Professional Documents

Culture Documents

09-Drilled Shaft Construction

Uploaded by

Muhammad Naufal0 ratings0% found this document useful (0 votes)

33 views3 pagesDdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDdf

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

33 views3 pages09-Drilled Shaft Construction

Uploaded by

Muhammad NaufalDdf

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Drilled Shaft Construction

Drilled Shaft Drilled shafts are constructed in diameters

Construction ranging from 18 inches to 12 feet or more

to provide deep foundations for buildings,

bridges, and retaining walls, and to stabilize

landslides.

Rekayasa Pondasi 2

Highly specialized construction techniques

Teknik Sipil S1- Universitas Riau have been developed to install drilled shafts

in conditions ranging from soft soils to hard

rock.

An auger is used to drill

Auger into soil that is strong Auger

enough to support itself

without casing or slurry.

The auger is inserted and A variety of types of

withdrawn repeatedly while augers have been

rotating, to drill a hole to developed for different

the required depth.

soil conditions.

Then the drilled hole is

filled with concrete, usually

with steel reinforcing so

that the drilled shaft will be This drill is designed

capable of resisting

bending moments and

for drilling into rock.

uplift as well as

compressive loads.

Auger This belling tool was

developed to make it

possible to construct

enlarged bases at the

bottoms of drilled

shafts.

The tool is expanded to

form the “bell,” and is

then retracted to

remove it from the hole.

The soil must be

capable of supporting

the belled shape until This core barrel can be used A rock core, removed from

concrete is tremied into to drill into rock. The core the ground for construction

the hole. (see next photo) is removed of a drilled shaft, sits on the

to form the hole for the ground next to the core

drilled shaft. barrel.

Concrete is placed in the

drilled hole using a tremy

pipe to prevent segregation

of the concrete, erosion of

the sides of the drilled hole,

and damage to the rebar

that would occur if the

This rebar cage is being The rebar cage is so

lowered into a drilled hole

concrete was allowed to

flexible that it needs to be

before the concrete is stabilized with cross bars to

free fall to the bottom of

poured to form the drilled ensure that it will keep its the shaft.

shaft. circular shape.

• Here a bentonite slurry is being

used to prevent collapse of the

sides of the hole, which has

been drilled in unstable ground.

• When the concrete flows out of

the tremy pipe at the bottom of

the shaft, it displaces the slurry,

which is lighter.

• The concrete weighs about 145

pounds per cubic foot, the

Thank You

slurry approximately half as

much.

• As the slurry is displaced

upward, overflowing the hole, it

is pumped to a storage tank for

cleaning and re-use on another

shaft.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Final Self Hypnosis Paperback For PrintDocument150 pagesFinal Self Hypnosis Paperback For PrintRic Painter100% (12)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Quanta To QuarksDocument32 pagesQuanta To QuarksDaniel Bu100% (5)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- BSH 7005-15Document129 pagesBSH 7005-15Mark InnesNo ratings yet

- DR S GurusamyDocument15 pagesDR S Gurusamybhanu.chanduNo ratings yet

- Sermon Manuscript Galatians 5:16-26Document9 pagesSermon Manuscript Galatians 5:16-26Nathaniel ParkerNo ratings yet

- Etextbook PDF For Pharmacology Connections To Nursing Practice 3rd EditionDocument61 pagesEtextbook PDF For Pharmacology Connections To Nursing Practice 3rd Editionkarla.woodruff22798% (45)

- Spare Part PhilosophyDocument27 pagesSpare Part Philosophyavaisharma50% (2)

- Taoist Master Zhang 张天师Document9 pagesTaoist Master Zhang 张天师QiLeGeGe 麒樂格格100% (2)

- Soundarya Lahari Yantras Part 6Document6 pagesSoundarya Lahari Yantras Part 6Sushanth Harsha100% (1)

- EP001 LifeCoachSchoolTranscriptDocument13 pagesEP001 LifeCoachSchoolTranscriptVan GuedesNo ratings yet

- Reaction Paper FinalDocument5 pagesReaction Paper FinalJelo RoxasNo ratings yet

- Battery Checklist ProcedureDocument1 pageBattery Checklist ProcedureKrauser ChanelNo ratings yet

- Electrical Engineering Lab Vica AnDocument6 pagesElectrical Engineering Lab Vica Anabdulnaveed50% (2)

- LPS 1131-Issue 1.2-Requirements and Testing Methods For Pumps For Automatic Sprinkler Installation Pump Sets PDFDocument19 pagesLPS 1131-Issue 1.2-Requirements and Testing Methods For Pumps For Automatic Sprinkler Installation Pump Sets PDFHazem HabibNo ratings yet

- Bossypants Autobiography and Womens SelvesDocument26 pagesBossypants Autobiography and Womens SelvesCamila Paz GutiérrezNo ratings yet

- Past Simple Vs Past ContinuousDocument3 pagesPast Simple Vs Past ContinuousNatalia SalinasNo ratings yet

- Engineering DrawingDocument1 pageEngineering DrawingDreamtech PressNo ratings yet

- Getting Started With Citrix NetScalerDocument252 pagesGetting Started With Citrix NetScalersudharaghavanNo ratings yet

- Dessler HRM12e PPT 01Document30 pagesDessler HRM12e PPT 01harryjohnlyallNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document1 pageS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)BaytolgaNo ratings yet

- EQ JOURNAL 2 - AsioDocument3 pagesEQ JOURNAL 2 - AsioemanNo ratings yet

- CRISTIAN COLCERIU - PERSONALITATI CLUJENE Prof - Dr.ing - POMPILIU MANEADocument21 pagesCRISTIAN COLCERIU - PERSONALITATI CLUJENE Prof - Dr.ing - POMPILIU MANEAcristian colceriu100% (2)

- B. Pengenalan Kepada Pengawal Mikro 1. Mengenali Sistem Yang Berasaskan Pengawal MikroDocument4 pagesB. Pengenalan Kepada Pengawal Mikro 1. Mengenali Sistem Yang Berasaskan Pengawal MikroSyamsul IsmailNo ratings yet

- G1000 Us 1014 PDFDocument820 pagesG1000 Us 1014 PDFLuís Miguel RomãoNo ratings yet

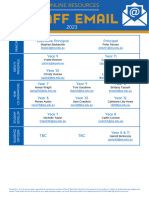

- 2023 Teacher Email ListDocument5 pages2023 Teacher Email ListmunazamfbsNo ratings yet

- Directorate of Technical Education, Admission Committee For Professional Courses (ACPC), GujaratDocument2 pagesDirectorate of Technical Education, Admission Committee For Professional Courses (ACPC), GujaratgamailkabaaaapNo ratings yet

- MolnarDocument8 pagesMolnarMaDzik MaDzikowskaNo ratings yet

- Tyler Nugent ResumeDocument3 pagesTyler Nugent Resumeapi-315563616No ratings yet

- Homeopatija I KancerDocument1 pageHomeopatija I KancermafkoNo ratings yet

- Unit 2 - Industrial Engineering & Ergonomics - WWW - Rgpvnotes.inDocument15 pagesUnit 2 - Industrial Engineering & Ergonomics - WWW - Rgpvnotes.inSACHIN HANAGALNo ratings yet