Professional Documents

Culture Documents

Conventional Jackets

Uploaded by

kayeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Conventional Jackets

Uploaded by

kayeCopyright:

Available Formats

Conventional Jackets

Figure 1: Conventional

Jacket

"Conventional jackets" can be divided into two (2) main categories: baffled and non-baffled.

Baffled jackets often utilize what is known as a spirally wound baffle. The baffle consist of a

metal strip wound around the inner vessel wall from the jacket utility inlet to the utility outlet.

The baffle directs the flow in a spiral path with a fluid velocity of 1-4 ft/s. The fabrication

methods does allow for small internal leakage or bypass around the baffle. Generally, bypass

flows can exceed 1/3 to 1/2 of the total circulating flow.

Conventional baffled jackets are usually applied with small vessels using high temperatures

where the internal pressure in more than twice the jacket pressure.

Spirally baffled jackets are limited to a pressure of 100 psig because vessel wall thickness

becomes large and the heat transfer is greatly reduced. In the case of an alloy reactor, a very

costly vessel can result. For high temperature applications, the thermal expansion differential

must be considered when choosing materials for the vessel and jacket. Design and construction

details are given in Division 1 of the ASME Code, Section VIII, Appendix IX, "Jacketed Vessel".

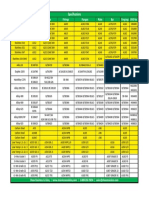

Heat Transfer Coefficients: Conventional Jackets without Baffles

(hj De / k) = 1.02 (NRe) 0.45 (NPr) 0.33 (De/ L) 0.4 (Djo/ Dji) 0.8 (NGr) 0.05 Eq. (1)

Figure 2: Schematic of Conventional

Jacket

Where:

hj = Local heat transfer coefficient on the jacket side

De = Equivalent hydraulic diameter

NRe = Reynolds Number

NPr = Prandtl Number

L = Length of jacket passage

Djo = Outer diameter of jacket

Dji = Inner diameter of jacket

NGr = Graetz number

The Reynolds Number is defined as:

NRe = DVρ/μ

Where D is the equivalent diameter, V is the fluid velocity, ρ is the fluid density, μ and is the

fluid viscosity.

The Prandtl Number is defined as:

NPr = Cp μ / k

Where Cp is the specific heat, μ is the viscosity, and k is the thermal conducitivity of the fluid.

The Graetz Number is defined as:

NGr = (m Cp) / (k L)

Where m is the mass flow rate, Cp is the specific heat, k is the thermal conducitivity, and L is the

jacket passage length.

The equivalent diameter is defined as follows:

De = Djo-Dji for laminar flow

De = ((Djo)2 - (Dji)2)/Dji for turbulent flow

Conventional Jackets with Baffles

For conventional jackets with baffles, the following can be used to calculate the heat transfer

coefficient:

hj De/k= 0.027(NRe)0.8 (NPr)0.33 (µ/µw)0.14 (1+3.5 (De/Dc) ) ( For NRe > 10,000) Eq. (2)

hj De/k = 1.86 [ (NRe) (NPr) (Dc/De) ] 0.33 (µ/µw)0.14 ( For NRe < 2100 ) Eq. (3)

Figure 3: Schematic of Conventional Jacket

with Baffle

Two new variables are introduced. Dc is defined as the centerline diameter of the jacket passage.

It is calculated as Dji + ((Djo-Dji)/2). The viscosity at the jacket wall is now defined as µw. When

calculating the heat transfer cofficients, an effective mass flow rate should be taken as 0.60 x

feed mass flow rate to account for the substantial bypassing that will be expected. De is defined

at 4 x jacket spacing. The flow cross sectional area is defined as the baffle pitch x jacket spacing.

You might also like

- Expansion Valves - Working PrincipleDocument3 pagesExpansion Valves - Working PrinciplePradeep Sukumaran100% (1)

- Rectangular Tanks:: Rectangle Tank DesignDocument23 pagesRectangular Tanks:: Rectangle Tank Designshna jabarNo ratings yet

- Grand Prix Engg.: Tag No. 90-EH-02Document6 pagesGrand Prix Engg.: Tag No. 90-EH-02Abhay UpadhyayNo ratings yet

- JSW Toranagallu 24m Gallery DesignDocument5 pagesJSW Toranagallu 24m Gallery DesignvivekNo ratings yet

- Design of circular silo bunkerDocument24 pagesDesign of circular silo bunkerJames AugustineNo ratings yet

- Rect TankDocument6 pagesRect TankSasikumar JothiNo ratings yet

- Conveyor Screws PDFDocument9 pagesConveyor Screws PDFldavilaluceralNo ratings yet

- Biodiesel FeasibilityDocument118 pagesBiodiesel FeasibilityAsadullah BalochNo ratings yet

- 181-F Secondary Reformer Jacket Cooling Water Pit - R0 (1) - 12082018 PDFDocument17 pages181-F Secondary Reformer Jacket Cooling Water Pit - R0 (1) - 12082018 PDFManish542No ratings yet

- Coaching 150 Pipe UpDocument150 pagesCoaching 150 Pipe Uprobert carbungco100% (1)

- Silo Capacity CalculationDocument1 pageSilo Capacity Calculationlbc123No ratings yet

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

- Dynamic Pressure For Circular Silos Under Seismic ForceDocument10 pagesDynamic Pressure For Circular Silos Under Seismic Forcesebastian9033No ratings yet

- Absorção ChillerDocument44 pagesAbsorção ChillergdaronaldoNo ratings yet

- Pipe and fittings document layout guideDocument28 pagesPipe and fittings document layout guidemhreteabNo ratings yet

- Screw ConveyorDocument4 pagesScrew ConveyorRaji SuriNo ratings yet

- WWW Mechanicalengineeringblog Com 2Document6 pagesWWW Mechanicalengineeringblog Com 2Mashudi FikriNo ratings yet

- Rotating TrolleyDocument12 pagesRotating TrolleyInderdeep TatlaNo ratings yet

- Burner specification document summaryDocument6 pagesBurner specification document summaryHafiz Muhammad AbubakarNo ratings yet

- Conveyor Design Summary ReportDocument1 pageConveyor Design Summary ReportAlejandro Castro0% (1)

- Lecture 8 Shaft DesignDocument65 pagesLecture 8 Shaft DesignYasir A. Al-ShataifNo ratings yet

- Design of ShaftDocument8 pagesDesign of ShaftPavan BabhaleNo ratings yet

- Calculating stack effect draft flow rate for flue gas stacks and chimneysDocument2 pagesCalculating stack effect draft flow rate for flue gas stacks and chimneysKarthick VelayuthamNo ratings yet

- Beam Deflection CalculationDocument2 pagesBeam Deflection CalculationAriful IslamNo ratings yet

- TUBESHEETDocument5 pagesTUBESHEETMehta MehulNo ratings yet

- Ellipsoidal Flange to Circular Conversion DimensionsDocument3 pagesEllipsoidal Flange to Circular Conversion Dimensionsnaveenkumar_madasettNo ratings yet

- MixerDocument10 pagesMixerKRYSTEL WENDY LAHOMNo ratings yet

- Appendix A1Document5 pagesAppendix A1Thomas Stephen100% (1)

- TF6 ReportDocument19 pagesTF6 ReportTing Kee Chuong100% (1)

- WI06-0260 Calculations For Obround Nozzle ConnectionsDocument4 pagesWI06-0260 Calculations For Obround Nozzle ConnectionskumarNo ratings yet

- iKW PER TRDocument19 pagesiKW PER TRAsif iqbalNo ratings yet

- Feasibility Study for Low-Energy Industrial ParkDocument53 pagesFeasibility Study for Low-Energy Industrial Parkkaye100% (1)

- Conventional JacketsDocument4 pagesConventional JacketsTerence TanNo ratings yet

- Standard Specification For Hot Insulation Piping EquipmentDocument62 pagesStandard Specification For Hot Insulation Piping EquipmentAri SupramonoNo ratings yet

- CasoEstudio PervaporaciónDocument17 pagesCasoEstudio PervaporaciónValentina SánchezNo ratings yet

- Design Calculations of Pitch Blade TurbineDocument6 pagesDesign Calculations of Pitch Blade TurbineAyaz_HasanjiNo ratings yet

- Development of a Cone: Dimensions, Calculations & WeightDocument1 pageDevelopment of a Cone: Dimensions, Calculations & WeightnileshNo ratings yet

- CEMA 6 Belt Conveyors Belt AlignmentDocument2 pagesCEMA 6 Belt Conveyors Belt Alignmentali kajbafNo ratings yet

- IIT Hyderabad Faculty Housing Design CalculationsDocument33 pagesIIT Hyderabad Faculty Housing Design CalculationssmijusNo ratings yet

- Hopper Calculation-9Document1 pageHopper Calculation-9Ujwal KhandokarNo ratings yet

- 9178 2 PDFDocument39 pages9178 2 PDFvivekNo ratings yet

- 00.02 Wear Calculations Chain ConveyorDocument1 page00.02 Wear Calculations Chain ConveyorSandy DumisaniNo ratings yet

- DheerajDocument7 pagesDheerajSaksham KakarNo ratings yet

- L-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECDocument1 pageL-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECevrim77No ratings yet

- Round and Rectangular Duct Structural DesignDocument1 pageRound and Rectangular Duct Structural DesignkiranNo ratings yet

- The Turning Movement of a Particle About the Axis of Rotation is Called the Angular Momentum of the Particle and is Measured by the Product of the Linear Momentum and the Perpendicular Distance of the Line of Action From the AxDocument24 pagesThe Turning Movement of a Particle About the Axis of Rotation is Called the Angular Momentum of the Particle and is Measured by the Product of the Linear Momentum and the Perpendicular Distance of the Line of Action From the AxSURAJ MAHATONo ratings yet

- Screw Conveyor Size 350, Input Data SR No Description Metric Unit in Fts SrnoDocument2 pagesScrew Conveyor Size 350, Input Data SR No Description Metric Unit in Fts SrnoTheodoros AtheridisNo ratings yet

- Design of paddle type agitator for effluent agitationDocument4 pagesDesign of paddle type agitator for effluent agitationuttam prabhuNo ratings yet

- TS 1600-140 - Datenblatt - V3Document2 pagesTS 1600-140 - Datenblatt - V3Ulfah Fauziyyah0% (1)

- KIRK KWM Mist EliminatorsDocument3 pagesKIRK KWM Mist EliminatorsperrychemNo ratings yet

- Crusher Capacity Calculation SheetDocument3 pagesCrusher Capacity Calculation SheetDaniel Garnando KristianNo ratings yet

- H1000e K FJDocument8 pagesH1000e K FJSyarif HidayatullahNo ratings yet

- S 101 Sodium Chloride Silo Specification Sheet and DesignDocument8 pagesS 101 Sodium Chloride Silo Specification Sheet and DesignBenedick Jayson MartiNo ratings yet

- Unit-5 Design of Belt DrivesDocument39 pagesUnit-5 Design of Belt DrivesCHANDRASEKARANNo ratings yet

- Conveyor CapacityDocument3 pagesConveyor Capacityx30patelNo ratings yet

- Conveyor Loads - CV100 & 110 PDFDocument4 pagesConveyor Loads - CV100 & 110 PDFJennifer HudsonNo ratings yet

- Bulk Handling Global - Bulk Handling GlobalDocument2 pagesBulk Handling Global - Bulk Handling Globalpvc333No ratings yet

- Design and Study of Floating Roofs For Oil Storage TanksDocument12 pagesDesign and Study of Floating Roofs For Oil Storage TanksDavid RodriguesNo ratings yet

- Catalogue R I Tang Đ NG Cơ Rulmeca PDFDocument8 pagesCatalogue R I Tang Đ NG Cơ Rulmeca PDFRulmeca Việt Nam100% (1)

- Calculation of bearing plate dimensionsDocument3 pagesCalculation of bearing plate dimensionsk.m.ariful islamNo ratings yet

- Standard SpecificationDocument1 pageStandard SpecificationĐạt TrầnNo ratings yet

- Calculate motor power for 35t LRF transfer carDocument2 pagesCalculate motor power for 35t LRF transfer carmech_abhiNo ratings yet

- Powder Cooler - BrochureDocument4 pagesPowder Cooler - BrochureAnonymous Cxriyx9HIX100% (1)

- Steel Beam DesignDocument36 pagesSteel Beam DesignTan Choon LengNo ratings yet

- What Is The Difference Between Screw Pitch and LeadDocument6 pagesWhat Is The Difference Between Screw Pitch and LeadnagarajNo ratings yet

- Table of Cryoscopic and Ebullioscopic ConstantsDocument1 pageTable of Cryoscopic and Ebullioscopic ConstantsBuddy KertunNo ratings yet

- Neutron Lifecycle Control in Nuclear ReactorsDocument18 pagesNeutron Lifecycle Control in Nuclear ReactorskayeNo ratings yet

- Media 228repDocument2 pagesMedia 228repkayeNo ratings yet

- Mobarak - Uganda Rainwater HarvestingDocument14 pagesMobarak - Uganda Rainwater HarvestingkayeNo ratings yet

- Lecture - 3 Nuclear FissionDocument11 pagesLecture - 3 Nuclear FissionkayeNo ratings yet

- 18bishop ECDocument25 pages18bishop ECAnand MurugananthamNo ratings yet

- EDTA Titration CurveDocument14 pagesEDTA Titration CurveM'maay WrtyNo ratings yet

- CH 20 Nuclear Math (p14)Document1 pageCH 20 Nuclear Math (p14)kayeNo ratings yet

- Feasibility Study - Pressurized Oxy-Fuel Approach To Carbon CaptureDocument57 pagesFeasibility Study - Pressurized Oxy-Fuel Approach To Carbon CapturekayeNo ratings yet

- Balancing Nuclear ReactionsDocument1 pageBalancing Nuclear ReactionskayeNo ratings yet

- Fick's Law ExplainedDocument11 pagesFick's Law ExplainedkayeNo ratings yet

- Nuclear Chemistry NotesDocument15 pagesNuclear Chemistry NotesJeevani BattulaNo ratings yet

- Lecture - 12 PoisoningDocument15 pagesLecture - 12 PoisoningkayeNo ratings yet

- Lecture - 13 Fuel DepletionDocument11 pagesLecture - 13 Fuel DepletionkayeNo ratings yet

- Lecture - 6 More On ModeratorsDocument16 pagesLecture - 6 More On ModeratorskayeNo ratings yet

- Mid Exam 2007 PDFDocument2 pagesMid Exam 2007 PDFkayeNo ratings yet

- Nuclear Power ReactorsDocument10 pagesNuclear Power ReactorskayeNo ratings yet

- The Economics of Nuclear PowerDocument13 pagesThe Economics of Nuclear PowerkayeNo ratings yet

- Steady State Diffusion Equation SolvedDocument16 pagesSteady State Diffusion Equation SolvedkayeNo ratings yet

- Controlled Nuclear FissionDocument12 pagesControlled Nuclear Fissionkaye100% (1)

- Lecture - 9 Two-Group Neutron DiffusionDocument12 pagesLecture - 9 Two-Group Neutron DiffusionkayeNo ratings yet

- The Nuclear Fuel CycleDocument7 pagesThe Nuclear Fuel CyclekayeNo ratings yet

- Boiling Water ReactorDocument1 pageBoiling Water ReactorkayeNo ratings yet

- Energy Balances and CO2 ImplicationsDocument6 pagesEnergy Balances and CO2 ImplicationskayeNo ratings yet

- Asia's Nuclear Energy GrowthDocument5 pagesAsia's Nuclear Energy GrowthkayeNo ratings yet

- Euratom Fp7 Fission Leaflet enDocument6 pagesEuratom Fp7 Fission Leaflet enAdel SukerNo ratings yet

- Nuclear Power - Need and FutureDocument54 pagesNuclear Power - Need and FuturekayeNo ratings yet

- Overview of Neutron Total Cross Sections PDFDocument39 pagesOverview of Neutron Total Cross Sections PDFkayeNo ratings yet

- Thermal Analysis of An Aluminum Heat SinkDocument7 pagesThermal Analysis of An Aluminum Heat Sinkapi-247715646No ratings yet

- Laboratory Activity 8 Specific-HeatDocument9 pagesLaboratory Activity 8 Specific-HeatJohn Hayden Dela CruzNo ratings yet

- Fisa Tehnica PEAD-MDocument3 pagesFisa Tehnica PEAD-MStefan StanciuNo ratings yet

- Heat Transfer in Pipe Flow - VDI Heat Atlas, 11. Edition 2013, G1Document2 pagesHeat Transfer in Pipe Flow - VDI Heat Atlas, 11. Edition 2013, G1Luis Fernando Castrillón MadrigalNo ratings yet

- A Review of Gas-Gas Heat Recovery SystemsDocument39 pagesA Review of Gas-Gas Heat Recovery SystemspinenamuNo ratings yet

- Solutions For Heat Transfer Quiz-II: D. Height of The CylinderDocument2 pagesSolutions For Heat Transfer Quiz-II: D. Height of The CylindermkvemulaNo ratings yet

- JNTU Previous Paper Questions ThermodynamicsDocument61 pagesJNTU Previous Paper Questions ThermodynamicsVishnu MudireddyNo ratings yet

- Chpt14 Chemical Reaction (Combustion) Cengel & BolesDocument40 pagesChpt14 Chemical Reaction (Combustion) Cengel & BolesDocumentos De Interés para IngenieríaNo ratings yet

- ChE 110A Problem Set No. 6 Thermodynamic CalculationsDocument2 pagesChE 110A Problem Set No. 6 Thermodynamic CalculationsYodhi PratamaNo ratings yet

- NP-DPDM-400 High Temperature Silicone Bath Fluid PDFDocument1 pageNP-DPDM-400 High Temperature Silicone Bath Fluid PDFBan ZanganaNo ratings yet

- ThermodynamicsDocument98 pagesThermodynamicsHardeep Singh BaliNo ratings yet

- P13-Analysis of Burning CandleDocument5 pagesP13-Analysis of Burning CandleRingo042No ratings yet

- Turbinas Evaporativas de GasDocument158 pagesTurbinas Evaporativas de GasluijamurNo ratings yet

- Measure thermal conductivity of metallic rods using Fourier's lawDocument19 pagesMeasure thermal conductivity of metallic rods using Fourier's lawHarshit AgarwalNo ratings yet

- Process Heat Transfer HofDocument156 pagesProcess Heat Transfer Hofvazzoleralex6884100% (1)

- Heat Transfer Assignment 1Document2 pagesHeat Transfer Assignment 1olenbearNo ratings yet

- Piping Insulation Types of Pipe Insulation With PDFDocument7 pagesPiping Insulation Types of Pipe Insulation With PDFSo SacarNo ratings yet

- Exp 4 Distillation Lab Handout HUMGDocument3 pagesExp 4 Distillation Lab Handout HUMGQuanhongLeNo ratings yet

- R-22 Refrigerant Pressure Chart R-22 Pressures, Quantities, Boiling Points, DataDocument7 pagesR-22 Refrigerant Pressure Chart R-22 Pressures, Quantities, Boiling Points, DataJeffry AlNo ratings yet

- Technical ReferenceDocument120 pagesTechnical ReferenceSimone RizzoNo ratings yet

- User Guide DwsimDocument8 pagesUser Guide DwsimZadky RiosNo ratings yet

- Building Ventilation Systems ExplainedDocument56 pagesBuilding Ventilation Systems ExplainedFranklinNo ratings yet

- Armoire Midea MfgaDocument1 pageArmoire Midea MfgalacothNo ratings yet

- Roof Pond and SkythermDocument19 pagesRoof Pond and SkythermAbishaTeslinNo ratings yet

- Boiler 2Document16 pagesBoiler 2Aatharva ChaudhariNo ratings yet