Professional Documents

Culture Documents

JSA Unloading

Uploaded by

anon_50254931Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSA Unloading

Uploaded by

anon_50254931Copyright:

Available Formats

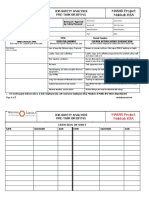

Job Safety Analysis

Task THINK

JSA FOR UNLOADING CONTAINER, GENERATOR & FUEL Before you

Being

Assessed TANK WORKS CHECK

Before you

Site JSA No. JSA-002 REV 0

PROCEED

Sheet

Recorded By Tasnim Date 14/02/18 Contractor 1 of 4

No.

Attendees:

NAME DESIGNATION COMPANY NAME DESIGNATION COMPANY

P.P.E. Requirements (indicate by marking “Y” or “N”) Note: This list is for selection of PPE above the minimum requirements specified by TPGM

Goggles [Y] Face Shield [N] Soft Mask P1 or P2 [Y] Respirator-1/4 or 1/2 or full face [N ] Airline/Hood [N] SCBA [N] Safety Harness [Y]

Disposable chemical suits [N] PVC Splash Suit/Hood [N] Chemical Apron [N ] Chemical Resistant Gloves [N ] Chemical Boots [N ]

Ear Muffs [N] UV Protection Cream [N]

Height Safety Requirements Anchor Strap [Y] Rescue Plan-Suspended Person [N] Scaffold Erection [Y] Work Vest [Y]

Full Body Harness [Y] Retractable Lanyard [Y] Inertia Reel [Y] Static line [N] Man Basket [N] EWP [N] Gondola [N ]

Confined Space Entry Requirements Vent/Purge [N] Gas Test/Log [N] Personal Monitor [N] Rescue plan [N] Harness for top entry [N]

Documentation Client PTW [ ] TPGM PTW [ ] Isolation-Lockout/ Tagout [ ] Isolation List [ ] Work Procedure [ ] P&ID [ ]

Prepared By: Tasnim Reviewed By TPGM HSE -Name: Approved By TPGM CM -Name:

Date: 28/06/2016 Date: / / Date: / /

Position: Signature: Signature:

Signature:

KEY GUIDEWORDS-HAZARD IDENTIFICATION

Safe Access/EgressFall From +2m Dropped Objects Loose Objects Slip/Trip Crush/Caught Between Fall Overboard

Rotation/Spin Residual Torque Entanglement Lift/Carry/Push/Pull Sharp Edges Pollution PTW Required

Chemicals PPE Heat/Fire/Explosion Heat Stress Over-Pressure Vacuum Change Control

Overload Bend/Distort Fail/Fracture/Break Collision Loss of Position Communications Confined Space

Job Safety Analysis

Task THINK

JSA FOR UNLOADING CONTAINER, GENERATOR & FUEL Before you

Being

Assessed TANK WORKS CHECK

Before you

Site JSA No. JSA-002 REV 0

PROCEED

Sheet

Recorded By Tasnim Date 14/02/18 Contractor 2 of 4

No.

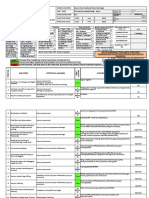

S.No Job description Potential Hazard/ Risk Person/s Risk Control Measures/ Mitigation Action by

Involved Rating

1. Mobilization of workers at Unauthorized personnel / Workers (4M) Ensure all personnel and team have attended the Person In

site Miscommunication / Communication HSE induction Charge &

Breakdown Conduct briefing before starting work in order to Supervisor

explain the risk

Make sure all teams involved are equipped with

PPE before starting work

Inspect all equipment thoroughly before using

Make sure all safety devices and guard are intact

and operable

Barricade where the erection work is to be carried

out and display a warning sign

Make sure all safety tools are already in place and

safe for use

2. Material delivery Unauthorized personnel Driver (4M) Ensure lorry driver carries valid driving license Supervisor

which is registered to the local authority

Ensure lorry driver possesses valid road tax and car

insurance

Material Fall Driver (8M) Ensure the driver maneuvers the lorry to the Supervisor

intended location at a given speed limit

Proper lashing must be provided by the lorry driver

to properly tie all the material to the lorry

Danger of being hit by lorry Workers (8M) Flagman to be available during movement of Supervisor

vehicle to the loading area

3. Material unloading Dangers of being hit by crane / Workers (8M)

Barricade the unloading area Supervisor

fork lift

Flagman to be available during the operation of

mobile crane / fork lift

Personnel Injury Workers (4M) Use appropriate gloves to protect hand from Supervisor

splinters and sharp edges

KEY GUIDEWORDS-HAZARD IDENTIFICATION

Safe Access/EgressFall From +2m Dropped Objects Loose Objects Slip/Trip Crush/Caught Between Fall Overboard

Rotation/Spin Residual Torque Entanglement Lift/Carry/Push/Pull Sharp Edges Pollution PTW Required

Chemicals PPE Heat/Fire/Explosion Heat Stress Over-Pressure Vacuum Change Control

Overload Bend/Distort Fail/Fracture/Break Collision Loss of Position Communications Confined Space

Job Safety Analysis

Task THINK

JSA FOR UNLOADING CONTAINER, GENERATOR & FUEL Before you

Being

Assessed TANK WORKS CHECK

Before you

Site JSA No. JSA-002 REV 0

PROCEED

Sheet

Recorded By Tasnim Date 14/02/18 Contractor 3 of 4

No.

4. Shifting of equipments from Limited access Workers/ (4M) Ensure the area is clear and have sufficient space Supervisor

storage to installation area Vehicles for both the vehicles and workers

Consult the respective authority at site for

clearance to shift the equipment

Improper base support Workers (4M) Lay pipe rollers or wooden planks or any approved Supervisor

supporting materials

Sit the switchgears on top of those materials which

will serve as base support for lifting and shifting

Request for inspection and approval of the support

setup from a competent personnel before the

shifting process

Personal Injury Workers (8M) Ensure all personnel know and follow established Supervisor

procedures for installation work

Ensure nobody is near to the equipment except

authorized personnel when shifting it from one

location to another

Fall of Objects / Tools Workers (8M) Remove or secure any moving parts of the Supervisor

equipment before the shifting work

Keep clear of all tools used before or during the

shifting process in their respective storage

locations.

KEY GUIDEWORDS-HAZARD IDENTIFICATION

Safe Access/EgressFall From +2m Dropped Objects Loose Objects Slip/Trip Crush/Caught Between Fall Overboard

Rotation/Spin Residual Torque Entanglement Lift/Carry/Push/Pull Sharp Edges Pollution PTW Required

Chemicals PPE Heat/Fire/Explosion Heat Stress Over-Pressure Vacuum Change Control

Overload Bend/Distort Fail/Fracture/Break Collision Loss of Position Communications Confined Space

Job Safety Analysis

Task THINK

JSA FOR UNLOADING CONTAINER, GENERATOR & FUEL Before you

Being

Assessed TANK WORKS CHECK

Before you

Site JSA No. JSA-002 REV 0

PROCEED

Sheet

Recorded By Tasnim Date 14/02/18 Contractor 4 of 4

No.

5. Lifting of equipments Limited access Workers (4M) Ensure the area is clear and have sufficient space Supervisor

for both the machineries and workers

Consult the respective authority at site for

clearance to shift the equipment

Electrical hazard Workers (8M) Ensure all tools are properly inspected and tagged Supervisor

Perform regular check on electrical tools for

leakages or malfunctions

Use of generator Workers (4M) Ensure generator is properly grounded and tagged Supervisor

Make sure all electrical tools and equipment are

plugged to extension cord with proper safety

features

Fire hazard

Workers (4M) Fire extinguisher placed near to generator in the Supervisor

event of fire emergency.

Fall of materials / tools Workers (4M) Supervisor

Secure all materials and tools properly during the

installation work

6. Housekeeping Slip and fall tripping Workers (4M) Clean-up all unused materials and dispose Supervisor

immediately once the job has been completed

Ensure proper housekeeping to be maintained

throughout the work progress

Personnel Injury Workers (4M) Use appropriate gloves to protect hand from Supervisor

splinters and sharp edges

KEY GUIDEWORDS-HAZARD IDENTIFICATION

Safe Access/EgressFall From +2m Dropped Objects Loose Objects Slip/Trip Crush/Caught Between Fall Overboard

Rotation/Spin Residual Torque Entanglement Lift/Carry/Push/Pull Sharp Edges Pollution PTW Required

Chemicals PPE Heat/Fire/Explosion Heat Stress Over-Pressure Vacuum Change Control

Overload Bend/Distort Fail/Fracture/Break Collision Loss of Position Communications Confined Space

You might also like

- JSA Installation of GearboxDocument2 pagesJSA Installation of Gearboxprasong100% (1)

- JSA For Cutting, Grinding and WeldingDocument4 pagesJSA For Cutting, Grinding and Weldingyc safety100% (3)

- JSA-Manual Lifting of MaterialsDocument3 pagesJSA-Manual Lifting of Materialsfrancis_e_tan75% (4)

- Job Safety Analysis (Jsa)Document11 pagesJob Safety Analysis (Jsa)Noraini Binti Osman50% (2)

- JSA G17 Lift Container With CraneDocument4 pagesJSA G17 Lift Container With CraneYosep Sapto Rahyudi100% (3)

- Column Erection JSA AnalysisDocument6 pagesColumn Erection JSA AnalysisRaghava Richhu100% (2)

- Jsa For TELESCOPING BOOM AERIAL LIFTDocument2 pagesJsa For TELESCOPING BOOM AERIAL LIFTVipul Shankar100% (1)

- Job Steps, Hazards and ControlsDocument4 pagesJob Steps, Hazards and ControlsCristina Rican100% (1)

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDocument15 pagesSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda BukshNo ratings yet

- JSA For Fabrication WorksDocument11 pagesJSA For Fabrication Workssurendra behera100% (3)

- JSA For Material ShiftingDocument3 pagesJSA For Material ShiftingMohammed Minhaj100% (1)

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingDocument4 pagesJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- JSA FORMAT For Materials LoadingDocument2 pagesJSA FORMAT For Materials LoadingVikky KumarNo ratings yet

- TEIPL-JSA-014 Manual Material HandlingDocument2 pagesTEIPL-JSA-014 Manual Material Handlingba ratnaparkhe67% (3)

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7Document4 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7abhijit janaNo ratings yet

- JSA Shut Down and Tie in Work PDFDocument6 pagesJSA Shut Down and Tie in Work PDFpjosesm80% (5)

- JsaDocument106 pagesJsaRoy Dwi PrasetyoNo ratings yet

- JHA-011 (Power Brush & Touch-Up Painting Activities 1)Document1 pageJHA-011 (Power Brush & Touch-Up Painting Activities 1)shaiful annuar50% (2)

- 0017 JS A Hot Job (Welding, Grinding & Cutting)Document4 pages0017 JS A Hot Job (Welding, Grinding & Cutting)Positivesolution100% (2)

- Work at Height Safety AnalysisDocument2 pagesWork at Height Safety AnalysiszebmechNo ratings yet

- SGD SAIPEM CAMP LOADING AND UNLOADINGDocument2 pagesSGD SAIPEM CAMP LOADING AND UNLOADINGsubhanmusadiq82% (55)

- Job Safety Analysis Sheet: FacilityDocument1 pageJob Safety Analysis Sheet: Facilitywahyu nugrohoNo ratings yet

- JSA Excavation PDFDocument6 pagesJSA Excavation PDFmohamedamine.zemouriNo ratings yet

- JSA-020-Safety Watch-Hot WorkDocument2 pagesJSA-020-Safety Watch-Hot WorkNishad MuhammedNo ratings yet

- JSA Cable LayingDocument2 pagesJSA Cable Layingnishanth100% (2)

- Job Safety Analysis: Operating A Metal LatheDocument3 pagesJob Safety Analysis: Operating A Metal LatheSafety DeptNo ratings yet

- JSA Template 2017-05-31 Cable Tray InstallationDocument19 pagesJSA Template 2017-05-31 Cable Tray InstallationJayvee Baradas ValdezNo ratings yet

- 052 Sand BlastingDocument2 pages052 Sand Blastingwilson mantilla100% (1)

- Jsa-Jha For Using of Hand ToolsDocument2 pagesJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- JSA of Drill Machine UseDocument1 pageJSA of Drill Machine UseSumair Khalid100% (1)

- Operating The Man LiftDocument1 pageOperating The Man LiftEllecer anthony Permejo67% (3)

- JSA To Perform Greasing of Motor BearingDocument9 pagesJSA To Perform Greasing of Motor BearingChung Trịnh100% (1)

- Jsa Grinding W Angle GrinderDocument2 pagesJsa Grinding W Angle GrinderMichael Angelo SanteNo ratings yet

- JSA CarpentryDocument2 pagesJSA Carpentrysubhanmusadiq91% (11)

- Tower Crane Installation SOP SummaryDocument3 pagesTower Crane Installation SOP SummaryRashidi RahmanNo ratings yet

- Jsa For Lifting Crane 016Document6 pagesJsa For Lifting Crane 016kiran kumar100% (1)

- Refueling JSA 4 08 2019 Rev.03 Near WaterDocument9 pagesRefueling JSA 4 08 2019 Rev.03 Near Waterrisky indra antariNo ratings yet

- Form JSA Lifting CraneDocument6 pagesForm JSA Lifting CraneYeti Srinurhayati100% (1)

- Jsa For Arc WeldingDocument3 pagesJsa For Arc Weldingtnssbhaskar100% (4)

- JSA - CABLE TERMINATION TITLEDocument4 pagesJSA - CABLE TERMINATION TITLESyed Yousuf Ali100% (1)

- JSA HandToolsDocument2 pagesJSA HandToolsCristina Rican100% (3)

- JSA No. 9 - Safe Use of Pneumatic and Power ToolsDocument2 pagesJSA No. 9 - Safe Use of Pneumatic and Power ToolsAshok Suresh100% (1)

- JSA For Forklift ActivitiesDocument5 pagesJSA For Forklift ActivitiesDedy Kurniawan0% (1)

- SAFE LIFTING WITH SCISSOR LIFTDocument6 pagesSAFE LIFTING WITH SCISSOR LIFTjokerseri100% (3)

- Job Safety Analysis Sheet: Arc Welding, Cutting, GrindingDocument1 pageJob Safety Analysis Sheet: Arc Welding, Cutting, GrindingalekyaNo ratings yet

- JSA Mechanical Activity Risk AssessmentDocument1 pageJSA Mechanical Activity Risk Assessmentjithin shankarNo ratings yet

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDocument16 pagesSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda Buksh60% (5)

- Hard Hat, Safety Glasses, Safety Boots Compulsory: PowerDocument9 pagesHard Hat, Safety Glasses, Safety Boots Compulsory: PowerEbeneshwar Anthony71% (7)

- JSADocument8 pagesJSAr afrianto100% (1)

- JsaDocument39 pagesJsajithin shankar100% (3)

- JSA - SK-erection & DismantlingDocument1 pageJSA - SK-erection & DismantlingEngr Tahir UL Haq100% (3)

- JSA Material HandlingDocument11 pagesJSA Material HandlingGanga Daran100% (3)

- JSA of Loading & Un Loading ActivitiesDocument3 pagesJSA of Loading & Un Loading ActivitiesMohammed Minhaj100% (1)

- Job Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSADocument2 pagesJob Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSAmahammed saleem100% (2)

- HIRA For Work at HeightDocument5 pagesHIRA For Work at HeightMD. Nayyar Mirza100% (1)

- Loading and Unloading Pile Pipes SafelyDocument4 pagesLoading and Unloading Pile Pipes SafelyOsiobe Ewomazino100% (1)

- JSEA - Hydro Test - 2833Document13 pagesJSEA - Hydro Test - 2833Amit Sharma100% (1)

- Renovation and Office Construction Risk AssessmentDocument8 pagesRenovation and Office Construction Risk AssessmentDol29No ratings yet

- New Permit Ptw & Ra.rev New(Iew-Ahp)Document15 pagesNew Permit Ptw & Ra.rev New(Iew-Ahp)Prashant KumarNo ratings yet

- JHA Dryer Hot CommissioningDocument5 pagesJHA Dryer Hot CommissioningJowel MercadoNo ratings yet

- 363-5 Machine Ride Control Actuator - Current Below NormalDocument3 pages363-5 Machine Ride Control Actuator - Current Below NormalArtin HykoNo ratings yet

- Estimate of Cycle Stand Extension Situated at Bhagat Singh College Jaora, Dist. RatlamDocument5 pagesEstimate of Cycle Stand Extension Situated at Bhagat Singh College Jaora, Dist. RatlamaasifahNo ratings yet

- Sourav Roy - Loan IQ AnalystDocument4 pagesSourav Roy - Loan IQ AnalystSourav RoyNo ratings yet

- Ship Stability 5Document31 pagesShip Stability 5jeaneva guiaoNo ratings yet

- The Writer Is A Young Boy Who Is Taken To The Railway Station To See Soldiers Departing For The Second World WarDocument2 pagesThe Writer Is A Young Boy Who Is Taken To The Railway Station To See Soldiers Departing For The Second World WarFariha RahmanNo ratings yet

- Xbox 14260984 Ssc2802 TX 4 A DatasheetDocument5 pagesXbox 14260984 Ssc2802 TX 4 A DatasheetBaye Dame DIOPNo ratings yet

- Euro FirefighterDocument2 pagesEuro FirefighterGustavo VydraNo ratings yet

- Iec61000 4 7 (Ed2.0) en - DDocument8 pagesIec61000 4 7 (Ed2.0) en - Dtwinvbooks100% (1)

- Diagnostic Trouble Code ChartDocument5 pagesDiagnostic Trouble Code ChartGregory AshleyNo ratings yet

- IJCSEIERDFEB20174Document10 pagesIJCSEIERDFEB20174TJPRC PublicationsNo ratings yet

- Ignition Characteristics of Cracked JP-7 FuelDocument4 pagesIgnition Characteristics of Cracked JP-7 Fuelfahrul3xNo ratings yet

- Emulsion BreakerDocument19 pagesEmulsion BreakerNovrie50% (2)

- Manual Erie 541NDocument43 pagesManual Erie 541NrichmondinnNo ratings yet

- Khatib Dissertation FinalDocument193 pagesKhatib Dissertation FinalMonalisa MohantyNo ratings yet

- Limodor: Ventilation According To DIN 18017-3Document16 pagesLimodor: Ventilation According To DIN 18017-3Petar BaricevicNo ratings yet

- Process Control Plan SCM100113Document20 pagesProcess Control Plan SCM100113Rohit MakhijaNo ratings yet

- Kinematics of Machinery ManualDocument29 pagesKinematics of Machinery ManualShubham NaikNo ratings yet

- Advance Diploma For CivilDocument4 pagesAdvance Diploma For CivilAung Naing Latt AungNo ratings yet

- Brochure Ef SchoolDocument2 pagesBrochure Ef SchoolperulapiaNo ratings yet

- Intelligent Traffic Manager - White PaperDocument12 pagesIntelligent Traffic Manager - White Paperharishv_scribdNo ratings yet

- Accuret-A20: Electrical SpecificationsDocument2 pagesAccuret-A20: Electrical SpecificationsClaudio CalabreseNo ratings yet

- VENTILADOR INDUSTRIAL enDocument4 pagesVENTILADOR INDUSTRIAL enFelipe BarrientosNo ratings yet

- Structural Analysis With The Finite Element Method. Linear StaticsDocument1 pageStructural Analysis With The Finite Element Method. Linear StaticsluchogilmourNo ratings yet

- Checklist for Training Cleaning StaffDocument1 pageChecklist for Training Cleaning StaffharrydrivesucrazyNo ratings yet

- Hydraulic Cylinder Seal Kits: Quality With Value GuaranteedDocument16 pagesHydraulic Cylinder Seal Kits: Quality With Value GuaranteedHenry GamboaNo ratings yet

- Machine Tools Questions and Answers - GrindingDocument4 pagesMachine Tools Questions and Answers - GrindingRohit GhulanavarNo ratings yet

- Richard GrisenthwaiteDocument25 pagesRichard GrisenthwaitecaarthiyayiniNo ratings yet

- S5 1-Bedroom Suite FloorplanDocument1 pageS5 1-Bedroom Suite FloorplanAdam HudzNo ratings yet

- Hex Head AVD 780 Installation Manual WEB PDFDocument77 pagesHex Head AVD 780 Installation Manual WEB PDFdasdsaNo ratings yet

- Ansys Fluent 14.0: Getting StartedDocument26 pagesAnsys Fluent 14.0: Getting StartedAoife FitzgeraldNo ratings yet