Professional Documents

Culture Documents

Design of Flexible Pavement Using Industrial Waste

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Flexible Pavement Using Industrial Waste

Copyright:

Available Formats

Volume 3, Issue 4, April – 2018 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Design of Flexible Pavement using Industrial Waste

B.Jeyanthi M.Sangeeth Kumar

M.Tech., Department of Civil Engineering Department of Civil Engineering

School of Environmental and Construction Technology School of Environmental and Construction Technology

Kalasalingam Academy of Research and Education Kalasalingam Academy of Research and Education

Kirshnankovil, virudhunagar 626126, India Kirshnankovil, virudhunagar 626126, India

R.Shanmuga Nathan B.Dheeparaj Muthiah

Department of Civil Engineering Department of Civil Engineering

School of Environmental and Construction Technology School of Environmental and Construction Technology

Kalasalingam Academy of Research and Education Kalasalingam Academy of Research and Education

Kirshnankovil, virudhunagar 626126, India Kirshnankovil, virudhunagar 626126, India

Abstract:- The large amount of Industrial wastes as techniques of highways, airports and residential building. For

increased year by year and disposal becomes a very serious these constructions should need good soil conditions for

problem. . Steel slag is a waste material generated as a by- foundations and embankments. Here the red soils are more

product during the manufacturing of steel from steel durability and shear strength. We have undergone many tests

industries. The quantity of creation is around 12611.8 T for finding the strength to support on the sub grade of the road

per year from different steel industries in the India. structure to improve by addition of steel slag. Sub grade is

Presently, it has no applications and dumped randomly on commonly compacted before the construction of a road,

the land available near the plants .It is necessary to exploit pavement or railway track, and is stabilized by the addition of

the steel slag waste effectively with technical development asphalt, lime, Portland cement or other modifiers.

in each field. By utilizing this slag in roads, the waste

material will be used and slag won’t cause any harmful II. LITERTAURE REVIEW

impact on the environment.

Sandip.S.patil, S.S.Bachhav, D.Y.K.Shirsagar ,

In this project, a typical steel slag was collected

investigated feasibility for use of steel slag in different layers

from a Steel industry and its feasibility for use in subgrade

of road construction was investigated. To improve its of road construction was investigated. To improve its

geotechnical engineering properties, the steel slag material was

Geotechnical engineering properties, the Steel Slag

mechanically stabilized with locally available soil in the range

material was mechanically stabilized with locally available

25%.www.ijeit.com/vol%205/issue%2011/ijeit1412201605_0

soil in the range of 1% - 10%.

5.pdfwww.ijeit.com/Vol%205/Issue%2011/IJEIT1412201605

The soil samples were collected from two sources (

_05.pdf

in Krishnan koil and in vatrap) and the CBR tests were

conducted for the raw samples and mixed with steel slag

Use of Steel slag in bituminous road construction,

with different proportions. Within this we identified that

mithun sawanth, yash lokhande, pratik lokhande, identified t

the CBR values are increased by adding the steel slags with

he chemical specification of slag where developed for

the proportions of 9.5% and 4% with the soil samples 1&2

respectively having high value of CBR. Therefore the utilization in the construction of embakement, sub-grade, sub-

thickness of the pavement with steel slag are also reduced base, upper layer of the road pavement.

www.irjet.net/archives/V4/i5/IRJET-V4I5558.pdf

from 85cm to 70cm and 80cm to72cm respectively with

cost effective manner.

Steel slag as a road construction, mohd.rosli hainin,

Keywords:- steel slag, red soil, minimize flexible pavement

thickness. Md.Maniruzzaman A. Aziz, ZulfiqarAli. reviewed the

engineering properties of steel slag and its utilization for road

I. INTRODUCTION construction in different layers.

www.jurnalteknologi.utm.my/index.php/jurnalteknologi/articl

The sub grade is the foundation of the pavement

e/view/4282

structure, on which the sub base is laid. The load-bearing

strength of sub grade is measured by California Bearing Ratio

A review on use of industrial waste in sub base of

(CBR) test, falling weight deflect meter back calculation and

flexible pavement, Chirag jain, Gyanebdra Sharma, Govind

other methods. The sub grade is the in suit material upon

vaishnav , reviewed the use of the material blast furnace slag,

which the pavement structure is been placed. The load is

coal fly ash, glass, reclaimed concrete pavement, reclaimed

transferred by the sub-grad effectively to the earth mass.

asphalt pavement, scrap tires etc. In sub-base layer of

However the locally available earth is used to construct the

pavement during construction will be a technical, economical

sub-grad but it becomes necessary that the sub-grad should be

and ecological blessing with all the limitation and gap.

of required strength. Although there is a tendency to look at

www.internationaljournalssrg.org/IJCE/2016/Volume3-

pavement performance in terms of pavement structure and mix

Issue5/IJCE-V3I5P155.pdf

design alone the sub-grade can often be the overriding factor

in the pavement performance. Urbanization and industrial

development in India need to concentrate on construction

IJISRT18AP485 www.ijisrt.com 330

Volume 3, Issue 4, April – 2018 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Steel slag as a road construction material, mohd. IV. COLLECTION OF SOIL SAMPLES AND

Rosli haini, MD. Maniruzzaman A. Aziz, Zulfiqar Ali, STEEL SLAG

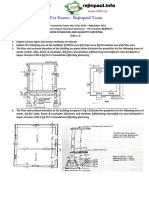

Successively recycled as an aggregate for the construction of Soil samples wre collected from two places. About

road, soil stabilization, and base and for the surfacing of 120kg of excavated soil samples were collected from two

flexible pavement. places, labelled properly and stored in the laboratory. Soil

www.jurnalteknologi.utm.my/index.php/jurnalteknologi/articl samples were air dried before using them for testing purpose.

e/view/4282 The steel stags were collected from Salem Sree Rengaraaj

Ispat (p) limited 5 roads Salem and also from welding

A Review on use of industrial waste in sub base of workshops in Salem. steel slag was sieved under 4.75mm

flexible pavement, Chirag jain, Gyanendra Sharma, Govind sieve Physical properties of the soil where determined as per

Vaishnav, Ishu Khanna, and Mohit Jaiman, India has a large IS specifications.

network of industries which deals with variety of products

among which many more are planned for distant future. This

amount increases with poor material and construction

techniques which is worthless. This paper presents a deep

review on the use of waste materials i.e. Blast Furnace Slag,

Coal fly ash, Glass, Reclaimed concrete pavement, Reclaimed

Asphalt Pavement, Scrap tires etc. in sub base layer of

pavement.

www.ijiert.org/admin/papers/1437309783_Volume%202%20I

ssue%207.pdf

Experimental Study on the Utilization of Fine Steel

Slag on Stabilizing High Plastic Sub grade Soil, Hussien

Aldeeky and Omar Al Hattamleh, The three major steel

manufacturing factories in Jordan dump their by-product, steel Fig 1:- Collection of Soil Samples and Steel Slag

slag, randomly in open areas, which causes many

environmental hazardous problems. Then 0%, 5%, 10%, 15%, A. Tests Done On Collected Soil Samples

20%, and 25% dry weight of soil of fine steel slag (FSSA) The tests such as sieve analysis, optimum moisture

were added and mixed into the prepared soil samples. From content and California Bearing Ratio Test(CBR) were

the test results, it is observed that 20% FSSA additives will conducted on both collected soil samples. Based on the

reduce plasticity index and free swell by 26.3% and 58.3%, obtained CBR values the thickness of pavements are

respectively. Furthermore, 20% FSSA additives will increase identified using CBR chart. Then the steel slag is added with

the unconfined compressive strength, maximum dry density, both the soil samples with different proportions and the

and CBR value by 100%, 6.9%, and 154%. corresponding CBR values were found out.

www.hindawi.com/journals/ace/2017/9230279/

Sieve Analysis

Utilisation of Steel Slag in Roads of Marathwada A sieve analysis is a practice or procedure used in civil

Region, Shubhada S. Koranne, S. S. Valunjkar, This slag is engineering to assess the particle size distribution of a granular

crushed; steel is again extracted from the slag, which is held in material. The size distribution is often of critical importance to

pores in the slag. About 18Percent steel slag of it has been the way the material performs in use of 4.75mm sieve

wasted (1percent finer slag and 1percent

B. Optimum Moisture Content Test (OMC)

Steel). After studying the properties of steel slag by The optimum water content of soil is the water

geotechnical engineering point of view, the engineering content at which a maximum dry unit weight can be achieved

properties of slag are too similar as compared to the natural after a given compaction effort. A max dry unit weight would

aggregates. Also the CBR value is found more than that of the have no voids in the soil. The test was useful in finding the

natural aggregate. By utilizing this slag in roads, the waste water content present in the collected soil samples, where the

Material will be used and slag won’t cause any harmful impact soil is sieved and dried in open surroundings for finding the

on the environment. www.ijer.in/ijer/publication/v5si1/37.pdf moisture content in the soil.

III. METHODOLOGY Then we have taken 3kg of soil sample and added 2%

to 10% of water in increasing order where the result was

Problem Identification correct in 8%. Then the OMC was constant for the soil

sample1 and for soil sample-2 the OMC was 6%.3kg of soil

Literature review

sample is taken for testing moisture content. OMC result for

Collection of soil samples and steel slags tested soil is 8%. Then, the water content has been specified

Testing of soil samples and used for the CBR test for finding the shear using 5kg of

Without steel slag red soil sample.

With steel slag with different proportions

Analysis and discussion

IJISRT18AP485 www.ijisrt.com 331

Volume 3, Issue 4, April – 2018 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Result of OMC for soil sample-1 pavements and its component layers. This is the most widely

used method for the design of flexible pavement.

AMOUNT OF WATER IN ML WEIGHT IN

WATER IN % KG California bearing ratio test were carried out with 5kg

6% 180 6236 soil sample the soil were taken and added with 8% water and

8% 240 6612 compacted in the mould with three layers and processed for

10% 300 6442 testing. During the testing process penetration in soil were

been noted from 0 to 12.5mm penetration and values residing

to 2.5mm and 5mm where proceeded foe calculation.

3

The CBR rating was developed for measuring the

2.5 load-bearing capacity of soils used for building roads. The

CBR can also be used for measuring the load-bearing capacity

2

of unimproved airstrips or for soils under paved airstrips. The

1.5 harder the surface, the higher the CBR rating, A CBR of 3

equates to tilled forml and, a CBR of 4.75 equates to turf of

RED SOIL

1 moist clay, while moist sand may have a CBR of 10. High

quality crushed rock has a CBR over80. The standard material

0.5 for this test is crushed. California limestone which has a value

of 100, meaning that it is not UN usual to see CBR values of

0 over 100 in well compacted areas.

6% 8% 10% = CBR [%]

For soil sample-2 = measured pressure for site soils [N/mm2]

= pressure to achieve equal penetration on standard soil

AMOUNT OF WATER IN ML WEIGHT IN [N/mm2]

WATER IN % KG

6% 180 6495

8% 240 6410

10% 300 6380

1.97

1.96

1.95

1.94

1.93

RED SOIL

1.92

1.91

1.9

6% 8% 10%

C. California Bearing Ratio Test (CBR)

Without WITH STEEL SLAG

Penetration steel slag 8% 9% 9.5% 10%

2.5mm 3.0 3.24 3.70 4.4 2.32

5mm 3.7 3.45 4 5.49 2.90

The California bearing ratio test is penetration test

meant for the evaluation of sub grade strength of roads and

pavements. The results obtained by these tests are used with

the empirical curves to determine the thickness of the

Fig 2: CBR load-bearing

IJISRT18AP485 www.ijisrt.com 332

Volume 3, Issue 4, April – 2018 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

The CBR Values for SAMPLE-I

V. CROSS SECTION OF PAVEMENT

Designed Thickness of 820mm

Fig 3:- Designed Thickness of 820mm

The CBR Values for SAMPLE-II

Without WITH STEEL SLAG

Penetration steel slag 4% 6% 7% 8%

2.5mm 2.71 3 3.07 2.63 2.19

5mm 3.07 3.30 3.15 3.08 3

Designed Thickness of 720mm

Fig 4:- Steel Slag

IJISRT18AP485 www.ijisrt.com 333

Volume 3, Issue 4, April – 2018 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

VI. RESULTS AND DISCUSSION [14]. I.M. Asi, H.Y. Qasrawi, F.I. Shalabi Use of steel slag

From the CBR values by using the IRC chart the aggregate in asphalt concrete mixes Can J Civil

pavement thickness were identified for both the samples. From Eng, 34 (8) (2007), pp. 902-911.

this we found out that by adding steel slag the thickness of the [15]. Hassan Ziari & Mohammad M.

pavement is reduced from 85cm to 70 cm for the sample1 with Khabiri(2007),Preventive maintenance of flexible

9.5% of steel slag and 80cm to 72cm for the sample 2 with pavement and mechanical properties of steel slag asphalt.

6% of steel slag. Therefore we can conclude that the waste Journal Of Environmental Engineering And Landscape

materials from steel industries can be used effective manner Management, 2007, Vol. XV, No 3,pp. 188– 192.

with economic consideration. [16]. K V Subrahmanyam, U Arun Kumar, Dr. PVV

Satyanarayana,(2014) A Comparative Study on

REFERENCES Utilization of Waste Materials in GSB Layer, SSRG

International Journal of Civil Engineering (SSRG-IJCE) –

[1]. Backhav, Durgesh Kshirsagar (2016), “Use of steel slag in Vol.1.Issue3 Aug. 2014 ISSN: 2348 – 8352,pp.10-14.

contruction of flexible pavement” Vol .5(2016) ,E- [17]. Mohd.Rosli Hainin, Md. Maniruzzaman A. Aziza,

ISSN:2277-3754,pp. 24-27. Zulfiqar Ali, Ramadhansyah Putra Jaya, Moetaz M. El-

[2]. Ivana Barisic, Sauja Dimter, Ivanka Netinger (2010), Sergany, Haryati Yaacob.(2015),Steel Slag as A Road

“Possibilities of application of slag in road construction” Construction Material, Journal Technology (Sciences &

(2010), ISSN: 1330-3651, PP. 523-528. Engineering) (2015)Vol.73:4, pp.33–38.

[3]. Prof.Mithum Sawant, yash Lokhande, Pratik Lokhande,

Karan Kute,Sajjad Mari,Swapnil Khutwad(2017), “Use of

steel slag in bituminous road construction”Vol. 4(2017),

E-ISSN: 2395-0056, PP. 2096-2097.

[4]. Chirag jain, Gyanendra Sharma, Govind Vaishnav, Ishu

Khanna, Mohit Jaiman, Asst Professor[Poornima Imtitutr

of Technology Jaipur](2016), “A Review on use of

industrial waste in sub-bas of flexible pavement “Vol.

3(2016),ISSN: 2348-8352,PP. 256-257.

[5]. Mohd. Rosli Hainin, Md. Maniruzzaman A. Aziza,

Zulfiqar Ali, Ramadhansyah Putra Jaya, Moetaz M. El-

Sergany, Haryati Yaacob.(2015), “Steel Slag as A Road

Construction Material” [University Teknologi

E-ISSN:2180-3722, pp.33-38. Malaysia](2015)Vol.73,

[6]. Irem Zeynep yildirim, Monica prezzi (2009) “Use of steel

slag in subgrade Applications” [principle investigator

school of civil engineering purdue university west

Lafayett.

[7]. George Wang, Yuhong Wang, Zhili Gao Use of steel slag

as a granular material: volume expansion prediction and

usability criteria J Hazard Mater, 184 (2010), pp. 555-560.

[8]. P.S. Kandhal, G.L. Hoffman Evaluation of steel slag fine

aggregate in hot-mix asphalt mixtures Transp Res

Rec, 1583 (1997), pp. 28-36

[9]. M. Maslehuddin, Alfarabi M Sharif, M. Shameem

Comparison of properties of steel slag and crushed

limestone aggregate concretes Constr Build

Mater, 17 (2003), pp. 105-112.

[10]. Shaopeng Wu, Yongjie Xue, Qunshan Ye Utilization

of steel slag as aggregates for stone mastic asphalt (SMA)

mixtures Build Environ, 42 (2007), pp. 2580-2585.

[11]. Weiguo Shen, Mingkai Zhou, Wei Ma Investigation

on the application of steel slag–fly ash–phosphogypsum

solidified material as road base material J Hazard

Mater, 164 (2009), pp. 99-104.

[12]. Ahmedzade Perviz, Burak Sengoz Evaluation of

steel slag coarse aggregate in hot mix asphalt concrete J

Hazard Mater, 165 (2010), pp. 300-305.

[13]. U. Bagampadde, H.I.A. Wahhab, S.A. Aiban

Optimization of steel slag aggregates for bituminous

mixes in Saudi Arabia J Mater Civil Eng, 11 (30) (1999).

IJISRT18AP485 www.ijisrt.com 334

You might also like

- An Experimental Study On Bituminous Mix Design Using Different Percentage of Crumb Rubber To Improve The Strength of PavementDocument22 pagesAn Experimental Study On Bituminous Mix Design Using Different Percentage of Crumb Rubber To Improve The Strength of PavementEditor IJTSRDNo ratings yet

- Resilient Modulus and Dynamic Modulus of Warm Mix AsphaltDocument8 pagesResilient Modulus and Dynamic Modulus of Warm Mix AsphaltJorge LuisNo ratings yet

- Open Letter To Honourable Shri Ashok Gehlot, Chief Minister of Rajasthan 31 May 2009Document3 pagesOpen Letter To Honourable Shri Ashok Gehlot, Chief Minister of Rajasthan 31 May 2009Prof. Prithvi Singh KandhalNo ratings yet

- Pavement Condition Analysis Using GISDocument6 pagesPavement Condition Analysis Using GISAmul ShresthaNo ratings yet

- On Modified BitumenDocument19 pagesOn Modified BitumenTejeshwini SNo ratings yet

- Article Text 463742 1 10 20190116 2Document7 pagesArticle Text 463742 1 10 20190116 2Jiu ShitzukiNo ratings yet

- Civil VII Pavement Materials and Construction 10cv763 Question PaperDocument3 pagesCivil VII Pavement Materials and Construction 10cv763 Question PaperPreethi BhoviNo ratings yet

- Open Letter To Hon. Narendra Modi On Gross Wastage of Public Funds On Bituminous Resurfacing of Rural RoadsDocument6 pagesOpen Letter To Hon. Narendra Modi On Gross Wastage of Public Funds On Bituminous Resurfacing of Rural RoadsProf. Prithvi Singh KandhalNo ratings yet

- Civil Highway Network System ReportDocument30 pagesCivil Highway Network System Reportsayali patilNo ratings yet

- Experimental Study on Permeable Concrete Pavement for Storm Water ManagementDocument28 pagesExperimental Study on Permeable Concrete Pavement for Storm Water ManagementVaidyanathan SivasubramanianNo ratings yet

- Chapter5 Part2Document42 pagesChapter5 Part2Aliya OthmanNo ratings yet

- INTERVIEWDocument5 pagesINTERVIEWMRITYUNJAY PANDEYNo ratings yet

- Material Related Aspects of Asphalt RecyclingDocument12 pagesMaterial Related Aspects of Asphalt RecyclingMatei PopaNo ratings yet

- Project Report for Maintenance of National HighwaysDocument6 pagesProject Report for Maintenance of National HighwaysSuyog GoreNo ratings yet

- Types of Pavements Explained: Flexible vs RigidDocument17 pagesTypes of Pavements Explained: Flexible vs RigidPereira KastroNo ratings yet

- A Study Report On Flexible Pavement Construction in VidishaDocument4 pagesA Study Report On Flexible Pavement Construction in VidishaIJRASETPublicationsNo ratings yet

- List of M.Tech Project WorksDocument2 pagesList of M.Tech Project WorksnaveenNo ratings yet

- A Study of Black Cotton Soil Stabilization With Lime and Waste Plastic Bottle StirrupDocument8 pagesA Study of Black Cotton Soil Stabilization With Lime and Waste Plastic Bottle StirrupIJRASETPublicationsNo ratings yet

- Irc 115 2014 FWD FLEXIBLEDocument4 pagesIrc 115 2014 FWD FLEXIBLESuyog GoreNo ratings yet

- Traffic AssignmentDocument19 pagesTraffic Assignmentレルス ツンデ100% (1)

- Research PaperDocument5 pagesResearch PapergvijaymNo ratings yet

- Civil Engineering Seminar on Mivan Formwork TechnologyDocument17 pagesCivil Engineering Seminar on Mivan Formwork TechnologyNikhil ThoteNo ratings yet

- Experimental Study On Concrete With Partial Replacement of Cement With Fly Ash & Coarse Aggregate by Ceramic TilesDocument7 pagesExperimental Study On Concrete With Partial Replacement of Cement With Fly Ash & Coarse Aggregate by Ceramic TilesIJSTENo ratings yet

- CENG 6305 - Chapter 4 - Granular Pavement Materials PDFDocument65 pagesCENG 6305 - Chapter 4 - Granular Pavement Materials PDFadane mekonnenNo ratings yet

- Perpetual Pavement and TSDGD YtsdDocument14 pagesPerpetual Pavement and TSDGD YtsdMashiur Rahman ShoyebNo ratings yet

- Asphalt Concrete (Commonly Called Asphalt, Blacktop, Macadam in Great Britain and Ireland) Is A CompositeDocument7 pagesAsphalt Concrete (Commonly Called Asphalt, Blacktop, Macadam in Great Britain and Ireland) Is A CompositeZerotheoryNo ratings yet

- Rural Road Construction Project ReportDocument33 pagesRural Road Construction Project ReportNandu KingsNo ratings yet

- A Study On Stabilization of Black Cotton Soil Using Rice Husk AshDocument10 pagesA Study On Stabilization of Black Cotton Soil Using Rice Husk AshMuhammad ShadabNo ratings yet

- Ronak InternshipDocument28 pagesRonak InternshipronakNo ratings yet

- Factors Affecting Pavement Design PDFDocument2 pagesFactors Affecting Pavement Design PDFKris33% (3)

- An Experimental Investigation On Rubberized ConcreteDocument7 pagesAn Experimental Investigation On Rubberized ConcreteIJIRSTNo ratings yet

- Anna Uni BE/BTECH CE6704 ESTIMATION QS Exam QsDocument4 pagesAnna Uni BE/BTECH CE6704 ESTIMATION QS Exam QsRejin Paul50% (2)

- Crumb Rubber Modified Bitumen Project AnalysisDocument52 pagesCrumb Rubber Modified Bitumen Project AnalysisAthira RaghavanNo ratings yet

- Modified Binders and Superpave Plus SpecificationsDocument2 pagesModified Binders and Superpave Plus Specificationsingmdtz_1No ratings yet

- Economic and Financial Analysis For Polymer Modified BitumenDocument11 pagesEconomic and Financial Analysis For Polymer Modified Bitumennicholas100% (1)

- Large Stone Asphalt Mixes: Design and ConstructionDocument38 pagesLarge Stone Asphalt Mixes: Design and ConstructionProf. Prithvi Singh Kandhal100% (1)

- Importance of Pavement Management SystemDocument77 pagesImportance of Pavement Management SystemUsman Latif100% (1)

- Civil-Vii-Pavement Materials and Construction (10CV763) - SolutionDocument36 pagesCivil-Vii-Pavement Materials and Construction (10CV763) - SolutionLokesh KNo ratings yet

- Surveying NotesDocument2 pagesSurveying NotesShrikedar PatilNo ratings yet

- Flexible Pavement: Click To Edit Master Title StyleDocument13 pagesFlexible Pavement: Click To Edit Master Title StyleFaisal SharifNo ratings yet

- Performance Evaluation of Flexible Pavements With Modified Bitumen BindersDocument8 pagesPerformance Evaluation of Flexible Pavements With Modified Bitumen BindersIJRASETPublicationsNo ratings yet

- Waste plastic guidelines for bituminous road mixesDocument24 pagesWaste plastic guidelines for bituminous road mixesRaja Kumar50% (2)

- Stone Mastic Asphalt: A Seminar Report OnDocument17 pagesStone Mastic Asphalt: A Seminar Report Onprajakta chaudhari100% (1)

- Lec - 8 Mix Design Applications PDFDocument68 pagesLec - 8 Mix Design Applications PDFAZIMERAWNo ratings yet

- Viscosity Grading of BitumenDocument2 pagesViscosity Grading of BitumenVenkateswarlu DanduNo ratings yet

- Mohamed Elfatih - TechnicalDocument11 pagesMohamed Elfatih - Technical6qwhnq9z4h100% (1)

- Perpetual PavementsDocument13 pagesPerpetual PavementsjayaramrddyNo ratings yet

- Fly Ash Rigid PavementDocument4 pagesFly Ash Rigid PavementRaghav100% (1)

- Study On Strength and Durability Properties of Ternary Blended Hybrid FRCDocument9 pagesStudy On Strength and Durability Properties of Ternary Blended Hybrid FRCIAEME PublicationNo ratings yet

- Transportation Engineering: Efforts By:-Gurpinder Singh Roll No. - 615/17 Submitted To: - Dr. Sanjeev NavalDocument35 pagesTransportation Engineering: Efforts By:-Gurpinder Singh Roll No. - 615/17 Submitted To: - Dr. Sanjeev NavalGurpinder SinghNo ratings yet

- Stone Matrix Asphalt Pavement 1Document26 pagesStone Matrix Asphalt Pavement 1JAYBHAY BHAGWATNo ratings yet

- Kandhal Q and A Part 1 On Confusion From Overlapping Viscosity Ranges of VG-30 and VG-40 Bitumen - 16 August 2017Document4 pagesKandhal Q and A Part 1 On Confusion From Overlapping Viscosity Ranges of VG-30 and VG-40 Bitumen - 16 August 2017Prof. Prithvi Singh Kandhal100% (1)

- Creep NCHRPDocument106 pagesCreep NCHRPFranklinNo ratings yet

- Axle Load Survey FormatDocument2 pagesAxle Load Survey FormatSatish BhairanattiNo ratings yet

- Letter To Hon. Narendra Singh Tomar About Wastage of Funds in Blacktopping Rural Roads in IndiaDocument6 pagesLetter To Hon. Narendra Singh Tomar About Wastage of Funds in Blacktopping Rural Roads in IndiaProf. Prithvi Singh KandhalNo ratings yet

- Pavement Design IntroductionDocument62 pagesPavement Design IntroductionblastmcNo ratings yet

- 1 What Is LevelingDocument19 pages1 What Is LevelingAbduraman Isa100% (1)

- Are Two Separate Test Samples Are Used in India To Determine The Flaky (Flat) and Elongated Particles in Each Aggregate Size Fraction? AnswerDocument5 pagesAre Two Separate Test Samples Are Used in India To Determine The Flaky (Flat) and Elongated Particles in Each Aggregate Size Fraction? AnswerProf. Prithvi Singh KandhalNo ratings yet

- Pavements and Its FailuresDocument19 pagesPavements and Its Failureschinmaya dharaNo ratings yet

- Research and Application of Hot In-Place Recycling Technology for Asphalt PavementFrom EverandResearch and Application of Hot In-Place Recycling Technology for Asphalt PavementNo ratings yet

- Advancing Healthcare Predictions: Harnessing Machine Learning for Accurate Health Index PrognosisDocument8 pagesAdvancing Healthcare Predictions: Harnessing Machine Learning for Accurate Health Index PrognosisInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Diabetic Retinopathy Stage Detection Using CNN and Inception V3Document9 pagesDiabetic Retinopathy Stage Detection Using CNN and Inception V3International Journal of Innovative Science and Research TechnologyNo ratings yet

- Comparatively Design and Analyze Elevated Rectangular Water Reservoir with and without Bracing for Different Stagging HeightDocument4 pagesComparatively Design and Analyze Elevated Rectangular Water Reservoir with and without Bracing for Different Stagging HeightInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design, Development and Evaluation of Methi-Shikakai Herbal ShampooDocument8 pagesDesign, Development and Evaluation of Methi-Shikakai Herbal ShampooInternational Journal of Innovative Science and Research Technology100% (3)

- Terracing as an Old-Style Scheme of Soil Water Preservation in Djingliya-Mandara Mountains- CameroonDocument14 pagesTerracing as an Old-Style Scheme of Soil Water Preservation in Djingliya-Mandara Mountains- CameroonInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Cyberbullying: Legal and Ethical Implications, Challenges and Opportunities for Policy DevelopmentDocument7 pagesCyberbullying: Legal and Ethical Implications, Challenges and Opportunities for Policy DevelopmentInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Impact of Digital Marketing Dimensions on Customer SatisfactionDocument6 pagesThe Impact of Digital Marketing Dimensions on Customer SatisfactionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Utilization of Date Palm (Phoenix dactylifera) Leaf Fiber as a Main Component in Making an Improvised Water FilterDocument11 pagesThe Utilization of Date Palm (Phoenix dactylifera) Leaf Fiber as a Main Component in Making an Improvised Water FilterInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Dense Wavelength Division Multiplexing (DWDM) in IT Networks: A Leap Beyond Synchronous Digital Hierarchy (SDH)Document2 pagesDense Wavelength Division Multiplexing (DWDM) in IT Networks: A Leap Beyond Synchronous Digital Hierarchy (SDH)International Journal of Innovative Science and Research TechnologyNo ratings yet

- Formulation and Evaluation of Poly Herbal Body ScrubDocument6 pagesFormulation and Evaluation of Poly Herbal Body ScrubInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Auto Encoder Driven Hybrid Pipelines for Image Deblurring using NAFNETDocument6 pagesAuto Encoder Driven Hybrid Pipelines for Image Deblurring using NAFNETInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Electro-Optics Properties of Intact Cocoa Beans based on Near Infrared TechnologyDocument7 pagesElectro-Optics Properties of Intact Cocoa Beans based on Near Infrared TechnologyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Explorning the Role of Machine Learning in Enhancing Cloud SecurityDocument5 pagesExplorning the Role of Machine Learning in Enhancing Cloud SecurityInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Survey of the Plastic Waste used in Paving BlocksDocument4 pagesA Survey of the Plastic Waste used in Paving BlocksInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Review: Pink Eye Outbreak in IndiaDocument3 pagesA Review: Pink Eye Outbreak in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Navigating Digitalization: AHP Insights for SMEs' Strategic TransformationDocument11 pagesNavigating Digitalization: AHP Insights for SMEs' Strategic TransformationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Automatic Power Factor ControllerDocument4 pagesAutomatic Power Factor ControllerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Hepatic Portovenous Gas in a Young MaleDocument2 pagesHepatic Portovenous Gas in a Young MaleInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Studying the Situation and Proposing Some Basic Solutions to Improve Psychological Harmony Between Managerial Staff and Students of Medical Universities in Hanoi AreaDocument5 pagesStudying the Situation and Proposing Some Basic Solutions to Improve Psychological Harmony Between Managerial Staff and Students of Medical Universities in Hanoi AreaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Review of Biomechanics in Footwear Design and Development: An Exploration of Key Concepts and InnovationsDocument5 pagesReview of Biomechanics in Footwear Design and Development: An Exploration of Key Concepts and InnovationsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Effect of Time Variables as Predictors of Senior Secondary School Students' Mathematical Performance Department of Mathematics Education Freetown PolytechnicDocument7 pagesThe Effect of Time Variables as Predictors of Senior Secondary School Students' Mathematical Performance Department of Mathematics Education Freetown PolytechnicInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Mobile Distractions among Adolescents: Impact on Learning in the Aftermath of COVID-19 in IndiaDocument2 pagesMobile Distractions among Adolescents: Impact on Learning in the Aftermath of COVID-19 in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Enhancing the Strength of Concrete by Using Human Hairs as a FiberDocument3 pagesEnhancing the Strength of Concrete by Using Human Hairs as a FiberInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Drug Dosage Control System Using Reinforcement LearningDocument8 pagesDrug Dosage Control System Using Reinforcement LearningInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Securing Document Exchange with Blockchain Technology: A New Paradigm for Information SharingDocument4 pagesSecuring Document Exchange with Blockchain Technology: A New Paradigm for Information SharingInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Intelligent Engines: Revolutionizing Manufacturing and Supply Chains with AIDocument14 pagesIntelligent Engines: Revolutionizing Manufacturing and Supply Chains with AIInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Formation of New Technology in Automated Highway System in Peripheral HighwayDocument6 pagesFormation of New Technology in Automated Highway System in Peripheral HighwayInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Perceived Impact of Active Pedagogy in Medical Students' Learning at the Faculty of Medicine and Pharmacy of CasablancaDocument5 pagesPerceived Impact of Active Pedagogy in Medical Students' Learning at the Faculty of Medicine and Pharmacy of CasablancaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Supply Chain 5.0: A Comprehensive Literature Review on Implications, Applications and ChallengesDocument11 pagesSupply Chain 5.0: A Comprehensive Literature Review on Implications, Applications and ChallengesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Making of Self-Disposing Contactless Motion-Activated Trash Bin Using Ultrasonic SensorsDocument7 pagesThe Making of Self-Disposing Contactless Motion-Activated Trash Bin Using Ultrasonic SensorsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Basic Facts For Homebooks Stage 7Document3 pagesBasic Facts For Homebooks Stage 7api-311857762No ratings yet

- Frame Fit Specs SramDocument22 pagesFrame Fit Specs SramJanekNo ratings yet

- Schippers and Bendrup - Ethnomusicology Ecology and SustainabilityDocument12 pagesSchippers and Bendrup - Ethnomusicology Ecology and SustainabilityLuca GambirasioNo ratings yet

- Green Screen Background Remover Using CV SystemDocument20 pagesGreen Screen Background Remover Using CV SystemSubhamNo ratings yet

- Active-Passive VoiceDocument18 pagesActive-Passive VoiceDivya JainNo ratings yet

- Đề Minh Họa 2020 Số 23 - GV Trang Anh - Moon.vnDocument22 pagesĐề Minh Họa 2020 Số 23 - GV Trang Anh - Moon.vnLily LeeNo ratings yet

- Aspen Plus Tutorial 5 Preparing and Configuring A Distillation Column Using RADFRACDocument13 pagesAspen Plus Tutorial 5 Preparing and Configuring A Distillation Column Using RADFRACRavi Kant TripathiNo ratings yet

- Interview QuestionsDocument3 pagesInterview Questionsاحتشام چوہدری100% (1)

- Gmail LogoDocument12 pagesGmail Logovinodram993480No ratings yet

- Mascot LD series hydraulic motor specsDocument6 pagesMascot LD series hydraulic motor specsM S GokulNo ratings yet

- Techniques-Of-Attitude-Scale-Construction FullDocument344 pagesTechniques-Of-Attitude-Scale-Construction FullLuthfi fharuq Al Fairuz67% (3)

- Carl Rogers, Otto Rank, and "The BeyondDocument58 pagesCarl Rogers, Otto Rank, and "The BeyondAnca ElenaNo ratings yet

- Physical Layer:: SwitchingDocument27 pagesPhysical Layer:: SwitchingPKSachanNo ratings yet

- Katja Kruckeberg, Wolfgang Amann, Mike Green-Leadership and Personal Development - A Toolbox For The 21st Century Professional-Information Age Publishing (2011)Document383 pagesKatja Kruckeberg, Wolfgang Amann, Mike Green-Leadership and Personal Development - A Toolbox For The 21st Century Professional-Information Age Publishing (2011)MariaIoanaTelecan100% (1)

- ManupptDocument65 pagesManupptKrishanarju VenkatesanNo ratings yet

- Caring Seedlings TLE Weekly PlanDocument3 pagesCaring Seedlings TLE Weekly PlanMarjorie RaymundoNo ratings yet

- Creative IndustriesDocument433 pagesCreative IndustriesDanielTavaresNo ratings yet

- CP QB PT-3 Harish KumarDocument3 pagesCP QB PT-3 Harish KumarVISHNU7 77No ratings yet

- FMBXXX Quick Manual v3.5Document18 pagesFMBXXX Quick Manual v3.5AMNo ratings yet

- Sample of Application Letter (Updated)Document4 pagesSample of Application Letter (Updated)Mizpah Sarah BautistaNo ratings yet

- 07-02-2023 MS QLNDocument3 pages07-02-2023 MS QLNSummaaaaNo ratings yet

- ME1001, ME1004, ME1005 - Basic Mech+Graphics+Workshop Pract.Document6 pagesME1001, ME1004, ME1005 - Basic Mech+Graphics+Workshop Pract.Mayank AgarwalNo ratings yet

- Overview On Image Captioning TechniquesDocument6 pagesOverview On Image Captioning TechniquesWARSE JournalsNo ratings yet

- DodupukegakobemavasevuDocument3 pagesDodupukegakobemavasevuMartian SamaanNo ratings yet

- Primera actividad economicaDocument3 pagesPrimera actividad economicamaria fernanda parraNo ratings yet

- Air Cooled Screw Chiller Performance SpecificationDocument2 pagesAir Cooled Screw Chiller Performance SpecificationDajuko Butarbutar100% (1)

- Query Operation 2021Document35 pagesQuery Operation 2021Abdo AbaborNo ratings yet

- List of SDAsDocument4 pagesList of SDAsAthouba SagolsemNo ratings yet

- Check List of MossesDocument319 pagesCheck List of MossesAshen NirodyaNo ratings yet

- CitationCJ4-CB Checklists B v1.2Document4 pagesCitationCJ4-CB Checklists B v1.2Joao Vitor RojasNo ratings yet