Professional Documents

Culture Documents

ABELLA, Edward A. April 16, 2018 10:30-11:30 MWF Engr. Kevin O. Obfan

Uploaded by

Edward Amoyen Abella0 ratings0% found this document useful (0 votes)

218 views6 pagesStrength of Materials Problem Set

Original Title

SoM ProbSet

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentStrength of Materials Problem Set

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

218 views6 pagesABELLA, Edward A. April 16, 2018 10:30-11:30 MWF Engr. Kevin O. Obfan

Uploaded by

Edward Amoyen AbellaStrength of Materials Problem Set

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

ABELLA, Edward A.

April 16, 2018

10:30–11:30 MWF Engr. Kevin O. Obfan

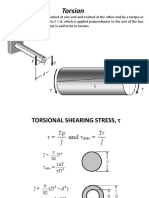

3. The steel shaft is formed by attaching a hollow shaft to a

solid shaft. Determine the maximum torque T that can be

applied to the ends of the shaft without exceeding a shear

stress of 70 MPa or an angle of twist of 2.5˚ in the 3.5-m

length. Use G = 83 GPa for steel.

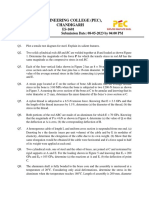

4. The solid compound shaft, made of three different materials,

carries the two torques shown. (a) Calculate the maximum

shear stress in each material. (b) Find the angle of rotation of

the free end of the shaft. The shear moduli are 28 GPa for

aluminum, 83 GPa for steel, and 35 GPa for bronze.

5. The shaft carries a total torque T0 that is uniformly

distributed over its length L. Determine the angle of twist of

the shaft in terms of T0, L, G, and J.

6. The ends of the compound shaft are attached to rigid walls.

The maximum shear stress is limited to 10 000 psi for the

bronze segment AB and 14 000 psi for the steel segment

BC. Determine the diameter of each segment so that each

material is simultaneously stressed to its permissible limit

when the torque T = 16 kip · ft is applied as shown. The shear

moduli are 6 x 106 psi for bronze and 12 x 106 psi for steel.

7. The stepped solid steel shaft ABC is attached to rigid

supports at each end. Determine the diameter of segment

BC for which the maximum shear stress in both segments

will be equal when the torque T is applied at B. Note that the

lengths of both segments are given and the diameter of

segment AB is 60 mm.

8. The four rigid gears, loaded as shown in the figure are

attached to a 2-in.-diameter steel shaft. Compute the angle

of rotation of gear A relative to gear D. Use G = 12 x 106 psi

for the shaft.

You might also like

- Torsion 01Document20 pagesTorsion 01Danielle Ruthie GalitNo ratings yet

- Mechanics of Materials 1 PDFDocument2 pagesMechanics of Materials 1 PDFEj ApeloNo ratings yet

- Sample Problem TorsionDocument4 pagesSample Problem TorsionAndre BocoNo ratings yet

- MechanicsDocument2 pagesMechanicsNicole De Leon Miday0% (1)

- Strength of Materials 4th Ed by Ferdinand L Singer Andrew Pytel Www07MettkDocument21 pagesStrength of Materials 4th Ed by Ferdinand L Singer Andrew Pytel Www07Mettkvjereme100% (3)

- Strength WorksheetDocument9 pagesStrength WorksheetHabtamu GetaNo ratings yet

- Unit 4 AssignmentsDocument5 pagesUnit 4 AssignmentsbattuarunNo ratings yet

- Ce205 A1m NilloDocument5 pagesCe205 A1m NilloAngelo NilloNo ratings yet

- Elementos Sometidos A TorsiónDocument4 pagesElementos Sometidos A TorsiónAnthony Ash EstradaNo ratings yet

- Ce234 Topic 06-07Document31 pagesCe234 Topic 06-07Nicholas Bonn SingNo ratings yet

- IM in Mech 132 Pages 29 31Document3 pagesIM in Mech 132 Pages 29 31JasleneDimarananNo ratings yet

- Tutorial 4Document6 pagesTutorial 4Ysgn MysgnNo ratings yet

- SOM Axial Deformation.Document24 pagesSOM Axial Deformation.yas22e5019No ratings yet

- Exercises of TorsionDocument3 pagesExercises of TorsionPham CongNo ratings yet

- Lesson 6 - TORSION PDFDocument30 pagesLesson 6 - TORSION PDFBaux/比叡0% (1)

- torsionDocument26 pagestorsionkidowapoNo ratings yet

- Workout No. 3 Poisson'S Ratio, Torsion, Helical Springs, Eccentrically Riveted ConnectionsDocument3 pagesWorkout No. 3 Poisson'S Ratio, Torsion, Helical Springs, Eccentrically Riveted Connectionsjpb1110% (3)

- Chapter 03Document83 pagesChapter 03Md. Mushfikur RahmanNo ratings yet

- MDB Assignment Ch3Document3 pagesMDB Assignment Ch3galicia.jhonflorence05No ratings yet

- Assignment No 1 MD-1..Document3 pagesAssignment No 1 MD-1..Yadnyesh TaNo ratings yet

- MOM2Tutorial 10-1Document3 pagesMOM2Tutorial 10-1Ishola mujeebNo ratings yet

- Simple Stresses and Strains PDFDocument2 pagesSimple Stresses and Strains PDFSai Krishna SK100% (1)

- Mech 103 Problem Set 3Document1 pageMech 103 Problem Set 3Reanna TabujaraNo ratings yet

- Strength of Materials Chapter 3 ProblemsDocument3 pagesStrength of Materials Chapter 3 ProblemsNEIVER ALEVIS CASTRO JULIONo ratings yet

- Mechanics of Deformable Bodies Solved ProblemsDocument10 pagesMechanics of Deformable Bodies Solved ProblemsYan NieNo ratings yet

- Strength Materials WorkshopDocument3 pagesStrength Materials WorkshopIsabella Gutierrez BurbanoNo ratings yet

- S. E. (Mechanical / Mechanical - SW / Automobile) 2012 CourseDocument3 pagesS. E. (Mechanical / Mechanical - SW / Automobile) 2012 CourseTejas AdakNo ratings yet

- Tutorial 4 CRC302Document1 pageTutorial 4 CRC302HarryNo ratings yet

- Homework 3 Shaft Design ProblemsDocument6 pagesHomework 3 Shaft Design ProblemsMd Aziq Md RaziNo ratings yet

- Lakas NG MateryalesDocument3 pagesLakas NG MateryalesDwight De LeonNo ratings yet

- Mechanics of Deformable Bodies Solved ProblemsDocument10 pagesMechanics of Deformable Bodies Solved ProblemsIsabelle LunaNo ratings yet

- Torsion and shafts calculationsDocument25 pagesTorsion and shafts calculationsLuckyNo ratings yet

- Thapar Institute Torsion TutorialDocument1 pageThapar Institute Torsion TutorialSimranjeet SinghNo ratings yet

- Assignment 1Document4 pagesAssignment 1TanmayNo ratings yet

- Assignment For IPEDocument4 pagesAssignment For IPEAbirHasanNo ratings yet

- Assignment Strength of MaterialsDocument11 pagesAssignment Strength of MaterialsVinay Korukonda0% (1)

- Mechanics of Deformable Bodies Solved ProblemsDocument10 pagesMechanics of Deformable Bodies Solved ProblemsYan NieNo ratings yet

- Notes Plate 2Document2 pagesNotes Plate 2Dawnald Pepito0% (1)

- Torsional StressDocument2 pagesTorsional StressNigel Ceasar SilvaNo ratings yet

- Torsion 3-1 IntroductionDocument8 pagesTorsion 3-1 IntroductionStephanie Danielle HizoleNo ratings yet

- Prob SheetDocument20 pagesProb SheetAditya ShuklaNo ratings yet

- Strength of Materials - Task 2. Chapter 3Document2 pagesStrength of Materials - Task 2. Chapter 3NEIVER ALEVIS CASTRO JULIONo ratings yet

- Topics - Deign of A Mechanical System - ME 881Document9 pagesTopics - Deign of A Mechanical System - ME 881Aamir AhmedNo ratings yet

- Problem Set 8 - Torsion and Flanged-Bolt CouplingDocument2 pagesProblem Set 8 - Torsion and Flanged-Bolt Couplingmanacc.travisNo ratings yet

- Som TutorialsDocument22 pagesSom TutorialsbaizubirajiNo ratings yet

- Torsion ProblemsDocument7 pagesTorsion ProblemsLouie G NavaltaNo ratings yet

- Homework Problems 4 (Due On Mar 23) - ModifiedDocument2 pagesHomework Problems 4 (Due On Mar 23) - Modified李尚倫No ratings yet

- Assignment 6 SolDocument7 pagesAssignment 6 SolVIPUL KOTHANo ratings yet

- Problem Set 2Document3 pagesProblem Set 2Jeff BayedNo ratings yet

- CE6306 STRENGTH OF MATERIALS PART-B TOPICSDocument8 pagesCE6306 STRENGTH OF MATERIALS PART-B TOPICSnkchandruNo ratings yet

- PropertiesDocument6 pagesPropertiesmarkalvinbonNo ratings yet

- Solid Mechanics Question BankDocument10 pagesSolid Mechanics Question BankMugilan VinsNo ratings yet

- Civl 2120 Ch3 QsDocument2 pagesCivl 2120 Ch3 QsTina ChenNo ratings yet

- Strength of Materials I: PROBLEM 1. Gear C in The Figure Provides ADocument2 pagesStrength of Materials I: PROBLEM 1. Gear C in The Figure Provides AzıptıNo ratings yet

- MOM Assignment IDocument3 pagesMOM Assignment IAll_regNo ratings yet

- How Two Boys Made Their Own Electrical Apparatus Containing Complete Directions for Making All Kinds of Simple Apparatus for the Study of Elementary ElectricityFrom EverandHow Two Boys Made Their Own Electrical Apparatus Containing Complete Directions for Making All Kinds of Simple Apparatus for the Study of Elementary ElectricityNo ratings yet

- Saint Louis University Lab Manual on ADC and DAC SimulationDocument14 pagesSaint Louis University Lab Manual on ADC and DAC SimulationEdward Amoyen AbellaNo ratings yet

- Research On Z-TransformsDocument50 pagesResearch On Z-TransformsEdward Amoyen AbellaNo ratings yet

- Faqs For European Customers: 1. What Are The Prices of The Tower Garden® and The Led Light Kit in Europe?Document5 pagesFaqs For European Customers: 1. What Are The Prices of The Tower Garden® and The Led Light Kit in Europe?Edward Amoyen AbellaNo ratings yet

- Saint Louis University Lab Manual on ADC and DAC SimulationDocument14 pagesSaint Louis University Lab Manual on ADC and DAC SimulationEdward Amoyen AbellaNo ratings yet

- Time Value of Money 1: Analyzing Single Cash FlowsDocument30 pagesTime Value of Money 1: Analyzing Single Cash FlowsEdward Amoyen AbellaNo ratings yet

- LayadCircuits Installation of Zipped Libraries v1Document4 pagesLayadCircuits Installation of Zipped Libraries v1Edward Amoyen Abella0% (1)

- LayadCircuits Saleng GSM v1 1 PDFDocument15 pagesLayadCircuits Saleng GSM v1 1 PDFEdward Amoyen AbellaNo ratings yet

- Cover 1Document1 pageCover 1Edward Amoyen AbellaNo ratings yet

- LM35 Precision Centigrade Temperature Sensors: 1 Features 3 DescriptionDocument36 pagesLM35 Precision Centigrade Temperature Sensors: 1 Features 3 DescriptionRambo333No ratings yet

- Entrepre Nuer ShipDocument14 pagesEntrepre Nuer ShipEdward Amoyen AbellaNo ratings yet

- LayadCircuits Kimat 3 LED Module UG v1 PDFDocument4 pagesLayadCircuits Kimat 3 LED Module UG v1 PDFEdward Amoyen AbellaNo ratings yet

- Z-Transform Properties and ApplicationsDocument49 pagesZ-Transform Properties and ApplicationsEdward Amoyen AbellaNo ratings yet

- LayadCircuits Saleng Uno UG v1 1 PDFDocument8 pagesLayadCircuits Saleng Uno UG v1 1 PDFEdward Amoyen AbellaNo ratings yet

- Max30102 PDFDocument32 pagesMax30102 PDFEdward Amoyen AbellaNo ratings yet

- Maximum Power Transfer OccursDocument67 pagesMaximum Power Transfer OccursEdward Amoyen Abella100% (1)

- DC MotorDocument92 pagesDC MotorEdward Amoyen AbellaNo ratings yet

- Common Emitter RC Coupled AmplifierDocument3 pagesCommon Emitter RC Coupled AmplifierEdward Amoyen AbellaNo ratings yet

- APA Referencing Guide PDFDocument40 pagesAPA Referencing Guide PDFEdward Amoyen AbellaNo ratings yet

- Common Ceramic Capacitor Values GuideDocument1 pageCommon Ceramic Capacitor Values GuideCalin AcroitoriteiNo ratings yet

- Signals ClassificationDocument4 pagesSignals ClassificationEdward Amoyen AbellaNo ratings yet

- Phase Difference and Phase ShiftDocument76 pagesPhase Difference and Phase ShiftEdward Amoyen Abella100% (1)

- LANDMARK Mosfet AmplifierDocument4 pagesLANDMARK Mosfet AmplifierEdward Amoyen AbellaNo ratings yet

- Signals Basic TypesDocument5 pagesSignals Basic TypesEdward Amoyen AbellaNo ratings yet

- SignalsDocument4 pagesSignalsSweqZNo ratings yet

- Signals and SystemsDocument27 pagesSignals and SystemsEdward Amoyen AbellaNo ratings yet

- RC Coupling: Experiment No. 1Document1 pageRC Coupling: Experiment No. 1Edward Amoyen AbellaNo ratings yet

- CH 17 PDFDocument22 pagesCH 17 PDFEdward Amoyen AbellaNo ratings yet

- LectureDocument57 pagesLectureAnonymous AyCl4LNo ratings yet

- CH 8 PDFDocument29 pagesCH 8 PDFEdward Amoyen AbellaNo ratings yet