Professional Documents

Culture Documents

Filler Metals For The Nuclear Industry (EN)

Uploaded by

Khaled FatnassiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Filler Metals For The Nuclear Industry (EN)

Uploaded by

Khaled FatnassiCopyright:

Available Formats

Filler Metals for the

Nuclear Industry

voestalpine Böhler Welding

www.voestalpine.com/welding

Joining 1/4

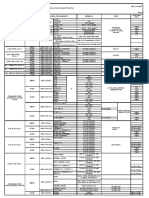

Alloy Group Welding Process Product Name Classification AWS/EN

C-Mn SMAW BÖHLER FOX EV 47 AWS A5.1-04 E7016-1H4R

EN ISO 2560-A E 38 4 B 42 H5

Phoenix 120 K AWS A5.1-04 E7018-1

Rm > 510 Mpa EN ISO 2560-A: E 42 5 B 32 H5

Rp0,2 > 420 Mpa RCC-M S2810

BÖHLER FOX EV 50 R AWS A5.1-04 E7018-1 H4R

EN ISO 2560-A E 42 5 B 42 H5

RCC-M: S2810

SAW Wire Union S 2 Si / BÖHLER EMS 2 AWS A5.17 EM12K

EN 756 S2Si

SAW Flux UV 418 TT / BÖHLER BB 24 -

EN ISO 14174 SA FB 1 55 AC H5

SAW Wire+Flux Union S 2 Si + UV 418 TT / AWS A5.17-SFA 5.17 F7A6-EM12K

Unalloyed Steels

BÖHLER EMS 2 + BÖHLER BB 24 RCC-M: S2860

SAW Wire Union S 3 Si AWS A5.17 EH12K

EN 756 S3Si

SAW Flux UV 418 TT -

EN ISO 14174 SA FB 1 55 AC H5

SAW Wire+Flux Union S 3 Si + UV 418 TT AWS A5.17-SFA 5.17 F7A8-EH12K

GTAW BÖHLER EMK 6 / Union I 52 AWS A5.18 ER70S-6

EN ISO 636-A W 42 5 W3Si1

RCC-M S 2840

BÖHLER EML 5 AWS A5.18 ER70S-3

EN ISO 636-A W 46 5 W2Si

RCC-M S2870

GMAW BÖHLER EMK 6 AWS A5.18 ER70S-6

EN ISO 14341-A G3Si1

RCC-M S 2840

FCAW BÖHLER Ti 52-FD AWS A5.20 E71T-1MJH8

EN ISO 17632-A T 46 4 P M 1 H10

C-1/4 Mo SMAW BÖHLER FOX EV 50 Mo R AWS A5.1-04 E7018-1

Rm > 560 Mpa EN ISO 2560-A:2010 E 42 5 B 42 H5

Rp0,2 > 480 MPa RCC-M S2810

Phoenix SH Schwarz 3 MK AWS A5.5-E 7018-G

EN ISO 2560-A: E 50 4 Mo B 42

C- 1/2 Mo SMAW BÖHLER FOX DMO Kb AWS A5.5 E7018-A1H4R

Rm > 550 Mpa EN ISO 2560-A E Mo B 42 H5

Rp0,2 > 470 Mpa SAW Wire Union S 2 Mo / BÖHLER EMS 2 Mo AWS A5.23: EA2

Low-alloyed Pressure Vessel Steels

EN 756: S2Mo

SAW Flux UV 420 TTR / BÖHLER BB 24 SC -

EN ISO 14174: SA FB 1 65 AC H5

SAW Wire+Flux Union S 2 Mo + UV 420 TTR AWS A5.17-SFA 5.17: F8A4-EA2-A2

BÖHLER EMS 2 Mo + BÖHLER BB

-

24 SC

GTAW Union I MoMn AWS A5.28: ER90S-D2

EN ISO 636-B: W 4 M31

BÖHLER DMO-IG AWS A5.28: ER70S-A1 (ER80S-G)

EN ISO 21952-A: W Mo Si

1 ¼ Cr ½ Mo SMAW Phoenix Chromo 1 / BÖHLER DCMS Kb AWS A5.5 E8018-B2

1 Cr ½ Mo EN ISO 3580-A ECrMo1 B 4 2 H5

GTAW Union ER 80S-B2 AWS A5.28 ER80S-B2

2 ¼ Cr 1 Mo SMAW Phoenix SH Chromo 2 KS AWS A5.5 E9015-B3

EN ISO 3580-A ECrMo2 B 4 2 H5 | EN ISO 3580-B

E 6215-2C1M

BÖHLER FOX CM 2 Kb AWS A 5.5 E9018-B3H4R

EN 1599 E CrMo2 B 4 2 H5

voestalpine Böhler Welding

01/2015

Joining 2/4

Alloy Group Welding Process Product Name Classification AWS/EN

GTAW BÖHLER CM 2-IG AWS A5.28 ER90S-G

EN ISO 21952-A W CrMo2Si | EN ISO 21952-B W

62 2C1M3

Union ER 90S-B3 AWS A5.28 ER90S-B3

0,8 Ni 1/2 Mo SMAW Phoenix SH Schwarz 3 K Ni 2 AWS A5.5: E9018-G

Rm > 550 Mpa EN ISO 2560-A - E 50 4 1NiMo B 42 H5

Rp0,2 > 345 Mpa BÖHLER FOX EV 65 R AWS A5.5 E8018-G

EN ISO 2560-A - E 55 6 1NiMo B 42 H5

RCC-M S2820B

SAW Wire Union S 3 Ni Mo 0,8 AWS A5.23 EG (EF2 Mod)

EN 756: S 50 4 FB S3Ni1Mo

SAW Flux UV 420 TTR -

EN ISO 14174 SA FB 1 65 DC

SAW Wire+Flux Union S 3 Ni Mo 0,8 + UV 420 TTR -

AWS A5.23 F9P4-EG-F2 N

GTAW Union I Ni Mo 0,8 AWS A 5.28 ER90S-G

EN 12534 W Z

Low-alloyed Pressure Vessel Steels

1 Ni 1/2 Mo SMAW Phoenix SH Schwarz 3 K Ni AWS A5.5: E9018-G

Rm > 620 Mpa EN ISO 2560-A E50 4 1 NiMo B 42 H5

Rp0,2 > 540 Mpa BÖHLER FOX EV 65 R+ AWS A5.5 E9018-G

EN 757 E 55 6 1 NiMo B 42 H5

RCC-M S 2820B

Comet J66 ELH Q5 AWS A5.5: E9018-G

EN 757:E 55 2Mn1 NiMo B 12 H5

Phoenix SH Schwarz 3 K Ni Mn AWS A5.5: E9018-G

SAW Wire Union S 3 NiMo 1 / BÖHLER S 3 NiMo AWS A5.23 EG (EF3 Mod.)

1-UP EN 756 S3Ni1Mo

SAW Flux UV 420 TTR / BÖHLER BB 24 SC -

EN ISO 14174 SA FB 1 65 DC

SAW Wire+Flux Union S 3 NiMo 1 + UV 420 TTR / AWS A5.23 F9P8-EG-F3 N

BÖHLER S 3 NiMo 1-UP + BÖHLER EN 756: S 50 4 FB S3Ni1Mo

BB 24 SC RCC-M S 2830A

GTAW Union I NiMo 1 AWS A5.28 ER90S-G

EN 12534: W Z

1½ Ni 0,5 Mo SMAW Phoenix SH Schwarz 3 K Ni M AWS A5.5: E9018-M

Rm > 620 Mpa EN ISO 2560-A E 50 4 1,5NiMo B 42 H5

Rp0,2 > 540 Mpa SAW Wire Union S 3 NiMoCr-M2 AWS A5.23 EM2

EN ISO 26304-A SZ 3Ni2,5CrMo

SAW Flux UV 418 TT-M2 -

EN ISO 14174 SA FB 1 65 AC H4

SAW Wire+Flux Union S 3 NiMoCr-M2 + UV 418 TT-M2 AWS: F9P4 EM2-M2

EN ISO 26304-A S 55 2 FB SZNi2,5CrMo

GTAW Union I NiMoCr-M2 AWS A 5.28 ER 100 S-1

2.5% Ni SMAW BÖHLER FOX 2.5 Ni AWS A5.5 E8018-C1H4R

Phoenix SH Ni 2 K 70 EN ISO 2560-A E 46 8 2Ni B 42 H5

SAW Wire Union S 2 Ni 2,5 AWS A5.23 ENi2

EN 756 S2Ni2

Low alloyed Ni Steel

SAW Flux UV 418 TT -

EN ISO 14174 SA FB 1 55 AC H5

SAW Wire+Flux Union S 2 Ni 2,5 + UV 418 TT AWS A5.17-SFA 5.17 F8A10-ENi2-Ni2

-

GTAW BÖHLER 2.5 Ni-IG AWS A5.28 ER80S-Ni2

EN ISO 636-A W2Ni2

GMAW BÖHLER 2.5 Ni-IG AWS A5.28 ER80S-Ni2

EN ISO 14341-A G2Ni2

voestalpine Böhler Welding

01/2015

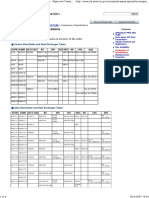

Joining 3/4

Alloy Group Welding Process Product Name Classification AWS/EN

3.5% Ni SMAW Phoenix SH Ni 2 K 80 AWS A5.5 E7018-C2L

EN ISO 2560-A E 46 8 2Ni B 42 H5

SAW Wire Union S 2 Ni 3,5 AWS A5.23 ENi3

Low alloyed Ni Steel

EN 756 S2Ni3

SAW Flux UV 418 TT -

EN ISO 14174 SA FB 1 55 AC H5

SAW Wire+Flux Union S 2 Ni 3,5 + UV 418 TT AWS A5.17-SFA 5.17 F8A15-ENi3-Ni3

-

GTAW Union I 3,5 Ni AWS A 5.28 ER80S-Ni 3

EN ISO 636-A W2Ni3

Austenitic SMAW BÖHLER FOX CN 24/13 R AWS A 5.4 E309L-15

S.S 309L EN 1600 E 23 12 B 2 2

Weld overlay BÖHLER FOX CN 24/13 AR AWS A 5.4 E309L-16

Buffer EN 1600 E 23 12 L R 3 2

Dissimilar Soudocrom L 309 L Q5 AWS A 5.4 E309L-16

EN 1600 E 23 12 L R 1 2

RCC-M S 2930

BÖHLER FOX CN 23/12 AR AWS A 5.4 E309L-17

EN 1600 E 23 12 L R 3 2

Thermanit 25/14 EW 309L-17 AWS A 5.4 E309L-17

EN 1600 E 23 12 L R 1 2

SAW Wire Thermanit 25/14 E309L / AWS A 5.9 ER309L

BÖHLER CN 23/12-UP EN 12072 S 23 12 L

SAW Flux Marathon 431 / EN 760 SA FB 2 DC

BÖHLER BB 202 -

SAW Wire+Flux Thermanit 25/14 E309L+ Marathon 431 RCC-M S 2950

BÖHLER CN 23/12-UP + BÖHLER -

GTAW BÖHLER CN 23/12-IG / AWS A 5.9 ER 309L

Thermanit 25/14 E 309L EN 12072 W 23.12 L

GMAW Thermanit 25/14 E309L Si AWS A 5.9 ER 309L Si

EN ISO 14343-A G 23 12 L Si

FCAW BÖHLER CN 23/12-FD AWS A 5.22: E309LT0-4

EN ISO 17633 A T 23 12 L R M (C) 3

Stainless Steel

S.S. 308 L SMAW BÖHLER FOX EAS 2 R / AWS A 5.4 E308L-15

Thermanit JE Spezial EN 1600 E 19 9 L B 2 2

BÖHLER FOX EAS 2-AR / AWS A 5.4 E308L-16

Thermanit JEW 308L-16 EN 1600 E 19 9L R 3 2

RCC-M S 2920

BÖHLER FOX EAS 2-A / AWS A 5.4 E308L-17

Thermanit JEW 308L-17 EN 1600 E 19 9 L R 3 2

SAW Wire Thermanit JE 308L / AWS A 5.9 ER308L

BÖHLER EAS 2-UP EN 12072 S 19 9 L

SAW Flux Marathon 431 / EN 760 SA FB 2 DC

BÖHLER BB 202 / -

BÖHLER BB 203 / -

RECORD IND 24 -

RECORD IND 27 EN 760 SA FB 2 Cr DC

SAW Wire+Flux Thermanit JE 308L + Marathon 431 / RCC-M S2940

BÖHLER EAS 2 -UP + BÖHLER -

GTAW BÖHLER EAS 2-IG / AWS A 5.9 ER308L

Thermanit JE 308L EN 12072 W 19 9 L

RCC-M S2910

FCAW BÖHLER EAS 2-FD AWS A 5.22: E308LT0-4

EN ISO 17633 A T 19 9 L R M (C) 3

S.S. 316 L SMAW BÖHLER FOX EAS 4 M R / AWS A 5.4 E316L-15

Thermanit GE Spezial EN 1600 E 19 12 3 L B 2 2

BÖHLER FOX EAS 4 M-AR / AWS A 5.4 E316L-16

Thermanit GEW 316L-16 EN 1600 E 19 12 3L R 3 2

RCC-M S 2925

voestalpine Böhler Welding

01/2015

Joining 4/4

Alloy Group Welding Process Product Name Classification AWS/EN

BÖHLER FOX EAS 4 M-A / AWS A 5.4 E316L-17

Thermanit GEW 316L-17 EN 1600 E 19 12 3 L R 3 2

SAW Wire Thermanit GE 316L / AWS A 5.9 ER316L

BÖHLER EAS 4 M-UP EN 12072 S 19 12 3 L

SAW Flux Marathon 431 / EN 760 SA FB 2 DC

BÖHLER BB 202 / -

BÖHLER BB 203 / -

RECORD IND 24 -

SAW Wire+Flux Thermanit GE 316L + Marathon 431 / RCC-M S 2945

BÖHLER EAS 4 M-UP + BÖHLER -

GTAW BÖHLER EAS 4 M-IG / AWS A 5.9 ER316L

Stainless Steel

Thermanit GE 316L EN 12072 W 19 12 3 L

RCC-M S 2915

FCAW BÖHLER EAS 4 M-FD AWS A 5.22: E316LT0-4

EN ISO 17633 A T 19 12 3 L R M (C) 3

Austenitic SMAW BÖHLER FOX SAS 2 R AWS A 5.4 E347-15

Nb Stabilized EN 1600 E19 9 Nb B 2 2

S.S 321/347 BÖHLER FOX SAS 2-A R AWS A5.4 E347-16

EN 1600 E 19 9 Nb R 3 2

SAW Wire Thermanit H-347 / AWS A 5.9 ER347

BÖHLER SAS 2-UP R EN 12072 S 19 9 Nb

SAW Flux Marathon 431 / EN 760 SA FB 2 DC

BÖHLER BB 202 / -

BÖHLER BB 203 / -

GTAW BÖHLER SAS 2-IG R / AWS A 5.9 ER347

Thermanit H-347 EN 12072 W 19 9 Nb

Alloy 600 SMAW UTP 068 HH / AWS 5.11 ENiCrFe-3 (mod.)

UNSN06600 BÖHLER FOX NIBAS 70/20 / EN ISO 14172 ENi6082

Thermanit Nicro 82 -

UTP 7015 / AWS 5.11 ENiCrFe-3

BÖHLER FOX NIBAS 70/15 / EN ISO 14173 ENi6182

Thermanit Nicro 182 -

GTAW UTP A 068 HH / AWS A 5.14 ERNiCr-3

BÖHLER NIBAS 70/20-IG / EN ISO 148274 S Ni 6082

Thermanit Nicro 82 RCC-M S 2985

GMAW UTP A 068 HH / AWS A 5.14 ERNiCr-3

BÖHLER NIBAS 70/20-IG / EN ISO 148274 S Ni 6082

Thermanit Nicro 82 -

Nickel-Base

Alloy 625 SMAW UTP 6222Mo / AWS A5.11 ENiCrMo-3

UNS06625 Thermanit 625 EN ISO 14172 ENi6625

GTAW UTP A 6222 Mo / AWS A5.14 ERNiCrMo-3

Thermanit 625 EN ISO 18274 S NI 6625

GMAW UTP A 6222 Mo / AWS A5.14 ERNiCrMo-3

Thermanit 625 EN ISO 18274 S NI 6625

Alloy 690 SMAW UTP 6229Mn / AWS A5.11 ENiCRFe-7

UNS06690 Thermanit 690 EN ISO 14172 ENi6152

RCC-M S 2986

GTAW Thermanit 690 AWS A5,14 ERNiCrFe-7

EN ISO 18274 S Ni 6052

RCC-M S 2981

GMAW Thermanit 690 AWS A5,14 ERNiCrFe-7

EN ISO 18274 S Ni6052

voestalpine Böhler Welding

01/2015

Strip Cladding

Deposited Alloy Welding Process Layer Strip Flux

S.S 308L SAW 1st Layer SOUDOTAPE 309 L Q5 RECORD INT 101 Q5

2nd Layer SOUDOTAPE 308 L Q5 RECORD INT 101 Q5

3rd Layer SOUDOTAPE 308 L Q5 RECORD INT 101 Q5

SAW 1st Layer SOUDOTAPE 309 L Q5 RECORD 9V308T1 Q5

2nd Layer SOUDOTAPE 308 L Q5 RECORD 8B308T2 Q5

3rd Layer SOUDOTAPE 308 L Q5 RECORD 8B308T2 Q5

Stainless Steel

SAW 1st Layer SOUDOTAPE 309 L Q5 RECORD INT 101 Q5

tensile strength >520 Mpa 2nd Layer SOUDOTAPE 308 L Q5 RECORD INT 120 Q5

3rd Layer SOUDOTAPE 308 L Q5 RECORD INT 120 Q5

ESW 1st Layer SOUDOTAPE 309 L Q5 RECORD EST 122 Q5

2nd Layer SOUDOTAPE 308 L Q5 RECORD EST 122 Q5

ESW High Speed 1st Layer SOUDOTAPE 309 L Q5 RECORD EST 136 Q5

2nd Layer SOUDOTAPE 308 L Q5 RECORD EST 136 CR Q5

S.S 347 SAW 1st Layer SOUDOTAPE 309 L Q5 RECORD INT 109 Q5

2nd Layer SOUDOTAPE 347 Q5 RECORD INT 109 Q5

Alloy 600 SAW 1st Layer SOUDOTAPE NiCr3 Q5 RECORD NiCr 3T Q5

2nd Layer SOUDOTAPE NiCr3 Q5 RECORD NiCr 3T Q5

3nd Layer SOUDOTAPE NiCr3 Q5 RECORD NiCr 3T Q5

ESW 1st Layer SOUDOTAPE NiCr3 Q5 RECORD EST 201 Q5

2nd Layer SOUDOTAPE NiCr3 Q5 RECORD EST 201 Q5

3rd Layer SOUDOTAPE NiCr3 Q5 RECORD EST 201 Q5

SAW 1st Layer SOUDOTAPE 690 Q5 RECORD NFT 690 Q5

Nickel-Base

Alloy 690 with strip

EQNiCrFe-14 2nd Layer SOUDOTAPE 690 Q5 RECORD NFT 690 Q5

3rd Layer SOUDOTAPE 690 Q5 RECORD NFT 690 Q5

ESW 1st Layer SOUDOTAPE 690 Q5 RECORD EST 690 Q5

2nd Layer SOUDOTAPE 690 Q5 RECORD EST 690 Q5

Alloy 690 with strip SAW 1st Layer SOUDOTAPE NiCrFe-7 Q5 RECORD NFT NiCrFe-7 Q5

EQNiCrFe-7 2nd Layer SOUDOTAPE NiCrFe-7 Q5 RECORD NFT NiCrFe-7 Q5

3rd Layer SOUDOTAPE NiCrFe-7 Q5 RECORD NFT NiCrFe-7 Q5

ESW 1st Layer SOUDOTAPE NiCrFe-7 Q5 RECORD EST NiCrFe-7 Q5

2nd Layer SOUDOTAPE NiCrFe-7 Q5 RECORD EST NiCrFe-7 Q5

voestalpine Böhler Welding

01/2015

Productfolder-056/2015/EN/GL

voestalpine Böhler Welding

Welding know-how joins steel

Customers in over 120 countries join the expertise of voestalpine Böhler Welding. Focused on filler metals,

voestalpine Böhler Welding offers extensive technical consultation and individual solutions for industrial welding

and soldering applications. Customer proximity is guaranteed by 40 subsidiaries in 28 countries, with the support

of 2,200 employees, and through more than 1,000 distribution partners worldwide. voestalpine Böhler Welding

offers three specialized and dedicated brands to cater our customers’ and partners’ requirements.

Böhler Welding – More than 2,000 products for joint welding in all conventional

arc welding processes are united in a product portfolio that is unique throughout the world.

Creating lasting connections is the brand‘s philosophy in welding and between people.

UTP Maintenance – Decades of industry experience and application know-how in the

areas of repair as well as wear and surface protection, combined with innovative and

custom-tailored products, guarantee customers an increase in the productivity and

protection of their components.

Fontargen Brazing – Through deep insight into processing methods and ways of application,

Fontargen Brazing provides the best brazing and soldering solutions based on proven

products with German technology. The expertise of this brand’s application engineers has

been formulated over many years of experience from countless application cases.

forwarded by:

Global Industry Segment Management

Nuclear Industry

T. +33 608607555

welding.nuclear@voestalpine.com

voestalpine Böhler Welding

01/2015

You might also like

- Wide-Lite Spectra Ten Series Brochure 1992Document6 pagesWide-Lite Spectra Ten Series Brochure 1992Alan MastersNo ratings yet

- Productlist ThermalPower enDocument6 pagesProductlist ThermalPower enprabhakar_metNo ratings yet

- Filler Metals Chemical Industry enDocument16 pagesFiller Metals Chemical Industry enslxantoNo ratings yet

- BW Bestseller Poster A3 2020 PreviewDocument8 pagesBW Bestseller Poster A3 2020 PreviewUtw InspeçõesNo ratings yet

- Electrodes SelectarcDocument138 pagesElectrodes Selectarcfediss2014100% (2)

- Filler Metals Chemical Industry enDocument16 pagesFiller Metals Chemical Industry enrakeshbablooNo ratings yet

- Hobart Hachene-590Document1 pageHobart Hachene-590Felipe montanaNo ratings yet

- Bavaria Flux BF 5.1Document3 pagesBavaria Flux BF 5.1Filipe CordeiroNo ratings yet

- Uv 419 TT-W: Classifi CationsDocument1 pageUv 419 TT-W: Classifi CationsBranko FerenčakNo ratings yet

- SWX - 110 Iso 14174Document4 pagesSWX - 110 Iso 14174wiNo ratings yet

- UTP For OffshoreDocument16 pagesUTP For Offshorekamals55No ratings yet

- Basic part numbers and codesDocument37 pagesBasic part numbers and codesMani Rathinam RajamaniNo ratings yet

- TS 16448 - Structural Field Welding_201407071322217372Document19 pagesTS 16448 - Structural Field Welding_201407071322217372mayNo ratings yet

- Pressure Vessel ITP Rev 0Document3 pagesPressure Vessel ITP Rev 0Enaam AtaallahNo ratings yet

- Manual Bohler 2021 12753672 - 1 PDFDocument516 pagesManual Bohler 2021 12753672 - 1 PDFOscar SermeñoNo ratings yet

- Select Arc Catalogue Part 1Document10 pagesSelect Arc Catalogue Part 1lionheartedNo ratings yet

- en - WW FactSheet - Main 01Document1 pageen - WW FactSheet - Main 01Mario FuentesklrlyNo ratings yet

- 40 32UNJF 3B: 18O1 Dimensions Are in Inches. Toleranc AnglesDocument1 page40 32UNJF 3B: 18O1 Dimensions Are in Inches. Toleranc AnglesRenato WatanabeNo ratings yet

- Böhler Fox EV 65 electrode for high-strength steelsDocument1 pageBöhler Fox EV 65 electrode for high-strength steelsMohamed AdelNo ratings yet

- Specification SummaryDocument25 pagesSpecification SummaryDeepak KumarNo ratings yet

- AA4Document19 pagesAA4Karthik P MuraliNo ratings yet

- Fox CN 23-12-ADocument1 pageFox CN 23-12-AVIRPOPNo ratings yet

- en WW FactSheet Main 01Document1 pageen WW FactSheet Main 01Samuel TanNo ratings yet

- SAW Content OnlyDocument19 pagesSAW Content OnlyIslam SahafayatNo ratings yet

- Industrial Batteries - Network Power Sonnenschein A600 Premium Quality For Uninterrupted CommunicationDocument16 pagesIndustrial Batteries - Network Power Sonnenschein A600 Premium Quality For Uninterrupted CommunicationglukkerNo ratings yet

- MS13Document5 pagesMS13Tommy ArjanggiNo ratings yet

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Document3 pagesProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'bagusrindi2801No ratings yet

- P0936-W19-FAN-GARAH-1 - Comfort Inn Olya RiyadhDocument30 pagesP0936-W19-FAN-GARAH-1 - Comfort Inn Olya Riyadhahmed ragabNo ratings yet

- BS88 LV Fuse Links & Fuse Holders: TTM - 50-040-01 TIA - 50-001-01Document4 pagesBS88 LV Fuse Links & Fuse Holders: TTM - 50-040-01 TIA - 50-001-01skodgeNo ratings yet

- Bohler Welding 1%nickel - CatalogueDocument8 pagesBohler Welding 1%nickel - CatalogueTasmanijskaNemaNo ratings yet

- Electrodes Consumables PDFDocument2 pagesElectrodes Consumables PDFravi00098No ratings yet

- E 7016 Product-SheetDocument1 pageE 7016 Product-SheetAlireza TakrimiNo ratings yet

- ALuminium ExtrusionDocument14 pagesALuminium ExtrusionJoanna BaileyNo ratings yet

- Ifs 2002PVDocument3 pagesIfs 2002PVdowNo ratings yet

- Main PCB and Display Module Diagrams and Part ListsDocument3 pagesMain PCB and Display Module Diagrams and Part ListsJosé MacedoNo ratings yet

- Classification: A A A A A ADocument2 pagesClassification: A A A A A ANaza GavaputriNo ratings yet

- Groupe Automobile Jeandot - Wrangler-448Document1 pageGroupe Automobile Jeandot - Wrangler-448DarkedgeNo ratings yet

- Solar Panel Motor Driver - BOMDocument1 pageSolar Panel Motor Driver - BOMmuhcemerNo ratings yet

- RaajRatna Electrodes Welding Flux AWS - A 5.17 F7A2-EM12KDocument2 pagesRaajRatna Electrodes Welding Flux AWS - A 5.17 F7A2-EM12KIslam SahafayatNo ratings yet

- 02112015000000B - Boehler FOX DCMS Ti - CeDocument1 page02112015000000B - Boehler FOX DCMS Ti - CeparbinaNo ratings yet

- 31163-NB66 BrevikSpare Parts R01Document1 page31163-NB66 BrevikSpare Parts R01Sergei KurpishNo ratings yet

- Welding ProcessesDocument28 pagesWelding ProcessesAnaswarpsNo ratings yet

- FOX CN 23-12 Mo-ADocument1 pageFOX CN 23-12 Mo-AVIRPOPNo ratings yet

- Electrodes EnglishDocument139 pagesElectrodes Englishcostelino72No ratings yet

- Cooper Bussmann SS 5F 1A BK DatasheetDocument5 pagesCooper Bussmann SS 5F 1A BK DatasheetKhaled BellegdyNo ratings yet

- PIPE AND TUBE - Comparison of SpecificationsDocument4 pagesPIPE AND TUBE - Comparison of Specificationsnate anantathatNo ratings yet

- Technical Manual: VanessaDocument7 pagesTechnical Manual: VanessaAnonymous LLLK3pqNo ratings yet

- Mild Steel Electrodes: Brand Aws A/Sfa 5.1 IS 814 DIN 1913 BS 639 EN 499Document5 pagesMild Steel Electrodes: Brand Aws A/Sfa 5.1 IS 814 DIN 1913 BS 639 EN 499mahendraNo ratings yet

- EFI ResistanceDocument3 pagesEFI ResistanceMuni Muniyappan33% (3)

- Cellulosic Electrodes: Brand AWS A/SFA 5.1/5.5 EN 499Document4 pagesCellulosic Electrodes: Brand AWS A/SFA 5.1/5.5 EN 499ashwini shuklaNo ratings yet

- Filler Metals: High Purity Solutions For Creep Resistant Steels - B2 SC and B3 SC AlloysDocument8 pagesFiller Metals: High Purity Solutions For Creep Resistant Steels - B2 SC and B3 SC AlloysimreNo ratings yet

- FPO22001 ASME Filer Metal Data SheetDocument5 pagesFPO22001 ASME Filer Metal Data Sheetyousab creator2No ratings yet

- Ref. No. 432982 - Cat. No. FEN36TD250KF: Representative ImageDocument3 pagesRef. No. 432982 - Cat. No. FEN36TD250KF: Representative ImageFelipe HerosNo ratings yet

- NSWE Company ProfileDocument9 pagesNSWE Company ProfileJuan RodriguezNo ratings yet

- Cap 11 PDFDocument41 pagesCap 11 PDFEnder AraujoNo ratings yet

- 406050110597eDocument4 pages406050110597emahdi aghamohamadiNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- Peugeot 206Document19 pagesPeugeot 206Khaled FatnassiNo ratings yet

- 0485 B1ha#m103 2 001Document1 page0485 B1ha#m103 2 001Khaled FatnassiNo ratings yet

- Data Sheet: Elcometer 236 DC Holiday DetectorDocument5 pagesData Sheet: Elcometer 236 DC Holiday DetectorKhaled FatnassiNo ratings yet

- Volkswagen Golf: Jump To Navigation Jump To SearchDocument23 pagesVolkswagen Golf: Jump To Navigation Jump To SearchKhaled FatnassiNo ratings yet

- Volkswagen Commercial VehiclesDocument14 pagesVolkswagen Commercial VehiclesKhaled FatnassiNo ratings yet

- Peugeot 407: Jump To Navigation Jump To SearchDocument12 pagesPeugeot 407: Jump To Navigation Jump To SearchKhaled FatnassiNo ratings yet

- Peugeot 406: Jump To Navigation Jump To SearchDocument11 pagesPeugeot 406: Jump To Navigation Jump To SearchKhaled FatnassiNo ratings yet

- Volkswagen Type 2Document25 pagesVolkswagen Type 2Khaled Fatnassi0% (1)

- Pipe-System PVC Thinwall SHC-30 CharlotteDocument1 pagePipe-System PVC Thinwall SHC-30 CharlotteKhaled FatnassiNo ratings yet

- Volkswagen Amarok: Jump To Navigation Jump To SearchDocument15 pagesVolkswagen Amarok: Jump To Navigation Jump To SearchKhaled FatnassiNo ratings yet

- Volkswagen PoloDocument33 pagesVolkswagen PoloKhaled FatnassiNo ratings yet

- Volkswagen Golf: Jump To Navigation Jump To SearchDocument23 pagesVolkswagen Golf: Jump To Navigation Jump To SearchKhaled FatnassiNo ratings yet

- Pickup TruckDocument9 pagesPickup TruckKhaled FatnassiNo ratings yet

- Volkswagen TransporterDocument11 pagesVolkswagen TransporterKhaled FatnassiNo ratings yet

- Mazda: Jump To Navigation Jump To SearchDocument20 pagesMazda: Jump To Navigation Jump To SearchKhaled Fatnassi0% (1)

- Fiat Automobiles S.p.A.: Jump To Navigation Jump To SearchDocument21 pagesFiat Automobiles S.p.A.: Jump To Navigation Jump To SearchKhaled FatnassiNo ratings yet

- Arc WeldingDocument11 pagesArc WeldingKhaled FatnassiNo ratings yet

- Heat FusionDocument4 pagesHeat FusionKhaled FatnassiNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Quality AssuranceDocument9 pagesQuality AssuranceKhaled FatnassiNo ratings yet

- Gas Tungsten Arc WeldingDocument14 pagesGas Tungsten Arc WeldingKhaled FatnassiNo ratings yet

- Quality ManagementDocument14 pagesQuality ManagementKhaled FatnassiNo ratings yet

- Quality InvestingDocument4 pagesQuality InvestingKhaled FatnassiNo ratings yet

- Manomètre MEI 0-40 Bars - VerticalDocument1 pageManomètre MEI 0-40 Bars - VerticalKhaled FatnassiNo ratings yet

- Quality ControlDocument8 pagesQuality ControlKhaled FatnassiNo ratings yet

- PipingDocument6 pagesPipingQasim aliNo ratings yet

- FCAWDocument5 pagesFCAWKhaled FatnassiNo ratings yet

- Submerged Arc WeldingDocument7 pagesSubmerged Arc WeldingKhaled FatnassiNo ratings yet

- InspectionDocument7 pagesInspectionKhaled FatnassiNo ratings yet

- Weld FamilyDocument10 pagesWeld FamilyKhaled FatnassiNo ratings yet

- Welding Map Chart NormDocument1 pageWelding Map Chart NormLorenzoNo ratings yet

- Copper and Copper AlloysDocument3 pagesCopper and Copper Alloyskevin herryNo ratings yet

- CSWIP 3.1 Welding Inspection Day 2 Questions and AnswersDocument62 pagesCSWIP 3.1 Welding Inspection Day 2 Questions and Answershaoues23No ratings yet

- Champ T400: The World Class Inverter Based DC WelderDocument2 pagesChamp T400: The World Class Inverter Based DC WelderWickyNo ratings yet

- Cast Iron Welding AlloysDocument4 pagesCast Iron Welding AlloysKhin Aung ShweNo ratings yet

- SS Piping Method StatementDocument11 pagesSS Piping Method Statementbrijesh shah50% (2)

- Kemppi Mastertig Mls Acdc PDFDocument3 pagesKemppi Mastertig Mls Acdc PDFikhyaul ibadNo ratings yet

- Types of Arc WeldingDocument20 pagesTypes of Arc WeldingEhigiator JosephNo ratings yet

- CES Business PresentationDocument50 pagesCES Business PresentationGary David CrowhurstNo ratings yet

- Promanu II WeldingDocument68 pagesPromanu II WeldingRyan FilbertNo ratings yet

- TIG Welding TutorialDocument7 pagesTIG Welding TutorialBasavaraj KaraningNo ratings yet

- ProductCatalogue 3rd Edition ESABDocument105 pagesProductCatalogue 3rd Edition ESABfjsfortaneNo ratings yet

- 15156-2-2003 (BS en Iso)Document50 pages15156-2-2003 (BS en Iso)mayav1No ratings yet

- Power Source Manual ENGDocument94 pagesPower Source Manual ENGzmatij240% (1)

- CSWIP NotesDocument32 pagesCSWIP NotesKhaled FatnassiNo ratings yet

- QW484BDocument1 pageQW484BMohamed Ahmed MaherNo ratings yet

- Welding Products (Pg164-180)Document17 pagesWelding Products (Pg164-180)EswaranNo ratings yet

- Railways Industry: To Increase Your Productivity, Optimize Maintenance and Repair With Long-Life Filler MetalsDocument2 pagesRailways Industry: To Increase Your Productivity, Optimize Maintenance and Repair With Long-Life Filler Metalskamals55No ratings yet

- Effect of Heat Input On Microstructure of Weld by Using 308L As Filler Metal and 304L As Base MetalDocument8 pagesEffect of Heat Input On Microstructure of Weld by Using 308L As Filler Metal and 304L As Base Metalshrikant tambeNo ratings yet

- Inconel 625 - Stick (SMAW) and TIG - MIG Welding ProcedureDocument6 pagesInconel 625 - Stick (SMAW) and TIG - MIG Welding ProcedureAngga ErlanggaNo ratings yet

- Excel - CCC - Soft Weld Metal - Gas ConsumptionDocument6 pagesExcel - CCC - Soft Weld Metal - Gas ConsumptionOctavian PanteaNo ratings yet

- Aws D10.12-00Document45 pagesAws D10.12-00Erick GoyesNo ratings yet

- Arc Welding Machine DesignDocument45 pagesArc Welding Machine DesignUbiracy ZanetiNo ratings yet

- WPS 02 PDFDocument2 pagesWPS 02 PDFZaidi100% (1)

- EML 2322L - Welding - MAE Design and Manufacturing LabDocument21 pagesEML 2322L - Welding - MAE Design and Manufacturing LabBhaiJan59No ratings yet

- Armstrong Svoemmervandudladere Katalog PDFDocument22 pagesArmstrong Svoemmervandudladere Katalog PDFShaheryar Akram Kang100% (1)

- 10.1515 - htmp-2013-0041 Performance and Life Assessment of Reformer TubesDocument14 pages10.1515 - htmp-2013-0041 Performance and Life Assessment of Reformer TubesFrancisco GonzalezNo ratings yet

- Tos and QuestionnaireDocument5 pagesTos and QuestionnaireIGNACIO, KYLA MAE, NATALIONo ratings yet

- Gas comparison chart for welding processesDocument1 pageGas comparison chart for welding processesAllen RosonNo ratings yet

- Fatigue Repair Database Steel Bridges Welds Defects DetailsDocument22 pagesFatigue Repair Database Steel Bridges Welds Defects DetailsKatyogleNo ratings yet