Professional Documents

Culture Documents

Armfield Oregon State Poster

Uploaded by

cgjp1203910 ratings0% found this document useful (0 votes)

83 views1 pageposter LLE

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentposter LLE

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

83 views1 pageArmfield Oregon State Poster

Uploaded by

cgjp120391poster LLE

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

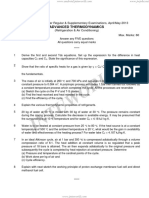

Liquid-Liquid Extraction Unit Operation

Objective: Introduction into ChE 415 Curriculum

Introduce Liquid-Liquid Extraction to Chemical

Engineering Senior Lab Doanh Nguyen, Dominick Smiddy, Kimberly Traeger

• Develop equilibrium distribution plot for ternary

Diagram courtesy of Armfield

system of kerosene-acetic acid-water

• Install/Characterize Armfield UOP5-MKII Liquid-

Figure 6. Johnson Hall at Oregon State University. LLE

Liquid Extraction (LLE) Unit unit installed in John 214.

• Develop Standard Operating Procedure and

project assignment for use in ChE 415 Student Deliverables

• Measure concentration of acetic acid removed

• Calculation of overall mass transfer coefficient

Background: (𝐾𝐾𝐿𝐿 𝑎𝑎)

Liquid-Liquid Extraction (LLE) is a unit operation • Find number of theoretical stages

that uses mass transfer as the driving force for • Scale up of design to industrial size

separation. There are two solvents involved and a

solute which is transferred from one to the other. In

our case, this is a continuous process in which Conclusions Thus Far:

deionized water removes acetic acid that is initially • Using the system in the continuous aqueous

mixed in kerosene. phase (kerosene droplets) design yields the

highest mass transfer of acetic acid

𝐹𝐹𝑆𝑆 - feed solvent mass flow rate • Higher flow rates of non-continuous phase

𝑥𝑥𝐹𝐹′ - weight fraction of solute in feed solvent Figure 2. Process Flow Diagram obtained from Armfield Instruction Manual showing a continuous, counter- increase the mass transfer area by decreasing

′ current flow process. DI water flows down and kerosene flows up the column due to differences in density.

𝑥𝑥𝑁𝑁𝑁𝑁 - weight fraction remaining in feed solvent Concentration of acetic acid is measured at the DI water inlet and outlet by conductivity probes.

the droplet size and increasing the amount of

𝑆𝑆𝑆𝑆 - extract solvent mass flow rate droplets flowing through the column

𝑦𝑦𝑆𝑆′ - weight fraction of solute initially in extract solvent

𝑦𝑦1′ - weight fraction in extraction solvent of solute

Mass Balance for solute: 𝑥𝑥𝐹𝐹′ 𝐹𝐹𝑆𝑆 + 𝑦𝑦𝑆𝑆′ 𝑆𝑆𝑆𝑆 = 𝑥𝑥𝑁𝑁𝑁𝑁

′

𝐹𝐹𝑆𝑆 + 𝑦𝑦1′ 𝑆𝑆𝑆𝑆

Future Work:

• Collect and analyze multiple trials of

Operating line equation: 𝐹𝐹𝑆𝑆 𝑦𝑦1′ − 𝑦𝑦𝑆𝑆′ experimental data

= ′ ′

𝑆𝑆𝑆𝑆 𝑥𝑥𝐹𝐹 − 𝑥𝑥𝑁𝑁𝑝𝑝 • Determine overall mass transfer coefficients

(𝐾𝐾𝐿𝐿 𝑎𝑎) as a function of flow

• Determine kerosene recycling feasibility

• Determine ranges of operating conditions (flow

rates & concentrations)

• Revise Standard Operating Procedure and

Figure 4. (Left) Snapshot at top of column, kerosene project assignment

set at 80 mL/min. (Right) Snapshot at middle of

column, kerosene set at 240 mL/min.

0.5

0.45

Acknowledgements:

H2O-80, Kero-240

0.4 • Oregon State University, CBEE Department for

weight % AA in water

0.35 H2O-160, Kero-80

0.3 the funding for our project

0.25

0.2

• John Cochran and Andy Brickman for their

0.15

0.1

assistance in the installation of the LLE unit

0.05 • Ese Ono-Sorhue: Armfield Project development

0

0 5 10 15 20 25 30 lead

Time (min)

Figure 1. Stagewise continuous LLE – method of analysis for • Dr. Philip Harding for his guidance

immiscible system. Diagram courtesy of Dr. Gregory Rorrer, Figure 3. UOP5-MKII in Johnson Hall Laboratory. Figure 5. (Black) Weight percent of acetic acid in water

OSU ChE 411 The unit included the extraction column, vs time data collected from LLE unit. Kerosene flow at

controller, and four reservoirs (feed, solvent, 80 mL/min, DI water flow at 160 mL/min. (Orange)

and two returns) Kerosene flow at 240 mL/min, DI water at 80 mL/min.

You might also like

- 03 Liquid Liquid ExtractionDocument28 pages03 Liquid Liquid ExtractionChelsea Martinez100% (5)

- Design and Synthesis of Chemical Absorption ProcessDocument62 pagesDesign and Synthesis of Chemical Absorption ProcesscoxinhoNo ratings yet

- SPE 102828 Field Success in Carbonate Acid Diversion, Utilizing Laboratory Data Generated by Parallel Flow TestingDocument14 pagesSPE 102828 Field Success in Carbonate Acid Diversion, Utilizing Laboratory Data Generated by Parallel Flow TestingzachNo ratings yet

- Proper Use of Equations of State For Compositional Reservoir SimulationDocument7 pagesProper Use of Equations of State For Compositional Reservoir SimulationjairNo ratings yet

- @buchi: Fat Determination: Comparison Between Soxhlet and Hot Extraction Using The Extraction Units E 812/E 816Document8 pages@buchi: Fat Determination: Comparison Between Soxhlet and Hot Extraction Using The Extraction Units E 812/E 816Jonyl Lomigo GarciaNo ratings yet

- BestBuchi 47 Soxlet Hot Extraction E-812 816 en NEU LowDocument8 pagesBestBuchi 47 Soxlet Hot Extraction E-812 816 en NEU LowelfanNo ratings yet

- Ccreportexamplesai PDFDocument2 pagesCcreportexamplesai PDFDinesh KumarNo ratings yet

- PVT & Eos ModelingDocument48 pagesPVT & Eos ModelingahouaNo ratings yet

- Guía 68Document7 pagesGuía 68GabyNo ratings yet

- IChemE Online Poster CompetitionDocument1 pageIChemE Online Poster CompetitionBilly HughNo ratings yet

- A Smarter Approach To Drastically Reduce Production Losses and To Provide Stable, Trouble-Free EHC FluidDocument3 pagesA Smarter Approach To Drastically Reduce Production Losses and To Provide Stable, Trouble-Free EHC FluidtruongtxNo ratings yet

- Laboratory Investigation and Field Use of A Novel Sand Cleanout Fluid System ForDocument5 pagesLaboratory Investigation and Field Use of A Novel Sand Cleanout Fluid System Formohamadi42No ratings yet

- Application Note Conductivity Measurement in Chemical Concentration Control en 68372Document2 pagesApplication Note Conductivity Measurement in Chemical Concentration Control en 68372Yesid DiazNo ratings yet

- AquaNereda Brochure 1017 WebDocument4 pagesAquaNereda Brochure 1017 WebdmnNo ratings yet

- Flyer ROTOCAV - Hydrodynamic CavitatorDocument2 pagesFlyer ROTOCAV - Hydrodynamic Cavitatorfsilassie8012No ratings yet

- SPE-108181 Transient Analysis-Hysys Dynamics and OLGADocument11 pagesSPE-108181 Transient Analysis-Hysys Dynamics and OLGAWilfred Enock100% (1)

- SPE-8400-MS - Benzoic Acid FlakesDocument8 pagesSPE-8400-MS - Benzoic Acid FlakeszachNo ratings yet

- Liquid Liquid ExtractionDocument42 pagesLiquid Liquid ExtractionNOR HIDAWATI ELIASNo ratings yet

- Reactive Processes Mass BalancesDocument18 pagesReactive Processes Mass Balanceslydia hiiNo ratings yet

- Distillation Column EfficiencyDocument7 pagesDistillation Column EfficiencyRafiah JobNo ratings yet

- 2.4 Absorption and StrippingDocument22 pages2.4 Absorption and StrippingskskskskNo ratings yet

- Supercritical Fluid ExtractionDocument37 pagesSupercritical Fluid ExtractionNASUKHA RIFAI RIFAINo ratings yet

- Destilacion Extractiva PDFDocument7 pagesDestilacion Extractiva PDFMORALES GUERRERO NAZIR HAELNo ratings yet

- Sample Preparation (Full Lecture 1-10) 1april19Document150 pagesSample Preparation (Full Lecture 1-10) 1april19kassim AliNo ratings yet

- Application Guide: Clean in Place Conductivity Monitoring SystemsDocument4 pagesApplication Guide: Clean in Place Conductivity Monitoring Systemspatitay036817No ratings yet

- Reservoir - Fluid Sampling & Characterization-Key To Efficient Reservoir Management PDFDocument12 pagesReservoir - Fluid Sampling & Characterization-Key To Efficient Reservoir Management PDFJesseNo ratings yet

- New solid-acid alkylation process scaled up using engineered catalystDocument6 pagesNew solid-acid alkylation process scaled up using engineered catalystChristian ChiodoNo ratings yet

- Kinetic Models of Supercritical Fluid ExtractionDocument13 pagesKinetic Models of Supercritical Fluid ExtractionDavide Di ZioNo ratings yet

- Aquasep Plus LL Coalescers LSS2F2HDocument4 pagesAquasep Plus LL Coalescers LSS2F2Hpo bangkokNo ratings yet

- High Performance Liquid Chromatography: Separation and Quantification of Components in Diet Soft DrinksDocument17 pagesHigh Performance Liquid Chromatography: Separation and Quantification of Components in Diet Soft DrinksAnonymous mKkg5dNo ratings yet

- Ratnakar, Phase Behavior Experiments and PVT Modeling of DME-brine-crudeDocument14 pagesRatnakar, Phase Behavior Experiments and PVT Modeling of DME-brine-crudeAllah BakhshNo ratings yet

- Liquid-Liquid-Extraction: Engineering - Apparatus - PlantsDocument12 pagesLiquid-Liquid-Extraction: Engineering - Apparatus - PlantsKarim GaberNo ratings yet

- Flowsheet separation train designDocument36 pagesFlowsheet separation train designharismulyadiumpNo ratings yet

- Exercise: Xercise BjectiveDocument16 pagesExercise: Xercise BjectiveRiccardo VianelloNo ratings yet

- 4 B.bradley SNL 2 Emug 2022 MsrffprkeDocument13 pages4 B.bradley SNL 2 Emug 2022 Msrffprkenelson churataNo ratings yet

- Liquid-Liquid Extraction TheoryDocument4 pagesLiquid-Liquid Extraction TheoryArifo Gunawan CahyanegoroNo ratings yet

- Liquid-Liquid Extraction Technology at Sulzer ChemtechDocument12 pagesLiquid-Liquid Extraction Technology at Sulzer ChemtechYanuar Sigit PramanaNo ratings yet

- NCC 06-Saturation PDFDocument4 pagesNCC 06-Saturation PDFRaed Al-nomanNo ratings yet

- Small Flow Liquid Liquid Coalescers FLTR Purple EngineeringDocument4 pagesSmall Flow Liquid Liquid Coalescers FLTR Purple EngineeringFLTR PURPLE E.No ratings yet

- 104SE-Combining New and Old Technologies - Inlet Diffuser and Random Packing Dramatically Improve Reactor PerformanceDocument10 pages104SE-Combining New and Old Technologies - Inlet Diffuser and Random Packing Dramatically Improve Reactor PerformanceSHINo ratings yet

- Adobe Scan 03 Jun 2023Document10 pagesAdobe Scan 03 Jun 2023Doctor premsagarNo ratings yet

- M.H. Ghatee, H. Ghazipour, Fluid Phase Equilib. 377 (2014) 76-81Document6 pagesM.H. Ghatee, H. Ghazipour, Fluid Phase Equilib. 377 (2014) 76-81PaulaGF88No ratings yet

- Lact BulletinDocument2 pagesLact Bulletinmember1000No ratings yet

- Proper Use of Equations of State For Compositional Reservoir SimulationDocument7 pagesProper Use of Equations of State For Compositional Reservoir SimulationmacapedNo ratings yet

- J Ces 2021 116827fvdfvzfvzfvzzfvzfvdDocument13 pagesJ Ces 2021 116827fvdfvzfvzfvzzfvzfvdValeria MoraesNo ratings yet

- Solid Liquid ExtractionDocument12 pagesSolid Liquid Extractionamime7730No ratings yet

- ExtractionDocument8 pagesExtractionChandraji KumarNo ratings yet

- Poster 4 Sedimentation (A2)Document1 pagePoster 4 Sedimentation (A2)Ramco33No ratings yet

- Reactive liquid-liquid extraction design methodology for succinic acid recoveryDocument15 pagesReactive liquid-liquid extraction design methodology for succinic acid recoveryMuhammad Arsalan AshrafNo ratings yet

- Osmotic Power Generation and Reverse Osmosis Desalination Hybrid SystemDocument4 pagesOsmotic Power Generation and Reverse Osmosis Desalination Hybrid SystemHasim BenziniNo ratings yet

- SPE 157996 Optimizing Water Injection Rates For A Water-Flooding FieldDocument6 pagesSPE 157996 Optimizing Water Injection Rates For A Water-Flooding FieldAzeem VeesarNo ratings yet

- Basic Diagrams in Extractive MetallurgyDocument50 pagesBasic Diagrams in Extractive MetallurgyBüşra DOĞRUNo ratings yet

- Thickeners and Clarifiers: Liquid / Solid SeparationDocument6 pagesThickeners and Clarifiers: Liquid / Solid Separationyounes1980No ratings yet

- SPEE Monograph 4 PDFDocument71 pagesSPEE Monograph 4 PDFRiaz AliNo ratings yet

- Ethyl Acrylate PDFDocument9 pagesEthyl Acrylate PDFPeri HabibovaNo ratings yet

- Liquid Liquidextraction PDFDocument9 pagesLiquid Liquidextraction PDFDaniel Francisco100% (1)

- Flowserve Pump Seal PlansDocument56 pagesFlowserve Pump Seal PlansDDNo ratings yet

- Aspen Plus Modeling of Distillation, Absorption and Stripping ProcessesDocument44 pagesAspen Plus Modeling of Distillation, Absorption and Stripping ProcessesWahab Maqbool100% (1)

- Turkel Vatsa 94Document7 pagesTurkel Vatsa 94junior.hmgNo ratings yet

- Liquid-Liquid Copper Extraction Process Perfected ExperimentsDocument4 pagesLiquid-Liquid Copper Extraction Process Perfected Experimentscgjp120391No ratings yet

- Ex MixingDocument7 pagesEx Mixingcgjp120391No ratings yet

- Safety Data Sheet: Di Deionised WaterDocument4 pagesSafety Data Sheet: Di Deionised Watercgjp120391No ratings yet

- ATEX Guidelines clarify Directive 2014/34/EUDocument238 pagesATEX Guidelines clarify Directive 2014/34/EUARTURONo ratings yet

- Teky's Tips: Mix Fluids As You Pump Them Through A Pipe LineDocument1 pageTeky's Tips: Mix Fluids As You Pump Them Through A Pipe Linecgjp120391No ratings yet

- LleDocument12 pagesLlecgjp120391No ratings yet

- Absorption of Carbon Dioxide Into WaterDocument13 pagesAbsorption of Carbon Dioxide Into WaterPetronela CozmaNo ratings yet

- Perfected Experiments RigsDocument3 pagesPerfected Experiments Rigscgjp120391No ratings yet

- Unit Lab Manual 2011Document114 pagesUnit Lab Manual 2011cgjp120391No ratings yet

- UsefulCalculations PDFDocument3 pagesUsefulCalculations PDFhbithoNo ratings yet

- Lab ManualDocument155 pagesLab ManualKieu Phuong PhamNo ratings yet

- Tray Dryer LabDocument6 pagesTray Dryer Labcgjp120391No ratings yet

- Mod. REC1/EV Mod. REC1c/EV Mod. REC1a/EV: Continuous Reaction (CSTR) Pilot PlantDocument2 pagesMod. REC1/EV Mod. REC1c/EV Mod. REC1a/EV: Continuous Reaction (CSTR) Pilot Plantcgjp120391No ratings yet

- Gas Cyclones: Eloise Jackson and Jigar PatelDocument24 pagesGas Cyclones: Eloise Jackson and Jigar Patelcgjp120391No ratings yet

- Ecre CD-CH13 PDFDocument78 pagesEcre CD-CH13 PDFPadmesh TvnNo ratings yet

- Batch Reactor Rate DeterminationDocument6 pagesBatch Reactor Rate DeterminationNurhazimah IsmailNo ratings yet

- UsefulCalculations PDFDocument3 pagesUsefulCalculations PDFhbithoNo ratings yet

- Experimental InvestigationDocument6 pagesExperimental Investigationcgjp120391No ratings yet

- Unit Lab Manual 2011Document114 pagesUnit Lab Manual 2011cgjp120391No ratings yet

- 1997 JFE p269 TsampDocument24 pages1997 JFE p269 Tsampcgjp120391No ratings yet

- Teky's Tips: Mix Fluids As You Pump Them Through A Pipe LineDocument1 pageTeky's Tips: Mix Fluids As You Pump Them Through A Pipe Linecgjp120391No ratings yet

- Armfield Dryer PriceDocument5 pagesArmfield Dryer Pricecgjp120391No ratings yet

- Concentration To ConductivitycurvesDocument30 pagesConcentration To Conductivitycurvescgjp120391No ratings yet

- Mass TransferDocument4 pagesMass Transfercgjp120391No ratings yet

- LAB8Document6 pagesLAB8cgjp120391No ratings yet

- Mod. REC1/EV Mod. REC1c/EV Mod. REC1a/EV: Continuous Reaction (CSTR) Pilot PlantDocument2 pagesMod. REC1/EV Mod. REC1c/EV Mod. REC1a/EV: Continuous Reaction (CSTR) Pilot Plantcgjp120391No ratings yet

- CoalescerDocument18 pagesCoalescer112dharmesh0% (1)

- Excstr PDFDocument7 pagesExcstr PDFcgjp120391No ratings yet

- Chemical Compatibility Chart Metallic Materials Used in Bal Seal ProductsDocument28 pagesChemical Compatibility Chart Metallic Materials Used in Bal Seal Productscgjp120391No ratings yet

- Printo TodayDocument97 pagesPrinto TodayAnonymous Wcj4C3jNo ratings yet

- Advanced Materials and StructuresDocument244 pagesAdvanced Materials and StructuresCarlos LlanoNo ratings yet

- Heat CapcityDocument6 pagesHeat CapcitysafNo ratings yet

- Kelompok 5 - Separation Soluble - Apbioproses 12.49Document46 pagesKelompok 5 - Separation Soluble - Apbioproses 12.49IndahLestariNanderNo ratings yet

- SMJC 2701 Exp2Document14 pagesSMJC 2701 Exp2norsiahNo ratings yet

- Thermodynamic Versus Kinetic Reaction Control, Diffusion ControlDocument7 pagesThermodynamic Versus Kinetic Reaction Control, Diffusion ControlenvirocompNo ratings yet

- 1.concentration Part 1Document6 pages1.concentration Part 1Dharmvir tantyNo ratings yet

- VSL Primary Gas StandardsDocument59 pagesVSL Primary Gas Standards分析室信箱No ratings yet

- Sounds Cool Q&AofcDocument2 pagesSounds Cool Q&AofcSaik SikshaNo ratings yet

- D0597189 CHEM12 C1700 SWBT Mig PDFDocument16 pagesD0597189 CHEM12 C1700 SWBT Mig PDFMr: Mohamed BesharaNo ratings yet

- Board of Intermediate Education, A.P., Vijayawada 1st Year - PHYSICS Modified Weightage of Marks (Blue-Print) According To Academy Text BookDocument2 pagesBoard of Intermediate Education, A.P., Vijayawada 1st Year - PHYSICS Modified Weightage of Marks (Blue-Print) According To Academy Text BookGnanNo ratings yet

- Steam TablesDocument28 pagesSteam TableszahoorNo ratings yet

- Physical Science Quarter 1 Module 4Document32 pagesPhysical Science Quarter 1 Module 4Luanne Jali-JaliNo ratings yet

- Bose-Einstein Condensation: A PreludeDocument8 pagesBose-Einstein Condensation: A PreludeSk. Golam Ali0% (1)

- Humidity Derate ChartDocument1 pageHumidity Derate ChartMd Sh100% (1)

- Heat Transfer 2Document3 pagesHeat Transfer 2lmoazhussamlNo ratings yet

- Advances in Composites PDFDocument123 pagesAdvances in Composites PDFNeetha ShenoyNo ratings yet

- Materials Science & Engineering B: SciencedirectDocument10 pagesMaterials Science & Engineering B: SciencedirectMuhammad BramansyahNo ratings yet

- Enhanced Efficiency and Stability of N-I-P Perovskite Solar Cells by Incorporation of Fluorinated Graphene in The Spiro-OMeTAD Hole Transport LayerDocument11 pagesEnhanced Efficiency and Stability of N-I-P Perovskite Solar Cells by Incorporation of Fluorinated Graphene in The Spiro-OMeTAD Hole Transport Layer北科大-洪珮倫No ratings yet

- 2245-2246 AspirinDocument2 pages2245-2246 AspirinPhoenixNo ratings yet

- Batch Drying With Vacuum Contact DryersDocument7 pagesBatch Drying With Vacuum Contact DryersBramJanssen76No ratings yet

- Boyle's Law Questions PDFDocument3 pagesBoyle's Law Questions PDFamvijayagopal100% (1)

- LOTADER GMA & LOTRYL IMPACT MODIFICATION OF POLYESTERSDocument30 pagesLOTADER GMA & LOTRYL IMPACT MODIFICATION OF POLYESTERSRajiva Joshi100% (1)

- Tephi and StabilityDocument56 pagesTephi and StabilityKristaRonaNo ratings yet

- Catalytic Dehydration of Methanol To Dimethyl Ether. Kinetic Investigation and Reactor SimulationDocument8 pagesCatalytic Dehydration of Methanol To Dimethyl Ether. Kinetic Investigation and Reactor SimulationLuiz Rodrigo AssisNo ratings yet

- Semi Detailed Lesson Plan in Electricity g71Document6 pagesSemi Detailed Lesson Plan in Electricity g71Edessa MasinasNo ratings yet

- Shock TubeDocument16 pagesShock TubeAhmed El MorsyNo ratings yet

- Beer Lambert LawDocument4 pagesBeer Lambert LawasjawolverineNo ratings yet

- 9D17101 Advanced ThermodynamicsDocument1 page9D17101 Advanced ThermodynamicssubbuNo ratings yet

- EE201 Notes 1 Introduction To SemiconductorDocument18 pagesEE201 Notes 1 Introduction To SemiconductoradamwaizNo ratings yet

- THE VERNE CODE: The Secret of the Anunnaki, Atlantis and the true shape of the Earth unveiledFrom EverandTHE VERNE CODE: The Secret of the Anunnaki, Atlantis and the true shape of the Earth unveiledRating: 4.5 out of 5 stars4.5/5 (20)

- Why We Die: The New Science of Aging and the Quest for ImmortalityFrom EverandWhy We Die: The New Science of Aging and the Quest for ImmortalityRating: 3.5 out of 5 stars3.5/5 (2)

- To Explain the World: The Discovery of Modern ScienceFrom EverandTo Explain the World: The Discovery of Modern ScienceRating: 3.5 out of 5 stars3.5/5 (51)

- This Is Your Brain On Parasites: How Tiny Creatures Manipulate Our Behavior and Shape SocietyFrom EverandThis Is Your Brain On Parasites: How Tiny Creatures Manipulate Our Behavior and Shape SocietyRating: 3.5 out of 5 stars3.5/5 (31)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 5 out of 5 stars5/5 (4)

- The Obesity Code: Unlocking the Secrets of Weight LossFrom EverandThe Obesity Code: Unlocking the Secrets of Weight LossRating: 5 out of 5 stars5/5 (3)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 3.5 out of 5 stars3.5/5 (31)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorFrom EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorRating: 4.5 out of 5 stars4.5/5 (137)

- Summary: Outlive: The Science and Art of Longevity by Peter Attia MD, With Bill Gifford: Key Takeaways, Summary & AnalysisFrom EverandSummary: Outlive: The Science and Art of Longevity by Peter Attia MD, With Bill Gifford: Key Takeaways, Summary & AnalysisRating: 4.5 out of 5 stars4.5/5 (41)

- Summary: Limitless: Upgrade Your Brain, Learn Anything Faster, and Unlock Your Exceptional Life By Jim Kwik: Key Takeaways, Summary and AnalysisFrom EverandSummary: Limitless: Upgrade Your Brain, Learn Anything Faster, and Unlock Your Exceptional Life By Jim Kwik: Key Takeaways, Summary and AnalysisRating: 5 out of 5 stars5/5 (8)

- When the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisFrom EverandWhen the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisRating: 3.5 out of 5 stars3.5/5 (2)

- The Marshmallow Test: Mastering Self-ControlFrom EverandThe Marshmallow Test: Mastering Self-ControlRating: 4.5 out of 5 stars4.5/5 (57)

- Crypt: Life, Death and Disease in the Middle Ages and BeyondFrom EverandCrypt: Life, Death and Disease in the Middle Ages and BeyondRating: 4 out of 5 stars4/5 (3)

- Sully: The Untold Story Behind the Miracle on the HudsonFrom EverandSully: The Untold Story Behind the Miracle on the HudsonRating: 4 out of 5 stars4/5 (103)

- Brain Rules (Updated and Expanded): 12 Principles for Surviving and Thriving at Work, Home, and SchoolFrom EverandBrain Rules (Updated and Expanded): 12 Principles for Surviving and Thriving at Work, Home, and SchoolRating: 4 out of 5 stars4/5 (702)

- The Fabric of Civilization: How Textiles Made the WorldFrom EverandThe Fabric of Civilization: How Textiles Made the WorldRating: 4.5 out of 5 stars4.5/5 (57)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldFrom EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldRating: 4.5 out of 5 stars4.5/5 (18)

- Lessons for Survival: Mothering Against “the Apocalypse”From EverandLessons for Survival: Mothering Against “the Apocalypse”Rating: 5 out of 5 stars5/5 (2)

- Summary and Interpretation of Reality TransurfingFrom EverandSummary and Interpretation of Reality TransurfingRating: 5 out of 5 stars5/5 (5)

- Mother Earth Spirituality: Native American Paths to Healing OurselvesFrom EverandMother Earth Spirituality: Native American Paths to Healing OurselvesRating: 3.5 out of 5 stars3.5/5 (11)