Professional Documents

Culture Documents

Fanuc Macro

Uploaded by

Deysi CardenasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fanuc Macro

Uploaded by

Deysi CardenasCopyright:

Available Formats

S. K.

Sinha / International Journal of Engineering Science and Technology

Vol. 2(12), 2010, 7616-7618

AUTOMATING FACING OPERATION

ON A CNC MACHINING CENTRE

S. K. SINHA

Department of Mechanical Engg.

Institute of Technology, Banaras Hindu University

Varanasi-221005, India

E-mail : sinha_nsit@yahoo.co.uk

Abstract

Facing is usually the first and an essential process on a CNC machining centre, using a face-milling cutter, on

any workpiece, because many a time, the workpiece is obtained through a “rough” casting process. The

advantage of a cast part is that a workpiece with slightly oversize dimensions is made available, usually

requiring very little machining. This saves machining costs. However, the inherent limitation of common casting

processes is inaccuracy in dimensions as well as surface roughness. Because of this reason, facing becomes the

first machining operation. On a CNC milling machine, this requires a facing program written in terms of G-

codes. Since dimensions of different workpieces are likely to be different, offering different areas to be faced,

the same program would not work on all workpieces. The present paper uses the latest macro-programming

technique, available on modern CNC machines, to develop a single program for workpieces of all dimensions.

Keywords

CNC; G-codes; Macro programming; Custom Macro B

1. Introduction

Machining, casting and forging are the most common manufacturing processes. Each technique has its own

advantages and limitations. For example, casting produces the weakest part whereas the strongest part is

produced by forging. However, an advantage with casting is that it is less expensive than a forging process,

Moreover, machinability of a cast part is extremely good. Therefore, in applications where too much strength is

not a criterion, casting becomes the first choice. However, inaccuracy in dimensions, along with surface

roughness, is the inherent limitation of a cast part. Hence, usually a cast part invariably requires some

machining, often facing being the first one.

When it comes to a facing operation, a G-code program can be written, mostly involving rapid traverse

(G00) and linear interpolation (G01). Though the actual program does depend on the control being used on the

machine, in a simple case such as this, the program would be essentially same for all the controls, because all

control manufactures use the same basic program codes, such as G00 for rapid traverse, G01 for linear

interpolation, G02 for clockwise circular interpolation, G03 for counterclockwise circular interpolation, and so

on [1, 2]. Therefore, while program portability is not really a problem, one does have to write a new program for

every new workpiece, because of difference in facing area/geometry. Moreover, since a CNC machine is pretty

expensive, one has to first prove a program before actually executing on the machine. Writing a program,

followed by proving it meticulously, is a time taking process. And if the services of an expert programmer are

not readily available, the company has to look for a suitable person, many a time from outside the company.

This not only increases the production cost, but also affects productivity adversely. Therefore, it is desirable to

have a ready-made program which could be used for workpieces of all dimensions. The aim of the present paper

is to develop such a general-purpose program.

2. Existing Solution

As discussed, separate programs for workpieces of different sizes need to be written. For example, consider

facing operation on a workpiece of 100 mm x 90 mm size, with a facing tool of 30 mm diameter. With the lower

left corner of the top surface selected as the program zero point, and using an overlap/clearance of 2 mm in

cutting passes, the following program can be written, which initially places the tool at position A and follows

the shown toolpath to reach position B in the end (see Fig. 1):

O0001; Program number

G21 G94; Millimeter mode and feed in mm/min selected

G91 G28 Z0; Z-homing

G28 X0 Y0; XY-homing

M06 T01; Tool change

ISSN: 0975-5462 7616

S. K. Sinha / International Journal of Engineering Science and Technology

Vol. 2(12), 2010, 7616-7618

Y

100

90

Facing tool

A

X

Fig. 1: Facing operation on a rectangular plate

G90 G00 G43 H01 Z200; Tool placed 200 mm above the workpiece

X-17 Y13; Tool placed at A (using 2 mm clearance)

Z2; Tool placed 2 mm above the workpiece, at position A

M03 S500; Spindle starts with 500 clockwise rpm

G01 Z-0.5 F60; Facing depth assumed to be 0.5 mm

G91 X134; First facing pass

Y28; Positioning for second facing pass

X-134; Second facing pass

Y28; Positioning for third facing pass

X134; Third facing pass

Y28; Positioning for fourth facing pass

X-134; Fourth facing pass, to reach position B

G00 Z200; Tool retracts, after facing is complete

M05; Spindle stops

M30; Execution ends and control resets

While there is nothing wrong with this program which will do the required facing without any problem,

the fact remains that this is a specific program for a specific job. If there is any change in the workpiece

dimension, a new program would need to be written. This would be a time-consuming process, since the

programmer will have to do all the calculations again, and verify the new program by meticulously analyzing its

simulation. Moreover, services of an expert programmer may not be available all the time.

4. Proposed Solution

The author presents a general-purpose program, using the latest macro-programming technique available on

modern CNC machines [3, 4], which can face workpieces of any dimension, without making any change in the

program. This program would need to be stored as a macro in the CNC memory, which may be called by any

program needing facing. Instead of fixed values, the macro has been developed in terms of variables, the initial

values of which are passed on to the macro, from the calling program, using the macro-call code G65. The tool

number and the offset number of the facing tool, and spindle rpm would need to be specified in the main

program (the macro-calling program), though it is possible to make the macro even more general by using

variables for these also, inside the macro. The specific language for writing the program is Fanuc Custom Macro

B. For other controls, minor changes in the program might be needed; the basic structure of the program would

remain unchanged. For using this program, the machine-table should be made datum for Z-axis. X/Y datum can

be placed at any convenient location. After clamping the workpiece onto the table, one would need to measure

the coordinates of the lower left corner, as well as the thickness (Z-coordinate) of the workpiece.

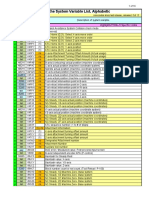

List of variables used in the macro:

Length (X-dimension) of workpiece, A #1

Width (Y-dimension) of workpiece, B #2

Overlap in facing passes, C #3

Facing tool diameter, D #7

Depth of cut, E #8

Facing feedrate in mm/min, F #9

Lower left corner X-coordinate #24

Lower left corner Y-coordinate #25

ISSN: 0975-5462 7617

S. K. Sinha / International Journal of Engineering Science and Technology

Vol. 2(12), 2010, 7616-7618

Z-coordinate of top surface of workpiece #26

Main program:

O0002; Program number

G21 G94; Millimeter mode and feed in mm/min selected

G91 G28 Z0; Z-homing

G28 X0 Y0; XY-homing

M06 T01; Desired tool placed in the spindle

M03 S500; Spindle starts with the desired clockwise rpm

G90 G00 G43 H01 Z200; Tool positioned at a safe height above the table

G65 P8000 A100 B90 C2 D30 E0.5 F60 X0 Y0 Z0; Macro call for dimensions/parameters of Fig. 1

G00 Z200; Tool retracts, after facing is complete

M05; Spindle stops

M30; Execution ends and control resets

Macro:

O8000; Program number (the so-called macro)

#100 = #2 + 2 * #3; Required facing width calculated, including clearance

G90 G00 X[#24 - #7 / 2 - #3] Y[#25 + #7 / 2 - #3]; Tool placed at A (using the clearance specified in #3)

Z[#26 + 2]; Tool positioned 2 mm above the workpiece, at position A

G91 G01 Z[- 2 - #8] F#9; Tool brought down to the specified facing depth

X[#1+ #7 + 2 * #3]; First facing pass

#100 = #100 - #7; Remaining facing width calculated

IF [#100 LE 0] GOTO 10; Jump to end if facing is complete

G00 Y[#7 - #3]; Lateral shift for the next facing pass

#101 = -1; Index for altering direction of facing

WHILE [#100 GT 0] DO 1; Execution in a loop till the entire width is faced

G01 X[#1 + #7 + 2 * #3] * #101; Next facing pass, in a direction opposite to the previous

facing pass

G00 Y[#7 - #3]; Lateral shift for the next facing pass

#100 = #100 - #7 + #3; Remaining facing width calculated

#101 = #101 * [- 1]; Sign of facing-direction index reversed

END 1; End of loop

N10 G90 G00 Z[#26 + 2]; Z-retraction to 2 mm above the workpiece

M99; Return to the calling program

5. Conclusion

Using the latest macro-programming technique available on high-end CNC machines, a general facing program

was developed which can be used to face workpieces of all dimensions, without incurring any extra cost or

compromising in quality. Such an approach results in increased efficiency of the manufacturing system, since

the enormous time consumed in developing and proving new programs is saved [5]. Manufacturing industry

needs such general-purpose programs for cutting manufacturing costs, in view of cut-throat competition in

manufacturing sector these days.

References

[1] Sinha, S. K., “CNC Programming (eighth edition),” Galgotia Publications Private Limited, New Delhi.

[2] Smid, Peter, “CNC Programming Handbook (third edition), Industrial Press Inc., New York.

[3] Sinha, S. K., “CNC Programming using Fanuc Custom Macro B,” McGraw-Hill Professional, New York.

[4] Smid, Peter, “Fanuc CNC Custom Macros,” Industrial Press Inc., New York.

[5] Djassemi, Manocher, “A Parametric Programming Technique for Efficient CNC Machining Operations,” 23rd International Conference on

Computers and Industrial Engineering, pp. 33-36.

ISSN: 0975-5462 7618

You might also like

- A Parametric Programming Technique For Efficient CNC Machining OpDocument4 pagesA Parametric Programming Technique For Efficient CNC Machining OpHarsha Chaitanya GoudNo ratings yet

- Custom MacroDocument31 pagesCustom Macroshiva d100% (1)

- Custom Macro BDocument25 pagesCustom Macro Bikebud100% (1)

- CNC Programming WorkshopDocument150 pagesCNC Programming WorkshopThanh BaronNo ratings yet

- G M Codes All CNCDocument24 pagesG M Codes All CNCParveen Kumar0% (1)

- FIVE-AXIS MACHINING ERROR CORRECTIONDocument10 pagesFIVE-AXIS MACHINING ERROR CORRECTIONhung0% (1)

- Doosan Puma MX Series PDFDocument68 pagesDoosan Puma MX Series PDFGuillermo RamirezNo ratings yet

- NTX 10006600 Post Manual 20120601Document197 pagesNTX 10006600 Post Manual 20120601Cristian VegaNo ratings yet

- FANUC Macro Program ProgrammingDocument16 pagesFANUC Macro Program ProgrammingVinsensius Herdani Agung Nugroho50% (4)

- Doosan-Fanuc High Speed ModeDocument2 pagesDoosan-Fanuc High Speed Modemarkoskitp100% (1)

- HaasLiveToolOpProgram - W - DS Manual PDFDocument70 pagesHaasLiveToolOpProgram - W - DS Manual PDFGuillermo RamirezNo ratings yet

- Heidenhain TNC 530 Probing CyclesDocument135 pagesHeidenhain TNC 530 Probing CyclesDivisionaryNo ratings yet

- Complete G Code ListDocument7 pagesComplete G Code ListRevolusiSoekarno100% (2)

- Custom Macro B Quick Reference GuideDocument2 pagesCustom Macro B Quick Reference GuideNickolas Gibbs100% (3)

- Mori Seiki GM CodeDocument10 pagesMori Seiki GM CodevusvusNo ratings yet

- Fanuc Lathe Programming GuideDocument93 pagesFanuc Lathe Programming GuidenguyenanhsoNo ratings yet

- Doosan Infracore EZ Guide-I Programming For Lathe.Document108 pagesDoosan Infracore EZ Guide-I Programming For Lathe.JohnPaulSmith1100% (1)

- Fanuc CNC Custom Macros - Programming Resources For Fanuc Custom Macro B Users - Peter Smid (Seduction28)Document336 pagesFanuc CNC Custom Macros - Programming Resources For Fanuc Custom Macro B Users - Peter Smid (Seduction28)bruno86% (21)

- M Ang G Code Mesin CNC Mori SeikiDocument13 pagesM Ang G Code Mesin CNC Mori SeikiWirdiIanNo ratings yet

- Fanuc G and M Code List PDFDocument2 pagesFanuc G and M Code List PDFBrandon0% (3)

- Fanuc Oi PDFDocument16 pagesFanuc Oi PDFGuillermo Ramirez100% (1)

- English Rotary RevRDocument114 pagesEnglish Rotary RevRssenn02No ratings yet

- Doosan Puma-ADVANCED 30 Series TC PROGRAMMING Rev4 With 31i AddendumDocument114 pagesDoosan Puma-ADVANCED 30 Series TC PROGRAMMING Rev4 With 31i AddendumCasey GroomsNo ratings yet

- Fanuc G68 Tilted Work Plane OperationDocument11 pagesFanuc G68 Tilted Work Plane OperationRelu ChiruNo ratings yet

- CNC Part ProgrammingDocument40 pagesCNC Part ProgrammingmsshahenterNo ratings yet

- Heidenhain FK-Programming TNC 530iDocument83 pagesHeidenhain FK-Programming TNC 530itonybullough100% (1)

- SystemVarsAlpha List OkumaDocument16 pagesSystemVarsAlpha List Okumaseb_dominique100% (2)

- Hass Programming Walk Through For MillsDocument22 pagesHass Programming Walk Through For MillsBiszopNo ratings yet

- Cincom Evolution Line: Sliding Headstock Type Automatic CNC LatheDocument8 pagesCincom Evolution Line: Sliding Headstock Type Automatic CNC Lathecmgankl100% (1)

- Haas VMC ManualDocument268 pagesHaas VMC Manualgaurav_mob33% (3)

- Daewoo Lathe Training Manual-FANUC O-TDocument104 pagesDaewoo Lathe Training Manual-FANUC O-TJAMES JUDY100% (1)

- Module 4Document59 pagesModule 4Musadiq Ahmed100% (1)

- Fanuc OT CNC Program Manual Gcode Training 588Document104 pagesFanuc OT CNC Program Manual Gcode Training 588Maximiliano GarciaNo ratings yet

- Alkart CNC Wizard 2014 Manual Revision 8Document80 pagesAlkart CNC Wizard 2014 Manual Revision 8aditoma44100% (4)

- Custom Macro Variable Peck Drilling Cycle MacroDocument2 pagesCustom Macro Variable Peck Drilling Cycle MacroRelu ChiruNo ratings yet

- Fanuc Macro Program Examples and Programming GuideDocument2 pagesFanuc Macro Program Examples and Programming Guidedvt0% (1)

- Easy Probing RenishawDocument29 pagesEasy Probing RenishawNicolae TabircaNo ratings yet

- Doosan Puma 2600yDocument24 pagesDoosan Puma 2600ybaumgconradoNo ratings yet

- Puma Work Ejector Tip ReplacementDocument3 pagesPuma Work Ejector Tip ReplacementpaulNo ratings yet

- FeatureCAM Reference ManualDocument2,359 pagesFeatureCAM Reference Manualdududadamike100% (2)

- Mastercam Shortcut KeysDocument1 pageMastercam Shortcut KeysAnil Kumar K P75% (4)

- Subroutines and MacrosDocument14 pagesSubroutines and MacrosShiva Krishna BhagavatulaNo ratings yet

- The Tool Measure Test of Fanuc VMCDocument5 pagesThe Tool Measure Test of Fanuc VMCRobert Dăboi100% (1)

- ISO Commands in Pitagora ENGDocument2 pagesISO Commands in Pitagora ENGCarlos Jadán100% (1)

- The Use of Variables, Macros and Subroutines and Compatibility With FANUC Parametric Programming ......................... 3Document10 pagesThe Use of Variables, Macros and Subroutines and Compatibility With FANUC Parametric Programming ......................... 3Jérôme GRANGENo ratings yet

- Fanuc Idocs ManualDocument21 pagesFanuc Idocs Manualsunhuynh100% (2)

- M32 OpcenitoDocument14 pagesM32 OpcenitoDilhet NadarevicNo ratings yet

- Mastercam To Mazatrol Post-Processor TutorialDocument78 pagesMastercam To Mazatrol Post-Processor TutorialbadnovaNo ratings yet

- Live Tool Drill TapDocument25 pagesLive Tool Drill TapRA Javier100% (1)

- Okuma OSP 5 Axis TrainingDocument49 pagesOkuma OSP 5 Axis TrainingRick WilliamsNo ratings yet

- A Parametric Programming Technique For Efficient CNC Machining Op PDFDocument4 pagesA Parametric Programming Technique For Efficient CNC Machining Op PDFpocerilloNo ratings yet

- Automatic Automatic Generating CNC-Code For Milling MachineGenerating CNC Code For Milling MachineDocument7 pagesAutomatic Automatic Generating CNC-Code For Milling MachineGenerating CNC Code For Milling MachineVikas Singh SisodiaNo ratings yet

- Lab Manual CNC LatheDocument10 pagesLab Manual CNC LatheSai Naga Sri Harsha100% (1)

- Tool Length SettingDocument2 pagesTool Length Settingkavadarci14No ratings yet

- FullDocument35 pagesFullsumanth100% (1)

- 3 Axis Surface MachiningDocument512 pages3 Axis Surface MachiningagrbovicNo ratings yet

- Cam SyllabusDocument28 pagesCam SyllabusRajueswarNo ratings yet

- EML 342/2 Lab Report on CNC MachiningDocument9 pagesEML 342/2 Lab Report on CNC MachiningMark SelvanNo ratings yet

- Cover Letter - Swapnil GandhiDocument1 pageCover Letter - Swapnil GandhiGopi NathNo ratings yet

- Niagara White PaperDocument11 pagesNiagara White PaperGopi NathNo ratings yet

- Elfit Arabia FZE: Preliminary Screening FormDocument1 pageElfit Arabia FZE: Preliminary Screening FormGopi NathNo ratings yet

- Post Processors - What's New in v9Document93 pagesPost Processors - What's New in v9Gopi NathNo ratings yet

- AlJazeera Jobs - Manufacturing EngineerDocument2 pagesAlJazeera Jobs - Manufacturing EngineerGopi NathNo ratings yet

- Useful FormulasDocument3 pagesUseful Formulasdeepa88No ratings yet

- Kassim Deen - United Arab Emirates - LinkedInDocument1 pageKassim Deen - United Arab Emirates - LinkedInGopi NathNo ratings yet

- Injection Moulding Machine - ElectronicaDocument6 pagesInjection Moulding Machine - ElectronicaGopi NathNo ratings yet

- Pipe Bender MechanicalDocument1 pagePipe Bender MechanicalGopi NathNo ratings yet

- M.E. Design Engineering SWPDocument1 pageM.E. Design Engineering SWPGopi NathNo ratings yet

- Hydraulics Basic FormulaDocument1 pageHydraulics Basic FormulaGopi NathNo ratings yet

- DivisionDocument1 pageDivisionGopi NathNo ratings yet

- Senthil Rangarajan - Covering LetterDocument1 pageSenthil Rangarajan - Covering LetterGopi NathNo ratings yet

- Daily Story Simile Stella Snow QueenDocument3 pagesDaily Story Simile Stella Snow Queenapi-300281604No ratings yet

- Dharma SeansDocument34 pagesDharma Seansdilaver kızakiNo ratings yet

- DR-ID330CL - Reference Guide - 897N202070 - Z72N100629 - RefDocument340 pagesDR-ID330CL - Reference Guide - 897N202070 - Z72N100629 - RefFernando ValleNo ratings yet

- RSMSSB Rajasthan Tax Assistant Exam SyllabusDocument5 pagesRSMSSB Rajasthan Tax Assistant Exam Syllabuszaibakhan8No ratings yet

- Unit Plan 7th GradeDocument21 pagesUnit Plan 7th Gradeapi-328252734No ratings yet

- Psychology and LanguageDocument15 pagesPsychology and LanguageJihannawalainiNo ratings yet

- Manufacturing Foundation R18A Student GuideDocument307 pagesManufacturing Foundation R18A Student GuideVictor MillanNo ratings yet

- Parang Foundation College Inc.: Course No. Descriptive Title Degree Program/ Year Level InstructressDocument4 pagesParang Foundation College Inc.: Course No. Descriptive Title Degree Program/ Year Level InstructressShainah Melicano SanchezNo ratings yet

- Grammar - Simple Past Tense StoryDocument2 pagesGrammar - Simple Past Tense StoryDon AndrewNo ratings yet

- ObjectDetection Tutorial PYNQDocument17 pagesObjectDetection Tutorial PYNQLEON, CHING-YAO TANGNo ratings yet

- NIE Institute of Technology Computer Network LabDocument33 pagesNIE Institute of Technology Computer Network LabManvanth B CNo ratings yet

- HP Superdome 2 Partitioning Administrator Guide (5900-1801, August 2011)Document110 pagesHP Superdome 2 Partitioning Administrator Guide (5900-1801, August 2011)Phuc NguyenNo ratings yet

- Anticipation Guides - (Literacy Strategy Guide)Document8 pagesAnticipation Guides - (Literacy Strategy Guide)Princejoy ManzanoNo ratings yet

- English Hoework Part 6Document18 pagesEnglish Hoework Part 6Putri Aisyah UtamiNo ratings yet

- Unit 3 The Teaching and Learning of ESOLDocument46 pagesUnit 3 The Teaching and Learning of ESOLIlya VilsonNo ratings yet

- The Impact of Learner Centered Teaching On Students Learning Skills and StrategiesDocument5 pagesThe Impact of Learner Centered Teaching On Students Learning Skills and StrategiesJers GivaNo ratings yet

- Semrush-Site Audit Issues-Www Whitehatjr Com-5 Déc. 2022Document11 pagesSemrush-Site Audit Issues-Www Whitehatjr Com-5 Déc. 2022Raghav sowryaNo ratings yet

- CSSE501 Inheritance and SubstitutionDocument30 pagesCSSE501 Inheritance and Substitutionsaleem010No ratings yet

- Siddesh Bhagwan Pingale: EducationDocument2 pagesSiddesh Bhagwan Pingale: EducationSiddesh PingaleNo ratings yet

- PriceDocument152 pagesPriceRaimundo TinoNo ratings yet

- LESSON PLAN - Kinds of WeatherDocument4 pagesLESSON PLAN - Kinds of WeatherSittie Naifa CasanNo ratings yet

- Who Is The Antichrist?Document9 pagesWho Is The Antichrist?United Church of GodNo ratings yet

- Running Head: Feelings of Melancholy and DeathDocument8 pagesRunning Head: Feelings of Melancholy and DeathYasemin S. ErdenNo ratings yet

- JavaScript Unit Testing Tools Cheat SheetDocument3 pagesJavaScript Unit Testing Tools Cheat SheetHéla Ben KhalfallahNo ratings yet

- The Dialogue of Salomon and Saturnus, With An Historical Introd. by John M. KembleDocument358 pagesThe Dialogue of Salomon and Saturnus, With An Historical Introd. by John M. Kemblekamion0No ratings yet

- Higher Nationals in Computing: Unit 19: Data Structures and Algorithms Assignment 1Document41 pagesHigher Nationals in Computing: Unit 19: Data Structures and Algorithms Assignment 1Nguyen Manh Hiep Long (FGW HCM)100% (1)

- Rite of Burning Palms For Ash WednesdayDocument2 pagesRite of Burning Palms For Ash WednesdayBesoy Legislador BasbañoNo ratings yet

- Q1 What Is New in 9.0 Ibm NotesDocument17 pagesQ1 What Is New in 9.0 Ibm NotesPrerna SinghNo ratings yet

- M18 - Communication À Des Fins Professionnelles en Anglais - HT-TSGHDocument89 pagesM18 - Communication À Des Fins Professionnelles en Anglais - HT-TSGHIbrahim Ibrahim RabbajNo ratings yet

- For Colored GirlsDocument8 pagesFor Colored GirlsLilaMuslimahNo ratings yet