowing sediment or scale from the boiler. They should be maintained in good working order and are to be opened

and closed carefully when used.

Starting fires in a boiler – Before starting fires in a cold boiler or restarting a fire that may have been accidentally

extinguished, the entire fireside of the boiler must be thoroughly ventilated (purged) with the dampers open to remove

unburned gases before attempting to relight the fire. Attempting to start a fire in a boiler with unburned gases is the most

common cause of boiler furnace explosions.

Boiler-room requirement – A current proper engineer’s license and log shall be posted in the boiler room. It is the

responsibility of the owner and the engineer to make sure the boiler is inspected annually.

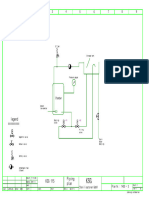

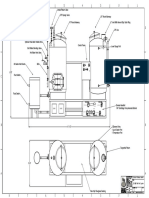

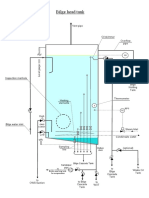

Hot-water systems – These systems are equipped with expansion tanks for the expansion and contraction of the water

as the temperature varies.

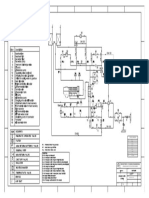

Firing cycle, power burners – The burner will start when the aquastat or pressuretrol calls for heat. The breeching

damper will open and the draft fan will purge the combustion chamber. The main gas or oil valve will be energized when

the pilot or ignition is proved.

Repairs – Any excessive overheating or burning, and any major repairs, must be reported to your boiler inspector.

Classification of boilers – High-pressure boilers are boilers operating at a steam or other vapor pressure in excess of 15

psig, or a water or other liquid boiler in which the pressure exceeds 160 psig, or has a temperature greater than 250 degrees

Fahrenheit. Others are low-pressure boilers.

License requirement – Minnesota Statutes §183.501 states "No person shall be entrusted with the operation of or

operate any boiler, steam engine or turbine who has not received a license of proper grade covering that boiler, steam engine

or turbine.

Study material – The Division of Boiler Inspection has no study material available and suggests you contact your nearest

technical college for classes or resource materials, or contact a library or bookstore for the appropriate book.

The following books may prove useful to boiler operators:

• Special Engineer: Safe Boiler Operation Fundamentals by ATP and Low Pressure Boilers by Frederick

M. Steingress

• Grade "C" licenses: Low Pressure Boilers by Frederick M. Steingress

• Grade "B" licenses: High Pressure Boilers by Frederick M. Steingress and H.J. Frost

• Grade "A" licenses: Steam Plant Operation by Woodruff and Lammers

• Grade "B" and "A" licenses: Stationary Engineering by Steingress, Frost and Walker

This document can be made available in alternative formats, such as large print,

Braille or audio, by calling (651) 284-5031; TTY call 1-800-627-3529.

Revised July 2013

ORIGINAL Source: Minnesota Department of Labor & Industry, https://www.dli.mn.gov/ccld/PDF/guide2saferboiler.pdf

You might also like

- Department of Labor: Guide2saferboilerDocument2 pagesDepartment of Labor: Guide2saferboilerUSA_DepartmentOfLaborNo ratings yet

- Iron Removal Treatment Plant Flow DiagramDocument1 pageIron Removal Treatment Plant Flow DiagramEtcl FactoryNo ratings yet

- KSG 115-119 - PlansDocument4 pagesKSG 115-119 - PlansRashad Biomedical EngineerNo ratings yet

- Roanoke Transformer RecycleDocument1 pageRoanoke Transformer RecycleDavid Adrián EsparzaNo ratings yet

- Dwg. No. 18030007-12.cooling Water SystemDocument1 pageDwg. No. 18030007-12.cooling Water SystemMas Dwi LestariNo ratings yet

- GD-46 Series: YS Housing Equipment Products That Protects "Comfortable" and "Safe" LivingDocument1 pageGD-46 Series: YS Housing Equipment Products That Protects "Comfortable" and "Safe" LivingArstNo ratings yet

- PC210LC-11 Sen06695-01 Troubleshooting For Hydraulic and MechanicalDocument70 pagesPC210LC-11 Sen06695-01 Troubleshooting For Hydraulic and MechanicaldatphuongNo ratings yet

- Masoneilan Power Industry Control SolutionsDocument24 pagesMasoneilan Power Industry Control SolutionsEko PrasetyoNo ratings yet

- Diagrama de Caldera CompletoDocument2 pagesDiagrama de Caldera CompletoedgardoNo ratings yet

- Reliable Solutions For Steam Generation Distribution Applications Brochure en 5180488Document3 pagesReliable Solutions For Steam Generation Distribution Applications Brochure en 5180488AlejandroNo ratings yet

- CAT - Feedwater Protection SystemDocument11 pagesCAT - Feedwater Protection SystemMurli RamchandranNo ratings yet

- Hydraulic Diagram D275A-2Document3 pagesHydraulic Diagram D275A-2gire_3pich2005100% (1)

- Utilitas PilotPlantDocument3 pagesUtilitas PilotPlantRaden SukmawatiNo ratings yet

- Roanoke Silo 1 To Silo 2-3Document1 pageRoanoke Silo 1 To Silo 2-3David Adrián EsparzaNo ratings yet

- Catalog - 2016 (Shinwoo Valve) 1.7MDocument20 pagesCatalog - 2016 (Shinwoo Valve) 1.7Mensi116No ratings yet

- WB March 2004Document8 pagesWB March 2004Caterine Jara CeaNo ratings yet

- Boiler Log HourlyDocument2 pagesBoiler Log Hourlymohamed abd el attyNo ratings yet

- 08 Welltest EquipmentDocument4 pages08 Welltest EquipmentdronneNo ratings yet

- TK-508 RH-DemandPump FearureSheetDocument2 pagesTK-508 RH-DemandPump FearureSheetJames LoewenNo ratings yet

- KVS PRESSURE REDUCING VALVEDocument3 pagesKVS PRESSURE REDUCING VALVEThúy VyNo ratings yet

- Boiler Log HourlyDocument2 pagesBoiler Log Hourlyismailenes_66145776No ratings yet

- Skematik Pompa Emerald Tp2-12Document2 pagesSkematik Pompa Emerald Tp2-12Kahfi DinaradjiNo ratings yet

- 9 Plumbing SanitaryDocument1 page9 Plumbing SanitarymdNo ratings yet

- Kinjal AttachedDocument1 pageKinjal AttachedNilay JethavaNo ratings yet

- Principal Drawing Hydraulic Diamec 262Document2 pagesPrincipal Drawing Hydraulic Diamec 262Orlando67% (3)

- Hydraulic Power Pack Minipack HPM TG2 XXX X S N N 05S C18CDDocument1 pageHydraulic Power Pack Minipack HPM TG2 XXX X S N N 05S C18CDjuniorNo ratings yet

- Logo Logo: Kettle Drain Pump Out WhirlpoolDocument1 pageLogo Logo: Kettle Drain Pump Out WhirlpoolchinsiNo ratings yet

- Hydraulic Mining Shovels Cat 6060/6060FSDocument9 pagesHydraulic Mining Shovels Cat 6060/6060FSEdison Pfoccori BarrionuevoNo ratings yet

- Hydraulic Mining Shovels Cat 60xx Basic Shovel Hydraulic - System DescriptionDocument24 pagesHydraulic Mining Shovels Cat 60xx Basic Shovel Hydraulic - System DescriptionMiguel Angel RodriguezNo ratings yet

- Automatic Recirculation ValvesDocument6 pagesAutomatic Recirculation ValvesCarlos SolerNo ratings yet

- Pltu Process OverviewDocument1 pagePltu Process OverviewDimasQiNo ratings yet

- Pltu Process Overview PDFDocument1 pagePltu Process Overview PDFTegar Ardian100% (1)

- 3 Week Report: Halini Oil Field - Batch-2Document6 pages3 Week Report: Halini Oil Field - Batch-2Muhammad AwaisNo ratings yet

- Anowara Knit Composite LTD SF-20-ModelDocument1 pageAnowara Knit Composite LTD SF-20-ModelMd SuruzzamanNo ratings yet

- DMF Relief ValveDocument1 pageDMF Relief ValveRealyn BermejoNo ratings yet

- Head TankDocument1 pageHead TankAndrzej KozłowskiNo ratings yet

- MDF - Denah IPALDocument1 pageMDF - Denah IPALIsa Muhammad KhamimNo ratings yet

- SM-Kobelco SK300LC-6E Szervíz (YC07U0623 )Document1,184 pagesSM-Kobelco SK300LC-6E Szervíz (YC07U0623 )Károly Vigh100% (2)

- IFlow Application Diagram 20201015Document10 pagesIFlow Application Diagram 20201015CTHNo ratings yet

- IFlow Application Diagram 20201015Document10 pagesIFlow Application Diagram 20201015CTHNo ratings yet

- Oxy Miser PDFDocument2 pagesOxy Miser PDFRafael CalleNo ratings yet

- The Challenge: Strong Deposit Build-Up The Solution: Selective Cleaning With WaterDocument1 pageThe Challenge: Strong Deposit Build-Up The Solution: Selective Cleaning With WaterErickNo ratings yet

- Schematic Sample HPDocument1 pageSchematic Sample HPMohammad ZeeshanNo ratings yet

- Daikin Refri Cable RXYQ16PTLDocument2 pagesDaikin Refri Cable RXYQ16PTLRicardo Barroso0% (1)

- Boiler Clearances: Peru Sourthern Peru S.ADocument2 pagesBoiler Clearances: Peru Sourthern Peru S.AJohan F. MonroyNo ratings yet

- 3 ProjDocument1 page3 ProjÍtalo Felipe Lira de moraisNo ratings yet

- Drawing Boiler PartsDocument1 pageDrawing Boiler PartsAnonymous FZs3yBHh7No ratings yet

- Western Type WC Indian Type WC: Cold Water Pipe Cold Water PipeDocument1 pageWestern Type WC Indian Type WC: Cold Water Pipe Cold Water PipeNilay JethavaNo ratings yet

- Condensate Feedwater System Part 1Document32 pagesCondensate Feedwater System Part 1Sam RajibNo ratings yet

- Vacuum - Condenser Presentasi 2Document17 pagesVacuum - Condenser Presentasi 2Neon PhoerbaNo ratings yet

- Jpee 2015041311191825Document7 pagesJpee 2015041311191825david limNo ratings yet

- RSW UNIT - Automatic Oil Return SystemDocument1 pageRSW UNIT - Automatic Oil Return SystemMauricioNo ratings yet

- Mer - We - db3120 - Domestic Hot Water Produc DiagramDocument6 pagesMer - We - db3120 - Domestic Hot Water Produc DiagramtienlamNo ratings yet

- Symbols Terms Refrig Air Con - EnglishDocument1 pageSymbols Terms Refrig Air Con - EnglishYang John (Rich-Tech1688)No ratings yet

- Tankless Water Heater DescalingDocument1 pageTankless Water Heater Descalingshunkadu2No ratings yet

- Válvula Control de Bomba - CLAVALDocument4 pagesVálvula Control de Bomba - CLAVALJose CabanaNo ratings yet

- 005 - Cat 6040AC - CAMP SIL BCS4 - Tank Pumps PMSDocument21 pages005 - Cat 6040AC - CAMP SIL BCS4 - Tank Pumps PMSJorby CuadrosNo ratings yet

- FOOD - The Definitive Shoppers Guide PDFDocument27 pagesFOOD - The Definitive Shoppers Guide PDFRonald KahoraNo ratings yet

- Dry System Manual PDFDocument66 pagesDry System Manual PDFDaneliuc SimionNo ratings yet

- Five CountBaccarat BookDocument138 pagesFive CountBaccarat BookRonald Kahora100% (3)

- 2014 NEC Electrical Instructor Manual and Student Worksheets Level 1 - PDFDocument352 pages2014 NEC Electrical Instructor Manual and Student Worksheets Level 1 - PDFLimuel Espiritu0% (1)

- Franklin Prosperity Report: Low-Cost, Low-Headache Businesses To Start in RetirementDocument17 pagesFranklin Prosperity Report: Low-Cost, Low-Headache Businesses To Start in RetirementRonald KahoraNo ratings yet

- Baccarat Attack StrategyDocument163 pagesBaccarat Attack StrategyAjay Parihar89% (9)

- Lesson 1Document27 pagesLesson 1Ronald KahoraNo ratings yet

- Loan Payment ScheduleDocument18 pagesLoan Payment ScheduleRonald KahoraNo ratings yet

- April 2019 FPRDocument17 pagesApril 2019 FPRRonald KahoraNo ratings yet

- Input Output: Int. Rate Rate Monthly Int. Rate Years # Pmts Pmts/yr Loan Amt PMT AmtDocument1 pageInput Output: Int. Rate Rate Monthly Int. Rate Years # Pmts Pmts/yr Loan Amt PMT AmtRonald KahoraNo ratings yet

- Input Output: Int. Rate Rate Years # Pmts Pmts/yr Loan Amt PMT AmtDocument1 pageInput Output: Int. Rate Rate Years # Pmts Pmts/yr Loan Amt PMT AmtRonald KahoraNo ratings yet

- Accounting Basics, Part 1: Accrual, Double-Entry Accounting, Debits & Credits, Chart of Accounts Journals And, LedgerDocument147 pagesAccounting Basics, Part 1: Accrual, Double-Entry Accounting, Debits & Credits, Chart of Accounts Journals And, LedgerThe Three Queens100% (1)

- Radiant Company ManualDocument40 pagesRadiant Company ManualPaunescu BogdanNo ratings yet

- April 2019 FPRDocument17 pagesApril 2019 FPRRonald KahoraNo ratings yet

- Bookkeeping Forms and Templates Book PDFDocument33 pagesBookkeeping Forms and Templates Book PDFRonald KahoraNo ratings yet

- Excel 2016 Basic Skills Complete EbookDocument120 pagesExcel 2016 Basic Skills Complete EbookRonald KahoraNo ratings yet

- 0818 FranklinDocument17 pages0818 FranklinRonald KahoraNo ratings yet

- Energysaver - Gov: Tips On Saving Money & Energy at HomeDocument44 pagesEnergysaver - Gov: Tips On Saving Money & Energy at HomeRonald KahoraNo ratings yet

- ManualDocument170 pagesManualRonald KahoraNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Manual First AidDocument176 pagesManual First AidRonald Kahora100% (2)

- Cost Acco UntingDocument400 pagesCost Acco UntingRuchi Kashyap100% (2)

- Chapter6 MasonryEstimating 0134405501Document8 pagesChapter6 MasonryEstimating 0134405501Ronald KahoraNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Plumbing 101Document234 pagesPlumbing 101Ronald Kahora100% (2)

- ManualDocument170 pagesManualRonald KahoraNo ratings yet

- Architectural Standards Graphic Student EditionDocument510 pagesArchitectural Standards Graphic Student EditionRonald Kahora100% (8)

- Trades Math Workbook PDFDocument32 pagesTrades Math Workbook PDFDiyaNegiNo ratings yet

- 2012 NC Building Level 1 Student WorksheetsDocument95 pages2012 NC Building Level 1 Student WorksheetsRonald KahoraNo ratings yet

- April 10, 2015 Strathmore TimesDocument28 pagesApril 10, 2015 Strathmore TimesStrathmore TimesNo ratings yet

- Mining Operational ExcellenceDocument12 pagesMining Operational ExcellencegarozoNo ratings yet

- Pe 1997 01Document108 pagesPe 1997 01franciscocampoverde8224No ratings yet

- Boiler Automation Using PLCDocument91 pagesBoiler Automation Using PLCKishor Mhaske100% (1)

- PM and Presidential Gov'ts Differ Due to Formal Powers and AppointmentDocument3 pagesPM and Presidential Gov'ts Differ Due to Formal Powers and AppointmentNikeyNo ratings yet

- Bamboo in AsiaDocument72 pagesBamboo in Asiafitria lavitaNo ratings yet

- Lala Lajpat Rai College: Public Relations Project Rough Draft Topic: Nike V/S AdidasDocument34 pagesLala Lajpat Rai College: Public Relations Project Rough Draft Topic: Nike V/S AdidasNikitha Dsouza75% (4)

- Computer Programmer or Software Developer or C++ or Visual BasicDocument6 pagesComputer Programmer or Software Developer or C++ or Visual Basicapi-77734404No ratings yet

- Maisie Klompus Resume 02Document1 pageMaisie Klompus Resume 02api-280374991No ratings yet

- DamaDocument21 pagesDamaLive Law67% (3)

- Forty Studies That Changed Psychology 5th Edition PDFDocument2 pagesForty Studies That Changed Psychology 5th Edition PDFsaid hassan0% (1)

- Marie Bjerede and Tzaddi Bondi 2012 - Learning Is Personal, Stories of Android Tablet Use in The 5th GradeDocument50 pagesMarie Bjerede and Tzaddi Bondi 2012 - Learning Is Personal, Stories of Android Tablet Use in The 5th Gradeluiz carvalhoNo ratings yet

- 12V Laptop ChargerDocument12 pages12V Laptop ChargerSharon Babu0% (1)

- Vda. de Villanueva vs. JuicoDocument3 pagesVda. de Villanueva vs. JuicoLucas Gabriel Johnson100% (1)

- PMUY supplementary document titleDocument1 pagePMUY supplementary document titleChandan Kumar Jha69% (67)

- Final ThoughtDocument6 pagesFinal ThoughtHaroon HussainNo ratings yet

- Module 2 - Introduction To A Web-AppDocument17 pagesModule 2 - Introduction To A Web-AppJASPER WESSLYNo ratings yet

- Netflix AccountsDocument2 pagesNetflix AccountsjzefjbjeNo ratings yet

- Time Division Muliple AccessDocument4 pagesTime Division Muliple AccessAbhishek RanaNo ratings yet

- Only PandasDocument8 pagesOnly PandasJyotirmay SahuNo ratings yet

- Understanding ProbabilityDocument14 pagesUnderstanding ProbabilityKajaraiNo ratings yet

- Lecture No 5Document41 pagesLecture No 5sami ul haqNo ratings yet

- Προσχέδιο Έκθεσης Γ.Γ. ΟΗΕ για Καλές ΥπηρεσίεςDocument20 pagesΠροσχέδιο Έκθεσης Γ.Γ. ΟΗΕ για Καλές ΥπηρεσίεςARISTEIDIS VIKETOSNo ratings yet

- Intra Cell HODocument10 pagesIntra Cell HOMostafa Mohammed EladawyNo ratings yet

- Project ProposalDocument6 pagesProject Proposalapi-386094460No ratings yet

- PR-Unit1-ERP EvolutionDocument13 pagesPR-Unit1-ERP EvolutionSiddhant AggarwalNo ratings yet

- Gram-Charlier para Aproximar DensidadesDocument10 pagesGram-Charlier para Aproximar DensidadesAlejandro LopezNo ratings yet

- Probe Filter 5.1 SNMP Support Reference GuideDocument8 pagesProbe Filter 5.1 SNMP Support Reference GuideOrlando MondlaneNo ratings yet

- HHF-1600 Direct-Drive Pump Utilization Parts ListDocument27 pagesHHF-1600 Direct-Drive Pump Utilization Parts ListJohn Simanca100% (1)

- LG Mini Split ManualDocument38 pagesLG Mini Split ManualMark ChaplinNo ratings yet