Professional Documents

Culture Documents

Dynamic vs. Static Trim Paper ID 24574

Uploaded by

Mery MărgineanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dynamic vs. Static Trim Paper ID 24574

Uploaded by

Mery MărgineanCopyright:

Available Formats

ENIRAM STUDIES

DYNAMIC VS. STATIC TRIMMING

HOW REAL-TIME DYNAMIC TRIMMING SAVES MORE FUEL THAN

STATIC TRIMMING

Exploring the key differences between static and dynamic vessel trim-

ming and how dynamic trimming offers the more cost-effective path to

finding the real time optimal trim for each and every voyage.

The trim of a vessel impacts the total force required to propel a vessel through wa-

ter, so for different loading conditions and speeds there is an optimum trim value. If the

vessel is not sailing at or near the optimum trim then it is experiencing more resistance

and in particular more wave making energy which again requires more power and fuel.

In today’s world of high fuel prices, it is recognized that trimming a vessel ef-

fectively can contribute to better fuel efficiency. To date many ship owners/op-

erators are still using static trim tables as the predominant method of obtain-

ing values for optimal trim. These static trim tables are prepared for the vessel in

simulated conditions and are usually calculated based on 2 or 3 variables for ex-

ample draft, speed etc. They are not able to reflect the dynamic external fac-

tors that affect a vessel at sea, such as weather, currents, wave-making, etc.

A more accurate way of calculating trim is to monitor vessel performance data in

real-time while taking account of the effect of dynamic conditions such as wind,

and sea state. This delivers a greater accuracy and insight into how the ves-

sel is performing and how this affects propulsion power and related fuel con-

sumption. Knowing the optimum dynamic trim, means knowing what an-

gle to the waterline the vessel should operate at in order to consume the least

amount of fuel. Using less fuel means lower bunker bills and CO2 emissions.

Static trim (measured when a vessel is not moving) and dynamic trim (measured

when a vessel is out at sea) invariably produce different results due to a com-

plex set of factors including vessel design, loading conditions, speed, weath-

er, and water depth. While using static trim tables can help vessel trimming

at sea, dynamic trimming is the certain way to pinpoint optimum efficiencies,

while building up a data repository for longer term efficiency benefits.

STATIC TRIM

Traditionally, optimal trim has been explored using tank testing – the results of

which are compiled into a static trim chart or table, which displays values for the

optimum trim for a reasonable number of speeds and drafts and pre-defined pa-

rameters. However, this method, does not take into account the effects of the re-

al-time variable conditions at sea. Generally, the static trim model focuses on the

bow to allocate the best angle to operate the vessel, and does not take account of

the height of the stern which would be a better indicator of propulsion efficiency.

Static vs. Dynamic Trim info@eniram.fi www.eniram.fi 1

The accuracy of static trim measurements is improved by sea/speed tri-

als run by shipyards, but these only cover the relatively small variation in en-

vironmental conditions the vessels are exposed to during testing.

In summary, static trimming works with a given set of pre-calculated figures

based on a number of variables. When dealing with prevailing conditions that op-

erate outside these parameters, optimum trimming cannot be supported.

DYNAMIC TRIM

With developments in data collection technology and analysis, today it is possible to

determine the actual trim of a vessel at sea at any given time, which can deliver signif-

icant efficiencies in fuel consumption. In 2007, Eniram pioneered the most accurate way

to measure dynamic trim by installing high-precision attitude sensors (inclinometers) on

board the vessel. Data collected from the sensors is combined with information gath-

ered from the vessel’s own systems relating to its performance in prevailing conditions.

This process takes account of the changing variables to calculate the effect of trim

on performance - including hydrodynamic forces, such as squat, propeller thrust

and manoeuvring rudder angles. It also factors in the impact of additional weath-

er conditions such as wind, sea state, rolling and surging as shown in Figure 1.

Figure 1 - The factors influencing a vessel’s trim

A value for the optimal trim is then calculated and displayed to the crew in real time

on the bridge. It takes the form of an easy to interpret traffic-light system for max-

imum clarity showing the actual dynamic trim at any given time and the extent to

which this is optimized. Indeed Eniram technology facilitates planning and integra-

tion of trimming as part of the normal operating procedures onboard a vessel.

Continuous data collection, filtering and analysis are used to constantly im-

prove the accuracy of the optimum trim. By collecting large amounts of data from

various factors affecting the energy usage of the vessels, it is also possi-

ble to monitor the power decomposition of a vessel. This can help an opera-

Static vs. Dynamic Trim info@eniram.fi www.eniram.fi 2

tor’s staff, onboard and onshore, to further pinpoint potential areas for im-

provement in other areas and to make fleet-wide performance comparisons.

In summary, dynamic trimming provides highly accurate trimming advice based

on the collection and analysis of exact real-time data on a vessel’s trim perfor-

mance. Operating at optimal trim using less power and fuel can also contrib-

ute to condition-based maintenance improvements and prolonged machine life.

A SIMPLE, VIABLE WAY TO CUT COSTS USING DYNAMIC TRIM

Knowing the facts behind performance is the key to managing fuel efficien-

cy and reducing costs. For example, a large cruise or container vessel can easi-

ly save 1,000 tonnes of fuel per year which is about $650,000 in today’s fuel pric-

es, and with this initiative, 3500 tonnes less of CO2 emissions don’t end up

polluting the atmosphere. In today’s eco-focused and highly-regulated ship-

ping world, this substantial operational benefit is one that ship owners and op-

erators should not ignore and of course it makes good business sense.

In fact, on average, Eniram’s customers, depending on the ves-

sel type, journey and length, achieve payback in less than a year.

ABOUT ENIRAM

Established in 2005, Eniram provides the maritime industry with decision support and

data analytics technology that reduce fuel consumption and emissions. The product

portfolio, created by experienced seafarers and technologists, ranges from single

onboard applications to comprehensive fleet analysis and is used by both small and

large shipping companies on vessels ranging from cruise liners, tankers, container ships,

bulkers, LNGs and ferries. These companies rely on Eniram’s technology to enhance their

vessel efficiency and operation and benefit from significant environmental savings and

enhanced information intelligence.

ENIRAM PROVIDES SHIP OPERATORS WITH

• Onboard applications delivering real-time guidance to maintain optimum vessel

performance for maximum fuel efficiency

• Fleet performance management tool to monitor and compare the actual perfor-

mance of each equipped vessel across an entire fleet

• Analytics services exploring the breadth, depth and velocity of the data collected

to further improve efficiencies and validate the results of other energy saving ini-

tiatives such as propeller changes, hull modifications and antifouling measures.

Visit our website www.eniram.fi or contact us for more information.

Captain Melvin Mathews

Director of Regulatory and Environment Solutions

Eniram Ltd.

melvin.mathews@eniram.fi

Static vs. Dynamic Trim info@eniram.fi www.eniram.fi 3

You might also like

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- STA Article 30jan2013 PDFDocument11 pagesSTA Article 30jan2013 PDFpriyoNo ratings yet

- Response Amplitude Operator - Wikipedia, The Free EncyclopediaDocument3 pagesResponse Amplitude Operator - Wikipedia, The Free EncyclopediaFuadNo ratings yet

- Variation - Swing MethodDocument5 pagesVariation - Swing MethodDuy Ngô0% (1)

- Document FileDocument68 pagesDocument Fileso100% (1)

- Sistema RSW-CSWDocument8 pagesSistema RSW-CSWDiego Trinidad100% (1)

- Design Optimization of The Lines of The Bulbous BowDocument12 pagesDesign Optimization of The Lines of The Bulbous BowFernando Raúl LADINONo ratings yet

- An Experimental and Theoritical Study of Planning Surfaces With Trim Flaps PDFDocument63 pagesAn Experimental and Theoritical Study of Planning Surfaces With Trim Flaps PDFGhalih Rasyid Prayogo100% (1)

- ITTC - Recommended Procedures and Guidelines: Practical Guidelines For Ship Self-Pro-pulsion CFDDocument10 pagesITTC - Recommended Procedures and Guidelines: Practical Guidelines For Ship Self-Pro-pulsion CFDcataiceNo ratings yet

- Proceedings - 27th Conference (Copenhagen 2014) - 1-6 Seakeeping CommitteeDocument80 pagesProceedings - 27th Conference (Copenhagen 2014) - 1-6 Seakeeping CommitteeSutiyo Ahad100% (2)

- Ship Design & Construction - SNAMEDocument9 pagesShip Design & Construction - SNAMEBrian FreemanNo ratings yet

- Pile Performance in Weathered Meta-Sedimentary Formation and KL LimestoneDocument6 pagesPile Performance in Weathered Meta-Sedimentary Formation and KL LimestoneMohd MuksinNo ratings yet

- Vibration of Deckhouse StructuresDocument10 pagesVibration of Deckhouse StructuresrthyhtNo ratings yet

- Butler - The Surface Effect ShipDocument54 pagesButler - The Surface Effect ShipJovic IlicNo ratings yet

- SEACOR Power SRC Board Meeting SummaryDocument7 pagesSEACOR Power SRC Board Meeting SummaryAmanda JohnsonNo ratings yet

- An Overview of The Prediction Methods For Roll Damping of ShipsDocument22 pagesAn Overview of The Prediction Methods For Roll Damping of ShipsВасил ЙордановNo ratings yet

- Tutorial1 150916211323 Lva1 App6891 PDFDocument13 pagesTutorial1 150916211323 Lva1 App6891 PDFpraveen@vshNo ratings yet

- ITTC Seakeeping Codes ProceduresDocument17 pagesITTC Seakeeping Codes Procedurespraveench1888No ratings yet

- A Practical System For Hydrodynamic Optimization of Ship Hull FormsDocument7 pagesA Practical System For Hydrodynamic Optimization of Ship Hull FormsSalma SherbazNo ratings yet

- The Propulsion & Manoeuvring Concept of The BCF-Super C - Class Double End FerriesDocument8 pagesThe Propulsion & Manoeuvring Concept of The BCF-Super C - Class Double End FerriesLelosPinelos123No ratings yet

- Seakeeping 19301en2 PDFDocument2 pagesSeakeeping 19301en2 PDFTullio OpattiNo ratings yet

- OLF - NSA Guidelines For Safe Handling and TowingDocument22 pagesOLF - NSA Guidelines For Safe Handling and TowingTomash VerbitskyNo ratings yet

- Plant Machinery Working Life Prediction Method Utilizing Reliability and Condition-Monitoring Data PDFDocument15 pagesPlant Machinery Working Life Prediction Method Utilizing Reliability and Condition-Monitoring Data PDFPradeep KunduNo ratings yet

- Efficient Hull Forms - What Can Be gained-HOLLENBACH - FRIESCH PDFDocument7 pagesEfficient Hull Forms - What Can Be gained-HOLLENBACH - FRIESCH PDFwaleedyehiaNo ratings yet

- Hiper2010 MelbourneDocument310 pagesHiper2010 MelbournemaciuluNo ratings yet

- MSC 85-3-2 Intact Stability Code 2008Document99 pagesMSC 85-3-2 Intact Stability Code 2008Habib SusiloNo ratings yet

- Bouckaert, Et Al, A Life Cycle Cost Analysis of The Application of A Hull Vane To An Offshore Patrol Vessel (FAST2105)Document10 pagesBouckaert, Et Al, A Life Cycle Cost Analysis of The Application of A Hull Vane To An Offshore Patrol Vessel (FAST2105)joene3No ratings yet

- ENGR 4011 Resistance & Propulsion of Ships Assignment 1: 2017Document1 pageENGR 4011 Resistance & Propulsion of Ships Assignment 1: 2017Bagas Somporn Supriadi PutraNo ratings yet

- Ship Structural Design and Anal - Owen F. HughesDocument1 pageShip Structural Design and Anal - Owen F. Hugheshaphong3000No ratings yet

- Hull Form Twin Skeg OptimizationDocument13 pagesHull Form Twin Skeg OptimizationLuis Angel ZorrillaNo ratings yet

- Tips For Building Global Ship Structure Finite Element (FE) Model in ANSYS MAPDL - IIIDocument3 pagesTips For Building Global Ship Structure Finite Element (FE) Model in ANSYS MAPDL - IIINishant VermaNo ratings yet

- GL Rules and Guidelines 2011Document6 pagesGL Rules and Guidelines 2011ruovNo ratings yet

- ENGR 4011 Resistance & Propulsion of Ships Assignment 3: 2018Document5 pagesENGR 4011 Resistance & Propulsion of Ships Assignment 3: 2018Luis De GraciaNo ratings yet

- Finite Element Analysis of Ship Structures Using A New Stiffened Plate ElementDocument14 pagesFinite Element Analysis of Ship Structures Using A New Stiffened Plate Elementmilad66teh100% (1)

- New IMO Requirements - 10th Edition - May 2004Document71 pagesNew IMO Requirements - 10th Edition - May 2004LucianNo ratings yet

- Simulation of Flow Around KCS HullDocument11 pagesSimulation of Flow Around KCS HullMilovan PericNo ratings yet

- Mesh ShipDocument7 pagesMesh ShipPranshu MalikNo ratings yet

- CFD Assignment May 2017Document2 pagesCFD Assignment May 2017蒲俊雄No ratings yet

- Report119 - Part5 of 5 InspectionsDocument11 pagesReport119 - Part5 of 5 InspectionshjdNo ratings yet

- Bretschneider SpectrumDocument9 pagesBretschneider SpectrumSunil Kumar P GNo ratings yet

- Holtrop - A Statistical Re-Analysis of Resistance and Propulsion DataDocument6 pagesHoltrop - A Statistical Re-Analysis of Resistance and Propulsion Datajimmyy90No ratings yet

- Quick Strip TheoryDocument11 pagesQuick Strip TheoryPopoo KyoNo ratings yet

- 1 s2.0 S0029801817301646 Main PDFDocument15 pages1 s2.0 S0029801817301646 Main PDFOdumoduChigozieUzomaNo ratings yet

- Risk Assessment of Ship Platform ColissionDocument6 pagesRisk Assessment of Ship Platform Colission123habib123fikriNo ratings yet

- (Mooring) : 1. GeneralDocument18 pages(Mooring) : 1. GeneralSushanta Kumar RoyNo ratings yet

- FEA Global Model PDFDocument9 pagesFEA Global Model PDFAbuBakarSiddkeRumiNo ratings yet

- Ultimate Limit State Design of Ship StructuresDocument256 pagesUltimate Limit State Design of Ship StructuresProrok NemanjaNo ratings yet

- Ship ManeuveringDocument10 pagesShip ManeuveringnfournarNo ratings yet

- Belenky, Vadim Sevastianov, Nikita B. Stability and Safety of Ships - Risk of Capsizing 2007Document455 pagesBelenky, Vadim Sevastianov, Nikita B. Stability and Safety of Ships - Risk of Capsizing 2007Mai Kawayapanik100% (1)

- Arc Length MethodDocument22 pagesArc Length MethodJoe Satch100% (1)

- High Speed Vessel RuddersDocument12 pagesHigh Speed Vessel RuddersbiondavNo ratings yet

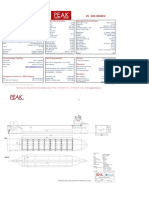

- Product Sheet Stan Tug 1606Document2 pagesProduct Sheet Stan Tug 1606Roda NiagaNo ratings yet

- FINEMarine FAQDocument62 pagesFINEMarine FAQAnson Novendra100% (1)

- E K I PDFDocument7 pagesE K I PDFPrasad SnNo ratings yet

- Determination of Ship Resistance Using HDocument22 pagesDetermination of Ship Resistance Using HSoma Gouthamachary oe19d009No ratings yet

- Lamb T.World-Class Shipbuil.2001.TRANS PDFDocument24 pagesLamb T.World-Class Shipbuil.2001.TRANS PDFairlanggaputraNo ratings yet

- Numerical Models for Submerged Breakwaters: Coastal Hydrodynamics and MorphodynamicsFrom EverandNumerical Models for Submerged Breakwaters: Coastal Hydrodynamics and MorphodynamicsNo ratings yet

- CatalogueDocument43 pagesCatalogueMery MărgineanNo ratings yet

- Exhaust Co2 EmissionDocument6 pagesExhaust Co2 EmissionMery MărgineanNo ratings yet

- Carousel TugDocument7 pagesCarousel TugMery MărgineanNo ratings yet

- Regulations For Danube NavigationDocument17 pagesRegulations For Danube NavigationMery MărgineanNo ratings yet

- Pompe in ParalelDocument6 pagesPompe in ParalelMery MărgineanNo ratings yet

- Technical English Vocabulary and Grammar Alison Pohl Nick Brieger 2002Document148 pagesTechnical English Vocabulary and Grammar Alison Pohl Nick Brieger 2002StellaMarisEnglish0% (1)

- Main Changes in BV RSS Edition July 2016Document4 pagesMain Changes in BV RSS Edition July 2016Mery MărgineanNo ratings yet

- Mecanica FluidelorDocument22 pagesMecanica FluidelorMery MărgineanNo ratings yet

- Algad TeorieDocument16 pagesAlgad TeorieMery MărgineanNo ratings yet

- Everdell Farshore Card ListDocument4 pagesEverdell Farshore Card Listkariko1992No ratings yet

- Almar PresentationDocument18 pagesAlmar PresentationhaciiiNo ratings yet

- Ever GivenDocument5 pagesEver GivenSusanaNo ratings yet

- Build Your Own Submarine: Puget Sound Navy MuseumDocument2 pagesBuild Your Own Submarine: Puget Sound Navy MuseumDaniele VirginioNo ratings yet

- Attack From Atlantis (1953) Lester Del Rey PDFDocument222 pagesAttack From Atlantis (1953) Lester Del Rey PDFAndrei Mihailescu100% (1)

- Unit 3 Going Places 3.1 Vocabulary: Word Pronunciation Translation Part of SpeechDocument38 pagesUnit 3 Going Places 3.1 Vocabulary: Word Pronunciation Translation Part of SpeechZara SargsyanNo ratings yet

- Test Bank For Brief Principles of Macroeconomics 7Th Edition by Gregory Mankiw Isbn 1285165926 9781285165929 Full Chapter PDFDocument36 pagesTest Bank For Brief Principles of Macroeconomics 7Th Edition by Gregory Mankiw Isbn 1285165926 9781285165929 Full Chapter PDFjessie.sell390100% (12)

- Major Cruises of WorldDocument7 pagesMajor Cruises of WorldAmanDeep SinghNo ratings yet

- Hoegh ScheduleDocument1 pageHoegh ScheduleNabil TamimiNo ratings yet

- Containers March 2011Document50 pagesContainers March 2011Parminder singh parmarNo ratings yet

- South Pacific: Samoa Solomon Islands Vanuatu Samoa AmericanDocument11 pagesSouth Pacific: Samoa Solomon Islands Vanuatu Samoa AmericanjohnnyorithroNo ratings yet

- General - Cyprus CyprusDocument6 pagesGeneral - Cyprus Cypruswaleed yehiaNo ratings yet

- Story of Adewale AssassinsDocument8 pagesStory of Adewale AssassinsMuflih Federick JacksonNo ratings yet

- Tempest Act 1: by Abhay BansalDocument8 pagesTempest Act 1: by Abhay BansalAbhay BansalNo ratings yet

- 2014 - Jan Otto - EEDI VerificationDocument20 pages2014 - Jan Otto - EEDI Verificationhamedullah mNo ratings yet

- Ship StructureDocument170 pagesShip Structuresasikumarmarine91% (11)

- Artikel Fikri-Dikonversi-DikonversiDocument11 pagesArtikel Fikri-Dikonversi-DikonversiAQSHANo ratings yet

- 10) Visitor Safety Orientation ChecklistDocument1 page10) Visitor Safety Orientation ChecklistDanilo OralNo ratings yet

- Body Plan Profile View: Offset TableDocument1 pageBody Plan Profile View: Offset TableSakib RafeeNo ratings yet

- New Types of Sea Going Multi Hull Ships With Superior Comfort Level and Safety Dubrovsky and Matveev 2005Document12 pagesNew Types of Sea Going Multi Hull Ships With Superior Comfort Level and Safety Dubrovsky and Matveev 2005Karen Katherine FaSaNo ratings yet

- Austal EPF Data Sheet - April 2020Document2 pagesAustal EPF Data Sheet - April 2020NugNo ratings yet

- SS PoliticianDocument7 pagesSS PoliticianSergio SorianoNo ratings yet

- ЧЕК ЛИСТDocument2 pagesЧЕК ЛИСТBasic ComplimentNo ratings yet

- Description Abis Bremen1Document2 pagesDescription Abis Bremen1Ahmed HossamNo ratings yet

- Air Draft Calculation WLTHCDocument2 pagesAir Draft Calculation WLTHCFajar Gemilang0% (1)

- Alimpolos, Christian R. BSMT LL - CanuposDocument3 pagesAlimpolos, Christian R. BSMT LL - Canuposjona100% (1)

- Ship'S Particulars: E.R. AmericaDocument1 pageShip'S Particulars: E.R. AmericaElena100% (1)

- Brunvoll As Strandgt. 4-6 NO-6415 Molde, Norway Phone: +47 71 21 96 00 Fax: +47 71 21 96 90 E-Mail: Office@brunvoll - No WWW - Brunvoll.noDocument2 pagesBrunvoll As Strandgt. 4-6 NO-6415 Molde, Norway Phone: +47 71 21 96 00 Fax: +47 71 21 96 90 E-Mail: Office@brunvoll - No WWW - Brunvoll.noSotila IonutNo ratings yet

- Impromptu Design ContestDocument7 pagesImpromptu Design ContestHarman Singh NagpalNo ratings yet

- FAROE ISLANDS Tourist Guide 2016 UK PDFDocument55 pagesFAROE ISLANDS Tourist Guide 2016 UK PDFSchneider F. IstvánNo ratings yet