Professional Documents

Culture Documents

03 Measurements

Uploaded by

Chidiebere Samuel OkogwuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

03 Measurements

Uploaded by

Chidiebere Samuel OkogwuCopyright:

Available Formats

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

3.0 MEASUREMENTS

This lecture on measurements will be confined to a description of the instruments

commonly used to measure current, voltage, power and energy. Commercial

resistance test sets are mentioned together with a brief outline of one or two digital

instruments

dc MEASUREMENT AND TROUBLESHOOTING

METER MOVEMENTS

Moving-coil Movement

In this type of meter movement, known as the d' Arsonval movement, the pointer is

deflected in proportion to the amount of current through a coil. Figure 1 a shows a

basic d' Arsonval meter movement. It consists of a coil of wire wound on a bearing

mounted assembly that is placed between the poles of a permanent magnet and a

pointer is attached to the moving assembly. When there is no current flow through

the coil, a spring mechanism keeps the pointer at its left-most (zero) position. When

current flows through the coil, electromagnetic forces act on the coil, causing a

rotation to the right. The amount of rotation depends on the amount of current;

Figure 1 b shows a construction view of the parts of a typical movement.

Figure 2 illustrates how the interaction of magnetic fields produces rotation of the coil

assembly. The current flows inward at the "cross" and outward at the "dot" in the

Olatunbosun, A Page 1 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

single winding shown. The inward current produces a clock-wise electromagnetic

field that reinforces the permanent magnet field at the bottom. The result is a

downward force on the right conductor as shown. An upward force is developed on

the left side of the coil where the current is outward. These forces produce a

clockwise rotation of the coil assembly.

Iron- Vane Movement

This type of movement consists basically of two iron bars placed within a coil. The

electromagnetic field produced by the current in the coil induces a north pole and a

south pole in the iron bars. The like poles repel each other, causing the moving

element to move away from the stationery element. The attached pointer is deflected

by the movement of the element in proportion to the current through the coil.

A "vane" is attached to the movement and is housed in air chamber for damping

purposes. Figure 3a illustrates the basic mechanism, and Figure 3b shows the

construction of the basic movement.

Olatunbosun, A Page 2 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

Electrodynamometer Movement

Figure 4a shows the basic electrodynamometer movement. It differs from the d'

Arsonval movement in that it uses an electromagnetic field rather than a permanent

magnetic field. Current in the stationary coil produces the electromagnetic field. The

pointer is attached to the moving coil. This type of movement is commonly used in

wattmeters. Figure 4b shows the construction of a typical movement.

Current Sensitivity and Resistance of the Meter Movement

The current sensitivity of a meter movement is the amount of current required to

deflect the pointer full scale (all the way to its right-most position). For example, a 1-

mA sensitivity means that when there is 1 mA through the meter coil, the needle is at

its maximum deflection. If 0.5 mA flows through the coil, the needle is at the halfway

point of its full deflection.

The movement resistance is simply the dc resistance of the coil wire used in the

movement.

Olatunbosun, A Page 3 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

THE AMMETER

A typical d' Arsonval movement might have a current sensitivity of 1 mA and a

resistance of 50Ω . In order to measure more than 1 mA, additional circuitry must be

used with the basic meter movement. Figure 5a shows a simple ammeter with a

shunt resistor across the movement. The purpose of the shunt resistor is to bypass

current in excess of 1 mA around the meter movement. For example, let us assume

that this meter must measure currents of up to 10 mA. Thus, for full-scale deflection,

the movement must carry 1 mA, and the shunt resistor must carry 9 mA, as indicated

in Figure 5b.

Determining the Shunt Value

In our example a proper value of shunt resistance must be used. The following

calculations illustrate how this resistance is determined. Since the shunt resistor RsH

and the 50 Ω meter movement are in parallel, the voltage drops across them are the

same; that is

VSH=VMM

But V SH = IsHRsH and V MM = IMMRMM , and therefore

IsH RSH = IMM RMM

Olatunbosun, A Page 4 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

I MM RMM (1mA)(50Ω )

RSH= = =5.56 Ω

I SH 9mA

Multiple-Range Ammeter

The example meter just discussed has only one range. It can measure currents from

0 to 10 mA and no higher. However, most practical ammeters have several ranges.

Each range must have a different shunt resistance, which is selected with a switch.

For example, Figure 6 shows a two-range ammeter. A 100-mA range is incorporated

with the 10=mA range previously described.

When the switch is in the 10-mA position, the

meter indicates 10- mA at full-scale deflection of

the pointer. When the switch is in the 100-mA

position, 100 mA is indicated at full scale.

The value of the 100-mA shunt resistor is

determined in the same manner used for the

10-mAshunt. At full scale, the voltage across

the movement is (1 mA) (50O) = 50 mV. Therefore, since the shunt must carry 99

mA at full scale, RSH = 50 mV/99 mA = 0.51 O. We can obtain other current ranges

by switching in appropriate values of shunt resistances.

Olatunbosun, A Page 5 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

Example 1

Show a three-range basic ammeter that

has a 1-A range in addition to the 10-mA

and 100-mA ranges of the example meter

just discussed.

Solution:

First, we must find the shunt resistance

for the 1-A range. Again V SH = (1 mA)

(50 O) = 50 mV. The shunt resistor must carry all of the 1 A except the 1 mA to

operate the movement at full scale. Thus,

ISH = 1 A -1mA = 0.999 A

50mV

RSH = =0.05 O

0.999 A

The three-stage meter is shown in Figure 7.

Olatunbosun, A Page 6 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

Effect of the Ammeter on the circuit

As you know, an ammeter is connected in series to measure the current in a circuit.

Ideally, the meter should not alter the current that it is intended to measure. In

practice, however, the meter unavoidably has some effect on the circuit, because its

internal resistance is connected in series

The internal resistance of the ammeter is the shunt resistance in parallel with tile coil

resistance of the movement. In our example meter, it is approximately 0.05 0 on the

1-A range. Figure 8b shows the meter on the 1-A range and connected to measure

the current in the circuit of Figure 8a. The 0.05 O internal resistance (RINT) of the

meter is negligible compared to the 100 O circuit resistance. Therefore, the meter

does not significantly alter the actual circuit current. This characteristic is necessary,

of course, because we do not want the measuring instrument to change the quantity

that is being measured and thus the accuracy of the measurement.

Ammeter Scales

A typical ammeter or milliammeter has more than one scale, each corresponding to

different range switch positions. Figure 9 shows a two-scale meter as an example.

This particular meter has four ranges, as indicated on the range switch diagram.

The scales are read in conjunction with the range switch as follows: If the range

switch is set at 10 mA or 100 mA, the top scale is used. If the range switch is set at

30 mA or 300 mA, the bottom scale is used. The range switch setting always

Olatunbosun, A Page 7 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

corresponds to the full-scale deflection current. For example, if the range switch is

set on 100 mA, the "10" mark on the top scale represents 100 mA.

THE VOLTMETER

The voltmeter utilizes the same type of movement as the ammeter. Different external

circuitry is added so that the movement will function to measure voltage in a circuit.

As you have seen, the voltage drop across the meter coil is dependent on the

current and the coil resistance. For example, a 50-µA, 1000-Ω movement has a full-

scale voltage drop of (50-µA). (1000-Ω ) = 50 mV. To use the meter to indicate

voltages greater than 50 mV, we must add a series resistance to drop any additional

beyond that which the movement requires for full-scale deflection. This resistance is

called the multiplier resistance and is designated RM.

A basic voltmeter is shown in Figure 10 with a single multiplier resistor for one range.

To make it to measure 1 V full scale, we must determine the value of the multiplier

resistance as follows: The movement drops 50 mV at full-scale current of 50µA.

Therefore, the multiplier resistor RM must drop the remaining voltage of 1 V- 50 mV =

950 mV. Since RM is in series with the movement, it also carries 50 µA at full scale.

Thus,

950mV

RM = = 19KΩ

50µA

Therefore, for 1- V full-scale deflection, the total resistance of the voltmeter is 20 K O

(the multiplier resistance plus the coil resistance).

Olatunbosun, A Page 8 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

Voltmeter Sensitivity

Voltmeter sensitivity is defined in terms of resistance per volt (O /V). The example

meter just discussed has a sensitivity of 20 KO/V, because it has a total resistance of

20 kO and a full-scale deflection of 1V. This is a common sensitivity figure for many

commercial meters.

Multi-range Voltmeter

The meter in Figure 10 has only one voltage range (1-V); that is, it can measure

voltages from 0 V to 1V. In order to measure higher voltages with the same

movement, additional multiplier resistors must be used. One multiplier resistor is

required for each additional range.

For the 50 µA movement, the total resistance required is 20 KO for each volt of the

full-scale reading. In other words, the sensitivity for the 50 µA movement is always

20 k O /V regardless of the range selected. Thus, the full-scale meter current is 50

µA in any range. For any range, we fmd the total meter resistance by multiplying the

sensitivity by the full-scale voltage for that range.

For example, for a 10-V range, RT = (20 k O /V) (10 V) = 200 K O.

The total resistance for the 1- V range is 20 K O; so RM for the 10- V range must be

200 KO -19 K O -1K O = 180 KO. This two-range voltmeter is shown in Figure 11.

Additional ranges require the appropriate value of multiplier resistance added in

series.

Olatunbosun, A Page 9 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

Example 2

Show the circuit for a basic voltmeter having 1- V, 10- V, and 100- V ranges

Solution:

We have already determined RM for the I-V and the 10-V ranges. We need only to

calculate the additional RM required for the 100- V range. This calculation is as

follows:

RT = (20 k O/V) (100 V) = 2 M O.

Now, we subtract the meter resistance of the existing two-range meter from 2 M O to

get the RM required for the 100- V range:

RM3 = RT -RM1 -RMM

= 2 MO - 180 kO -19 k O -1 k O

= 2 M O -200 k O

= 1.8 k O

The schematic for this three-range voltmeter is shown in Figure 12.

Olatunbosun, A Page 10 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

Loading Effect of a Voltmeter

As you know, a voltmeter is always connected in parallel with the circuit component

across which the voltage is to be measured. Thus, it is much easier to measure

voltage than current, because you must break a circuit to insert an ammeter in

series. You simply connect a voltmeter across the circuit without disrupting the circuit

or breaking a connection.

Since some current is required through the voltmeter to operate the movement, the

voltmeter has some effect on the circuit to which it is connected. This effect is called

loading. However, as long as the meter resistance is much greater than the

resistance of the circuit across which it is connected, the loading effect is negligible.

This characteristic is necessary because we don't want the measuring instrument to

change the voltage that it is measuring.

Figure 13a shows a simple resistive circuit. Part b of the figure shows the same

circuit but with higher resistor values.

Example 3

Determine the exact voltage that would be measured with a 20-k O /V voltmeter

across R2 in the circuit of Figure 13.

Solution:

In the circuit of Part a, the meter is in parallel with the 1-k O R2. The combined

resistance of the meter and R2 is

(200KΩ )(1KΩ ) = 0.995KΩ

200K Ω

Using the voltage divider rule, we determine V 2 as follows:

0.995K Ω

V2 = (12V )= 5.985V

1.995KΩ

Olatunbosun, A Page 11 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

Without the meter's loading effect, V2 is 6 V. The meter loading produces an error of

15 mV, which in most cases is not enough to worry about. Figure 14 illustrates this

situation.

In the circuit of Part b, the meter is in parallel with the 200 k O R2. The combined

resistance of the meter and R2 is

(200 K O x 200 K O)/(200 K O + 200 K O) = 200 K O/2 = 100K O.

Using the voltage divider formula, we find V2 as follows:

100K Ω

V= (12V )= 4V

300KΩ

In this situation, the error is 2 V, which is unacceptable. The voltmeter loading is

significant, and this voltmeter could not be used in this case.

You would have to use a voltmeter with a higher internal resistance (the internal

resistance of a meter is usually referred to as input impedance).

Figure 15 illustrates this second case.

Olatunbosun, A Page 12 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

THE OHMMETER

The meter movement used for the ammeter and the voltmeter can also be adapted

for use in an ohmmeter. The ohmmeter is used to measure resistance values.

A basic one-stage ohmmeter is shown in Figure 16a. It contains a battery and a

variable resistor in series with the movement. To measure resistance, we connect

the leads across the external resistor to be measured, as shown in Part b. This

connection completes the circuit, allowing the internal battery to produce current

through the movement coil, causing a deflection of the pointer (needle) proportional

to the value of the external resistance being measured.

Zero Adjustment

When the ohmmeter leads are open, as in Figure 17a, the pointer is at full left scale,

indicating infinite (a) resistance (open circuit). When the leads are shorted, as in

Figure 17b, the pointer is at full scale, indicating zero resistance.

The purpose of the variable resistor is to adjust the current so that the pointer is at

exactly zero when the leads are shorted. It is used to compensate for changes in the

internal battery voltage due to aging.

Olatunbosun, A Page 13 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

Ohmmeter Scales

Figure 18 shows one type of ohmmeter scale. Between zero and infinity (00), the

scale is marked to indicate various resistor values. Because the values decrease

from left to right, this scale is called a back-off scale

Let us assume that a certain ohmmeter uses a 50-µA, 10000 movement and has an

internal1.5- V battery. A current of 50-µA produces a full-scale deflection when the

test leads are shorted. To have 50 µA, the total ohmmeter resistance is 1.5 V/50 µA

= 30 kΩ . Therefore, since the coil resistance is 1 kΩ , the variable zero adjustment

resistor must be set at 30 k.Ω -1 kΩ = 29 kΩ .

Suppose that a 120-kΩ resistor is connected to the ohmmeter leads. This combined

with the 30- kΩ internal meter resistance; the total R is 150 kΩ . The current is 1.5 V

/150 kΩ = 10 µA, which is 20% of the full-scale current and which appears on the

scale as shown in Figure 18. Now, if a 45-kΩ resistor is connected to the ohmmeter

leads, a current of 1.5 V/75 kΩ = 20 µA, which is 40% of the full-scale current flows

in the circuit. This is marked on the scale shown. Additional calculations of this type

show that the scale is non-linear. It is more compressed toward the left side than the

right side.

Olatunbosun, A Page 14 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

Multiple-Range Ohmmeter

An ohmmeter usually has several ranges. These typically are labelled R x 1, R x10,

R x100, R x 1k, R x 10k, R x 100k, and R x 1M, although some ohmmeters may not

have all of the ranges mentioned. These range settings are interpreted differently

from those of the ammeter or voltmeter. The reading on the ohmmeter scale is

multiplied by the factor indicated by the range setting. For example, if the pointer is

at 20 on the scale and the range switch is set at R x 100, the actual resistance

measurement is 20 x 100, or 20 ill. This example is illustrated in Figure 19 for a

typical scale.

To measure small resistances, you must use a higher ohmmeter current than is

needed for measuring large resistance values. Shunt resistors are used to provide

multiple ranges on the ohmmeter to measure a range of resistance values from very

small to very large. F or each range, a different value of shunt resistance is switched

in .The shunt resistance increases for a higher ohm ranges and is always equal to

the centre scale reading on any range. In some meters, a higher battery voltage is

used for the highest ohm range A typical circuit is shown in Figure 20.

Olatunbosun, A Page 15 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

The MEGGER

The 'MEGGER' is basically an ohmmeter arranged to test insulation. There are

several models. The most commonly used types are the model WM4 (the 'WEE

MEGGER@), which has a hand generator, and the battery-operated tester. Both

types are used for testing insulation and continuity.

The simplified circuits for the WM4 'MEGGER' are shown in Figure 21. Diagram (a)

is the circuit for insulation test and diagram (b) that for the continuity test. For

simplicity, the changeover from one circuit to the other is done by means of a switch.

The generator consists of a permanent magnet rotated by hand through suitable

gearing. This induces alternating current in the stator winding, which is fed to the

ohmmeter circuit via a voltage doubler circuit consisting of two diodes and two

capacitors. The test voltage is 250 V or 500 V.

The ohmmeter movement consists of two coils fixed at an angle to each other. The

control or pressure coil is connected across the generator output in series with

resistor D. This coil replaces the control spring in other types of instruments, and

when the generator handle is turned it causes the pointer to move towards infinity.

For insulation tests the deflecting or current coil is connected to the generator output

in series with the insulation resistance under test and the deflecting circuit resistance

C. This coil causes the pointer to move towards zero. The instrument measures the

ratio of the currents in the two coils, which will depend only on the resistance of the

insulation being tested. Thus the instrument is an ohmmeter and it is calibrated in

megohms and thousands of ohms.

For continuity tests (figure 21(b» the changeover switch connects the deflecting coil

in parallel with the resistance under test, so that for very low resistances the

deflecting coil current is small and the pointer will move anticlockwise, that is, the

scale reads in the opposite sense from that used for insulation tests. For the

continuity test a reduced voltage is applied by using only part of the stator winding.

The scale is calibrated in ohms.

Olatunbosun, A Page 16 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

Tests of an installation and equipment and the location of faults

Most simple tests can be carried out using a 'MEGGER' continuity and insulation

tester.

Before any tests are made the circuit or equipment must be isolated from the supply

by opening the circuit switch or circuit breaker or removing the circuit fuses. Further

precautions are generally necessary, especially in large installations and where the

tests are being carried out at a point remote from the control switchgear.

When a circuit has been isolated the following insulation tests can be made using a

'MEGGER ' .All fuse links are left in the circuit except those, which had to be

removed in order to isolate the circuit.

1. All conductors are connected together electrically and the test made between

these conductors and the earth connector. All fuse links must be in place and all

switches closed. The insulation resistance should not be less than 1 MQ.

2. If possible, all appliances and equipment, including lamps and motors, should be

removed or disconnected from the circuit and all switches closed. If this is not

possible, switches controlling equipment left connected should be opened. The test

is now made between each conductor in turn and the other conductors in the circuit.

Again, the insulation resistance should not be less than 1 MQ.

3. A test between the terminals and the casing or framework of each piece of

equipment should give an insulation resistance of not less than 0.5 MQ.

If lower values than these are obtained, then the circuit should be investigated to find

if a fault exists or is developing. Faults may develop owing to the presence of

moisture, deterioration of insulation due to heat or chemical vapours, or mechanical

damage to the cable or equipment. It may be necessary to sections the system in

order to locate the position of the fault.

Olatunbosun, A Page 17 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

When testing equipment, such as motors, for a fault it may be necessary to separate

armature from field windings, rotor from stator windings, or, in ac motors and

equipment, to separate the phase windings where this is possible. Starters should be

tested as separate items. With transformers, each phase winding should be tested

as separately if possible, in order to isolate a fault, and the insulation test should be

made between primary and secondary windings.

It is possible, where long lengths of cable are concerned, either in series or in

parallel, for a low insulation resistance to be obtained. This is due to the fact that all

insulation resistances are in parallel. This is illustrated by Figure 22.

Generally, the ammeter, voltmeter, and ohmmeter functions are combined into a

single instrument for economy and convenience. This instrument is called a

multimeter; some multifunction meters are called volt-ohm-milliammeter, abbreviated

VOM.

Olatunbosun, A Page 18 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

TROUBLE

SHOOTIN

G

Definition of

Troublesho

oting:

Troubleshoot

ing can be

defined as the process of recognizing the symptoms of a malfunction, identifying the

possible causes, and locating the failed component or components using a

systematic procedure. In order to be an effective trouble-shooter, you must

understand the basic operation of the circuit or system on which you are working,

and you must know how to use the test equipment required to do the job.

Olatunbosun, A Page 19 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

Effective troubleshooting requires a familiarity with possible failure modes of the

components in an electrical or electronic system. For example, resistors most always

become open or their resistance changes to a much higher value when they fail,

incandescent lamps open, and dc power supplies or batteries produce either

insufficient voltage or no voltage at all.

A resistor can bum out and open if it is dissipating more power than it is rated for.

Also, a resistor that is operated well below its power rating is less likely to fail than

one operated at or near its rated value.

The power in any resistor in a circuit under test can be established by measuring the

voltage across the resistor as shown in Figure 23a. Using the formula p = y21R, the

power can be calculated from the measured voltage and the known value of the

resistor. If the resistance value is not known, the power can be determined from the

voltage and current measurements, as shown in Figure 23b, using the formula p =

VI. Ideally, a resistor should be operated at no more than one-half of its power rating

to assure long life.

Checking a Resistance Value

If you suspect that the value of a resistor is not the same as its colour code or

labelling indicates, it can be checked with an ohmmeter or the ohmmeter function of

a multimeter.

In order to check accurately the value of a resistor, it must be disconnected from the

circuit. This prevents possible damage to the ohmmeter due to any voltage source in

the circuit under test; it also prevents an inaccurate measurement caused by any

other resistive elements that may appear in parallel with the resistor in question.

Olatunbosun, A Page 20 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

Two general rules should be followed when making a resistance measurement in a

circuit: (1) disconnect the circuit from the power supply; and (2) disconnect the

resistor from the circuit by

removing at least one of

its leads from its circuit

connection. This is

illustrated in Figure 24a.

Olatunbosun, A Page 21 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

In addition to resistance measurements, the ohmmeter can be used to check

continuity from one point to another in a circuit. The purpose of a continuity check is

to see if a direct connection exists between the two given points. If there is a direct

connection, the ohmmeter indicates either infinity or a finite resistance as shown if

Figure 24b and c.

Using the Voltmeter and Ammeter

You already know how the basic operation of the voltmeter and ammeter and how

they are used to make circuit measurements. The following comments should be

noted:

• When connecting meters in a circuit under test, always turn the power off first

• Always connect the dc ammeter in series with the component through which

current is to be measured. This requires breaking the circuit and inserting the

meter. The positive terminal must go toward the most positive side of the

circuit.

• Always connect the dc voltmeter in parallel with the component across which

the voltage is to be measured. The positive terminal must go toward the most

positive side of the circuit.

• Set the range switches to ranges higher than the anticipated current or

voltage in order to prevent "pegging" the meter when power is turned back on.

• Turn the power on and adjust the range switches to get the most accurate

measurement.

Olatunbosun, A Page 22 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

BASIC ac MEASURING INSTRUMENTS

Meters

We have just finished the discussion on the basic meter movements in relation to dc

measurements. The d' Arsonval movement is restricted to dc only, because a

unidirectional current is required to produce an upscale deflection as a result of the

fixed magnetic field. For ac measurement of current and voltage, an additional

circuitry is required. This additional circuitry consists of a rectifier, which converts ac

to dc. There are two types of rectifiers: half-wave and full-wave.

A half-wave rectifier is shown in block form in Figure 25a with its input and output.

The ac input is converted to pulsating dc on every positive half-cycle. The full-wave

rectifier converts the ac to pulsating dc on both the positive and the negative half-

cycles, as indicated in Figure 25b.

Basically, in ac meter the rectifier precedes the meter movement. The movement

responds to the average value of the pulsating dc. The scale can be calibrated to

show r.m.s. average or peak values, because these relationships are fixed

mathematically, as you have learned. Figure 26 shows a basic meter with a full-wave

rectifier for converting ac to dc

The electrodynamometer movement can be used to measure both dc and ac

quantities with no additional circuitry .A change in current direction does not alter the

upscale deflection, because both the stationary and the movable coils experience a

reversal of their magnetic fields.

Olatunbosun, A Page 23 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

The Oscilloscope

The oscilloscope, or scope for short, is one of the most widely used and versatile test

instruments. It displays on a screen the actual wave shape of a voltage from which

amplitude, time, and frequency measurements can be made.

The oscilloscope is built around the cathode ray tube (CRT), which is the device that

displays the waveforms. The screen of the scope is the front of the CRT (Figure 27).

Olatunbosun, A Page 24 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

Cathode Ray Tube (CRT)

The CRT is a vacuum device containing an electron gun that emits a narrow,

focused beam of electrons. A phosphorescent coating on the face of the tube forms

the screen. The beam is electronically focused and accelerated so that it strikes the

screen, causing light to be emitted at the point of impact.

Figure 28 shows the basic construction of a CRT. The electron gun assembly

contains a heater, a cathode, a control grid, and accelerating and focusing grids. The

heater carries current that indirectly heats the cathode, which in turn emits electrons.

The amount of voltage on the control grid determines the flow of electrons and thus

the intensity of the beam. The electrons are accelerated by the accelerating grid and

are focused by the focusing grid into a narrow beam that converges at the screen.

The beam is further accelerated to a high speed after it leaves the electron gun by a

high voltage on the anode surfaces of the CRT.

Deflection of the Beam

The purpose of the deflection plates in the CRT is to produce a "bending" or

deflection of the electron beam. This deflection allows the position of the point of

impact on the screen to be varied. There are two sets of deflection plates. One set

for vertical deflection, and the other set is for horizontal deflection.

Figure 29 shows a front view of the CRT's deflection plates. One plate from each set

is normally grounded as shown. If there is no voltage other plates, as in Figure 29a,

the beam is not deflected and hits the centre of the screen. If a positive voltage is on

the vertical plate, the beam is attracted upward, as indicated in Part b of the figure.

Remember that opposite charges attract. If a negative voltage is applied, the beam is

deflected downward because like charges repel, as shown in Part c.

Likewise, a positive or a negative voltage on the horizontal plate deflects the beam

right or left, respectively, as shown in Figure 29d and e. The amount of deflection is

proportional to the amount of voltage on the plates.

Olatunbosun, A Page 25 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

Sweeping the Beam Horizontally

In normal oscilloscope operation, the beam is horizontally deflected from left to right

across the screen at a certain rate. This sweeping action produces a horizontal line

or trace across the screen, as shown in Figure 30.

The rate at which the beam is swept across the screen establishes a time base. The

scope screen is divided into horizontal (and Vertical) divisions, as shown in Figure

30. For a given time base, each horizontal division represents a fixed interval of time.

For example, if the beam takes 1 second for a full left-to-right sweep, then each

division represents 0.1 second. All scopes have provisions for selecting various

sweep rates.

The actual sweeping of the beam is accomplished by application of a sawtooth

voltage across the horizontal plates, as illustrated in Figure 31. When the sawtooth is

at its maximum negative peak, the beam is deflected to its left-most screen position.

This deflection is due to maximum repulsion from the right deflection plate.

As the sawtooth voltage increases, the beam moves toward the centre of the screen.

When the sawtooth voltage is zero, the beam is at the centre of the screen, because

there is no repulsion or attraction from the plate. As the voltage increases positively,

the plate attracts the beam, causing it to move toward the right side of the screen. At

the positive peak of the sawtooth, the beam is at its right-most screen position.

The rate at which the sawtooth goes from negative to positive is determined by its

frequency, which in turn establishes the sweep rate of the beam.

Olatunbosun, A Page 26 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

When the sawtooth makes the abrupt change from positive back to negative, the

beam is rapidly returned to the left side of the screen, ready for another sweep.

During this "flyback" time, the beam is blanked out and thus does not produce a

trace on the screen.

How a Wave-Form Pattern Is Produced

The main purpose of the scope is to display the waveform of a voltage under test. To

do so, we apply the voltage under test across the vertical plates through a vertical

amplifier circuit. As you have seen, a voltage across the vertical plates causes a

vertical deflection of the beam. A negative voltage causes the beam to go below the

centre of the screen, and a positive voltage makes it go above centre.

Assume, for example, that a sine wave voltage is applied across the vertical plates,

as a result, the beam moves up and down on the screen. The extent that the beam

moves above or below the centre depends on the peak value of the sine wave

voltage. At the same time that the beam is being deflected vertically, it is also

sweeping horizontally, causing the vertical voltage wave form to be traced out across

the screen as shown in Figure 32. All scopes provide for the calibrated adjustment of

the vertical deflection, so each vertical division represents a known amoW1t of

voltage

Olatunbosun, A Page 27 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

Olatunbosun, A Page 28 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

Oscilloscope Controls

There are a wide variety of oscilloscopes available, ranging from relatively simple

instruments with limited capabilities and much more sophisticated models that

provide a variety of optional functions and precision measurements. Regardless of

their complexity, however, all scopes have certain operational features in common.

Figure 33 shows a representative oscilloscope front panel.

FIGUIRE 33' Representative dual-trace oscilloscope front panel.

Screen: In the upper portion of Figure 33 is the CRT screen. There are 8 vertical

divisions and 10 horizontal divisions indicated with grid lines or graticules. A

standard screen size is 8 cm x 10 cm. The screen is coated with phosphor that emits

light when struck by the electron beam.

Power Switch and Light: This switch turns the power on and off to the scope. The

light indicates when the power is on.

Intensity: This control knob varies the brightness of the trace on the screen. Caution

should be used so that the intensity is not left too high for an extended period of

Olatunbosun, A Page 29 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

time, especially when the beam forms a motionless dot on the screen. Damage to

the screen can result from excessive intensity.

Focus: This control focuses the beam so that it converges to a tiny point at the

screen. An-out-of-focus condition results in a fuzzy trace.

Horizontal Position: This control knob adjusts the neutral horizontal position of the

beam. It is used to reposition horizontally a waveform display for more convenient

viewing or measurement.

Seconds/Division: This selector switch sets the horizontal sweep rate. It is the time

base control. The switch selects the time interval that is to be represented by each

horizontal division in seconds, milliseconds, or microseconds. The setting in Figure

33 is at 10 µs. Thus, each of the ten horizontal divisions represents 10 µs: so there

are 100µs from the extreme left of the screen to the extreme right.

One cycle of the displayed sine wave covers eight horizontal divisions. Therefore,

the period of the sine wave is (8 div) (10 µs/div) = 80µs. From this the frequency can

be calculated as f= 1/T = 1/80 µs = 12.5 kHz. If the sec/div switch is moved to a

different setting, the displayed sine wave will change correspondingly. If it is moved

to a lower time setting, fewer cycles will be displayed.

If it is moved to a higher time setting, more cycles will be displayed

Trigger Control: These controls allow the beam to be triggered from various

selected sources. The triggering of the beam causes it to begin its sweep across the

screen. It can be triggered from an internally generated signal derived from an input

signal, or from the line voltage, or from an externally applied trigger signal. The

modes of triggering are auto, normal, and TV .In the auto mode, a trigger occurs in

the absence of an adequate trigger signal. In the normal mode, a trigger signal must

be present for the sweep to occur. The TV mode provides triggering on the TV field

or TV line signals. The slope switch allows the triggering to occur on either the

positive-going slope or the negative-going slope of the trigger waveform. The level

control selects the amplitude point on the trigger signal at which the triggering

occurs.

Olatunbosun, A Page 30 of 31 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Measurements

Basically, the trigger controls provide for synchronization of the sweep waveform and

the input signal waveform. As a result, the display of the input signal is stable on the

screen, rather than appearing to drift across the screen.

Volts/Division: The example scope in Figure 33 is a dual-trace type, which allows

two waveforms to be displayed simultaneously. Many scopes have only single-trace

capability. Notice that there are two identical volts/ div selectors. There is a set of

controls for each of the two input channels.

The volts/div selector switch sets the number of volts to be represented by each

division on the vertical scale. For example, the displayed sine wave is applied to

channel land covers four vertical divisions from the positive peak to the negative

peak. The volt/div switch for channel is set at 50mV, which means that each vertical

division represents 50 mV. Therefore, the peak-to-peak value of the sine wave is

(4div) (50 mV/div) = 200mV. If a lower setting were selected, the displayed wave

would cover more vertical divisions. If a higher setting were selected, the displayed

wave would cover fewer vertical divisions.

Notice that there is a set of three switches for selecting channel (CH 1), channel (CH

2), or dual trace. Either input signal can be displayed separately, or both can be

displayed as illustrated.

Vertical Position: The two vertical position controls move the traces up or down for

easier measurement or observation.

ac-gnd-dc-Switch: This switch, located below the volts/div control, allows the input

signal to be ac coupled, dc coupled, or grounded. The ac coupling eliminates any dc

component on the input signal. The dc coupling permits dc values to be displayed.

The ground position allows a zero volt reference to be established on the screen.

Input: The signals to be displayed are connected into the channel 1 and channel 2

input connectors. This connection is normally done via a special probe that minimize

the loading effect of the scope's input resistance and capacitance on the circuit being

measured.

Olatunbosun, A Page 31 of 31 Univation

You might also like

- 3202.31.DIES - INSTRUMENT TUBING SCHEDULE.24018 - Rev03Document5 pages3202.31.DIES - INSTRUMENT TUBING SCHEDULE.24018 - Rev03Chidiebere Samuel OkogwuNo ratings yet

- Alternative Source For Gas Supply To Indorama ProjectDocument4 pagesAlternative Source For Gas Supply To Indorama ProjectChidiebere Samuel OkogwuNo ratings yet

- 3202.31.DIES - INSTRUMENT CABLE SCHEDULE.24015 - Rev02Document6 pages3202.31.DIES - INSTRUMENT CABLE SCHEDULE.24015 - Rev02Chidiebere Samuel OkogwuNo ratings yet

- Dragnet Abstract Reasoning Test 1&2 SolutionsDocument10 pagesDragnet Abstract Reasoning Test 1&2 SolutionsChidiebere Samuel OkogwuNo ratings yet

- Errosion: Nozzle Segment Indication ZonesDocument1 pageErrosion: Nozzle Segment Indication ZonesChidiebere Samuel OkogwuNo ratings yet

- Family KKS Maintenance Period Detail PM TasksDocument6 pagesFamily KKS Maintenance Period Detail PM TasksChidiebere Samuel OkogwuNo ratings yet

- Install PDFDocument12 pagesInstall PDFMd NazrulNo ratings yet

- Alternative Gas Supply for IndoramaDocument19 pagesAlternative Gas Supply for IndoramaChidiebere Samuel OkogwuNo ratings yet

- VerbalReasoningTest1 QuestionDocument12 pagesVerbalReasoningTest1 QuestionChidiebere Samuel OkogwuNo ratings yet

- Start Time SN Job Step Hazard Harzard Controls Status CommentsDocument3 pagesStart Time SN Job Step Hazard Harzard Controls Status CommentsChidiebere Samuel OkogwuNo ratings yet

- Thin Material: Nozzle Segment Indication ZonesDocument1 pageThin Material: Nozzle Segment Indication ZonesChidiebere Samuel OkogwuNo ratings yet

- Nozzle Segment Indication Zones GuideDocument1 pageNozzle Segment Indication Zones GuideChidiebere Samuel OkogwuNo ratings yet

- Start Time SN Job Step Hazard Hazard Controls Status CommentsDocument3 pagesStart Time SN Job Step Hazard Hazard Controls Status CommentsChidiebere Samuel OkogwuNo ratings yet

- Nozzle Segment Indication Zones: A B C B D D E FDocument1 pageNozzle Segment Indication Zones: A B C B D D E FChidiebere Samuel OkogwuNo ratings yet

- TTD Setup For Ajax (2015 - 11 - 23 10 - 24 - 32 UTC)Document1 pageTTD Setup For Ajax (2015 - 11 - 23 10 - 24 - 32 UTC)Chidiebere Samuel OkogwuNo ratings yet

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocument2 pagesKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuNo ratings yet

- KVAERNER ENERGY LTD THERMAL POWER DIVISION CSD FIELD TECHNICAL INSTRUCTIONDocument2 pagesKVAERNER ENERGY LTD THERMAL POWER DIVISION CSD FIELD TECHNICAL INSTRUCTIONChidiebere Samuel OkogwuNo ratings yet

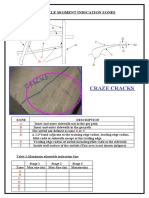

- Craze Cracks: Nozzle Segment Indication ZonesDocument1 pageCraze Cracks: Nozzle Segment Indication ZonesChidiebere Samuel OkogwuNo ratings yet

- Field Technical Instruction: John Brown Engineering Customer Service DivisionDocument2 pagesField Technical Instruction: John Brown Engineering Customer Service DivisionChidiebere Samuel OkogwuNo ratings yet

- Kvaerner Energy LTD Thermal Power Division C.S.D. Field Technical InstructionDocument2 pagesKvaerner Energy LTD Thermal Power Division C.S.D. Field Technical InstructionChidiebere Samuel OkogwuNo ratings yet

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocument1 pageKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuNo ratings yet

- FTI0257Document3 pagesFTI0257Chidiebere Samuel OkogwuNo ratings yet

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocument2 pagesKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuNo ratings yet

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocument2 pagesKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuNo ratings yet

- Technical Information Letter: Five-Wire Flame Detector System ReplacementDocument1 pageTechnical Information Letter: Five-Wire Flame Detector System ReplacementChidiebere Samuel OkogwuNo ratings yet

- Technical Information Letter: Replacement of 6B ST Age-2 BucketsDocument1 pageTechnical Information Letter: Replacement of 6B ST Age-2 BucketsChidiebere Samuel OkogwuNo ratings yet

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocument2 pagesKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuNo ratings yet

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocument2 pagesKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuNo ratings yet

- Technical Information Letter: Load Coupling Nut EventDocument1 pageTechnical Information Letter: Load Coupling Nut EventChidiebere Samuel OkogwuNo ratings yet

- Technical Information Letter: Excessive Gas Fuel Flow at Start-Up (F-Class)Document5 pagesTechnical Information Letter: Excessive Gas Fuel Flow at Start-Up (F-Class)Chidiebere Samuel Okogwu100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Tenor Ax Voip Multipath/Gateway Switch: Product GuideDocument131 pagesTenor Ax Voip Multipath/Gateway Switch: Product GuideEdgar A CanizalezNo ratings yet

- EM100 Training PDFDocument111 pagesEM100 Training PDFAris Bodhi R0% (1)

- Part 1 Piping SystemsDocument22 pagesPart 1 Piping SystemsfacebookshopNo ratings yet

- HIS 770B Series-User ManualDocument33 pagesHIS 770B Series-User ManualVishwas MaritronicsNo ratings yet

- Katalog Firme MGDocument74 pagesKatalog Firme MGJovanNisNo ratings yet

- Introduction To Computing ReviewerDocument2 pagesIntroduction To Computing ReviewerKyle AbiogNo ratings yet

- WindowsITPro Magazine 2013-05Document88 pagesWindowsITPro Magazine 2013-05kflimNo ratings yet

- AHLSTAR™ Process Pumps: The Heart of Your ProcessDocument16 pagesAHLSTAR™ Process Pumps: The Heart of Your ProcessRubenOrtegaNo ratings yet

- A11Document1 pageA11MichiNo ratings yet

- Complete 2010/2011 Catalog - Architecture, Landscape, DesignDocument9 pagesComplete 2010/2011 Catalog - Architecture, Landscape, DesignDoki86No ratings yet

- To Download The TCPro Application-1Document42 pagesTo Download The TCPro Application-1Shahrizan Abdul RahmanNo ratings yet

- Clerk Cum Data Entry Operator Recruitment 2018Document25 pagesClerk Cum Data Entry Operator Recruitment 2018Pankaj VermaNo ratings yet

- Major Events ReviewedDocument81 pagesMajor Events ReviewedNanda Win LwinNo ratings yet

- Richard Bandler's Guide to Harnessing HypnosisDocument3 pagesRichard Bandler's Guide to Harnessing HypnosisChristy Mayo0% (1)

- EMI and ACDocument14 pagesEMI and ACbharathNo ratings yet

- WavelengthPeriodFrequency QuestionsDocument2 pagesWavelengthPeriodFrequency QuestionssalmasomaNo ratings yet

- Tools For Pipe Welding: W E L D T E C HDocument24 pagesTools For Pipe Welding: W E L D T E C HChano HanokNo ratings yet

- GST Project Report SummaryDocument14 pagesGST Project Report SummaryWwe MomentsNo ratings yet

- Computer Awareness For IBPS - SBI - RRB PO & Clerks - Edu GeeksDocument3 pagesComputer Awareness For IBPS - SBI - RRB PO & Clerks - Edu GeeksVivek SharmaNo ratings yet

- PDFDocument76 pagesPDFRavishankarNo ratings yet

- Market and Influencer Mapping for Orient Bell Ltd in Calicut RegionDocument12 pagesMarket and Influencer Mapping for Orient Bell Ltd in Calicut RegionJomin PjoseNo ratings yet

- Pipe Material Specs (MCP)Document106 pagesPipe Material Specs (MCP)BoulHich BoulHichNo ratings yet

- Tollgate-Based Project Management TemplateDocument9 pagesTollgate-Based Project Management TemplateKulanthaivelu RamasamyNo ratings yet

- Unit Outline - EnS5257 Microprocessor SystemsDocument3 pagesUnit Outline - EnS5257 Microprocessor SystemsAnup VanarseNo ratings yet

- SOP Purchasing Manual 2011 PDFDocument220 pagesSOP Purchasing Manual 2011 PDFerpNo ratings yet

- HSBC Placement Paper Aptitude ReasoningDocument6 pagesHSBC Placement Paper Aptitude ReasoningRatnadeep Mitra67% (3)

- Q603 - Nte159Document2 pagesQ603 - Nte159daneloNo ratings yet

- Chemical Engineer Skill SetDocument2 pagesChemical Engineer Skill SetJunaid AhmadNo ratings yet

- Final PPT BpoDocument21 pagesFinal PPT BpoPradeepNo ratings yet

- DTFT Analysis in MATLABDocument7 pagesDTFT Analysis in MATLABRUTUJA MADHURENo ratings yet