Professional Documents

Culture Documents

Magnetic Drive Pumps Polypropylene Magnetic Drive Process Pumps

Uploaded by

Mạnh Đạt NguyễnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Magnetic Drive Pumps Polypropylene Magnetic Drive Process Pumps

Uploaded by

Mạnh Đạt NguyễnCopyright:

Available Formats

Pump identification AMP

AMP 40 - 110 1 CF F 055 J - D 2 series

Pump size 40: 50A X 40A Motor pole 2

(Suction X Discharge) 50: 65A X 50A Special version

Impeller size 110mm to 165mm Mark Drain Base Special version

A Standard

Impeller range 1 Without drain

S Special

With base

Material of CF: High density carbon / D Standard

With drain

Bearing / Spindle High purity alumina caramic X Special

KK: SiC / SiC B Standard

Without drain

Magnetic drive pumps

Type of motor F: Flange motor Y Special

Without base

Motor output 037: 3.7kW E Standard

With drain

055: 5.5kW Z Special

075: 7.5kW

Polypropylene magnetic drive process pumps

Standard for J: JIS flange + JIS motor

pipe connection and motor * A: ANSI flange + JIS motor

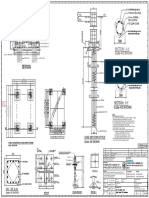

Dimensions

(L) (L)

With base type A Without base type A

g g

B B

Highly durable structure Non contact system

A ductile cast iron shell adds strength

and durability to the polypropylene wet The pump design features a mechanism

to withstand abnormal operating. High H

ends. The rear casing which is subject magnet power of the rare earth magnets

H

f

f

to the highest stress, is reinforced with prevents the magnet capsule coming

an FRP cover to increase strength. The into contact with the thrust ring of the a 2-ø14

rear casing, thus preventing melting of W b c

14

b

maximum allowable casing pressure of a

c

h

components due to heat generation. W e

1.0MPa is a highlight feature amongst This greatly improves resistance against d Note: The dimensions may differ with the type of motor installed.

With base type in mm

polypropylene pumps. abnormal operating in comparison with Model Motor (W) H (L) a b c (d) (e) f g h A B Mass kg

conventional magnetic drive pumps. 3.7kW 625 115

Unique design prevents Non contact system

AMP40-1 5.5kW

7.5kW

400 410

689

350 150 540 800 130 250 80 4-ø19 40A 50A

135

abnormal operation 3.7kW 625 115

The pump design features a Non contact Bearing AMP50-1 5.5kW 400 410

689

350 150 540 800 130 250 80 4-ø19 50A 65A

135

7.5kW

system. The pump exhibits outstanding Rear ring

durability in air ingress to the suction. Without base type in mm

Model Motor W H (L) a b c f g A B Mass kg

Note: Dry running is not permitted. 3.7kW 625 285 85

AMP40-1 5.5kW 280 340 220 90 180 80 40A 50A 105

689 365 The AMP series are magnetic drive process pumps with polypropylene wet ends,

7.5kW 110

Back pullout system 3.7kW 625 285 90 featuring a unique configuration which gives greatly improved tolerance

The back pullout system allows easy AMP50-1 5.5kW 280 340 689 220 90 365 180 80 50A 65A 110 to abnormal operating conditions (Non contact system).

maintenance and inspection without 7.5kW

removing piping. The motor can be

Rear thrust

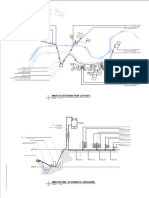

safely removed without chemical leakage Iwaki dry running protector DR series (Option) Specification 50/60Hz

(Pumps on base plates only). Model DR is electric current sensing type dry running protector. Model DR-10 DR-20

It detects the decreased load current (lower limit) to stop the pump

Motor power 200 to 240V three phase 380 to 440V three phase

when it runs dry or runs with air sucking in.

Applied motor 0.4 to 7.5kW 0.75 to 15kW

Modular design and low It can detect over-load, too.

Power control 100 to 240V single phase

maintenance cost Power V 100V ±10%single phase 200 to 240V ±10%single phase

The pump is a modular design for ease of Input 3.5W

maintenance. Specific adjustments such Detective current 0.5 to 32.0A

Current transformer(CT) Built-in

as centering or checking clearances are Outer dimension D80 X W153 X H122

Note: The dry run protector can not be used along with inverter.

not required. Any wear part can simply

be replaced individually and reduces

maintenance costs.

w w w. iwak ipum ps. j p

6-6 Kanda-Sudacho 2-chome Chiyoda-ku Tokyo 101-8558 Japan TEL : (81)3 3254 2935 FAX : 3 3252 8892 The posting and copying from this catalogue without permission is not accepted firmly.

European office : IWAKI Europe GmbH TEL: (49)2154 9254 0 FAX: 2154 9254 48 U.S.A. : IWAKI America Inc. TEL: (1)508 429 1440 FAX: 508 429 1386

Germany : IWAKI Europe GmbH TEL: (49)2154 9254 50 FAX: 2154 9254 55 Argentina : IWAKI America Inc. (Argentina Branch) TEL: (54)11 4745 4116

Holland : IWAKI Europe GmbH (Netherlands Branch) TEL: (31)547 293 160 FAX: 547 292 332 Singapore : IWAKI Singapore Pte Ltd. TEL: (65)6316 2028 FAX: 6316 3221

Italy : IWAKI Europe GmbH (Italy Branch) TEL: (39)0444 371115 FAX: 0444 335350 Indonesia : IWAKI Singapore (Indonesia Branch) TEL: (62)21 6906606 FAX: 21 6906612

Spain : IWAKI Europe GmbH (Spain Branch) TEL: (34)93 37 70 198 FAX: 93 47 40 991 Malaysia : IWAKIm Sdn. Bhd. TEL: (60)3 7803 8807 FAX: 3 7803 4800

Belgium : IWAKI Belgium N.V. TEL: (32)13 67 02 00 FAX: 13 67 20 30 Australia : IWAKI Pumps Australia Pty Ltd. TEL: (61)2 9899 2411 FAX: 2 9899 2421

Denmark : IWAKI Nordic A/S TEL: (45)48 24 2345 FAX: 48 24 2346 Hong Kong : IWAKI Pumps Co., Ltd. TEL: (852)2607 1168 FAX: 2607 1000

Finland : IWAKI Suomi Oy TEL: (358)9 2745810 FAX: 9 2742715 China : GFTZ IWAKI Engineering & Trading Co., Ltd. TEL: (86)20 84350603 FAX: 20 84359181

France : IWAKI France S.A. TEL: (33)1 69 63 33 70 FAX: 1 64 49 92 73 : IWAKI Pumps (Shanghai) Co., Ltd. TEL: (86)21 6272 7502 FAX: 21 6272 6929

Norway : IWAKI Norge AS TEL: (47)23 38 49 00 FAX: 23 38 49 01 Korea : IWAKI Korea Co.,Ltd. TEL: (82)2 2630 4800 FAX: 2 2630 4801

Sweden : IWAKI Sverige AB TEL: (46)8 511 72900 FAX: 8 511 72922 Taiwan : IWAKI Pumps Taiwan Co., Ltd. TEL: (886)2 8227 6900 FAX: 2 8227 6818

Switzerland : IWAKI (Schweiz) AG TEL: (41)26 674 93 00 FAX: 26 674 93 02 Thailand : IWAKI (Thailand) Co.,Ltd. TEL: (66)2 322 2471 FAX: 2 322 2477

U.K. : IWAKI Pumps (UK) Ltd. TEL: (44)1743 231363 FAX: 1743 366507 Vietnam : IWAKI Pumps Vietnam Co., Ltd. TEL: (84)613 933456 FAX: 613 933399

( )Country codes

Caution for safety use: Before use of pump, read instruction manual carefully to use the product correctly.

Actual pumps may differ from the photos. Specifications and dimensions are subject to change without prior notice. For further details please contact us.

Legal attention related to export.

Our products and/or parts of products fall in the category of goods contained in control list of international regime for export control.

Please be reminded that export license could be required when products are exported due to export control regulations of countries.

CAT-A 0065-02 2011.01.2000.SXN

Polypropylene magnetic drive process pumps

AMP40 AMP50

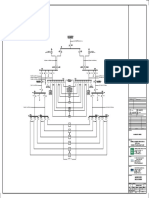

The AMP series are magnetic drive process pumps with polypropylene wet ends, Construction Performance curves

featuring a unique configuration which gives greatly improved tolerance to

1 Front casing AMP40-1 AMP50-1

abnormal operating conditions (Non contact system). Applications cover a wide Drive magnet

Shaft Power (kW)

Shaft Power (kW)

6 6

165

5 5

range of light chemical duties from acid to alkaline. 50Hz 165

160 4

50Hz

160

150 4

150 140

140 3 130 3

130 120

2 110 2

120

3 Impeller 110 1 1

10 Rear thrust 40 0 40 0

8 Mouth ring

2 Rear casing 30

165

30

Head(m)

Head(m)

160

20 150 20

140 165

160

130 140 150

10 10 130

110 120 110 120

0 0

0 100 200 300 400 500 600 0 200 400 600 800 1000 1200

Capacity (L/min) Capacity (L/min)

Shaft Power (kW)

7 9

Shaft Power (kW)

160 6 160 8

150 150 7

60Hz 140 5 60Hz 140

4 6

130 130 5

120 3 120 4

110 2 110 3

1 2

50 0 1

50 0

40 160

Rear casing cover 150 40 160

Head(m)

30

7 Liner ring 150

Head(m)

140 30

20 130

6 Spindle 9 Rear ring 120 20 140

110 110 120 130

10

5 Bearing 10

0 0

4 Magnet capsule 0 100 200 300 400 500 600 0 200 400 600 800 1000 1200

11 Gasket Capacity (L/min) Capacity (L/min)

Wet-end materials Pump size 50Hz 60Hz

Model Impeller size

Suction X Discharge Capacity L/min Head m Capacity L/min Head m

Materials CF KK 165 35

1 Front casing 160 32.5 46.5

2 Rear casing CFRPP 150 28.5 41

3 Impeller AMP40-1 50 X 40 140 208 25 34.5

250

4 Magnet capsule CFRETFE 130 20.5 29

5 Bearing High density carbon 120 17 24

6 Spindle 110 13 19.5

High purity alumina ceramic

7 Liner ring SiC 165 33

8 Mouth ring PTFE (with filler) 160 31 44.5

9 Rear ring High purity alumina ceramic 150 27 38

10 Rear thrust AMP50-1 65 X 50 140 417 22.5 33

PTFE 500

11 Gasket 130 18 27

Note: Liquid temperature range 0 to 80˚C Maximum operating pressure 1.0 MPa 120 15 21.5

Note: Please contact us for corrosion resistance. 110 12 18.5

You might also like

- Horizontal Pump Curve for 420EXHV Pump with 150mm DischargeDocument1 pageHorizontal Pump Curve for 420EXHV Pump with 150mm Dischargeachmadj1405No ratings yet

- At Intersection: Wall Base ReinforcingDocument9 pagesAt Intersection: Wall Base ReinforcingJet ArcaNo ratings yet

- KSCP hardened steel spur and helical gears specificationsDocument1 pageKSCP hardened steel spur and helical gears specificationsqwerty 12345No ratings yet

- Aux SLDDocument1 pageAux SLDthnaikNo ratings yet

- 6x4 impulsor metalicoDocument1 page6x4 impulsor metalicojestaciontNo ratings yet

- SI 5NB0A 001 00 Eng - v1 - m56577569830747488Document1 pageSI 5NB0A 001 00 Eng - v1 - m56577569830747488brassoyNo ratings yet

- Warman International LTD.: WPA 64A01M Issued SEP 1999 Gland Sealed PumpDocument1 pageWarman International LTD.: WPA 64A01M Issued SEP 1999 Gland Sealed PumpFlávio Carvalho FlávioNo ratings yet

- Attachment 3 - Warman® 86AH Pump Performance Curve - Condition 1 BoosterDocument1 pageAttachment 3 - Warman® 86AH Pump Performance Curve - Condition 1 Boosterachmadj1405No ratings yet

- H-12 Tiang Lampu SorotDocument1 pageH-12 Tiang Lampu Sorotyazeed yasminNo ratings yet

- PVDF - Chemical - Resistance - ChartDocument22 pagesPVDF - Chemical - Resistance - ChartИбрагим НурмамедовNo ratings yet

- Electrical distribution board layoutDocument1 pageElectrical distribution board layoutBudi HahnNo ratings yet

- 01c8ac75-a951-4cc6-9205-790ed5720afbDocument1 page01c8ac75-a951-4cc6-9205-790ed5720afbamitNo ratings yet

- Drainage and road design detailsDocument1 pageDrainage and road design detailsPraveen CyssanNo ratings yet

- 40A TP MCCB TP MCCB 100A TP MCCB 100A TP MCCB 40A: Desert Palace Gen. Cont. Co. L.L.CDocument25 pages40A TP MCCB TP MCCB 100A TP MCCB 100A TP MCCB 40A: Desert Palace Gen. Cont. Co. L.L.CBelal HHNo ratings yet

- Chemical Resistance Chart FybrocDocument22 pagesChemical Resistance Chart Fybrocshahul_2k5No ratings yet

- Balancing Tank Access ManholeDocument1 pageBalancing Tank Access ManholemanuNo ratings yet

- 50890-1000 Brochure 2005Document2 pages50890-1000 Brochure 2005Juasadf IesafNo ratings yet

- South Tse Tank Addc Electrical Drawing Approval (1) ..Document1 pageSouth Tse Tank Addc Electrical Drawing Approval (1) ..Swami NathanNo ratings yet

- Seccionador SDF145WOESDocument1 pageSeccionador SDF145WOESMelvin Enoc Chavarría ZelayaNo ratings yet

- Aluminium terminal pad specificationsDocument1 pageAluminium terminal pad specificationsMelvin Enoc Chavarría ZelayaNo ratings yet

- Propeller FanDocument19 pagesPropeller FanPrakash RaoNo ratings yet

- Predicted. Use As First Guide Only. FGD Acceptance Criteria According To Iso 9906 With No Negative ToleranceDocument1 pagePredicted. Use As First Guide Only. FGD Acceptance Criteria According To Iso 9906 With No Negative ToleranceGabriel MarinoNo ratings yet

- H76642-10 LO DiagramDocument1 pageH76642-10 LO DiagramFandrio PermataNo ratings yet

- Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2Document1 pageWpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2risa ridmaNo ratings yet

- AC-DC Power Supplies Ordering GuideDocument7 pagesAC-DC Power Supplies Ordering GuideVishwakarma EnterprisesNo ratings yet

- Motor Lincoln 286 TSCDocument5 pagesMotor Lincoln 286 TSCJose BarreroNo ratings yet

- AC-DC Power Supplies Ordering GuideDocument6 pagesAC-DC Power Supplies Ordering GuideRoberto MichelenaNo ratings yet

- Autonics E30s ManualDocument1 pageAutonics E30s ManualAndrez BermudezNo ratings yet

- Pile cap reinforcement detailsDocument1 pagePile cap reinforcement detailsZahid Hasan ZituNo ratings yet

- Compact 2000 Series: D Deessc CR Riippttiio ON N A AN NC Ciilllla AR RY Y Eeq QU Uiippm Meen NTTDocument3 pagesCompact 2000 Series: D Deessc CR Riippttiio ON N A AN NC Ciilllla AR RY Y Eeq QU Uiippm Meen NTTfire fightingNo ratings yet

- GreenMAX fuel filter specificationsDocument2 pagesGreenMAX fuel filter specificationsGari ChalcoNo ratings yet

- Pesek Group II Lubes Storage-EpcmDocument11 pagesPesek Group II Lubes Storage-EpcmKARTHIK SGNo ratings yet

- Horizontal Single-Stage Centrifugal PumpsDocument52 pagesHorizontal Single-Stage Centrifugal PumpsMorgan HengNo ratings yet

- Wpa1210a01/1 Wpa1210a01/1 Wpa1210a01/1 Wpa1210a01/1 Wpa1210a01/1 Wpa1210a01/1 Wpa1210a01/1Document1 pageWpa1210a01/1 Wpa1210a01/1 Wpa1210a01/1 Wpa1210a01/1 Wpa1210a01/1 Wpa1210a01/1 Wpa1210a01/1Dhruv PatelNo ratings yet

- Jak1 Aur El DWG A 0 9038 (F)Document1 pageJak1 Aur El DWG A 0 9038 (F)Budi HahnNo ratings yet

- SUBMERSUBAL PUMP SeriesDocument1 pageSUBMERSUBAL PUMP SeriesYehude Guillen RomeroNo ratings yet

- Open Surface Drain With Close Cover: Slab Rebar Section 1Document1 pageOpen Surface Drain With Close Cover: Slab Rebar Section 1Manish Krishna BarunNo ratings yet

- Ram pump water supply systemDocument1 pageRam pump water supply systemYesTaratNo ratings yet

- Hvac BasmentDocument1 pageHvac BasmentMahmoud AhmedNo ratings yet

- ACEDGE Compressor CatalogueDocument48 pagesACEDGE Compressor CatalogueNuttee BulbonNo ratings yet

- Especificaciones Tecnicos de Los EngranajesDocument1 pageEspecificaciones Tecnicos de Los EngranajesGary Hans Aüe AnteloNo ratings yet

- Common Service Panel SLDDocument1 pageCommon Service Panel SLDVikasNehraNo ratings yet

- Block A Structure CombinedDocument32 pagesBlock A Structure CombinedUdit AmatNo ratings yet

- H.E Shk. Hammad Bin Jassim Bin Jabor Al-Thani: United Development CompanyDocument1 pageH.E Shk. Hammad Bin Jassim Bin Jabor Al-Thani: United Development CompanyHamid KhanNo ratings yet

- DS4510 5010Document2 pagesDS4510 5010Andie Hart100% (1)

- 1 DCPDocument9 pages1 DCPArif Budiman100% (1)

- Slipway Pulley Foundation - 5 (16!05!19) (1) - ModelDocument1 pageSlipway Pulley Foundation - 5 (16!05!19) (1) - ModelA.K.M Shafiq MondolNo ratings yet

- 2-Phase With Sand TrapDocument2 pages2-Phase With Sand TrapYaqoob IbrahimNo ratings yet

- Single Line Diagram - ElectricalDocument1 pageSingle Line Diagram - ElectricalSikandar KhanNo ratings yet

- 2465 KG Bobcat s450 TechnficheDocument4 pages2465 KG Bobcat s450 TechnficheKasidinNo ratings yet

- Wpa1210a20 1Document1 pageWpa1210a20 1carlos.delatorreNo ratings yet

- RIE93266 Instruction GuideDocument1 pageRIE93266 Instruction GuideMarco Antonio CastilloNo ratings yet

- Nash Compressors enDocument3 pagesNash Compressors enAli MadandarNo ratings yet

- DR412i Maintenance Kit PlannerDocument2 pagesDR412i Maintenance Kit PlannerEmanuel Nicolas VillarruelNo ratings yet

- Reinforced concrete foundation plan and section detailsDocument1 pageReinforced concrete foundation plan and section detailsAnde BhanuNo ratings yet

- RCP6 (S) SA4C - p13 14Document2 pagesRCP6 (S) SA4C - p13 14TuanNo ratings yet

- Solar PanelDocument1 pageSolar Panelzachary.ocwNo ratings yet

- Drawing 2000 MM - PT Trans Power Shaft 6.5 InchiDocument1 pageDrawing 2000 MM - PT Trans Power Shaft 6.5 InchimadpethalNo ratings yet

- Toyota Camry 2AZ Wiring DiagramDocument69 pagesToyota Camry 2AZ Wiring Diagramgian marco llamoja100% (6)

- Colorful Chalkboard Classroom Labels and OrganizersFrom EverandColorful Chalkboard Classroom Labels and OrganizersNo ratings yet

- Welcome To ABCDocument2 pagesWelcome To ABCMạnh Đạt NguyễnNo ratings yet

- Untitled Notebook PDFDocument2 pagesUntitled Notebook PDFMạnh Đạt NguyễnNo ratings yet

- ABC Handbook 02Document94 pagesABC Handbook 02Asbury Park PressNo ratings yet

- Binatrol Diaphragm Bin Monitors: Installation & OperationDocument4 pagesBinatrol Diaphragm Bin Monitors: Installation & OperationMạnh Đạt NguyễnNo ratings yet

- 17Document6 pages17Mạnh Đạt NguyễnNo ratings yet

- WelcomeDocument5 pagesWelcomeCatNo ratings yet

- FFFFDocument1 pageFFFFMạnh Đạt NguyễnNo ratings yet

- Reason SkillsDocument176 pagesReason Skillsjnanmol007100% (9)

- BBC Learning EnglishDocument12 pagesBBC Learning EnglishDhe Rahmat Albanjari100% (65)

- SAP Enabled RF GunDocument4 pagesSAP Enabled RF Gunvijay_sudha100% (1)

- Vaghodia Compressor STNDocument41 pagesVaghodia Compressor STNAyaanNo ratings yet

- Saso 2221 2004 eDocument18 pagesSaso 2221 2004 eshafeeqm3086No ratings yet

- PVC Accessories Manufacturer in DubaiDocument13 pagesPVC Accessories Manufacturer in DubaiPolyfab Plastic Industry LLCNo ratings yet

- Bulk Carriers (A Detailed Synopsis) : Maritime TradeDocument8 pagesBulk Carriers (A Detailed Synopsis) : Maritime TradeAnonymous UCveMQNo ratings yet

- Geosynthetic Refoirced SoilDocument21 pagesGeosynthetic Refoirced SoilDanilo BoteroNo ratings yet

- Lathe MachineDocument9 pagesLathe MachineJung HoonNo ratings yet

- Ford 3600 Quick Reference Parts GuideDocument7 pagesFord 3600 Quick Reference Parts GuideFrancisco SilvaNo ratings yet

- Technical Specifications For Ash Handling System 3x135mwDocument16 pagesTechnical Specifications For Ash Handling System 3x135mwananthiNo ratings yet

- San Salvador v1 InstructionsDocument11 pagesSan Salvador v1 InstructionsAtul SartapeNo ratings yet

- PHB PCS7 eDocument528 pagesPHB PCS7 eSaad BroNo ratings yet

- Astm A 6-11Document63 pagesAstm A 6-11giannerysNo ratings yet

- FLENDER - 2LP3021-0BJ50-6ZA0-Z - B41+C00+C82+G30+G36+H00+H10+P0B+P14+P88+P95+Y01+Y02+Y20+Y21+Y23 - Datasheet - enDocument3 pagesFLENDER - 2LP3021-0BJ50-6ZA0-Z - B41+C00+C82+G30+G36+H00+H10+P0B+P14+P88+P95+Y01+Y02+Y20+Y21+Y23 - Datasheet - enoscar_jfrNo ratings yet

- KOBELCO Arm Shock CountermeasureDocument204 pagesKOBELCO Arm Shock CountermeasurePHÁT NGUYỄN THẾ100% (8)

- Mitsubishi Diesel Engine Manual Foreword and Table of ContentsDocument31 pagesMitsubishi Diesel Engine Manual Foreword and Table of ContentsRickNo ratings yet

- Operation and Maintenance of Radial GatesDocument39 pagesOperation and Maintenance of Radial Gatespitamber100% (3)

- Fault Tree Analysis For Oil Tank Fire and Explosion PDFDocument9 pagesFault Tree Analysis For Oil Tank Fire and Explosion PDFridanormaNo ratings yet

- Automatic Voltage Regulator Installation ManualDocument10 pagesAutomatic Voltage Regulator Installation ManualDaiane MendesNo ratings yet

- Spark Test of Metals: B B A ADocument4 pagesSpark Test of Metals: B B A ALovely NievesNo ratings yet

- Salt Cake John N. HyrnDocument14 pagesSalt Cake John N. HyrndavidNo ratings yet

- IGNOU-HHML Motorcycle Technician Competency Development ProgrammeDocument25 pagesIGNOU-HHML Motorcycle Technician Competency Development Programmekulshreshtha_mNo ratings yet

- Heat Setting Fabrics for Dimensional StabilityDocument5 pagesHeat Setting Fabrics for Dimensional StabilityFathi MustafaNo ratings yet

- Photography Business Proposal for Cabatuan, IsabelaDocument30 pagesPhotography Business Proposal for Cabatuan, IsabelaUy SamuelNo ratings yet

- Planning&Expansion of Hospital BuildingDocument9 pagesPlanning&Expansion of Hospital BuildingramanNo ratings yet

- Harga Mesin Jahit Typical:: Juki DDL 8100eDocument2 pagesHarga Mesin Jahit Typical:: Juki DDL 8100eRismapleNo ratings yet

- Dictionary of Boiler TerminologyDocument27 pagesDictionary of Boiler TerminologyAlka Seltzer100% (34)

- C4Document4 pagesC4tommy lanyonNo ratings yet

- Volvo V40 CCDocument4 pagesVolvo V40 CCgv_Scribd0% (2)

- ME 530 Near-Net Shape Manufacturing Instructor Dr. Neda FabrisDocument20 pagesME 530 Near-Net Shape Manufacturing Instructor Dr. Neda FabrisAnsul SinghNo ratings yet

- Berkeley Pump SeriesDocument36 pagesBerkeley Pump SeriesJMFPNo ratings yet