Professional Documents

Culture Documents

Issue No 17 Strain Hardening Strength PDF

Uploaded by

88No1FanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Issue No 17 Strain Hardening Strength PDF

Uploaded by

88No1FanCopyright:

Available Formats

Issue No.

17 – May 2010 Updated from Original November 2000 Publication

Permanent Deformation

Strain Hardening & Strength

Can be Your Friend – A The August 2000 edition of Technical Tidbits (issue 14) covered the topics of dislocations and plastic

discussion on mechanism strain. It was discussed that all permanent deformation of the metal comes from the movement of

of material strengthening crystalline imperfections known as dislocations through the grains in the metal. This month’s edition will

by permanently examine how strain hardening uses deformation as a method of adding strength to a metal.

deforming materials

through work hardening. Strain hardening is one of the most commonly used means of adding strength to an alloy. It is simply the

use of permanent deformation to increase the strength of the metal. Other names for strain hardening are

cold work and work hardening. No discussion of strain hardening would be complete without mention of

Cold the term “temper”. Temper is a description of the amount and type of processing done to a material at the

Work mill, including cold work and thermal treatments. This is what is meant when an alloy is described as half

hard, full hard, spring temper, etc.

Strain

When a material is permanently deformed, the dislocations move until they are stopped by something else

Hardening in the crystalline lattice. In Issues 14 and 15 of Technical Tidbits it was described how grain boundaries

and alloying elements interfere with the movement of dislocations. However, one of the most effective

Work dislocation stoppers is another dislocation. Where dislocations run on different planes and intersect, they

Hardening cannot pass through each other. The dislocations pile up against each other, and can become intertwined.

This dislocation entanglement prevents any further permanent deformation of that particular grain,

Temper without the use significantly greater energy. This greatly increases the strength of the material under any

subsequent loading.

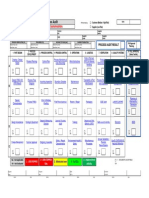

Dislocation Figure 1 shows what theoretically happens during strain hardening. A certain amount of strain

Entanglement (deformation) is put into the material (gray line). When the load is removed, the material returns to a state

of zero stress along a path perpendicular to the elastic loading line (purple squares). When the material is

Annealing reloaded, it follows the same path up to the original stress-strain curve (blue line). However, the material’s

elastic limit has been increased by a certain amount. The new yield strength (green dotted line) is now

Recrystallize substantially higher than the old yield strength (dashed red line). However, the total elongation available

has now diminished. This increase in strength will therefore diminish ductility and formability.

Figure 2 shows the cold rolling process used to increase the temper of strip materials. The strip is passed

between two rollers that exert heavy pressure. The strip is compressed through the gap and becomes much

longer and thinner. The grains in the metal also become elongated. This permanent deformation causes the

dislocations to pile up, which increases the strength of the material. Additionally, the larger grain boundary

area serves as an inhibitor to subsequent dislocations.

30

Stress Strain Curve

20 Normal Loading

Stress

Normal Unloading

The next issue of Reloading

Technical Tidbits will 10 Old Yield Strength

New Yield Strength

focus on thermal

strengthening 0

0 10 Strain 20 30 40

mechanism.

Figure 1. Stress-Strain Curve Figure 2. Representation of Cold Work

with Strain Hardening Illustrated Being Rolled into Copper Alloy Strip

©2010 Brush Wellman Inc.

Strain Hardening and Strength (continued)

The degree of cold reduction determines the strength of a metal. As the percent cold work increases, so

does the strength. Conversely, the total elongation decreases as cold work increases. Figure 3 shows

the relationship between strength, elongation, and cold work for yellow brass. As the percent cold work

increases, there are diminishing returns on strength. This is due to the fact that at higher reductions,

there are fewer free dislocations to become entangled. Also, the elongation (ductility, formability)

decreases rapidly with cold work. Since the material is less able to plastically deform, fracture becomes

much more likely

At high levels of cold work, the material becomes very difficult to further process or form. If it must be

formed, or reduced further in thickness, then annealing becomes necessary. This is a high temperature Please contact your local

soak, which causes the grains to recrystallize. Old grains are obliterated, and new grains, complete sales representative for

further information on

with new dislocations, start to grow. All effects of the prior cold work disappear. This returns the

strain hardening or other

strength and elongation of the material to the starting (no cold work) value. The material is then ready

questions pertaining to

for any further cold work that may be necessary. The final temper of a strain-hardened material is

Brush Wellman or our

actually the amount of cold work applied to it after the final anneal. Annealing must be done at a high

products.

enough temperature and at a long enough time to destroy the old grains. Still, the time must be short

enough and the temperature low enough to prevent new grains from growing too large.

Cold work is one of the most important means of improving the strength of metals. However, a balance

must be struck between the amount of strength imparted to the metal and the amount of ductility lost.

Harder tempers like spring and superspring have high strength and low ductility (bad formability),

whereas softer tempers like annealed and 1/4 hard have low strength and high ductility (very good

formability). When choosing a material for a connector, it is best to use the highest strength material

that still meets the formability requirements of the design.

100

STRENGTH (KSI)

60%

80

ELONGATION

60 40%

Figure 3. Effect of Cold Work

40 YIELD STRENGTH

TENSILE STRENGTH

on Strength and Ductility

% ELONGATION 20%

20

0 0%

0% 10% 20% 30% 40% 50% 60% 70%

% COLD REDUCTION

Figure 4. Growth of New

Grains within old Grains during

Annealing and Recrystallization

Heat Source

Written by Mike Gedeon of Brush Wellman’s Alloy Customer Technical Service Department. Health and Safety

Mr. Gedeon’s primary focus is on electronic strip for the telecommunications and computer Handling copper beryllium in

markets with emphasis on Finite Element Analysis (FEA) and material selection. solid form poses no special

health risk. Like many

industrial materials, beryllium-

containing materials may pose a

health risk if recommended safe

handling practices are not

followed. Inhalation of airborne

beryllium may cause a serious

Brush Wellman Inc. lung disorder in susceptible

individuals. The Occupational

6070 Parkland Blvd. Safety and Health

Mayfield Heights, OH 44124 Administration (OSHA) has set

(216) 486-4200 mandatory limits on

(216) 383-4005 Fax occupational respiratory

exposures. Read and follow the

(800) 375-4205 Technical Service guidance in the Material Safety

Data Sheet (MSDS) before

working with this material. For

additional information on safe

handling practices or technical

data on copper beryllium,

contact Brush Wellman Inc.

©2010 Brush Wellman Inc.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- HR Audit ChecklistDocument4 pagesHR Audit Checklistpielzapa50% (2)

- Pegas Scroll Saw Blade Selection Chart Bear Woods SupplyDocument4 pagesPegas Scroll Saw Blade Selection Chart Bear Woods Supply88No1FanNo ratings yet

- JKR 2012 SITE INVESTIGATION SCHEDULE OF RATESDocument0 pagesJKR 2012 SITE INVESTIGATION SCHEDULE OF RATESAjoy Zulfadhli0% (1)

- The Effects of Abrasives On Electrical Submersible Pumps: Brown L. WilsonDocument5 pagesThe Effects of Abrasives On Electrical Submersible Pumps: Brown L. WilsonAnonymous VNu3ODGavNo ratings yet

- EN1886Document4 pagesEN1886ramesh100% (1)

- Clause Applicability Matrix R5 - 5 HandbookDocument14 pagesClause Applicability Matrix R5 - 5 Handbook88No1FanNo ratings yet

- TS/IATF16949 Certification Guide in 40 StepsDocument5 pagesTS/IATF16949 Certification Guide in 40 Steps88No1FanNo ratings yet

- Process AuditDocument15 pagesProcess Auditdesurkarb100% (2)

- TS/IATF16949 Certification Guide in 40 StepsDocument5 pagesTS/IATF16949 Certification Guide in 40 Steps88No1FanNo ratings yet

- 2016 QMS Docs Procs Forms MatrixDocument1 page2016 QMS Docs Procs Forms Matrix88No1FanNo ratings yet

- MPI Reference Guide 2011Document20 pagesMPI Reference Guide 2011Telo VendoNo ratings yet

- Go digital with safety checklistsDocument84 pagesGo digital with safety checklists88No1FanNo ratings yet

- Shainin AmeliorDocument40 pagesShainin AmeliorOsman Tig100% (1)

- Supplier Audit ChecklistDocument28 pagesSupplier Audit Checklist88No1FanNo ratings yet

- International Material Grade Comparison TableDocument9 pagesInternational Material Grade Comparison Tablenyamuk06100% (4)

- Shainin AmeliorDocument40 pagesShainin AmeliorOsman Tig100% (1)

- 1 Introduction To Nondestructive TestingDocument36 pages1 Introduction To Nondestructive TestingPedro AscanioNo ratings yet

- 8D Problem Solving GuideDocument51 pages8D Problem Solving Guide88No1Fan100% (1)

- MPI Reference Guide 2011Document20 pagesMPI Reference Guide 2011Telo VendoNo ratings yet

- MPI Reference Guide 2011Document20 pagesMPI Reference Guide 2011Telo VendoNo ratings yet

- 15-Inch Planer-Molder: Operating Instructions and Parts ManualDocument40 pages15-Inch Planer-Molder: Operating Instructions and Parts Manual88No1FanNo ratings yet

- International Material Grade Comparison TableDocument9 pagesInternational Material Grade Comparison Tablenyamuk06100% (4)

- Work Method Tips PDFDocument32 pagesWork Method Tips PDF88No1Fan100% (1)

- PDFDocument4 pagesPDF88No1FanNo ratings yet

- D4U Ch17 PDFDocument10 pagesD4U Ch17 PDF88No1FanNo ratings yet

- D4 Leigh Dovetail Jig CH14Document18 pagesD4 Leigh Dovetail Jig CH1488No1FanNo ratings yet

- 15-Inch Planer-Molder: Operating Instructions and Parts ManualDocument40 pages15-Inch Planer-Molder: Operating Instructions and Parts Manual88No1FanNo ratings yet

- D4U Ch17 PDFDocument10 pagesD4U Ch17 PDF88No1FanNo ratings yet

- D4 Leigh Dovetail Jig CH10Document14 pagesD4 Leigh Dovetail Jig CH1088No1FanNo ratings yet

- D4 Leigh Dovetail Jig CH16Document4 pagesD4 Leigh Dovetail Jig CH1688No1FanNo ratings yet

- D4 Leigh Dovetail Jig CH16Document4 pagesD4 Leigh Dovetail Jig CH1688No1FanNo ratings yet

- D4 Leigh Dovetail Jig CH11Document6 pagesD4 Leigh Dovetail Jig CH1188No1FanNo ratings yet

- D4 Leigh Dovetail Jig CH10Document14 pagesD4 Leigh Dovetail Jig CH1088No1FanNo ratings yet

- How To Size A Room Air Conditioner PDFDocument3 pagesHow To Size A Room Air Conditioner PDFKo PaukNo ratings yet

- Elbows Couplings and Nipples BrochureDocument8 pagesElbows Couplings and Nipples BrochurekimiesmithNo ratings yet

- 9.9 Diaphragms-With-Interior-Shearwalls PDFDocument4 pages9.9 Diaphragms-With-Interior-Shearwalls PDFnickNo ratings yet

- 2.hisense VRF-Key Features - Installation ReferencesDocument84 pages2.hisense VRF-Key Features - Installation ReferencesridNo ratings yet

- PDF Standard Construction Productivity Norms ManpowerDocument1 pagePDF Standard Construction Productivity Norms ManpowereldredvongaringNo ratings yet

- AlcoTec Alloy Filler ChartDocument1 pageAlcoTec Alloy Filler CharttxspacecadetNo ratings yet

- 12.0 Moment and Shear Coefficient For Solid Slab: L Effective Span F Total Ultimate Load 1.35gDocument1 page12.0 Moment and Shear Coefficient For Solid Slab: L Effective Span F Total Ultimate Load 1.35gKumaresvaranNo ratings yet

- CR Content in Alloy Steel and Phosphate CoatingsDocument8 pagesCR Content in Alloy Steel and Phosphate Coatingsgacm98No ratings yet

- Rupture DiscDocument2 pagesRupture Discbigs1303No ratings yet

- 5 6052876558186578075Document38 pages5 6052876558186578075NISHIKANTA MONDALNo ratings yet

- DATA BOOK FOR CONSTRUCTION PROJECTSDocument66 pagesDATA BOOK FOR CONSTRUCTION PROJECTSvishnukesavieam10% (1)

- Sm-Etabs GuideDocument5 pagesSm-Etabs GuidetaroNo ratings yet

- Section 1: Conventional Blast Pots and SparesDocument10 pagesSection 1: Conventional Blast Pots and SparesIgor NhamanoNo ratings yet

- Routsis Injection Molding ReferenceDocument176 pagesRoutsis Injection Molding ReferenceRupesh PillaiNo ratings yet

- Princesa Bridge Narrative ReportDocument9 pagesPrincesa Bridge Narrative ReportRodelo OngNo ratings yet

- Overtime AccomplishmentDocument9 pagesOvertime AccomplishmentKate PerezNo ratings yet

- Philips Lighting 1Document45 pagesPhilips Lighting 1Manisankar DhabalNo ratings yet

- Schletter Product Component ListDocument39 pagesSchletter Product Component ListKirsten HernandezNo ratings yet

- Styrolution TDS400900481370Document3 pagesStyrolution TDS400900481370joshNo ratings yet

- Descriptive Analysis of Advantages and Disadvantages of Expanded Polystyrene Monolytic Panels - EPSDocument11 pagesDescriptive Analysis of Advantages and Disadvantages of Expanded Polystyrene Monolytic Panels - EPSWilson Bryan RegaladoNo ratings yet

- Rheolate® 212 - ElementisDocument2 pagesRheolate® 212 - ElementisHiba NaserNo ratings yet

- Ampt - Advanced Materials Processing TechniquesDocument26 pagesAmpt - Advanced Materials Processing TechniquesIshaan ThakerNo ratings yet

- U DiesDocument1 pageU DiesadrianNo ratings yet

- PR-3Document1 pagePR-3Fernanda QuelNo ratings yet

- 13 Concrete Repairs 4CDocument17 pages13 Concrete Repairs 4CMina SaflorNo ratings yet

- Jurnal Skripsi JulDocument22 pagesJurnal Skripsi JulGogelNo ratings yet

- Housekeeping ScheduleDocument2 pagesHousekeeping ScheduleZeyya Nikka Cordova Pingad100% (1)