Professional Documents

Culture Documents

RCM - Reliability Centered Maintenance: Reliable - Efficient - User-Friendly

Uploaded by

Matko ŽajaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RCM - Reliability Centered Maintenance: Reliable - Efficient - User-Friendly

Uploaded by

Matko ŽajaCopyright:

Available Formats

Reliable – Efficient – User-friendly

RCM - Reliability Centered Maintenance

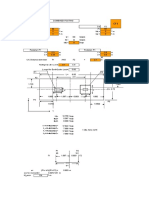

Maintenance is one of the areas in which there is most DORF-LS1 DORF-LS2

potential for power utilities to cut costs. It is possible

I=0.357 I=0.371

C=66.0 C=11.0

D=46.9 D=8.0

Itot=0.001 Itot=0.001

to implement an optimum maintenance strategy if the

condition and importance of equipment can be

DORF-LS3 DORF-LS4 MVRUR4_A

I=1.627 I=1.695 I=0.474

C=5.0 C=14.0 C=50.5

D=4.7 D=11.1 D=36.1

determined cost-effectively.

Itot=0.006 Itot=0.006 Itot=0.360

MVRUR4_L

T=1.395 h

Pr=49.590 min/yr

The method of reliability-centered maintenance is

W=0.247 MWh/yr MVRUR6_L

MVRUR5_A C=2032.542 €/yr T=6.786 h

I=0.318 Pr=241.163 min/yr

C=48.7 W=0.985 MWh/yr

implemented in the NEPLAN-Maintenance software

RUR_C3 RUR_C8 D=34.7 C=7353.095 €/yr

I=0.360 I=0.376 Itot=0.241

MVRUR5_L

C=33.0 C=42.0 T=1.395 h

D=23.6 D=30.0 Pr=49.564 min/yr RUR_L1

Itot=0.360 Itot=0.376

program, which fits smoothly into the famous NEPLAN-

W=0.405 MWh/yr I=42.534

C=3331.212 €/yr C=63.0

D=74.6

Itot=42.534

Reliability module. The primary advantages of the MVRUR1_A

I=0.316

C=52.1

D=37.1

computer-aided implementation and documentation of Itot=0.239

MVRUR1_L RUR_C6

maintenance strategies are reproducibility on the basis of

T=3.991 h I=0.376

Pr=18.712 min/yr C=39.0

W=0.153 MWh/yr D=27.8

C=811.135 €/yr Itot=0.376

selected criteria and the fact that the company’s RUR_C4

I=0.360

RUR_C5

I=0.360

maintenance expertise is preserved. NEPLAN-

C=36.0 C=60.0

D=25.7 D=42.7

Itot=0.360 Itot=0.360

Maintenance can also be used excellently for DORF-LS1

I=0.357

MVRUR2_L

T=3.991 h

Pr=18.712 min/yr

MVRUR3_L

DORF-LS2

T=3.986 h

Pr=18.685 min/yr

I=0.371

W=0.076 MWh/yr

reinvestment strategies.

W=0.153 MWh/yr

C=66.0

MVRUR2_A C=811.135 €/yr MVRUR3_A C=11.0

C=403.811 €/yr

I=0.316

D=46.9

C=33.7

I=0.187 D=8.0

C=44.4

Itot=0.001

D=24.1

Itot=0.239

D=31.6 Itot=0.001

Itot=0.142

DORF-LS3 DORF-LS4

I=1.627 I=1.695

C=5.0 C=14.0

D=4.7 D=11.1

Itot=0.006 Itot=0.006

Integration with NEPLAN-Reliability:

The results from the reliability calculation

(importance) are combined with the condition

evaluation of the maintenance module and

displayed in the NEPLAN-single line diagram

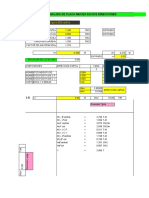

NEPLAN-Maintenance Module:

The left side of the picture shows the

assessment sheet of the current component. The

diagram shows all calculated conditions (y-axes)

and all importance’s (x-axes) of all components.

The importance can be calculated by the

NEPLAN-Reliability module or defined in the

maintenance module. Components in the red

area have a bad condition and should be

replaced.

Budget Evaluation Tool

Combined Transformer

Comment RCM TBM

Start year calculation period 2007 2007

Replacement costs 50000 50000

Maintenance costs 8000 8000

Replacement cycle 40 40

Maintenance cycle 10 10 The integrated chart

Replacement limit 70 70 manager shows the

Maintenance limit 40 40 influence of each

Total components 936 936 criterion to the overall

Number of components for replacement 42 53

conditions

Number of components for maintenance 32 73

Total costs replacement 2100000 2650000

Total costs maintenance 256000 584000

Budget 2356000 3234000

More information and free DEMO at

At your fingertips: Budget evaluation of RCM and TBM

can easily be compared www.neplan.ch

You might also like

- Cbe 40a HW7Document3 pagesCbe 40a HW7Huỳnh Huy ĐắcNo ratings yet

- L=159.4 mm D D U W m K A π D A π (0.021) =0.066 m A π D A π (0.01365) =0.0429 m A A D D A A U W m K ∆ T =5 ℃ T Lmtd= T T T T T T T T A L Q U A Lmtd Q A Q QDocument1 pageL=159.4 mm D D U W m K A π D A π (0.021) =0.066 m A π D A π (0.01365) =0.0429 m A A D D A A U W m K ∆ T =5 ℃ T Lmtd= T T T T T T T T A L Q U A Lmtd Q A Q QEriane GarciaNo ratings yet

- Final CH PDFDocument7 pagesFinal CH PDFNaveen DikshitNo ratings yet

- Green: Note 1: Put The Values in Cell of and ColorDocument2 pagesGreen: Note 1: Put The Values in Cell of and ColorAbu BiduNo ratings yet

- A Report: Compact Verilog-A PN Junction Photodiode ModelDocument13 pagesA Report: Compact Verilog-A PN Junction Photodiode ModelDilan ByteNo ratings yet

- EE303 Solutions PDFDocument87 pagesEE303 Solutions PDFgaus silaban100% (1)

- GMM FinalDocument7 pagesGMM FinalIntan Masyitha IrwanNo ratings yet

- Combined Footing DesignDocument12 pagesCombined Footing DesignPAWANNo ratings yet

- 05 - Energy BalanceDocument28 pages05 - Energy BalanceNoman AslamNo ratings yet

- Hitungan IRBADocument243 pagesHitungan IRBAImaaNo ratings yet

- Hitungan IRBADocument243 pagesHitungan IRBAImaaNo ratings yet

- Deflection CalculationDocument6 pagesDeflection CalculationSuhas MangaloreNo ratings yet

- Esquema: Cliente: Nombre: NúmeroDocument1 pageEsquema: Cliente: Nombre: NúmeroedwinNo ratings yet

- Modeling and Study of Wind Turbine Driven Dfig Using Three Level InverterDocument9 pagesModeling and Study of Wind Turbine Driven Dfig Using Three Level InverterNadia BnNo ratings yet

- Chiller Assignment ME0106042Document1 pageChiller Assignment ME0106042AhmadDanialAsraffNo ratings yet

- Losa Maciza en Dos Direcciones. LOSA DE TANQUES ELEVADOSDocument7 pagesLosa Maciza en Dos Direcciones. LOSA DE TANQUES ELEVADOSEstefania PerezNo ratings yet

- Calculos Del Rri: TOP HYP HYPDocument5 pagesCalculos Del Rri: TOP HYP HYPLuis Alberto MendezNo ratings yet

- Disc Ceramic Capacitors: How To OrderDocument2 pagesDisc Ceramic Capacitors: How To OrderJuan GomezNo ratings yet

- This Sheet Is Prepared According To The AISC (13 Edition) Using LRFD MethodDocument9 pagesThis Sheet Is Prepared According To The AISC (13 Edition) Using LRFD MethodsopnanairNo ratings yet

- AISC Propiedades y Pesos - TOTALDocument41 pagesAISC Propiedades y Pesos - TOTALjuanchi1979scribdNo ratings yet

- Differential Protection 20MVA Transformer 33-11KVDocument11 pagesDifferential Protection 20MVA Transformer 33-11KVarsalanhamid100% (3)

- 7li1ag6 Blo M2 (87L) Sfcsc103ebl Rev0Document5 pages7li1ag6 Blo M2 (87L) Sfcsc103ebl Rev0rey pamelo navarroNo ratings yet

- Ultra Fine Grinder: Date: 24-10-2019Document5 pagesUltra Fine Grinder: Date: 24-10-2019UsamaNo ratings yet

- Desain JembatanDocument3 pagesDesain JembatandedyNo ratings yet

- Uji Akar Unit - Pendekatan Augmented Dickey-Fuller (ADF)Document16 pagesUji Akar Unit - Pendekatan Augmented Dickey-Fuller (ADF)fikhi cahyaniNo ratings yet

- Tut 6 Ideal and Nonideal Solutions - SolutionsDocument19 pagesTut 6 Ideal and Nonideal Solutions - SolutionsAsma NasserNo ratings yet

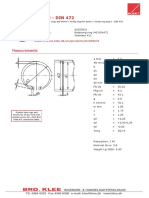

- Data Sheet: Circlip Ring Type J - DIN 472Document1 pageData Sheet: Circlip Ring Type J - DIN 472danielNo ratings yet

- Activation Energy (Calculations)Document2 pagesActivation Energy (Calculations)Roma KaristiNo ratings yet

- PDF 13Document2 pagesPDF 13Ercan Umut DanışanNo ratings yet

- Asentamientos Elasticos WordDocument6 pagesAsentamientos Elasticos WordMonica PintoNo ratings yet

- Scaffold Tube CapacityDocument2 pagesScaffold Tube CapacityVignesh Ramalingam100% (1)

- Trabajo Turbinas de Gas 2019-1Document4 pagesTrabajo Turbinas de Gas 2019-1Fabián Yesid R. LeónNo ratings yet

- Directional Inverse Time Overcurrent Relay For Meshed Distribution Systems With Distributed Generation With Additional Continuous Relay SettingsDocument6 pagesDirectional Inverse Time Overcurrent Relay For Meshed Distribution Systems With Distributed Generation With Additional Continuous Relay SettingsFinolaNo ratings yet

- Area BDocument2 pagesArea Bzms msswiNo ratings yet

- Midterm Exam 51047: Industrial Waste Management & ControlDocument6 pagesMidterm Exam 51047: Industrial Waste Management & ControlStephannie SyNo ratings yet

- Temperauture.: Prob. Solution: GivenDocument9 pagesTemperauture.: Prob. Solution: Givenharsh patelNo ratings yet

- Long Term Deflection - Between Grid 2&C1 (2nd Floor)Document2 pagesLong Term Deflection - Between Grid 2&C1 (2nd Floor)Nishant Kumar GoelNo ratings yet

- Alhar Coba Sendiri 14 Jul 20.14Document21 pagesAlhar Coba Sendiri 14 Jul 20.14Kelvin RamadhanNo ratings yet

- Business Statistics Analysis For The Performance of Harvells India LTDDocument10 pagesBusiness Statistics Analysis For The Performance of Harvells India LTDbhavitha birdalaNo ratings yet

- Static Calculations - AisladoresDocument4 pagesStatic Calculations - AisladoresfabianNo ratings yet

- Belt CalculationDocument61 pagesBelt CalculationtranceinttNo ratings yet

- Calculation of Deflection: Deflection Due To ShrinkageDocument4 pagesCalculation of Deflection: Deflection Due To ShrinkagerammohanNo ratings yet

- Siklus OttoDocument2 pagesSiklus Ottomuhammadalamin131203No ratings yet

- Theoretical Calculations-1Document3 pagesTheoretical Calculations-1Behara Dinesh Kumar patnaikNo ratings yet

- TBD1Document1 pageTBD1MichenerparkNo ratings yet

- LogDocument6 pagesLogアーノルドNo ratings yet

- Centrifugal Pump Calculation For Safety Shower-Rev.03Document22 pagesCentrifugal Pump Calculation For Safety Shower-Rev.03Ashish PawarNo ratings yet

- Perhitungan Tugas DrainaseDocument12 pagesPerhitungan Tugas Drainasenarendra.22073No ratings yet

- (Centrifugal Pump Calculation For DM PW Water To R-401Document20 pages(Centrifugal Pump Calculation For DM PW Water To R-401Ashish PawarNo ratings yet

- Latihan SoalDocument3 pagesLatihan Soalinka anandaNo ratings yet

- Electric Power Distribution Engineering 3rd Gonen Solution ManualDocument10 pagesElectric Power Distribution Engineering 3rd Gonen Solution Manualcarolrosejylcd100% (14)

- TablesDocument2 pagesTablesamgad12No ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Sonnenschein A600_TechnicaldataDocument10 pagesSonnenschein A600_TechnicaldataMatko ŽajaNo ratings yet

- RM6 Katalog HRDocument46 pagesRM6 Katalog HRMatko ŽajaNo ratings yet

- Wing 4 OPzS 200 EN201711 1Document1 pageWing 4 OPzS 200 EN201711 1freddysh4330No ratings yet

- How To Assemble An Electrical Switchbboard Technical GuideDocument292 pagesHow To Assemble An Electrical Switchbboard Technical GuideMatko ŽajaNo ratings yet

- Test Disconnect Terminal Block - URTK/SP - 0311126: Key Commercial DataDocument20 pagesTest Disconnect Terminal Block - URTK/SP - 0311126: Key Commercial DataMatko ŽajaNo ratings yet

- Odvodnik Prenapona - Katalog DEHNDocument264 pagesOdvodnik Prenapona - Katalog DEHNMatko ŽajaNo ratings yet

- Product Data Sheet: Dehnguard® Modular DG M TNC 440 (952 303)Document1 pageProduct Data Sheet: Dehnguard® Modular DG M TNC 440 (952 303)Matko ŽajaNo ratings yet

- Us SBS2V PS 001 - 0914Document4 pagesUs SBS2V PS 001 - 0914Matko ŽajaNo ratings yet

- NEPLAN TransmissionModules-1 PDFDocument45 pagesNEPLAN TransmissionModules-1 PDFMatko Žaja100% (1)

- NSYTRV42 Redna Stezaljka 4mm2 1P 1x1 Siva SchneiderDocument3 pagesNSYTRV42 Redna Stezaljka 4mm2 1P 1x1 Siva SchneiderMatko ŽajaNo ratings yet

- Nº Nota SAP 1976487: Número Versión Respons. Status Tratamiento Estado Estructura Idioma TXT - Breve ComponenteDocument8 pagesNº Nota SAP 1976487: Número Versión Respons. Status Tratamiento Estado Estructura Idioma TXT - Breve ComponenteDavid RoqueNo ratings yet

- Iecee Od-2025-B-2016Document21 pagesIecee Od-2025-B-2016krivitskiNo ratings yet

- 1490Document8 pages1490Ahmed SaadNo ratings yet

- Bpo KpoDocument19 pagesBpo KpoRuchita MehtaNo ratings yet

- Exhibit J - List of Vendor and SubcontractorDocument62 pagesExhibit J - List of Vendor and SubcontractorpragatheeskNo ratings yet

- Technical ManualDocument32 pagesTechnical ManualMihaiNo ratings yet

- DFMADocument12 pagesDFMAbfazil100% (1)

- Course Presentation IATF 16949-2016Document62 pagesCourse Presentation IATF 16949-2016Madhukar Sinha100% (6)

- Circulation - Defining and Planning (May 2012)Document15 pagesCirculation - Defining and Planning (May 2012)Briccio0% (1)

- Castrol Spheerol EPLDocument2 pagesCastrol Spheerol EPLDiego GalvanNo ratings yet

- Dominos Customer Story Infographic RoadmapDocument1 pageDominos Customer Story Infographic RoadmapAishwarya MathurNo ratings yet

- Quality Control Plan TemplateDocument3 pagesQuality Control Plan Templatejon aquinoNo ratings yet

- Parking Access Design Standards Handbook 2010Document25 pagesParking Access Design Standards Handbook 2010Sopheak ThapNo ratings yet

- Control Valve Selection Requirements Learning Instrumentation PDFDocument5 pagesControl Valve Selection Requirements Learning Instrumentation PDFv noteNo ratings yet

- Effective Total Quality Management in Textile Dyeing IndustriesDocument3 pagesEffective Total Quality Management in Textile Dyeing IndustriesMd. Jakir HossenNo ratings yet

- 21 Sumitava CVDocument2 pages21 Sumitava CVchatuusumitavaNo ratings yet

- Sop Piling WorkDocument2 pagesSop Piling WorkamirNo ratings yet

- Creating and Administering Analytics and Reports v13Document108 pagesCreating and Administering Analytics and Reports v13sieger74No ratings yet

- Narrative Statement NPP-0050-QENFB Infra Structure & Utility BuildingsDocument16 pagesNarrative Statement NPP-0050-QENFB Infra Structure & Utility BuildingsLokesh KonganapalleNo ratings yet

- Water Plane ComputationDocument14 pagesWater Plane ComputationAchonk Gio VelenoNo ratings yet

- Tips and Hints For Sharing Data PDFDocument5 pagesTips and Hints For Sharing Data PDFMadhuri MalayathiNo ratings yet

- Airbus Annual Report 2018 PDFDocument324 pagesAirbus Annual Report 2018 PDFBryant BryantNo ratings yet

- HCI 534E/544E - Winding 311: Technical Data SheetDocument9 pagesHCI 534E/544E - Winding 311: Technical Data SheetMd ShNo ratings yet

- P6 - Anprod - Total Productivity ModelDocument17 pagesP6 - Anprod - Total Productivity ModelNicko Nur RakhmaddianNo ratings yet

- TheModelEngineersHandbook TubalCainDocument226 pagesTheModelEngineersHandbook TubalCainDan Agu100% (21)

- Checklist For Rope Suspended Platform HSE OCP 16Document1 pageChecklist For Rope Suspended Platform HSE OCP 16Mohamed KamalNo ratings yet

- 18 - Decrypting Innovation - A Practical Approach - Francesco Fazio - DoblinDocument61 pages18 - Decrypting Innovation - A Practical Approach - Francesco Fazio - DoblinBenício Avellar100% (1)

- WPS-PQR ListDocument1 pageWPS-PQR ListSandra SandersNo ratings yet

- Product Leaflet - Portable CNC Cutting MachineDocument2 pagesProduct Leaflet - Portable CNC Cutting Machineabhics67No ratings yet