Professional Documents

Culture Documents

Fire Pumps Sensing Lines

Uploaded by

Tanvir AhmedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fire Pumps Sensing Lines

Uploaded by

Tanvir AhmedCopyright:

Available Formats

QUICK

RESPONSE

Saving life and property through effective licensing, plan review,

and inspection of fire protection systems.

January 2009

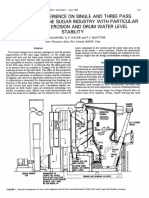

FIRE PUMPS ñ SENSING LINES

A

D

B

A = Fire Pump Sensing Line

To

B = Jockey Pump Sensing Line System

C = Fire Pump Controller

C

D = Jockey Pump Controller

From

Supply

E

F

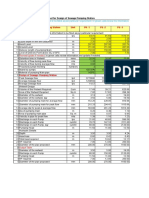

Most commonly the pump controller is connected to the fire protection system by means of piping

know as a sensing or pilot line. Each pump, including the jockey pump, shall have its own individual

controller and each controller shall have its own individual sensing line. The sensing line is

connected to the fire protection system between its respective pump discharge check valve and the

discharge control valve (E and F).

The size of the sensing lines shall be a minimum of Ω-inch and must be of non-corrosive metallic

pipe or tube (brass, copper, stainless steel). Galvanized pipe is not corrosion resistant enough to be

suitable for sensing line use. Plastic pipe is corrosion resistant, however, due to it being easily

damaged, it too is not suitable for sensing line use.

To absorb pressure surges and protect the controller pressure switch from damage, two check valves

shall be installed in each sensing line. These check valves shall be at least five feet apart. To aid in

dampening, a small 3/32î hole shall be drilled into the clapper of each check valve. Where the water

is clean, ground-face unions with noncorrosive diaphragms drilled with a nominal 3/32î orifice shall be

permitted in place of the check valves.

Lastly, control valves are not allowed to be installed in the sensing line.

Quick Response is presented monthly by the

Minnesota State Fire Marshal ñ Fire Protection Section

www.fire.state.mn.us

You might also like

- For 500 GPM CalDocument56 pagesFor 500 GPM CalNeal JohnsonNo ratings yet

- FHC - Sprinkler Hydraulic Calculation Software For The Fire Sprinkler IndustryDocument4 pagesFHC - Sprinkler Hydraulic Calculation Software For The Fire Sprinkler IndustryAisha Riaz100% (1)

- Pressure-Sensing Line Problems and SolutionsDocument10 pagesPressure-Sensing Line Problems and SolutionsAhmad Adel El TantawyNo ratings yet

- Part of Nfpa 20 Handbook 2016Document12 pagesPart of Nfpa 20 Handbook 2016احمد الجزار200750% (2)

- 6special Protection SystemDocument59 pages6special Protection SystemGurusumiNo ratings yet

- Guideline For TSP FM200 Systems Rev6 PDFDocument13 pagesGuideline For TSP FM200 Systems Rev6 PDFeng_alaa1977100% (1)

- Nfpa 45Document19 pagesNfpa 45moha19841100% (1)

- Fs2011 FullDocument242 pagesFs2011 FullryankckoNo ratings yet

- Foam Liquid Concentrates - Ul Product Iq SolbergDocument15 pagesFoam Liquid Concentrates - Ul Product Iq SolbergLuis Alberto Serrano MesaNo ratings yet

- Piping Sensing Line Layout of Fire Pump and Jockey PumpDocument1 pagePiping Sensing Line Layout of Fire Pump and Jockey Pumpاحمد الجزار200750% (2)

- Kidde AE Spec - ADS Using Novec 1230-01-2015Document6 pagesKidde AE Spec - ADS Using Novec 1230-01-2015kuraimundNo ratings yet

- Jockey PumpDocument5 pagesJockey PumpBrandon LeonardNo ratings yet

- Fire Fighting Presentation Ali Hassan-Compressed-Pages-71-140Document70 pagesFire Fighting Presentation Ali Hassan-Compressed-Pages-71-140Crypto India100% (1)

- Installation of stationary fire pumpsDocument3 pagesInstallation of stationary fire pumpsAbdülhamit KAYYALİ100% (1)

- Va CadDocument4 pagesVa Cadrov1976No ratings yet

- CyberCat 2015 FULL PrintoutDocument430 pagesCyberCat 2015 FULL PrintoutKrishna Kumar100% (1)

- Sprinkler Design ChecklistDocument3 pagesSprinkler Design ChecklistVigneshNo ratings yet

- NFPA 13 Sprinkler System Design Density Curves - Where Did They Come From - Sprinklers Content From Fire Protection Engineering PDFDocument7 pagesNFPA 13 Sprinkler System Design Density Curves - Where Did They Come From - Sprinklers Content From Fire Protection Engineering PDFBùi Trần Trung HậuNo ratings yet

- Water Mist Nozzle GW M5 PDFDocument6 pagesWater Mist Nozzle GW M5 PDFZulfi Andrie ZulkiarNo ratings yet

- 800024-004 Diom Manual, Ihp Co2Document47 pages800024-004 Diom Manual, Ihp Co2rulo zamora mendez100% (1)

- Approval Standard For Fire Alarm Signaling Systems: Class Number 3010Document34 pagesApproval Standard For Fire Alarm Signaling Systems: Class Number 3010Sayed HashemNo ratings yet

- Sapphire Manual PN570590Document101 pagesSapphire Manual PN570590FitflowPeruNo ratings yet

- Water Curtain Installation RequirementsDocument2 pagesWater Curtain Installation RequirementsKapal TerbangNo ratings yet

- Warehouse Regulatory RequirementsDocument15 pagesWarehouse Regulatory Requirementsliaw_zi_yang100% (2)

- Deluge Valve Technical DataDocument14 pagesDeluge Valve Technical DataKeshodbana KeshodNo ratings yet

- NTC Book FlyerDocument1 pageNTC Book FlyerRob JanousekNo ratings yet

- Design Installation Operation and MaintenanceDocument116 pagesDesign Installation Operation and Maintenancedaniel_afpNo ratings yet

- Egress-Nfpa 101 Life Safety CodeDocument2 pagesEgress-Nfpa 101 Life Safety Codecapitanhall0% (1)

- Hose Stream Demands - Part 1Document4 pagesHose Stream Demands - Part 1Sergio Garro100% (1)

- TFBP Deluge and Preaction Systems BrochureDocument6 pagesTFBP Deluge and Preaction Systems BrochureangeltandinganNo ratings yet

- Inergen Sizing CalculationDocument3 pagesInergen Sizing CalculationStephanie Webb0% (1)

- Fire Protection Hydraulic CalculationsDocument25 pagesFire Protection Hydraulic CalculationsSuryakant Solanki100% (1)

- What is the maximum spacing for sprinklerpiping hangers installed in concreteDocument188 pagesWhat is the maximum spacing for sprinklerpiping hangers installed in concreteMama CassNo ratings yet

- System Design: Total Flooding Extinguishing SystemDocument45 pagesSystem Design: Total Flooding Extinguishing SystemsureshkanuboyinaNo ratings yet

- Multiple Foam Deluge SystemDocument10 pagesMultiple Foam Deluge SystemTrần VânNo ratings yet

- Fire Damper 5Document44 pagesFire Damper 5Nedunuri.Madhav MurthyNo ratings yet

- Inergen SpecDocument19 pagesInergen SpecMargaret DaughertyNo ratings yet

- Helipad Foam Fire Protection ManualDocument12 pagesHelipad Foam Fire Protection ManualKhairil ShanklyNo ratings yet

- Globe Alarm Check Valve Installation and Maintenance GuideDocument36 pagesGlobe Alarm Check Valve Installation and Maintenance GuideAbdul Majeed KottaNo ratings yet

- System Design: Total Flooding Extinguishing SystemDocument45 pagesSystem Design: Total Flooding Extinguishing SystemJose Antonio LaraNo ratings yet

- Pressure Independent Control ValveDocument12 pagesPressure Independent Control Valvekya_leyNo ratings yet

- Viking EMEA Special Systems Workshop SFPE EngineersDocument92 pagesViking EMEA Special Systems Workshop SFPE EngineersjoseNo ratings yet

- Fixed Water Spray Demand Calculations For Fire Protection of TanksDocument2 pagesFixed Water Spray Demand Calculations For Fire Protection of TanksKyaw Kyaw AungNo ratings yet

- Guideline For TSP FM200 Systems Rev8Document12 pagesGuideline For TSP FM200 Systems Rev8binhhnNo ratings yet

- Technical Specification - Fire and JockeyDocument2 pagesTechnical Specification - Fire and JockeyKenneth CastroNo ratings yet

- IFPA SFPE NFPA 20 2016 and Beyond PDFDocument50 pagesIFPA SFPE NFPA 20 2016 and Beyond PDFzattie89No ratings yet

- Reliable Storage Sprinklers BrochureDocument26 pagesReliable Storage Sprinklers Brochureari78100% (1)

- Design Philosophy FPS-LPG Terminal Bhatinda PDFDocument6 pagesDesign Philosophy FPS-LPG Terminal Bhatinda PDFAlvin SmithNo ratings yet

- A Tutorial To Getting Started With FHC: Hydraulic Calculation Software For Water Based Fire Protection SystemsDocument7 pagesA Tutorial To Getting Started With FHC: Hydraulic Calculation Software For Water Based Fire Protection SystemsZaw Moe Khine100% (1)

- SKUM Over The Top Foam Generators OFG OFGR - FDS14334 0214 LRDocument4 pagesSKUM Over The Top Foam Generators OFG OFGR - FDS14334 0214 LRValentin A.No ratings yet

- Sprinkler Protection For High Bay and Automated Storage in Warehouse Type Storage FacilitiesDocument11 pagesSprinkler Protection For High Bay and Automated Storage in Warehouse Type Storage FacilitiesJose Gregorio Prada RodriguezNo ratings yet

- Fire Protection Engineering in Building DesignFrom EverandFire Protection Engineering in Building DesignRating: 4.5 out of 5 stars4.5/5 (5)

- Fire pump sensing lines: installation and requirementsDocument1 pageFire pump sensing lines: installation and requirementsStory LoveNo ratings yet

- Fire Pump Controllers Critical for Fire ProtectionDocument1 pageFire Pump Controllers Critical for Fire ProtectionLe DucNo ratings yet

- Fire Pump Jockey Pump ExplainedDocument1 pageFire Pump Jockey Pump ExplainedDylan RamasamyNo ratings yet

- Fire Pump Bypass System ExplainedDocument1 pageFire Pump Bypass System Explainedefac7No ratings yet

- ChecklistDocument10 pagesChecklistsa heNo ratings yet

- 2-Weekly Flaire Igination TestDocument1 page2-Weekly Flaire Igination Testahmaddsouki2005No ratings yet

- Asco firePumpSensingLine RGDocument1 pageAsco firePumpSensingLine RGΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- Ky©Dzjx M VM WWW÷ Wedkb KV Úvbx WJWG Uw: ( C U Vevsjvi Gkwu KV Úvbx) 137/G, WMWWG GWFWBD, Lvjkni, PæmövgDocument3 pagesKy©Dzjx M VM WWW÷ Wedkb KV Úvbx WJWG Uw: ( C U Vevsjvi Gkwu KV Úvbx) 137/G, WMWWG GWFWBD, Lvjkni, PæmövgTanvir AhmedNo ratings yet

- IELTS Practise Materials General TrainingTestDocument58 pagesIELTS Practise Materials General TrainingTestPaul Kabeya25% (4)

- Evsjv 'K M Ru: Iwr÷Vw© Bs WW G-1Document16 pagesEvsjv 'K M Ru: Iwr÷Vw© Bs WW G-1Tanvir AhmedNo ratings yet

- Labour Law, 2006 (Amended Upto 2013)Document129 pagesLabour Law, 2006 (Amended Upto 2013)F.A. AminNo ratings yet

- Manual MP280Document707 pagesManual MP280Alex Ionut TNo ratings yet

- P.1.19.01 135.190 Thermal DetectorsDocument2 pagesP.1.19.01 135.190 Thermal DetectorsTanvir AhmedNo ratings yet

- Padma LPG DealerDocument55 pagesPadma LPG DealerTanvir AhmedNo ratings yet

- H61 0Document13 pagesH61 0Neal JohnsonNo ratings yet

- A795Document6 pagesA795Ron HarmonNo ratings yet

- 6 KonuttipiDocument12 pages6 KonuttipiTanvir AhmedNo ratings yet

- EWC1Document2 pagesEWC1Tanvir AhmedNo ratings yet

- b9110 SHP ProDocument4 pagesb9110 SHP ProTanvir AhmedNo ratings yet

- Prevod 2 - SpinklersDocument16 pagesPrevod 2 - SpinklersAnonymous qc1LPxDcNo ratings yet

- Autodesk Building SystemsDocument52 pagesAutodesk Building SystemsTanvir AhmedNo ratings yet

- Pipe hanger spacing & weight chartDocument1 pagePipe hanger spacing & weight chartSandi ApriandiNo ratings yet

- Fire Fighting and Fire Prevention ManualDocument28 pagesFire Fighting and Fire Prevention ManualGodofredo PabloNo ratings yet

- As 12 New FeaturesDocument2 pagesAs 12 New FeaturesTanvir AhmedNo ratings yet

- Entry Level Firefighter Exam Study Guide: Austin Fire DepartmentDocument16 pagesEntry Level Firefighter Exam Study Guide: Austin Fire DepartmentTanvir AhmedNo ratings yet

- 2014 Cepapers W02Document31 pages2014 Cepapers W02Tanvir AhmedNo ratings yet

- Safer Boiler OperationDocument2 pagesSafer Boiler OperationUmangtarangNo ratings yet

- Fee, I: Efe F FDocument2 pagesFee, I: Efe F FTanvir AhmedNo ratings yet

- How PDF Works: Gary StaasDocument35 pagesHow PDF Works: Gary StaasTanvir AhmedNo ratings yet

- 2 Durood BenifitsDocument3 pages2 Durood BenifitsTanvir AhmedNo ratings yet

- 3 41 Special Benifits of DuroodDocument6 pages3 41 Special Benifits of DuroodTanvir AhmedNo ratings yet

- Bangladesh NFPA High Level ReportDocument34 pagesBangladesh NFPA High Level ReportTanvir AhmedNo ratings yet

- 4 Benifits of DuroodDocument5 pages4 Benifits of DuroodTanvir AhmedNo ratings yet

- SocialBehavior AdabulMuasharat MaulanaAshrafAliThavi PDFDocument55 pagesSocialBehavior AdabulMuasharat MaulanaAshrafAliThavi PDFTanvir AhmedNo ratings yet

- 5 Virtues of SurasDocument20 pages5 Virtues of SurasTanvir AhmedNo ratings yet

- 2D Box Falling into WaterDocument22 pages2D Box Falling into Waterclimax1364No ratings yet

- Hydrocarbon Crack SystemDocument2 pagesHydrocarbon Crack SystemLucian Si Silvia PoneaNo ratings yet

- 4th - Flow Across Banks of TubesDocument16 pages4th - Flow Across Banks of TubesPrakash AchyuthanNo ratings yet

- VCF LPG or Propane at Various DensitiesDocument4 pagesVCF LPG or Propane at Various DensitiesEdgar GuardiaNo ratings yet

- Tescom Technical Training - Pressure Regulators Explained - Ver1.1Document19 pagesTescom Technical Training - Pressure Regulators Explained - Ver1.1Amod DeshpandeNo ratings yet

- Troy2016 - Article - Life Cycle Assessment of Membrane-Based Carbon CaptureDocument14 pagesTroy2016 - Article - Life Cycle Assessment of Membrane-Based Carbon CaptureGhochapon MongkhonsiriNo ratings yet

- Turbo Tutorial API 619 5thDocument33 pagesTurbo Tutorial API 619 5thmishraengg100% (2)

- A New Calculation Approach To The Energy Balance of A Gas Turbine Including A Study of The Impact of The Uncertainty of Measured ParametersDocument8 pagesA New Calculation Approach To The Energy Balance of A Gas Turbine Including A Study of The Impact of The Uncertainty of Measured Parameters..........................No ratings yet

- Fuel Cell EnginesDocument19 pagesFuel Cell EnginesyocomonNo ratings yet

- R32 Floor Ceiling Type Inverter Air Conditioner SpecificationsDocument1 pageR32 Floor Ceiling Type Inverter Air Conditioner SpecificationsMichael MallariNo ratings yet

- Equation Chapter 1 Section 1379 - 14-04 - fluids at rest - solve problems 8-24Document6 pagesEquation Chapter 1 Section 1379 - 14-04 - fluids at rest - solve problems 8-24Bradley Nartowt, PhDNo ratings yet

- Pressure Relief Valve 3/4" - 1"Document5 pagesPressure Relief Valve 3/4" - 1"Gisella Mariel RubilarNo ratings yet

- R-513A Refrigerant Spec SheetDocument2 pagesR-513A Refrigerant Spec SheetMarc AnmellaNo ratings yet

- Pointers For Doing Nitrogen Calculations: Required Nitrogen Volume (Gal) NVF Volume + 10000 1. 1 93. 12Document15 pagesPointers For Doing Nitrogen Calculations: Required Nitrogen Volume (Gal) NVF Volume + 10000 1. 1 93. 12nauriNo ratings yet

- 6478 651939 1.+Fluid+MechanicsDocument29 pages6478 651939 1.+Fluid+MechanicsCharelle Hazel EzehNo ratings yet

- Section 12 - Compressed Air System - Group 12Document3 pagesSection 12 - Compressed Air System - Group 12Miodrag HuberNo ratings yet

- Annexure 32 - Tool For Design of Sewage Pumping StationDocument1 pageAnnexure 32 - Tool For Design of Sewage Pumping Stationkad-7No ratings yet

- CompreDocument3 pagesCompreJohn Dominic B. EugenioNo ratings yet

- Pumps & Piping Hydraulics Lecture-1 HydraulicsDocument25 pagesPumps & Piping Hydraulics Lecture-1 HydraulicsshazNo ratings yet

- Techno-economic analysis of coal-to-olefins process with CCSDocument10 pagesTechno-economic analysis of coal-to-olefins process with CCSAlbertus ArdikaNo ratings yet

- MCPlus - Turnover System Management Summary - ExcelDocument1,345 pagesMCPlus - Turnover System Management Summary - ExcelEugene DAn EMCONo ratings yet

- IPTC 10382 Experience With Simulation of Condensate Banking Effects in Various Gas/Condensate ReservoirsDocument10 pagesIPTC 10382 Experience With Simulation of Condensate Banking Effects in Various Gas/Condensate ReservoirsAdanenche Daniel EdohNo ratings yet

- SCBADocument4 pagesSCBAKirtishbose ChowdhuryNo ratings yet

- Kaplan Design Marko KogovsekDocument10 pagesKaplan Design Marko KogovsekIvan Batistic BeloNo ratings yet

- PSVDocument8 pagesPSVMohamed Sayed AbdoNo ratings yet

- Eaton: Parts InformationDocument8 pagesEaton: Parts InformationJose De Jesus Castillo GonzalezNo ratings yet

- Correcting vacuum column design flaws to maximize diesel recoveryDocument4 pagesCorrecting vacuum column design flaws to maximize diesel recoverys k kumarNo ratings yet

- Operating Experience On Single and Three Pass BoilersDocument7 pagesOperating Experience On Single and Three Pass Boilersbonginkosi mathunjwaNo ratings yet

- Turbomachinery Part4 Turbocompressors Axial v1Document15 pagesTurbomachinery Part4 Turbocompressors Axial v1Sami SaleemNo ratings yet

- Mechanical equipment components at TAHAS Oil & Gas AcademyDocument2 pagesMechanical equipment components at TAHAS Oil & Gas Academytotol90No ratings yet

- Liquade Brochure - English 1.1Document12 pagesLiquade Brochure - English 1.1Asima Jaya TamaNo ratings yet