Professional Documents

Culture Documents

BASE PLATE DESIGN

Uploaded by

vinujohnpanickerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BASE PLATE DESIGN

Uploaded by

vinujohnpanickerCopyright:

Available Formats

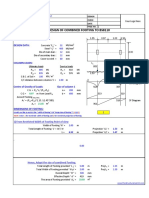

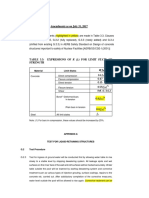

BASE PLATE DESIGN (BS CODE)

Design for Axial, Shear Load and Moments.

Column Section 305x305x118

dc bf

Column Data 305x305x118 314.50 307.40

Tw Tf

12.00 18.70

5748.38

Base Plate Size

Length lp /(hp) 600 mm

Width bp 600 mm

Concrete Pedestal Data

Length L' 2000 mm

Width W' 2000 mm

Area of Steel in tension zone As 1500 mm2

Anchor Bolt Data

Dia of Bolt d 24 mm

Anchor Bolt Grade 8.8

Number of Bolts n 8 nos

Anchor Bolt Embedded Length without Cover Le 400 mm

Edge Distance k 75 mm

Edge Distance h 525 mm

Center to Center distance l1 75 mm

l2 150 mm

l3 150 mm

l4 150 mm

l5 75 mm

Dist from flange to egde of plate L1 142.75 mm

Weld Data

Weld Size Sw 10

Material Stress

Yield Stress of Plate Pyp 275 N/mm2

Bearing strength of Plate Pbp 460 N/mm2

Bearing Stress of Anchor Bolt Pbb 1000 N/mm2

Tensile strength of Anchor bolt Pt 560 N/mm2

Shear Stress of anchor bolt Ps 375 N/mm2

Concrete cube strength fcu 40 N/mm2

Yield stress of column Py 275 N/mm2

Weld Strength Pyw 215 N/mm2

Load Data

Axial Force Fy (N) 300 KN

Moment about - X Mx 400 KN-M

Moment about - Z Mz KN-M

Shear along - X Fx 75 KN

Shear along - Z Fz KN

Resultant Shear Fs 75 KN

Step - 1

Check for Tension in Bolts

b = M/N 1333.33 mm

Distance to the edge of compressive block

X/2 = L/2 - b -1033.33 mm

Compression C = 0.6 fcu bp X -29760

C<N

Tension in Anchor Bolts, Ignore Step-1 goto Step -2

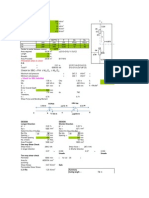

Step-2

C = 0.6 fcu bp X Eq-1

T=C-N Eq-2

M = T (h-hp/2) + C (hp-X/2) Eq-3

M = 0.6fcu bp X (h - X/2) - N(h-hp/2) From Eq-1 & 2 into 3

7200 h(sq) - 7560000 h + 467500000 =0

1 h(sq) - 1050 h 64930.56 =0

X= 984.01

65.99

X= 65.99 mm

Substituting the Value in Eq-1 and Eq-2

C 950.19 KN

T 650.19 KN

Step - 3

(a) Compression Side Bending

e = L1 - 0.8sw 134.75

mc = 0.6fcuX (e-X/2) 161147.83

mc = 0.6fcu e2/2 217890.75

mc = 217890.75 Nmm Per mm width

tp = required base plate thickness = (4mc /Pyp)0.5 56.30 mm

Step -4

Tension Side Bending

m = L1 -k - 0.8sw 59.75 mm

mt =T x m 38848799.33 Nmm

tp = required base plate thickness tp = (4mt/Pypbp)0.5 30.69 mm

Adopted Thickness of Plate = 56.30 mm

Step - 5

Anchorage

Number of Bolts in Tension nt = n/2 4.00 Nos

Tension force per bolt T/nt 162.55 KN

Anchor plate Lap 1380.00 mm

Check for free edges Req (1.5 Le ) 600.00 mm

Available 700.00 mm

Edgedistancesatified

P 6180.00 mm

fv = average shear stress over effective depth = T/(P x Le) 0.26 N/mm2

Vc = design concrete shear stress

Vc = 0.79/1.25 x [100As/P Le]1/3 x [400/Le]1/4 x [fcu/25]1/3 0.29 N/mm2

If [100As/P Le]1/3 is < 0.15, use 0.15 0.39 use 0.39

If [400/Le]1/4 is < 1, use 1. 1.00 use 1.00

fv < Vc, OK

Anchor Bolt bond along the embedded length

From BS 8110 cl. 3.12.8.3 & 3.12.8.4 the basic requirement is

fb = anchorage bond stress = T / (n p d L) 5.39

fbu = design ultimate anchorage bond stress = 0.28fcu0.5 5.60

fb < fbu, OK

Step - 6

Tension in Bolts

Allowable Tension per Bolt Ftall = Pt*d2*3.14/4 253.21 KN

Actual Tension per Bolt Ftacc =T/nt 162.55 KN

Ok

Step - 7

Shear

Check if Shear is transferred through friction 0.3 N 90.00 OK

Design horizontal shear force H = ns pss + nt pts

psAs for bolt shear or 169.56 KN

dtp Pb for bolt bearing on base plate or 621.52 KN

6d2fcu for bolt bearing on concrete 138.24 KN

Pss 138.24 KN

0.4 ps As for bolt shear or 150.00 KN

dtpPb for bolt bearing on base plate 621.52 KN

6d2fcu for bolt bearing on concrete 138.24 KN

Pts 138.24 KN

H = ns pss + nt pts 1105.92 KN

OK

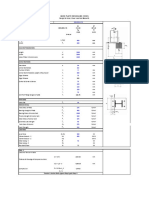

Step - 8

Shear Lugs (AISC Approach)

Cylinderical Strength of Concrete fc' 32.00 N/mm2

Shear lug area required Al =Fs/(0.8fc') 2930.60 mm2

Assume Width of Shear lug < Base plate width blug 300.00 mm

Embeddment Depth dlug 9.77 mm

Using Cantilever model of lug thickness Ml = V (G + dlug/2)

Thickness of Grout G 25.00

Ml 88.24 KN-mm

Ml= f Pyp Z

Section Modulus Z = blugtlug2/4

Thickness of Shear Lug required tlug 10.99 mm

Concrete failure width a 2000.00 mm

Edge distance of shear lug elug 500.00 mm

b 509.77 mm

Projected area of failure Av 1016606.71 mm2

Shear Capacity of Concrete in front of lug Vu = 4 ffc0.5 Av 1432.29 KN

Ok

Step - 9

Tension Weld Design

Tension Capacity of Flange bf Tf Py 1580.80 KN

Forces in tension flange Tfla = M/(dc-tf) - N x Af/Ac 1235.92 KN

OK

Weld force per mm wf = Tfla /(2bf-tw) 2.05 KN/mm

Weld throat required wf/pyw 9.54 mm

You might also like

- Connection Design Steel Base Plate Bs5950 v2015 01Document4 pagesConnection Design Steel Base Plate Bs5950 v2015 01Anonymous j9PxwnoNo ratings yet

- End-Plate-Design BS CodeDocument15 pagesEnd-Plate-Design BS CodeRaymond SabadoNo ratings yet

- Column to Girder Connection CalculationDocument15 pagesColumn to Girder Connection CalculationNitesh SinghNo ratings yet

- StaircaseDocument2 pagesStaircaseMAGED MOHMMED AHMED QASEMNo ratings yet

- Base Plate INDIA CODEDocument4 pagesBase Plate INDIA CODEbama sankari100% (1)

- Base Plate DesignDocument3 pagesBase Plate DesignVinayak MadiNo ratings yet

- Deck SheetDocument2 pagesDeck SheetmaheshbandhamNo ratings yet

- End Plate Moment Connection (Bolt)Document72 pagesEnd Plate Moment Connection (Bolt)mengxiao74No ratings yet

- Anchor Bolt Design Per IS LSMDocument6 pagesAnchor Bolt Design Per IS LSMdebjyoti_das_6No ratings yet

- Purlin DesignDocument6 pagesPurlin DesignAnonymous mcHqIfbnV1No ratings yet

- Beam Design With RCCDocument24 pagesBeam Design With RCCOsarieme Osakue100% (1)

- Calculation Sheet: 71197 Design For Pile Cap - Two Piles PP DJM MVLDocument3 pagesCalculation Sheet: 71197 Design For Pile Cap - Two Piles PP DJM MVLV.m. RajanNo ratings yet

- Combined Footing DesignDocument3 pagesCombined Footing DesignThe Structural WorldNo ratings yet

- Strap FootingDocument30 pagesStrap Footinganon_140586866No ratings yet

- Purlin Design ReportDocument12 pagesPurlin Design Reportarif_rubin100% (1)

- Weld ConnectionDocument70 pagesWeld ConnectionSudhakar KrishnamurthyNo ratings yet

- Base Slab Design - RampDocument6 pagesBase Slab Design - RampSuresh Mahalingam100% (1)

- DESIGN OF QUINTUPLE PILECAP (BEAM THEORY) - 50 DIA PILESDocument16 pagesDESIGN OF QUINTUPLE PILECAP (BEAM THEORY) - 50 DIA PILESMidhun BabuNo ratings yet

- Design of Isolated FootingDocument10 pagesDesign of Isolated Footingramdev panditNo ratings yet

- Chequered Plate PlatformDocument3 pagesChequered Plate PlatformFilip RisteskiNo ratings yet

- Anchor Bolt CHKDocument17 pagesAnchor Bolt CHKPriya GNo ratings yet

- Design of Splicing of RafterDocument3 pagesDesign of Splicing of Rafterkeerthivasan_mrvNo ratings yet

- Footing Design As Per BSDocument18 pagesFooting Design As Per BSGautam PaulNo ratings yet

- Base PlateDocument13 pagesBase PlateNaga Manikanta TatikondaNo ratings yet

- Base Plate Design-1 - J BoltDocument41 pagesBase Plate Design-1 - J BoltGautam PaulNo ratings yet

- MOMENT EndplateDocument10 pagesMOMENT EndplateALPHYL BALASABASNo ratings yet

- Purlin DesignDocument34 pagesPurlin Designhemantkle2uNo ratings yet

- Composite Slab DesignDocument6 pagesComposite Slab DesignFranklyn GenoveNo ratings yet

- Cleat Angle ConnectionDocument3 pagesCleat Angle ConnectionSrishti Project ConsultantsNo ratings yet

- Design of Steel Plate - R0 - 20.04.21Document1 pageDesign of Steel Plate - R0 - 20.04.21Srishti Project ConsultantsNo ratings yet

- Steel Rafter Section For Eave Roof Section ReductionsDocument25 pagesSteel Rafter Section For Eave Roof Section ReductionsJanaka KarunarathnaNo ratings yet

- Depth of Fixity & Pile DesignDocument2 pagesDepth of Fixity & Pile DesignSoumya BandyopadhyayNo ratings yet

- Stair Case Design Single FlightDocument3 pagesStair Case Design Single Flightrahul100% (1)

- DESIGN of Combined-FootingDocument2 pagesDESIGN of Combined-FootingsPringShockNo ratings yet

- Pinned Base (I-Section) : Design CapacitiesDocument8 pagesPinned Base (I-Section) : Design CapacitiesAwais HameedNo ratings yet

- Load Table for Durbar and Chequer Plate FlooringDocument1 pageLoad Table for Durbar and Chequer Plate Flooringanuj3936No ratings yet

- Indian Codes - Steel Design Per IS 800:2007Document3 pagesIndian Codes - Steel Design Per IS 800:2007dineshNo ratings yet

- Typical Anchor BoltsDocument33 pagesTypical Anchor BoltslucianduNo ratings yet

- CHS Base Plate DesignDocument1 pageCHS Base Plate DesignOlusegun S. AjibolaNo ratings yet

- Spreadsheet to Calculate Composite BeamsDocument2 pagesSpreadsheet to Calculate Composite BeamsJustin MusopoleNo ratings yet

- End Plate DesignDocument26 pagesEnd Plate DesignNitesh SinghNo ratings yet

- Design of Steel Beam to Column Bolted ConnectionDocument3 pagesDesign of Steel Beam to Column Bolted ConnectionibrahimNo ratings yet

- Design of anchor bolts and base plate for pinned H-columnDocument4 pagesDesign of anchor bolts and base plate for pinned H-columnSunil PulikkalNo ratings yet

- Connection Design SteelDocument19 pagesConnection Design Steelबिजेन्द्र प्रधानNo ratings yet

- Staircase Beam Design - 2Document28 pagesStaircase Beam Design - 2Sai Sushank67% (3)

- Base Plate Andf Anchor Bolt Design For Minor Axis MomentDocument2 pagesBase Plate Andf Anchor Bolt Design For Minor Axis MomentSunil Pulikkal100% (1)

- Column Base PlateDocument3 pagesColumn Base PlatePurnima ArkalgudNo ratings yet

- Footing DesignDocument37 pagesFooting DesignnaveenaeeNo ratings yet

- Design of Base PlateDocument3 pagesDesign of Base Plateravi4paperNo ratings yet

- Column Foundation ConnectionDocument3 pagesColumn Foundation Connectionmdelacua2No ratings yet

- Design of Base Plate Anchor Bolt TitleDocument3 pagesDesign of Base Plate Anchor Bolt Titleabdul kareeNo ratings yet

- 6-Bracing Connection - TDocument2 pages6-Bracing Connection - TMUTHUKKUMARAMNo ratings yet

- Corbel BS8110Document3 pagesCorbel BS8110Nugraha BintangNo ratings yet

- BASE PLATE DESIGN CHECKDocument4 pagesBASE PLATE DESIGN CHECKAbhay ThakurNo ratings yet

- Base Plate Design BS CodeDocument3 pagesBase Plate Design BS CodeFodor ZoltanNo ratings yet

- CALCULATION SHEET DESIGNDocument2 pagesCALCULATION SHEET DESIGNrammohanNo ratings yet

- 05-1 Base Plate-FixedDocument49 pages05-1 Base Plate-FixedJames AugustineNo ratings yet

- Fixed Normal 575Document8 pagesFixed Normal 575mohanNo ratings yet

- Design For 3-Pile GroupDocument4 pagesDesign For 3-Pile GroupP&D CIRCLE PWDNo ratings yet

- Ariyoor BridgeDocument1 pageAriyoor BridgevinujohnpanickerNo ratings yet

- The Story of A Luxury Villa at Pattom, Trivandrum, As Told by Icloud HomesDocument26 pagesThe Story of A Luxury Villa at Pattom, Trivandrum, As Told by Icloud HomesvinujohnpanickerNo ratings yet

- Sl. No. Particulars Cost % of Cost Summary of CostDocument1 pageSl. No. Particulars Cost % of Cost Summary of CostvinujohnpanickerNo ratings yet

- Form For Nomination / Cancellation of Nomination: (To Be Filled in by Individual Applying Singly or Jointly)Document2 pagesForm For Nomination / Cancellation of Nomination: (To Be Filled in by Individual Applying Singly or Jointly)vinujohnpanickerNo ratings yet

- Schedule of BTech Admission 2018Document3 pagesSchedule of BTech Admission 2018vinujohnpanickerNo ratings yet

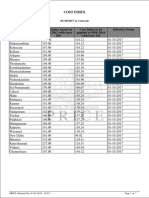

- Price: Public Works DepartmentDocument1 pagePrice: Public Works DepartmentvinujohnpanickerNo ratings yet

- Regdoc 0 TRSCDocument193 pagesRegdoc 0 TRSCAnil MehtaNo ratings yet

- How To Make Adobe Acrobat PDF Files From Autocad Drawings and MW Word Files, and Excel FilesDocument18 pagesHow To Make Adobe Acrobat PDF Files From Autocad Drawings and MW Word Files, and Excel FilesvinujohnpanickerNo ratings yet

- LUSAS RC Frame Design OptionDocument2 pagesLUSAS RC Frame Design OptionvinujohnpanickerNo ratings yet

- Existing Road OVERLAY & WIDENING KM 60+000-km 70+000 Reconstruction OVERLAY & WIDENING KM 75+000 - KM 82+173Document1 pageExisting Road OVERLAY & WIDENING KM 60+000-km 70+000 Reconstruction OVERLAY & WIDENING KM 75+000 - KM 82+173vinujohnpanickerNo ratings yet

- IAHE Brainstorming Session on Long-Span BridgesDocument2 pagesIAHE Brainstorming Session on Long-Span BridgespeterNo ratings yet

- Machamthode Hydraulic CalculationDocument3 pagesMachamthode Hydraulic CalculationvinujohnpanickerNo ratings yet

- Foundations Structures Railway BridgesDocument166 pagesFoundations Structures Railway BridgesvinujohnpanickerNo ratings yet

- Annexure V 16 - 17Document3 pagesAnnexure V 16 - 17vinujohnpanickerNo ratings yet

- Foundations Structures Railway BridgesDocument166 pagesFoundations Structures Railway BridgesvinujohnpanickerNo ratings yet

- Chainage DetailsDocument3 pagesChainage DetailsvinujohnpanickerNo ratings yet

- Hydraulic Calculation Ariyoor BridgeDocument3 pagesHydraulic Calculation Ariyoor Bridgevinujohnpanicker100% (1)

- CE 382 L6 - Shear and Moment Diagrams PDFDocument42 pagesCE 382 L6 - Shear and Moment Diagrams PDFparamarthasom1974No ratings yet

- Upgrading Punalur To Ponkunnam Road (SH 8) Package 8C: KM 60+000 (Placherry) To KM 82+173 (Ponkunnam) On Engineering, Procurement, Construction (Epc)Document1 pageUpgrading Punalur To Ponkunnam Road (SH 8) Package 8C: KM 60+000 (Placherry) To KM 82+173 (Ponkunnam) On Engineering, Procurement, Construction (Epc)vinujohnpanickerNo ratings yet

- Schedule of Beams at Level - 4500: Ajay Kadam AssociatesDocument1 pageSchedule of Beams at Level - 4500: Ajay Kadam AssociatesvinujohnpanickerNo ratings yet

- Schedule of Slabs Reinforcement Details Level 4500Document1 pageSchedule of Slabs Reinforcement Details Level 4500vinujohnpanickerNo ratings yet

- Item Unit Qty Rate AmountDocument17 pagesItem Unit Qty Rate AmountvinujohnpanickerNo ratings yet

- Receipt No Paid On Paid Amount Payment ModeDocument5 pagesReceipt No Paid On Paid Amount Payment ModevinujohnpanickerNo ratings yet

- P & P 2 - Excel SheetDocument18 pagesP & P 2 - Excel SheetvinujohnpanickerNo ratings yet

- Structural Engineer Seeks Global BIM Management Master'sDocument1 pageStructural Engineer Seeks Global BIM Management Master'svinujohnpanicker100% (1)

- Structural Engineer Seeks Global BIM Management Master'sDocument1 pageStructural Engineer Seeks Global BIM Management Master'svinujohnpanicker100% (1)

- Cover Page - GFC A3 PDFDocument1 pageCover Page - GFC A3 PDFvinujohnpanickerNo ratings yet

- How To Generate Your Own Column Interaction DiagramDocument81 pagesHow To Generate Your Own Column Interaction DiagramMarlo AristorenasNo ratings yet

- Item Unit Qty Rate AmountDocument17 pagesItem Unit Qty Rate AmountvinujohnpanickerNo ratings yet

- 1278 - 2013 03 08 16 26 40 - 1362740200 PDFDocument198 pages1278 - 2013 03 08 16 26 40 - 1362740200 PDFvinujohnpanickerNo ratings yet

- ESPs Two Phase FlowDocument26 pagesESPs Two Phase FlowScott YoungNo ratings yet

- Dej/Wondirad Physics UEE Equilibrium 2003-2011Document3 pagesDej/Wondirad Physics UEE Equilibrium 2003-2011Lemi NegesoNo ratings yet

- Theories of Ion Exchange in SoilsDocument21 pagesTheories of Ion Exchange in SoilsTenkurala srujanaNo ratings yet

- Symmetry in Quantum Mechanics: C, P, T SymmetriesDocument13 pagesSymmetry in Quantum Mechanics: C, P, T SymmetriesAtikshaNo ratings yet

- Wireless Power Transmission Using Resonance CouplingDocument6 pagesWireless Power Transmission Using Resonance CouplingKarthik DmNo ratings yet

- TRB PG Syllabus For All Subjects WDocument41 pagesTRB PG Syllabus For All Subjects WBOSS BOSSNo ratings yet

- Mechanics of FluidsDocument64 pagesMechanics of FluidsShiva U100% (2)

- Thin Airfoil TheoryDocument10 pagesThin Airfoil TheoryAli Al-hamalyNo ratings yet

- 2.12 Mass Spectra and IRDocument30 pages2.12 Mass Spectra and IRSandyDavidNo ratings yet

- Stellar SpectraDocument37 pagesStellar SpectraSowgata ChowdhuryNo ratings yet

- Electromagnetics in Power Engineering SimulationDocument8 pagesElectromagnetics in Power Engineering SimulationSamuel NóbregaNo ratings yet

- Physics XII CH 8 Physics Assertion Reasoning Electromagnetic WavesDocument4 pagesPhysics XII CH 8 Physics Assertion Reasoning Electromagnetic WavesNjan KL16么PorottaNo ratings yet

- C3 Integration - AreasDocument7 pagesC3 Integration - AreasAhmed MohamedNo ratings yet

- Generalized Amplitude Damping Channel: The Single Greatest Qubit Mystery in Quantum Shannon TheoryDocument80 pagesGeneralized Amplitude Damping Channel: The Single Greatest Qubit Mystery in Quantum Shannon TheoryMark M. Wilde100% (1)

- Protections of Devices and CircuitsDocument69 pagesProtections of Devices and CircuitsAtiq Ur RehmanNo ratings yet

- Tesla 3 6 9 With ReligionDocument21 pagesTesla 3 6 9 With ReligionRegaldna Felix91% (11)

- Identify The Choice That Best Completes The Statement or Answers The QuestionDocument5 pagesIdentify The Choice That Best Completes The Statement or Answers The Questiontwinckel mae bienesNo ratings yet

- Vaimanika-Sastra and Flying VimanasDocument3 pagesVaimanika-Sastra and Flying VimanasAleksander StrukeljNo ratings yet

- A Quantum Model About Coherence To Understand Non Ionizing Radiation, Geesink, June 2013Document146 pagesA Quantum Model About Coherence To Understand Non Ionizing Radiation, Geesink, June 2013marcelogiovaneNo ratings yet

- Fabrication of Quantum Dots PDFDocument2 pagesFabrication of Quantum Dots PDFMelanieNo ratings yet

- Lab Report #2 Bragg ScatteringDocument10 pagesLab Report #2 Bragg ScatteringJohn FiveNo ratings yet

- Measure conductivity accurately with cell constantDocument14 pagesMeasure conductivity accurately with cell constantGugan RajNo ratings yet

- Study of Lateral Load Carrying Capacities of Piles in Layered Soils Using PLAXIS 3DDocument6 pagesStudy of Lateral Load Carrying Capacities of Piles in Layered Soils Using PLAXIS 3Dneerad mohan100% (1)

- Practical Hydraulic & Pneumatic Systems: Operations and TroubleshootingDocument28 pagesPractical Hydraulic & Pneumatic Systems: Operations and TroubleshootingYOO SHINNo ratings yet

- Experimental Comparison of Single and Multistage Air Compressor EfficienciesDocument11 pagesExperimental Comparison of Single and Multistage Air Compressor EfficienciesJohn barry CorpuzNo ratings yet

- 4 Lab Sheet BDA27401 Sem 1 20182019 Edition1 2018Document73 pages4 Lab Sheet BDA27401 Sem 1 20182019 Edition1 2018Zarul IkramNo ratings yet

- F. Reif - Statistical Physics - Chapter 1 PDFDocument51 pagesF. Reif - Statistical Physics - Chapter 1 PDFIndrawati WilujengNo ratings yet

- Ahmed HassanDocument4 pagesAhmed Hassanah_hassanNo ratings yet

- Kausel - Stiffness MatrixDocument19 pagesKausel - Stiffness MatrixkozloNo ratings yet

- IP 15 Calculations in Support of IP15 The Area Classification Code For Petroleum Installations November 2001Document63 pagesIP 15 Calculations in Support of IP15 The Area Classification Code For Petroleum Installations November 2001Yonatan Cristie100% (2)