Professional Documents

Culture Documents

LZMC1-A100 80-100 240V 55 Ka

Uploaded by

Giovanni Bautista RamirezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LZMC1-A100 80-100 240V 55 Ka

Uploaded by

Giovanni Bautista RamirezCopyright:

Available Formats

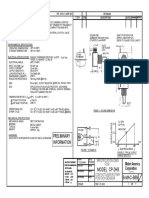

Circuit-breaker,�3�p,�100A

Part�no. LZMC1-A100-I

Article�no. 111895

Similar to illustration

Delivery�programme

Product range Circuit-breaker

Protective function System and cable protection

Standard/Approval IEC

Installation type Fixed

Release system Thermomagnetic release

Construction size LZM1

Number of poles 3 pole

Standard equipment Box terminal

Switching�capacity

400/415 V 50/60 Hz Icu kA 36

Rated�current�=�rated�uninterrupted�current

Rated current = rated uninterrupted current In = Iu A 100

Setting�range

Overload trip

Ir A 80 - 100

Short-circuit releases

Non-delayed Ii = In x … 6 - 10

Technical�data

General

Standards IEC/EN 60947, VDE 0660

Protection against direct contact Finger and back-of-hand proof to VDE 0106 part 100

Climatic proofing Damp heat, constant, to IEC 60068-2-78

Damp heat, cyclic, to IEC 60068-2-30

Mechanical shock resistance (10 ms half-sinusoidal shock) according to IEC g 20 (half-sinusoidal shock 20 ms)

60068-2-27

Safe isolation to EN 61140

Between auxiliary contacts and main contacts V AC 500

between the auxiliary contacts V AC 300

Weight kg 1.05

Mounting position Vertical and 90° in all directions

With XFI earth-fault release:

- NZM1, N1, NZM2, N2: vertical and

90° in all directions

with plug-in unit

- NZM1, N1, NZM2, N2: vertical, 90°

right/left

with withdrawable unit:

- NZM3, N3: vertical, 90° left

- NZM4, N4: vertical

with remote operator:

- NZM2, N(S)2, NZM3, N(S)3,

NZM4, N(S)4: vertical and 90° in all

directions

12/08/2015 111895 - HPL-ED2015 V17.0 EN 1/9

Direction of incoming supply as required

Degree of protection

Device In the area of the HMI devices: IP20 (basic protection type)

Enclosures with insulating surround: IP40with door coupling rotary handle: IP66

Terminations Tunnel terminal: IP10

Phase isolator and band terminal: IP00

Circuit-breakers

Rated current = rated uninterrupted current In = Iu A 100

Rated surge voltage invariability Uimp

Main contacts V 6000

Auxiliary contacts V 6000

Rated operational voltage Ue V AC 690

Overvoltage category/pollution degree III/3

Rated insulation voltage Ui V 690

Use in unearthed supply systems V

690

Switching�capacity

Rated short-circuit making capacity Icm

240 V 50/60 Hz Icm kA 121

400/415 V 50/60 Hz Icm kA 76

440 V 50/60 Hz Icm kA 63

525 V 50/60 Hz Icm kA 24

690 V 50/60 H Ic kA 14

Rated short-circuit breaking capacity Icn Icn

Icu to IEC/EN 60947 test cycle O-t-CO Icu kA

240 V 50/60 Hz Icu kA 55

400/415 V 50/60 Hz Icu kA 36

440 V 50/60 Hz Icu kA 30

525 V 50/60 Hz Icu kA 12

690 V 50/60 Hz Icu kA 8

Ics to IEC/EN 60947 test cycle O-t-CO-t-CO Ics kA

230 V 50/60 Hz Ics kA 55

400/415 V 50/60 Hz Ics kA 36

440 V 50/60 Hz Ics kA 22.5

525 V 50/60 Hz Ics kA 6

690 V 50/60 Hz Ics kA 6

Maximum back-up fuse, if the expected short-circuit currents at the installation

location exceed the switching capacity of the circuit-breaker.

Utilization category to IEC/EN 60947-2 A

Rated making and breaking capacity

Rated operational current Ie A

AC-1

380 V 400 V Ie A 160

415 V Ie A 125

690 V Ie A 160

AC--3

380 V 400 V Ie A 100

415 V Ie A 100

660 V 690 V Ie A 100

Lifespan, mechanical Operations 20000

Lifespan, electrical

AC-1

400 V 50/60 Hz Operations 10000

415 V 50/60 Hz Operations 10000

690 V 50/60 Hz Operations 7500

12/08/2015 111895 - HPL-ED2015 V17.0 EN 2/9

AC-2, AC-3

415 V 50/60 Hz Operations 7500

690 V 50/60 Hz Operations 5000

Max. operating frequency Ops/h 120

Current heat losses per pole at Iu are based on the maximum rated operational W 16.7

current of the frame size.

For current heat loss per pole the specification refers to the maximum rated

operational current of the frame size.

Total downtime in a short-circuit ms < 10

Terminal�capacity

Standard equipment Box terminal

Overview Basic

equipment

Box ● - - -

terminal

Screw - ● ● ●

connection

accessory

consideration

Box - ● ● -

terminals

Screw ● - - ●

connection

Tunnel ● ● ● ●

terminal

connection

● ● ● ●

on

rear

Strip - - - ●

terminal

Round copper conductor

Box terminal

Solid mm

2 1 x (10 - 16)

2 x (6 - 16)

Stranded mm

2 1 x (25 - 70)

2 x 25

Tunnel terminal

Solid mm

2 1 x (16 - 95)

Stranded mm

2

Stranded mm

2 1 x (25 - 95)

Bolt terminal and rear-side connection

Direct on the switch

Solid mm

2 1 x (10 - 16)

2 x (6 - 16)

Stranded mm

2 1 x (25 - 70)

2 x 25

Al conductors, Cu cable

Solid mm

2 1 x 16

Stranded mm

2

Stranded mm

2 1 x (25 - 95)

Cu strip (number of segments x width x segment thickness)

Box terminal

min. mm 2 x 9 x 0.8

max. mm 9 x 9 x 0.8

Copper busbar (width x thickness) mm

Bolt terminal and rear-side connection

Screw connection M8

Direct on the switch

min. mm 12 x 5

max. mm 16 x 5

Control cables

mm

2 1 x (0.75 - 2.5)

2 x (0.75 - 1.5)

12/08/2015 111895 - HPL-ED2015 V17.0 EN 3/9

Design�verification�as�per�IEC/EN�61439

Technical data for design verification

Rated operational current for specified heat dissipation In A 100

Equipment heat dissipation, current-dependent Pvid W 21.9

IEC/EN 61439 design verification

10.2 Strength of materials and parts

10.2.2 Corrosion resistance Meets the product standard's requirements.

10.2.3.1 Verification of thermal stability of enclosures Meets the product standard's requirements.

10.2.3.2 Verification of resistance of insulating materials to normal heat Meets the product standard's requirements.

10.2.3.3 Verification of resistance of insulating materials to abnormal heat Meets the product standard's requirements.

and fire due to internal electric effects

10.2.4 Resistance to ultra-violet (UV) radiation Meets the product standard's requirements.

10.2.5 Lifting Does not apply, since the entire switchgear needs to be evaluated.

10.2.6 Mechanical impact Does not apply, since the entire switchgear needs to be evaluated.

10.2.7 Inscriptions Meets the product standard's requirements.

10.3 Degree of protection of ASSEMBLIES Does not apply, since the entire switchgear needs to be evaluated.

10.4 Clearances and creepage distances Meets the product standard's requirements.

10.5 Protection against electric shock Does not apply, since the entire switchgear needs to be evaluated.

10.6 Incorporation of switching devices and components Does not apply, since the entire switchgear needs to be evaluated.

10.7 Internal electrical circuits and connections Is the panel builder's responsibility.

10.8 Connections for external conductors Is the panel builder's responsibility.

10.9 Insulation properties

10.9.2 Power-frequency electric strength Is the panel builder's responsibility.

10.9.3 Impulse withstand voltage Is the panel builder's responsibility.

10.9.4 Testing of enclosures made of insulating material Is the panel builder's responsibility.

10.10 Temperature rise The panel builder is responsible for the temperature rise calculation. Eaton will

provide heat dissipation data for the devices.

10.11 Short-circuit rating Is the panel builder's responsibility. The specifications for the switchgear must be

observed.

10.12 Electromagnetic compatibility Is the panel builder's responsibility. The specifications for the switchgear must be

observed.

10.13 Mechanical function The device meets the requirements, provided the information in the instruction

leaflet (IL) is observed.

Technical�data�ETIM�6.0

Low-voltage industrial components (EG000017) / Power circuit-breaker for trafo/generator/installation prot. (EC000228)

Electric engineering, automation, process control engineering / Low-voltage switch technology / Circuit breaker (LV < 1 kV) / Circuit breaker for power transformer, generator and system

protection (ecl@ss8.1-27-37-04-09 [AJZ716010])

Rated permanent current Iu A 100

Rated voltage V 690 - 690

Rated short-circuit breaking capacity lcu at 400 V, 50 Hz kA 36

Overload release current setting A 80 - 100

Adjustment range short-term delayed short-circuit release A 0-0

Adjustment range undelayed short-circuit release A 600 - 1000

Integrated earth fault protection No

Type of electrical connection of main circuit Frame clamp

Device construction Built-in device fixed built-in technique

Suitable for DIN rail (top hat rail) mounting No

DIN rail (top hat rail) mounting optional Yes

Number of auxiliary contacts as normally closed contact 0

Number of auxiliary contacts as normally open contact 0

Number of auxiliary contacts as change-over contact 0

Switched-off indicator available No

With under voltage release No

Number of poles 3

Position of connection for main current circuit Front side

Type of control element Rocker lever

12/08/2015 111895 - HPL-ED2015 V17.0 EN 4/9

Complete device with protection unit Yes

Motor drive integrated No

Motor drive optional No

Degree of protection (IP) IP20

Characteristics

12/08/2015 111895 - HPL-ED2015 V17.0 EN 5/9

12/08/2015 111895 - HPL-ED2015 V17.0 EN 6/9

12/08/2015 111895 - HPL-ED2015 V17.0 EN 7/9

Dimensions

Blow out area, minimum clearance to other parts

12/08/2015 111895 - HPL-ED2015 V17.0 EN 8/9

Additional�product�information�(links)

IL01203007Z�circuit-breaker�LZM.1(-4),�switch-disconnector�LN1

IL01203007Z circuit-breaker LZM.1(-4), switch- ftp://ftp.moeller.net/DOCUMENTATION/AWA_INSTRUCTIONS/IL01203007Z2011_01.pdf

disconnector LN1

12/08/2015 Eaton Industries GmbH 9/9

http://www.eaton.eu

© 11/2015 by Eaton Industries GmbH

111895 - HPL-ED2015 V17.0 EN

You might also like

- Delivery Programme: Circuit-Breaker, 3 P, 320A Part No. LZMC3-A320-I Article No. 111954Document9 pagesDelivery Programme: Circuit-Breaker, 3 P, 320A Part No. LZMC3-A320-I Article No. 111954Rodolfo Manuel Alarcón TroncosoNo ratings yet

- Circuit-Breaker, 3p, 100A Part No. NZMB1-A100 Catalog No. 259079 EL-Nummer (Norway) 4358704Document9 pagesCircuit-Breaker, 3p, 100A Part No. NZMB1-A100 Catalog No. 259079 EL-Nummer (Norway) 4358704shashirajNo ratings yet

- DATASHEET - NZM 3 MoellerDocument10 pagesDATASHEET - NZM 3 MoellerJa AkNo ratings yet

- Eaton 265763 NZMH4 AE630 en - GBDocument7 pagesEaton 265763 NZMH4 AE630 en - GBJuan LópezNo ratings yet

- Eaton 271423 NZMC2 A250 en - GB PDFDocument9 pagesEaton 271423 NZMC2 A250 en - GB PDFMarin DanielNo ratings yet

- Switch-Disconnector 3p 400A BG3 Part No. N3-400 Catalog No. 266019 EL-Nummer (Norway) 4358918Document6 pagesSwitch-Disconnector 3p 400A BG3 Part No. N3-400 Catalog No. 266019 EL-Nummer (Norway) 4358918Hui ChenNo ratings yet

- Eaton ns1 125 Na Molded Case SwitchDocument9 pagesEaton ns1 125 Na Molded Case SwitchregecartNo ratings yet

- Circuit-Breaker, 3p, 630A Part No. NZMN3-AE630 Catalog No. 259115 EL-Nummer (Norway) 0004358788Document10 pagesCircuit-Breaker, 3p, 630A Part No. NZMN3-AE630 Catalog No. 259115 EL-Nummer (Norway) 0004358788Constantin UdreaNo ratings yet

- Eaton 265912 NZMN4 4 AE1000 en - GBDocument5 pagesEaton 265912 NZMN4 4 AE1000 en - GBnelson1235No ratings yet

- Circuit-Breaker, 3p, 63A Part No. NZMN1-M63 Catalog No. 265720 EL-Nummer (Norway) 0004358899Document9 pagesCircuit-Breaker, 3p, 63A Part No. NZMN1-M63 Catalog No. 265720 EL-Nummer (Norway) 0004358899zesasiNo ratings yet

- Eaton 207379 P3 100 I5 SVB N en - GBDocument6 pagesEaton 207379 P3 100 I5 SVB N en - GBsamsularief03No ratings yet

- UntitledDocument3 pagesUntitledSaanounNo ratings yet

- Chave EatonDocument6 pagesChave EatonWesly Carvalho SoeiroNo ratings yet

- Similar To Illustration: Motor Rating AC-23A, 50 - 60 HZDocument6 pagesSimilar To Illustration: Motor Rating AC-23A, 50 - 60 HZJENNYNo ratings yet

- 2028366isolator Moeller EatonDocument7 pages2028366isolator Moeller EatonCarlos AlbertoNo ratings yet

- Eaton 015036 T0 5 8361 E en - GBDocument6 pagesEaton 015036 T0 5 8361 E en - GBSeoane GustavoNo ratings yet

- Similar To Illustration: Motor Rating AC-23A, 50 - 60 HZDocument5 pagesSimilar To Illustration: Motor Rating AC-23A, 50 - 60 HZsyahril boonieNo ratings yet

- Eaton 092394 T5B 3 7 E en - GBDocument6 pagesEaton 092394 T5B 3 7 E en - GBJorge AmayaNo ratings yet

- Rastavne Letve SchrackDocument49 pagesRastavne Letve SchrackdragishablNo ratings yet

- Eaton 7kW 3 Pole Isolator DatasheetDocument6 pagesEaton 7kW 3 Pole Isolator DatasheetProject1 Tech7No ratings yet

- Ficha Técnica Interruptor General 32 ADocument5 pagesFicha Técnica Interruptor General 32 AJosé IturvideNo ratings yet

- Eaton 041097 P1 25 EA SVB en - GBDocument6 pagesEaton 041097 P1 25 EA SVB en - GBAnonymous jW9BkgbQmENo ratings yet

- EatonDocument6 pagesEatonkarmadewaNo ratings yet

- Telemecanique PDFDocument16 pagesTelemecanique PDFRM HaroonNo ratings yet

- Catalogue Metalwork A62 A69pdfDocument8 pagesCatalogue Metalwork A62 A69pdfLeonardo JaraNo ratings yet

- SMLJ Transient Voltage Suppressor Diode Series: Features ApplicationsDocument5 pagesSMLJ Transient Voltage Suppressor Diode Series: Features Applicationsmgkdsfg lgfhNo ratings yet

- RM-ST180 Jan 2021Document2 pagesRM-ST180 Jan 2021Jorge Rodriguez AlvaradoNo ratings yet

- Delivery Programme: Step Switchflush Mounting Part No. T0-6-8271/E Article No. 015124 Catalog No. Ct06-8271-DokbqDocument6 pagesDelivery Programme: Step Switchflush Mounting Part No. T0-6-8271/E Article No. 015124 Catalog No. Ct06-8271-DokbqHoratiu CostinNo ratings yet

- J&D Transformateur de Courant Ouvrant 25a 10ma Compteur Energie ComDocument2 pagesJ&D Transformateur de Courant Ouvrant 25a 10ma Compteur Energie ComChancys MbembaNo ratings yet

- Contact Block EatonDocument2 pagesContact Block EatonsydifiaNo ratings yet

- Hojas Técnicas y Dimensiones de Supresores de PicosDocument8 pagesHojas Técnicas y Dimensiones de Supresores de PicosCrissCarreraNo ratings yet

- Electricos MT IUSADocument5 pagesElectricos MT IUSALanh GonzáLezNo ratings yet

- Eaton 066168 Emt6 DBK en GBDocument4 pagesEaton 066168 Emt6 DBK en GBAriel TorresNo ratings yet

- Serie KGDocument10 pagesSerie KGDanner Rodolfo Santisteban CheroNo ratings yet

- SMBJ-Q Transient Voltage Suppressor Diode Series: Features ApplicationsDocument7 pagesSMBJ-Q Transient Voltage Suppressor Diode Series: Features ApplicationsYaju JotosNo ratings yet

- Eaton 066166 EMT6 en - GBDocument3 pagesEaton 066166 EMT6 en - GBSiva RamanNo ratings yet

- Model LA-ST120: AC Distribution Panel UnitDocument2 pagesModel LA-ST120: AC Distribution Panel UnitDaniel JovelNo ratings yet

- 2945466Document9 pages2945466Marian NNo ratings yet

- SMCJ TVS BournsDocument5 pagesSMCJ TVS BournsImia FamilieNo ratings yet

- Chint Nc6 DatasheetsDocument3 pagesChint Nc6 DatasheetsRoberto VillegaaNo ratings yet

- 06 Katalog Charge - GB PDFDocument16 pages06 Katalog Charge - GB PDFhemobay837No ratings yet

- Каталог Klr Переключатели EngDocument38 pagesКаталог Klr Переключатели Engkormakov1996No ratings yet

- 7 8 S R 1 0 0 Series: For Assistance or To Order, CallDocument7 pages7 8 S R 1 0 0 Series: For Assistance or To Order, Calllunalo marcNo ratings yet

- 7 8 S R 1 0 0 Series: For Assistance or To Order, CallDocument6 pages7 8 S R 1 0 0 Series: For Assistance or To Order, CallLuis Enrique De los Santos FarfánNo ratings yet

- APLV Product Manual - (For Reference Only - See PAXLVA or PAXLVD For New Designs)Document8 pagesAPLV Product Manual - (For Reference Only - See PAXLVA or PAXLVD For New Designs)Abena GlezNo ratings yet

- DS7 EatonDocument5 pagesDS7 EatonBenício AvellarNo ratings yet

- Emt6-Dbk (066168)Document6 pagesEmt6-Dbk (066168)hasan ziaeeNo ratings yet

- Outdoor LBS - R-Series-FlyerDocument4 pagesOutdoor LBS - R-Series-FlyerKmj KmjNo ratings yet

- Moeller on-OfF SwitchDocument5 pagesMoeller on-OfF SwitchR JNo ratings yet

- En 278425Document4 pagesEn 278425Haralambescu AndreiNo ratings yet

- Eaton 269471 Emt6 KDB en GBDocument4 pagesEaton 269471 Emt6 KDB en GBAriel TorresNo ratings yet

- OVR T2 3N 80-440s P QS Surge Protective DeviceDocument4 pagesOVR T2 3N 80-440s P QS Surge Protective DeviceAchira DasanayakeNo ratings yet

- 3-phase-SE4K SE5K SE7K SE8K SE9K SE10K SE12.5KDocument2 pages3-phase-SE4K SE5K SE7K SE8K SE9K SE10K SE12.5KИгорьNo ratings yet

- iC60N Circuit Breakers iC60N Circuit Breakers: Curve B, C, D Curve B, C, DDocument4 pagesiC60N Circuit Breakers iC60N Circuit Breakers: Curve B, C, D Curve B, C, DLe Duc ThanhNo ratings yet

- 1NA1566-2AA30-0CC0-Z A65+K11+K97+L27: Data Sheet For Three-Phase Squirrel Cage Motor Simotics HV C Article Number OptionsDocument2 pages1NA1566-2AA30-0CC0-Z A65+K11+K97+L27: Data Sheet For Three-Phase Squirrel Cage Motor Simotics HV C Article Number OptionsDavid Nunez VeraNo ratings yet

- Surge Arrester-Class I+ Class II MG25/275-S/PN50: Power Supply SystemDocument2 pagesSurge Arrester-Class I+ Class II MG25/275-S/PN50: Power Supply SystemDuy ChuNo ratings yet

- Bloque de Contato MollerDocument3 pagesBloque de Contato MollerlizxcanoNo ratings yet

- Passive and Discrete Circuits: Newnes Electronics Circuits Pocket Book, Volume 2From EverandPassive and Discrete Circuits: Newnes Electronics Circuits Pocket Book, Volume 2No ratings yet

- APD165C-6: 165 kVA / 132 KWDocument4 pagesAPD165C-6: 165 kVA / 132 KWGiovanni Bautista RamirezNo ratings yet

- ABB Brakers 1SDC210004D0204Document286 pagesABB Brakers 1SDC210004D0204radugorceaNo ratings yet

- Step InsulatorsDocument3 pagesStep InsulatorsGiovanni Bautista RamirezNo ratings yet

- 1848460Document6 pages1848460Giovanni Bautista RamirezNo ratings yet

- 3.1 Tableros PB Ul EatonDocument4 pages3.1 Tableros PB Ul EatonGiovanni Bautista RamirezNo ratings yet

- Switches and Breakers Guide for Power Supply ReliabilityDocument92 pagesSwitches and Breakers Guide for Power Supply ReliabilityGiovanni Bautista RamirezNo ratings yet

- Austin Hughes and Bill Drury (Auth.) Electric Motors and Drives. Fundamentals, Types and Applications 2013Document123 pagesAustin Hughes and Bill Drury (Auth.) Electric Motors and Drives. Fundamentals, Types and Applications 2013megamaster2010No ratings yet

- Preliminary Information: B-MAC-B69 Model Cp-2HbDocument1 pagePreliminary Information: B-MAC-B69 Model Cp-2HbCykhong KhongNo ratings yet

- 5ef8ba92ac095a5b2bafd850 - Post Glover Different Types of Neutral Grounding - 2020Document102 pages5ef8ba92ac095a5b2bafd850 - Post Glover Different Types of Neutral Grounding - 2020Yosep GunawanNo ratings yet

- Research Proposal (Plaza)Document10 pagesResearch Proposal (Plaza)Edmarjan ConcepcionNo ratings yet

- AIS 123 Part3 FDocument35 pagesAIS 123 Part3 FkamaleshsNo ratings yet

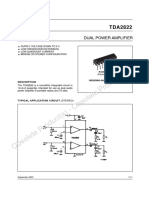

- Tda 2822Document11 pagesTda 2822RICHIHOTS2No ratings yet

- MoogDocument4 pagesMoogHamzaKadNo ratings yet

- Class A Power AmplifiersDocument13 pagesClass A Power AmplifiersPrasitNo ratings yet

- About HVDCDocument29 pagesAbout HVDCserban_elNo ratings yet

- Enclosure Form of SegregationDocument18 pagesEnclosure Form of Segregationkkn1234No ratings yet

- 901 1000e-1 PDFDocument52 pages901 1000e-1 PDFVladoNo ratings yet

- Technical Training Guide for Haulotte CDX Diagnostic Level 2Document209 pagesTechnical Training Guide for Haulotte CDX Diagnostic Level 2DNo ratings yet

- Study On Leakage Current Characteristics and Computer Simulation of Semiconducting Glazed Insulator Under Clean and Salt Fog ConditionDocument4 pagesStudy On Leakage Current Characteristics and Computer Simulation of Semiconducting Glazed Insulator Under Clean and Salt Fog ConditionKamello Assis100% (1)

- Penetration of Microwaves Into AluminumDocument5 pagesPenetration of Microwaves Into AluminumJohn Michael WilliamsNo ratings yet

- Columbs LawDocument6 pagesColumbs Lawasadaliawanatd1No ratings yet

- HV Quick Reference CatalogueDocument9 pagesHV Quick Reference CatalogueSergio PediconiNo ratings yet

- Wiring DiagramsDocument70 pagesWiring DiagramsEmerson Fonte Dos Santos FreireNo ratings yet

- Specs Siemens 1PV51XXDocument1 pageSpecs Siemens 1PV51XXGaizka UgaldeNo ratings yet

- Experiment Title: Bias Point Detail Analysis of DC Circuit With Dependent Sources Using Pspice SchematicsDocument4 pagesExperiment Title: Bias Point Detail Analysis of DC Circuit With Dependent Sources Using Pspice SchematicsMD Tanjil MiaNo ratings yet

- CDJ 100SDocument28 pagesCDJ 100SMarcos ZanelliNo ratings yet

- Datasheet PDFDocument14 pagesDatasheet PDFprabhav agnihotriNo ratings yet

- Vision™ OPLC™: V130-33-TA24 Installation GuideDocument10 pagesVision™ OPLC™: V130-33-TA24 Installation GuideOscar CanedoNo ratings yet

- PSM FULL CombinedDocument80 pagesPSM FULL CombinedASHUTOSHNo ratings yet

- Service Manual: SCD-XE670Document88 pagesService Manual: SCD-XE670IjazNo ratings yet

- TC7117Document14 pagesTC7117eryNo ratings yet

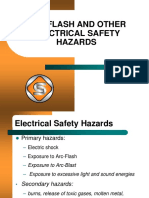

- Arc Flash and Electrical Safety HazardsDocument24 pagesArc Flash and Electrical Safety HazardsJulios Charl Panuncialman TagupaNo ratings yet

- BBJ-Series explosion-proof audible and visual alarm (IIC、tD)Document1 pageBBJ-Series explosion-proof audible and visual alarm (IIC、tD)Sigit RiyadiNo ratings yet

- Cabinets DatasheetDocument2 pagesCabinets DatasheetAhmad SaeedNo ratings yet

- Iso 15257Document34 pagesIso 15257Danilo AmendolaNo ratings yet

- Rajiv Gandhi Technological University, Bhopal (MP) : M.E./ M.Tech. Power SystemsDocument28 pagesRajiv Gandhi Technological University, Bhopal (MP) : M.E./ M.Tech. Power SystemsDenise NelsonNo ratings yet

- MSB Schematic - BSE1 (62) XX-01 - (T1)Document1 pageMSB Schematic - BSE1 (62) XX-01 - (T1)Miguel Louie Sarigumba IIINo ratings yet