Professional Documents

Culture Documents

Weld Symbol

Uploaded by

blithevincentCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Weld Symbol

Uploaded by

blithevincentCopyright:

Available Formats

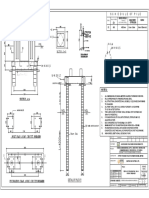

GENERAL NOTES: WELDED STEEL FABRIC NOTES: VERTICAL STIFFENER & LINTEL BEAM DETAILS

CONCRETE NOTES: 01 sheet of 08

1) STANDARD L BEND FOR BRICKWALLS:

Unless otherwise stated the following specifications shall apply to all structural works 1. All concrete workmanship and materials shall be in accordance with SS CP 65. 17. Provision of openings through structures 150 150

BUILDING AND CONSTRUCTION AUTHORITY

200

in this contract. 2. All sizes of concrete elements do not include the thickness of applied finishes. (a) All openings through slabs shall be tapered at the sides if concrete infill is 1. Vertical R C stiffeners, horizontal beams and R C lintel beams shall be

1. All drawings/details are to be read in conjunction with the architectural drawings and 3. Beam width is written first followed by the depth (eg.: 200x600) and includes the required. Openings without concrete infill need not be tapered. T13 trimming bars

provided for all brickwalls in accordance to the table below: APPROVED UNDER SECTION 5/SECTION 5A OF THE

slab thickness. shall be provided all round as shown thus : BUILDING CONTROL ACT (CAP 29)

200

200

other consultant drawings and with such other instructions that might be issued

A layer of minimum 50 mm thick lean concrete (concrete grade 15) shall be laid 150

during the course of the contract. Discrepancies (if any) are to be reported to the 4. 25 25

Architect/Engineer for clarification before proceeding further. directly below the base of all structures in contact with the ground unless Project Ref No : A1193-01034-2017-ST01

otherwise shown.

2. Lot boundary lines and main building gridlines are to be set out by a Licensed

5. Material Strength 2) STANDARD LAP

Surveyor and submitted to the Architect/Engineer for approval before commencing 2

(a) Concrete used shall be of Grade 35 with a minimum crushing strength of 35 N/mm

piling/building works. The Contractor must also check and verify all dimensions

at 28 days unless otherwise specified. For entrance culvert & entrance approach slab,

and levels before commencement of works.

use Grade 40 concrete with a minimum crushing strength of 40 N/mm 2 at 28 days. 450 50 50 450

3. The Contractor shall incorporate all M & E works in accordance with the approved For pilecaps, footings, stumps, r.c. retaining walls, ground beams, ground slabs,

M & E drawings. Approval from the Structural Engineer must be obtained where non-suspended slabs, covered drain, slab over drain, cut-off drain & compound drain,

embedment of these works in the reinfored concrete structure or provisions of use Grade 35 concrete with a minimum crushing strength of 35 N/mm 2at 28 days. 450

openings through structure is required. (b) Steel reinforcement denoted by bar symbol 'R' shall be of mild steel plain bar

4. The Contractor shall allow and conduct all the construction tests as precribed complying with SS2. (Characteristic Strength = 250 N/mm 2)

in the Building Control Regulations 1989. Such tests must be carried out by an (c) Steel reinforcement denoted by bar symbol 'T' shall be of high yield deformed bars ..............................................................

Slab Bottom Steel/Walls and Others Slab Top Steel Over Beam only

accredited laboratory. complying with SS2. (Characteristic Strength = 460 N/mm 2) For Commissioner Of Building Control

450

5. Only drawings labelled with the stamp "FOR CONSTRUCTION" are to be used

Note: The number in front of the the bar symbol denotes the number of pieces of 3) SINGLE-BEND FABRIC AT SLAB

that bar and the number following the bar symbol denotes the nominal bar

for construction. The Contractor shall also ensure that the latest revised drawing

diameter in millimeters (eg. 2T20 denotes 2 nos. of 20 mm. diameter

issued to him is used for construction should there be any revision.

high yield deformed bars).

6. The Engineer's drawings are not to be scaled. Only marked dimensions are to be used.

(d) Welded Steel Fabric complying with SS32.

Any discrepancy should be reported to the Engineer before proceeding further.

6. Concrete cover to main reinforcement shall be :

7. All dimensions are in millimeters unless otherwise stated. (a) Slab Top : 25mm PE'S ENDORSEMENT:

8. The Contractor shall be responsible for maintaining the structure during construction Bottom : 25mm (35mm for 1st storey)

in a stable condition and for ensuring that no part shall be overstressed under (b) Beam Top : 30mm (40mm for 1st storey) Appendix B : STANDARD CERTIFICATION BY THE

construction activities. Bottom : 30mm (40mm for 1st storey) QUALIFIED PERSON FOR STRUCTURAL WORKS

Sides : 30mm (40mm for 1st storey)

9. The Contractor shall advise the Engineer when reinforcement is ready for inspection. 1). In accordance with Regulation 9 of the Building Control Regulations,

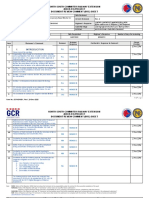

(c) Wall : 25mm Plan of Top Reinforcement at Slab Isometric View I, MOHAMAD AYUB HASSAN, the Qualified Person for structural works

Adequate notice shall be given to enable inspection to be carried out before concreting.

(d) Column : 35mm appointed under section 8 (1)(a) or 11(1)(d)(i) of the Building Control Act,

10. For strengthening of existing structural elements, the concrete cover of existing structural (e) Parapet : 25mm

(b) All openings through beams are to be trimmed with T13 bars as shown below. 4) DOUBLE-BEND FABRIC AT SLAB

hereby submit the detailed structural plans and design calculations prepared

elements must be scrabbled to expose the existing reinforcements and must apply any unless otherwise indicated in the beams details. The Contractor shall check

(f) Canopy : 25mm by me and certify that they have been prepared in accordance with the

approved bonding agent for the proper bonding of existing and new concrete. The and ensure accuracy in the alignment, size and shape of all openings and 2. Unless otherwise shown in drawings, the typical lintol details as shown below

(g) Pilecap Top : 75mm provisions of the Building Control Regulations, the Building Control Act and

contractor shall avoid damaging the existing main reinforcements. Sides : 75mm

recesses. No opening shall be formed without prior approval from the engineer. shall apply to all brickwall door openings construction. any other written law pertaining to buildings and construction for the time

being in force.

Bottom : 50mm (FROM CUT-OFF LEVEL)

STRUCTURAL STEEL NOTES: (h) Footing Base Top

Sides

: 50mm

: 50mm

2).I further certify that these detailed structural plans and design calculations

are in reference to Project Reference No: A1193-01034-2017-ST01

Bottom : 50mm 3). Total number of structural plans submitted: 08

1. All structural steel shall be compliance to BC1:2012.

(i) Earth Retaining Wall Top : 50mm and total number of pages of design calculations in this book: 72

300 min.

2. Grade S275 hot rolled steel sections shall be used for all structural steel members. Sides : 50mm

The quality and strength of all members, joint connections, bolts, nuts, washers, welds Bottom : 50mm Appendix D : STANDARD CERTIFICATION BY THE PROFESSIONAL

(j) Water Retaining Structures 40mm for faces in contact with water Plan of Top Reinforcement at Slab Isometric View ENGINEER FOR WORKS INVOLVING ADDITIONS AND ALTERATIONS

and electrodes and their applications shall be in accordance with relevant British

Standards. All defective, sub-standard or undersized members and connections 30mm for faces not in contact with water OPENING

shall be rejected. 50mm for faces in contact with ground & 5) ANCHORAGE LENGTH I, MOHAMAD AYUB HASSAN , hereby certify that I have inspected the existing building and

7. Reinforcements are represented diagrammatically and not necessarily shown in 500 COVER 500 BEAM SECTION investigated its overall structure and that, in my opinion, the building is capable of resisting the

3. All welding shall be carried out in accordance with the weld symbols shown in the forces and moments which may be increased or altered by reason of the repairs, alterations or

true projection. additions shown in the building plans.

drawings and conform with BS5950 Part 1: 2000. For unspecified welding, butt weld

8. All splices in reinforcement shall be made only in the positions shown or as

BEAM ELEVATION

shall be full penetration weld with size equal to the thickness of the members to be 3. Refer to Architectural drawings for location of all brickwalls.

otherwise approved by the Engineer. 18. All vertical and horizontal construction joints in basement slab and wall to be

butt-joined, fillet weld shall be 6mm weld, all round the member. If the quality of

welding is in doubt, the Contractor shall undertake to conduct testing to the satisfaction 9. Welding of reinforcement shall not be permitted without the approval of the Engineer. provided with approved waterstop. All such construction joints to be pressure

of the Engineer. 10. All reinforcements shall be supported in its correct position so as not to be displaced grouted by specialist irrespective of whether they leaked or not. 3500 MAX. I ON

AL EN

during concreting on approved bar chairs at 1000 mm maximum centres. S G

4. All structural bolts shall be shown prefixed with the letter 'M' for metric series and S

FE

IN

11. Construction joints shall be properly formed and used only where shown or

shall conform with the following British Standards :

P RO

EE

specifically approved by the Engineer.

CIVIL

R

Type of Bolt Abbreviation Standards 12. Spacer bars required to separate the layers of main reinforcements in beams

3500 MAX.

Black Bolt BB BS 4190

and foundations shall be of T25 bars with spacing between 750mm min and Main-wires Cross-wires MOHAMAD AYUB HASSAN

High Strength Bolt HS BS 3692 1500mm max. 2722

High Strength Friction HSFG BS 4604 13. All R.C. kerbs are to be cast together with the beam/slab in one operation.

Grip Bolt 14. All reinforcements/dowel bars left exposed for a period of time are to be coated 250 SI N E 05-03-2018

G AP OR

with cement grout to prevent rusting. The cement grout must be removed before Date

Hilti Anchor Bolts Varies Manufacturer's Specifications

concreting. B

5. Bearing surface shall be planed to true bed and abutting surfaces be closely fitted Qualified Person for Structural Works

15. All beams exceeding 10m long and slab panels exceeding 4.5m span in the shorter

125

to ensure full bearing and close contact between assembled members. Holes for Signature and Stamp

bolts shall be shop-drilled with size 1.5mm larger than the external diameter of direction shall be adequately propped after the removal of formwoks. The props

the bolts and shall not be subsequently tampered with. are to be remained for 28 days from the day of casting unless with the approval

of the Engineer. B

SWIMMING POOL WALL AND SLAB

A-A

6. Steel members to be encased in concrete, connecting surfaces using HSFG bolts

16. No holes, chases or embedment of pipes other than those shown in the structural BASEMENT WALL AND SLAB

3500 MAX.

and areas to be welded shall be free from scale, dust, grease and paint. All

drawings shall be made in the concrete members without prior approval by the Engineer. (EJECTOR PIT, SPRINKLER TANK-SIMILAR)

steel area to be painted shall be primed with a coat of red lead oxide or zinc

chromate. 19. All fresh concrete shall be satisfactorily cured and protected by approved means A A 125

7 Paint Primer from the rain, sun and drying wind to maintain suitable temperature and moisture.

TYPICAL DETAILS ALONG SLAB W/ DROP

After preparation by wire brushing or blasting, one coat of approved inorganic

Zinc Primer 'DNT' Nitto Zettar OL HB or approved equivalent at 75 microns DFT 52Ø BAR

shall be applied before erection. (TENSION LAP)

REV DATE AMENDMENT

8. Undercoat and Finish Coat

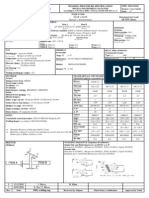

WELD SYMBOLS AND ILLUSTRATIONS ULTIMATE ANCHORAGE & LAP LENGTH

300

After priming the steel and making due allowance for the minimum overcoating

period, one undercoat of approved Epoxy Micaceous Iron Oxide Intermediate paint

Weld

FOR PLAIN & DEFORMED BARS CLIENT

Illustration (The number

'DNT' Eponics -20T at 75 microns DFT per coat or approved equivalent and Type of Weld Sketch Symbol indicates weld size in mm) (For Grade 30 Concrete)

finished with one top coat of approved Epoxy paint 'DNT' Eponics -20T at 75 MUHAMMADIYAH ASSOCIATION

microns DFT per coat or approved equivalent after installation to its final position. 14 Jalan Selamat

This shall apply to all steel members inside buildings. For steel members directly FOR BRICKWALLS OVER 3.50 m. HIGH

Singapore 418534

exposed to weather, 2 coats of approved Acrylated Polyol/Polyisocyanate Resin

paint 'DNT' V-Top # 188 at 40 microns DFT per coat shall be applied after the

TYPICAL REINFORCEMENT ARRANGEMENTS 3500 MAX. B-B

undercoats. All paint colour for finish coat are to be consistent and approved

Fillet IN DROP BEAMS CONTRACTOR

by the Architect. 150

52Ø

9. 5 % of all the total welded joints shall be tested with Non-Destructive Testing (NDT)

(TENSION LAP)

methods such as Magnetic Particle Testing (MT), Penetrant Testing (PT),

125

Radiographic Testing (RT), Ultrasonic Testing (UT) or any other approved methods.

3500 MAX.

TIMBER NOTES:

Square Butt C C C-C

1. All timber shall be Keruing (Standard Grade) or equivalent.

ARCHITECT

TYPICAL CRANKED BAR IN BEAM STANDARD VERTICAL

FOUNDATION NOTES: Single V Butt Note: STIFFENER DETAILS

Where bars of different sizes lap each other, the lap length shall,

1. ALL THE FOUNDATIONS ARE AT BASEMENT LEVEL

unless otherwise shown, be based on the smaller size bar.

2. ALLOWABLE SOIL BEARING PRESSURE = 100 kN/m² Double V Butt

3. 1 NO. OF PLATE LOAD TEST TO BE CONDUCTED TO 3 TIMES SOIL BEARING PRESSURE

450 min.

AT BASEMENT LEVEL. FOR BRICKWALLS UP TO 3.50 m. HIGH

Single Bevel

WELDED STEEL FABRIC PROPERTIES Butt

600

(COMPLYING WITH SS32) PROJECT

Double Bevel

Butt

PROPOSED ADDITIONS AND ALTERATIONS TO

TYPICAL SLAB DETAIL EXISTING 2-STOREY ASSOCIATION BUILDING

250

Edge WITH ATTIC

UNDER BRICKWALL

(COMPRESSION LAP)

Seal

300

SMALLER BAR

37Ø

DROP

DRAWING DESCRIPTION

600

100

BEAM DEPTH

Weld All TYPICAL BOUNDARY WALL GENERAL NOTES

Round

BASE DETAIL

Date: 05-03-2018 Scale: AS SHOWN

BRICKWALL WIDTH Drawn: TALIM Designed: ENGINEER Checked: ENGINEER

Weld on Site

BEAM WIDTH

No. 672A KLANG LANE #01-97

TYPICAL PERIMETER BEAM DETAIL Singapore 211672

TYPICAL COLUMN/WALL BAR SPLICE &

UNDER BRICKWALL WITH DROP Tel : 62924804 Fax : 62934401

ANCHORAGE LENGTHS Hp : 91808938 Email : pe@mahaconsultants.com.sg

Drawing No: MAHA-14JS-S01 Rev. No: 00

14JS-ST02-DWG.dwg

You might also like

- Bolt AnchorageDocument6 pagesBolt AnchoragesdewssNo ratings yet

- Saudi Aramco Oil Company: SECTION 05520 Handrails Railings & Bollard Part 1 GeneralDocument12 pagesSaudi Aramco Oil Company: SECTION 05520 Handrails Railings & Bollard Part 1 GeneralAbid HussainNo ratings yet

- Welding & NDE Summary Sheet (BE)Document12 pagesWelding & NDE Summary Sheet (BE)MulPXNo ratings yet

- QCS 2014 - Section 2, Part 14 Appendix ADocument1 pageQCS 2014 - Section 2, Part 14 Appendix AJenna Mortel-DoligolNo ratings yet

- SMARTIA M8200 Glass RailingsDocument15 pagesSMARTIA M8200 Glass RailingsFragkioudakis Michael0% (1)

- S AA GEN CDF (Civ Design Fundamental) (Rev.0 2009)Document17 pagesS AA GEN CDF (Civ Design Fundamental) (Rev.0 2009)Mohammad Al JedyNo ratings yet

- Commerical Stair and Handrail Guard Requirements Compressed PDFDocument4 pagesCommerical Stair and Handrail Guard Requirements Compressed PDFMohd parvezNo ratings yet

- Ut Report-1 PDFDocument1 pageUt Report-1 PDFsureshrathod2No ratings yet

- Side Reinforcement in BeamsDocument1 pageSide Reinforcement in Beams11 Sqn RERNo ratings yet

- Welder Qualification ReportDocument2 pagesWelder Qualification ReportSyed Mahmud Habibur RahmanNo ratings yet

- Burj Al Baher Curtain Wall SpecsDocument73 pagesBurj Al Baher Curtain Wall SpecsmcbluedNo ratings yet

- KSS Candidate Screening Sheet: Kindly Attach Updated Personal PhotoDocument2 pagesKSS Candidate Screening Sheet: Kindly Attach Updated Personal PhotoMohamed Osama El GendiNo ratings yet

- Profis Anchor Design for KWIK HUS-EZ AnchorDocument6 pagesProfis Anchor Design for KWIK HUS-EZ AnchorJester AbucayNo ratings yet

- A1-40 Metal CladdingDocument16 pagesA1-40 Metal Claddinglwin_oo2435No ratings yet

- CIRIA Restraint WallDocument5 pagesCIRIA Restraint WallMajdoline SadeddineNo ratings yet

- Standards and Tolerances GuideDocument74 pagesStandards and Tolerances GuideJoseph Cloyd L. LamberteNo ratings yet

- AB 036090 001 Joints For Cement Lined Pipe PDFDocument1 pageAB 036090 001 Joints For Cement Lined Pipe PDFfdfazfzNo ratings yet

- 2022-03-24 ITP For Fabrication and Erection of StructuralDocument7 pages2022-03-24 ITP For Fabrication and Erection of StructuraljaymarNo ratings yet

- 06.17 Roadworks - Road DrainageDocument12 pages06.17 Roadworks - Road DrainageKishanshettyNo ratings yet

- ACI 207.3R - Practices in Evaluation of Existing Massive Concrete Structures (1994)Document16 pagesACI 207.3R - Practices in Evaluation of Existing Massive Concrete Structures (1994)tariqkhanNo ratings yet

- Status of Manufacturing RecordsDocument64 pagesStatus of Manufacturing RecordsNicolaus Yana OctoraNo ratings yet

- Structural DrawingsDocument28 pagesStructural DrawingsJason Cuison100% (1)

- WPS 856110.016 Rev 3Document1 pageWPS 856110.016 Rev 3laz_kNo ratings yet

- Welding Qualification As Per AWS D1.1Document19 pagesWelding Qualification As Per AWS D1.1Ouni AchrefNo ratings yet

- BS EN 288-2:1992 Welding Procedure SpecificationDocument12 pagesBS EN 288-2:1992 Welding Procedure SpecificationCocaCodaNo ratings yet

- BC3 2013Document27 pagesBC3 2013hutuguoNo ratings yet

- Non-Conformance Report: DescriptionDocument8 pagesNon-Conformance Report: DescriptionHirushan MenukaNo ratings yet

- FRP Lighting PolesDocument16 pagesFRP Lighting PolesManish VaghelaNo ratings yet

- Dr. N V Nayak: Engineering Innovations in Concrete and Pile FoundationsDocument39 pagesDr. N V Nayak: Engineering Innovations in Concrete and Pile FoundationsGautam PaulNo ratings yet

- A Simple Guide On How To Become A Registered Engineer in NigeriaDocument4 pagesA Simple Guide On How To Become A Registered Engineer in NigeriaOLUWASEUN QUADRINo ratings yet

- Three Standards : Workshop 4 March 2010 Hong KongDocument5 pagesThree Standards : Workshop 4 March 2010 Hong Konginigo38No ratings yet

- DrawingDocument1 pageDrawingahmedNo ratings yet

- Difference between bending and bucklingDocument8 pagesDifference between bending and bucklingPacha Khan KhogyaniNo ratings yet

- Qms Form Arch & Civil ChecklistDocument32 pagesQms Form Arch & Civil ChecklistMatt CerosNo ratings yet

- 16 B 2 Lec 18Document1 page16 B 2 Lec 18Jade Marielle DugeniaNo ratings yet

- Schedule of pile depth and reinforcement detailsDocument1 pageSchedule of pile depth and reinforcement detailsManas MondalNo ratings yet

- North South Commuter Railway Extension (Nscr-Ex) Project Document Review Comment (DRC) SheetDocument3 pagesNorth South Commuter Railway Extension (Nscr-Ex) Project Document Review Comment (DRC) SheetJohnny ManaidNo ratings yet

- Handrail Coring Check (Calculation)Document56 pagesHandrail Coring Check (Calculation)Rey GonzalesNo ratings yet

- Aisc 207-16 Audit Guide All Fabricator and Manufacturer Programs and EndorsementsDocument20 pagesAisc 207-16 Audit Guide All Fabricator and Manufacturer Programs and EndorsementsScott NorrisNo ratings yet

- Unicare Profile ComboDocument44 pagesUnicare Profile CombosaliqNo ratings yet

- Walkdown & Punch PointsDocument23 pagesWalkdown & Punch PointsshijomonthomasNo ratings yet

- AcceptanceCriteriaforPrecastStoneVeneer Ac51 PDFDocument5 pagesAcceptanceCriteriaforPrecastStoneVeneer Ac51 PDFjaykmseNo ratings yet

- Nitoseal 777 PDFDocument4 pagesNitoseal 777 PDFmilanbrasinaNo ratings yet

- MasterSeal 550Document2 pagesMasterSeal 550Muhammad Abdul Wajid RaiNo ratings yet

- Industries: The Manila'S Expert EngineersDocument12 pagesIndustries: The Manila'S Expert EngineersJohn Carlos Moralidad CriticaNo ratings yet

- I-963 Welder Certificate Smaw-Gtaw-1Document1 pageI-963 Welder Certificate Smaw-Gtaw-1nivedithdigitals onlineservices100% (1)

- Eslon: SCH80 PVC & CPVC Piping Systems Specifications & Engineering ManualDocument112 pagesEslon: SCH80 PVC & CPVC Piping Systems Specifications & Engineering ManualseksonNo ratings yet

- One Stop Solution For Streetlight Poles ....Document20 pagesOne Stop Solution For Streetlight Poles ....Sambit MohapatraNo ratings yet

- Template Quality Assurance Inspection and Test PlanDocument2 pagesTemplate Quality Assurance Inspection and Test PlanSiva Naga Prasad TadipartiNo ratings yet

- Open web girder erection planDocument1 pageOpen web girder erection planyogendraNo ratings yet

- D1 - 1 2020 - Structural Welding Code-Steel-02Document1 pageD1 - 1 2020 - Structural Welding Code-Steel-02Trung NguyenNo ratings yet

- Earthworks Specification for Ain Tsila Gas DevelopmentDocument30 pagesEarthworks Specification for Ain Tsila Gas DevelopmentZaidiNo ratings yet

- Method Statement For General Door-Window Fitting-ReplacementDocument12 pagesMethod Statement For General Door-Window Fitting-ReplacementAhmed saberNo ratings yet

- DWST-MTHL-QP014 BoltTighteningProcedureDocument11 pagesDWST-MTHL-QP014 BoltTighteningProcedureDeepak Upadhayay0% (1)

- MEP Connection For Seismic ZoneDocument217 pagesMEP Connection For Seismic Zonesyed AffanNo ratings yet

- Itp GRPDocument4 pagesItp GRPJo FrancescNo ratings yet

- Wind LoadDocument5 pagesWind LoadPATEL JIGARNo ratings yet

- S-1 General NotesDocument1 pageS-1 General NotesEngr. Robnick PaduaNo ratings yet

- Hathoda Industrial STR - 34ft 0Document1 pageHathoda Industrial STR - 34ft 0Manoj AjudiaNo ratings yet

- Floor Layout PlanDocument1 pageFloor Layout PlanDereck W MarieNo ratings yet

- 055 - 2021-Circular On Spe (Tunnelling) For Lta Tunnelling ProjectsDocument10 pages055 - 2021-Circular On Spe (Tunnelling) For Lta Tunnelling ProjectsblithevincentNo ratings yet

- See Distribution List: Downloaded From CORENETDocument7 pagesSee Distribution List: Downloaded From CORENETblithevincentNo ratings yet

- Chloride Resistance of Concrete: Factors and TestsDocument37 pagesChloride Resistance of Concrete: Factors and TestsCarlos Augusto Sánchez Rondón100% (1)

- On-Site Stormwater Detention Tank SystemsDocument80 pagesOn-Site Stormwater Detention Tank SystemsL YO Pin100% (1)

- Bca Understanding The Approved Document Sections C To P v10Document102 pagesBca Understanding The Approved Document Sections C To P v10blithevincentNo ratings yet

- Framework On Observational Method PDFDocument23 pagesFramework On Observational Method PDFblithevincentNo ratings yet

- LTA Changes To Ltas Car Parking Standards and Gazetting of Designated Car Lite PrecinctsDocument29 pagesLTA Changes To Ltas Car Parking Standards and Gazetting of Designated Car Lite PrecinctsblithevincentNo ratings yet

- Revised Green Mark Criteria and Amendments To Enviornmental Sustainability MeasuresDocument7 pagesRevised Green Mark Criteria and Amendments To Enviornmental Sustainability MeasuresblithevincentNo ratings yet

- Guidelines Rock IdentificationDocument17 pagesGuidelines Rock IdentificationLordM00n100% (2)

- Code of Practice ON Surface Water Drainage: Seventh Edition - Dec 2018Document66 pagesCode of Practice ON Surface Water Drainage: Seventh Edition - Dec 2018blithevincentNo ratings yet

- Guideline On Reuse of Existing PilesDocument9 pagesGuideline On Reuse of Existing PilesblithevincentNo ratings yet

- On-Site Stormwater Detention Tank SystemsDocument80 pagesOn-Site Stormwater Detention Tank SystemsL YO Pin100% (1)

- Uality EE Ethod: For Procurement of Accredited Checking (AC) ServicesDocument14 pagesUality EE Ethod: For Procurement of Accredited Checking (AC) ServicesblithevincentNo ratings yet

- Circular On Extension of QFM To Procurement For AC ServicesDocument2 pagesCircular On Extension of QFM To Procurement For AC ServicesblithevincentNo ratings yet

- Car Cost UpdateDocument11 pagesCar Cost UpdateblithevincentNo ratings yet

- 06-02-27 Load Testing Handbook (2006)Document29 pages06-02-27 Load Testing Handbook (2006)JeerawatNo ratings yet

- c8-10 Structural TimberworkDocument20 pagesc8-10 Structural TimberworkblithevincentNo ratings yet

- Pile Capacity - Calculation MethodsDocument11 pagesPile Capacity - Calculation Methodsblithevincent100% (1)

- Cross Laminated Timber - CLT - A Breakthrough in Smart ConstructionDocument53 pagesCross Laminated Timber - CLT - A Breakthrough in Smart ConstructionblithevincentNo ratings yet

- Fiber Reinforced Shotcrete For Tunnel LiningsDocument14 pagesFiber Reinforced Shotcrete For Tunnel Liningsblithevincent0% (1)

- Tale of 2 Deep Singapore Basements and How 3D Modeling Led To A Leaner Design and Keener Construction Programme - EiSandaDocument13 pagesTale of 2 Deep Singapore Basements and How 3D Modeling Led To A Leaner Design and Keener Construction Programme - EiSandablithevincentNo ratings yet

- Circular On Deadlines For Mandatory Bim e SubmissionDocument6 pagesCircular On Deadlines For Mandatory Bim e SubmissionblithevincentNo ratings yet

- Design Guide On Use of High Strength ConcreteDocument105 pagesDesign Guide On Use of High Strength ConcreteM HAFEEZ RAJANo ratings yet

- Module 7 - Slope StabilityDocument176 pagesModule 7 - Slope Stabilityblithevincent50% (2)

- COP On Buildability 2013Document64 pagesCOP On Buildability 2013blithevincentNo ratings yet

- BC1 2008 Design Guide On Use of Structural SteelDocument89 pagesBC1 2008 Design Guide On Use of Structural SteelfongheeNo ratings yet

- South Beach Development-IstructE Conference Singapore 2012Document20 pagesSouth Beach Development-IstructE Conference Singapore 2012blithevincentNo ratings yet

- NASSPA Retaining Wall Comparison Technical Report 2009Document90 pagesNASSPA Retaining Wall Comparison Technical Report 2009Russ PopeNo ratings yet

- HRSG Erection GuideDocument56 pagesHRSG Erection GuideUtku Kepcen50% (2)

- Cost Estimate and Unit Rate Analysis For Building ProjectDocument57 pagesCost Estimate and Unit Rate Analysis For Building ProjectKinfe Dufera Gonfa80% (10)

- Common Errors in Truss DesignDocument15 pagesCommon Errors in Truss DesignMilton Alexander Rivera TorresNo ratings yet

- CE 241 - 01 Composite BeamsDocument91 pagesCE 241 - 01 Composite BeamsSwarna RkNo ratings yet

- Preliminary design Rules of thumb for reinforced concrete structuresDocument6 pagesPreliminary design Rules of thumb for reinforced concrete structuresOyens EstoyeNo ratings yet

- CRCM Manual 2 9 16Document33 pagesCRCM Manual 2 9 16سجى وليدNo ratings yet

- BS-123 2017 Guidelines For Checking Suitability of Existing Sub-Structure of Bridges For 25T-2008 LoadingDocument58 pagesBS-123 2017 Guidelines For Checking Suitability of Existing Sub-Structure of Bridges For 25T-2008 LoadingM PMNo ratings yet

- Topic: Concrete at Early AgeDocument33 pagesTopic: Concrete at Early AgechristianNo ratings yet

- Load Calculation Met Arm - 2 - EscalatorDocument3 pagesLoad Calculation Met Arm - 2 - Escalatorvrajan1988No ratings yet

- MiTek Guide For Roof Truss Installation PDFDocument32 pagesMiTek Guide For Roof Truss Installation PDFXavier KaNo ratings yet

- Fabric Formwork Systems Used in Marine Construction: Martin G. Hawkswood Proserve LTDDocument13 pagesFabric Formwork Systems Used in Marine Construction: Martin G. Hawkswood Proserve LTDVishwas BhatNo ratings yet

- Civil works estimate for Asthor shed constructionDocument2 pagesCivil works estimate for Asthor shed constructionravi4781No ratings yet

- Biyaya Ni EcnarDocument14 pagesBiyaya Ni EcnarKiesha SantosNo ratings yet

- The Basohil Cable Stayed BridgeDocument7 pagesThe Basohil Cable Stayed BridgeNagar NitinNo ratings yet

- 22FI0002 Construction Schedule, S-Curve, Manpower & Eqpt Sched - R1Document29 pages22FI0002 Construction Schedule, S-Curve, Manpower & Eqpt Sched - R1Dennis SagaoNo ratings yet

- Direct Analysis Method TipsDocument25 pagesDirect Analysis Method TipsJair Pereira AbrigoNo ratings yet

- Labour Rates From NetDocument5 pagesLabour Rates From NetmailshinysNo ratings yet

- Construction Box CulvertDocument4 pagesConstruction Box CulvertKhalid OsmanNo ratings yet

- Design of Steel Structures Sample Question PaperDocument6 pagesDesign of Steel Structures Sample Question PaperRajiv BondeNo ratings yet

- RAM Connection Verification ManualDocument47 pagesRAM Connection Verification ManualBenedict OgbaghaNo ratings yet

- Guide To Compressive Membrane Action: Prepared For The Concrete Brldge Development GroupDocument46 pagesGuide To Compressive Membrane Action: Prepared For The Concrete Brldge Development GroupChhandak BiswasNo ratings yet

- Natural Red Clay Interlocking PantileDocument6 pagesNatural Red Clay Interlocking PantileArnisNo ratings yet

- Steelpac Proposal For Energypac Engineering Ltd. Ltd.Document22 pagesSteelpac Proposal For Energypac Engineering Ltd. Ltd.kaosar alamNo ratings yet

- BEMO RAIL BV Rail Technology SystemsDocument19 pagesBEMO RAIL BV Rail Technology SystemsAulia OkkyNo ratings yet

- Slab Design CalculationsDocument21 pagesSlab Design CalculationsLucas Construction SolutionsNo ratings yet

- Eurocode 3: EN 1993-1-8:2005/AC:2009 + CEB Design Guide: Design of Fastenings in ConcreteDocument5 pagesEurocode 3: EN 1993-1-8:2005/AC:2009 + CEB Design Guide: Design of Fastenings in ConcretegunasekaranNo ratings yet

- Project Cost Estimate and Breakdown for Commercial Building RenovationDocument2 pagesProject Cost Estimate and Breakdown for Commercial Building RenovationlhyteNo ratings yet

- Rigid Frame Structure ThesisDocument109 pagesRigid Frame Structure ThesisAdil Khan Hasan KhailNo ratings yet

- MBMA 96load CombinationsDocument2 pagesMBMA 96load CombinationsAmlan DasNo ratings yet