Professional Documents

Culture Documents

p103-Stts-gec-Asi-ms-hvac-002 Method Statemenr For Installation of Chemical Dosing, Chilled Water Pump Pressurization Units

Uploaded by

Anandu AshokanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

p103-Stts-gec-Asi-ms-hvac-002 Method Statemenr For Installation of Chemical Dosing, Chilled Water Pump Pressurization Units

Uploaded by

Anandu AshokanCopyright:

Available Formats

STTS WIDEBODY AIRCRAFT FACILITY

METHOD STATEMENR FOR INSTALLATION OF CHILLED WATER PUMPS

METHOD STATEMENR FOR

INSTALLATION OF CHEMICAL DOSING, CHILLED WATER PUMP,

PRESSURIZATION UNITS

Document No: P103-STTS-GEC-ASI-MS-HVAC-001

REV. DATE DESCRIPTION GENFOCUS ASI/WSP

PREPARED APPROVED

DOCUMENT No. REV DATE

Page 0 of 8

P103-STTS-GEC-ASI-MS-ELE-001 00 27-05-2018

STTS WIDEBODY AIRCRAFT FACILITY

METHOD STATEMENR FOR INSTALLATION OF CHILLED WATER PUMPS

000 27-05-18 Issued for Approval QA/QC PM

1.0 PURPOSE

The purpose of this method statement is to define procedure to be followed during

installation, Testing and commissioning of chilled water pumps, chemical dosing and

pressurization units.

2.0 SCOPE

The scope of this method statement is to provide guidelines for installation, Testing

and commissioning of chilled water pumps, chemical dosing and pressurization units. All

works shall be conducted in conformance with relevant project drawings

/specifications and good industry practices.

3.0 TOOLS & EQUIPMENTS

3.0.1 Fork Lift/Crane.

3.0.2 Portable Drilling Machine/ Grinding Machine & Angle Cutter.

3.0.3 Sprit Level/Level threads

3.0.4 Measuring tape

3.0.5 Portable Hand Tools

3.0.6 Chain block

4.0 RESPONSIBILITY

4.1 PROJECT MANAGER:

DOCUMENT No. REV DATE

Page 1 of 8

P103-STTS-GEC-ASI-MS-ELE-001 00 27-05-2018

STTS WIDEBODY AIRCRAFT FACILITY

METHOD STATEMENR FOR INSTALLATION OF CHILLED WATER PUMPS

4.1.1 To be the focal point for all over interfaces and other communications with the

company and contractor as required during project execution.

4.1.2 Ensure that adequate quality measures are being undertaken.

4.1.3 He shall identify and secure necessary resources, determining the task that

must be completed, assigning the tasks and delegating authority.

4.1.4 He is responsible for planning of site organization, resource mobilization,

subcontracting, site operation, construction methods and scheduling.

4.1.5 Ensure all the keys staffs are on site during execution.

4.1.6 He shall coordinate all site safety issues to HSE Personnel for corrective

Action

4.1.7 Ensure all specialist vendor representative availability

4.2 SITE ENGINEERS/ SUPERVISOR

4.2.1 Responsible for the coordination of all electromechanical activities,

coordination with other discipline and between various engineers/specialist

vendor on sites

4.2.2 Ensure all permits are available for works on site and all safety precautions are

taken.

4.2.3 Responsible to ensure sufficient and adequate resources are secured and

provided to MEP team.

4.2.4 To direct and coordinate with MEP team and other Engineers and specialist

vendor for effective execution on site.

4.2.5 To report back to Division Manager/ Project Manager relevant MEP progress,

bottlenecks cost control and other issues.

4.2.6 Reviewing MEP Daily, Weekly & Monthly Progress reports.

DOCUMENT No. REV DATE

Page 2 of 8

P103-STTS-GEC-ASI-MS-ELE-001 00 27-05-2018

STTS WIDEBODY AIRCRAFT FACILITY

METHOD STATEMENR FOR INSTALLATION OF CHILLED WATER PUMPS

4.2.7 Responsible for completing of all MEP punch items and project close out,

handover documentation and operation maintenance manual, training etc.

4.3 QA/QC ENGINEER

4.3.1 Ensure all inspections are raised and conducted as per the contract

specifications, approved shop drawings & Method statements.

4.3.2 Ensure all current issues of procedures, approved material and shop drawing

and standards are available at the point of use.

4.3.3 Ensure the total quality control for installation work. He shall liaise with

Company for inspection of installation works.

4.3.4 Inspect for any damage during, handling and storage.

4.3.5 Monitor the quality of work & insure that fulfilment of specified requirement

and that all quality records related to work are completed.

4.3.6 Contractor shall inspect the same work to initiate IRF for company approval.

4.3.7 Maintain Comprehensive inspection and test records for any further references.

4.4 SAFETY OFFICER

4.4.1 Training has to be conducted and all the hazards have to be identified before

starting the work.

4.4.2 To make sure that Personnel Protective Equipment’s (PPE) are used by the

Task Force during execution at site.

4.4.3 Risk related to the activity shall be assessed and addressed as required.

4.4.4 To provide training for the work force in order to execute the activity safely.

4.4.5 Carry out regular and random inspection on site and record observation.

4.4.6 Ensure all lifting tackles/equipment’s are specified

DOCUMENT No. REV DATE

Page 3 of 8

P103-STTS-GEC-ASI-MS-ELE-001 00 27-05-2018

STTS WIDEBODY AIRCRAFT FACILITY

METHOD STATEMENR FOR INSTALLATION OF CHILLED WATER PUMPS

5.0 INSTALLATION PROCEDURE

5.1 Preparation

5.1.1 Ensure that the proper clearance is available from civil side before

commencement of works.

5.1.2 Ensure that the work area is clean and safe for carrying out the activities.

5.1.3 Prior to start of works, it shall be ensured that the relevant shop drawings and

coordination drawings are approved.

5.1.4 Check the dimensions of the foundations for the chilled water pumps

dimensions and ensure the suitability.

5.2 Installation of Pumps

5.2.1 Ensure all civil clearance are obtained

5.2.2 Mark the locations of the pump base frame as per the drawing.

5.2.3 Install the inertia base/pumps as per Approved Drawings.

5.2.4 Shift the pumps to the place of installation in safe manner. Use hand

trolley/folk lift/crane as applicable/required as per site conditions.

5.2.5 Alignment of coupling arrangement between motor and pumps, after pump

installation shall be rechecked by the pump supplier before testing.

5.2.6 Ensure proper coupling guards are provided, where applicable.

5.2.7 Complete the piping/rubber couplings and valve package installation as per

approved drawings. Remove the ends caps fixed on the inlet and outlet flanges.

5.2.8 Install the electrical power connections by the competent technician as per

approved drawings.

DOCUMENT No. REV DATE

Page 4 of 8

P103-STTS-GEC-ASI-MS-ELE-001 00 27-05-2018

STTS WIDEBODY AIRCRAFT FACILITY

METHOD STATEMENR FOR INSTALLATION OF CHILLED WATER PUMPS

5.2.9 Provide grounding wiring as per approved drawings/manufacturers instruction.

5.2.10 Check bolt and nuts for the tightness.

5.2.11 Follow the manufacturer’s instructions while installing the pump

5.3 Installation of Manual Dosing Pot

5.3.1 The manual dosing pot shall be mounted and installed in a vertical position.

5.3.2 Position the unit so that the filling funnel is easily accessible for addition of

chemicals.

5.3.3 Ensure adequate clearance for a collection bucket below the drain point.

5.3.4 The inlet point will be at the bottom end of the manual dosing pot.

5.3.5 The outlet will be at the top end of the manual dosing pot.

5.3.6 Ensure adequate clearance for air release valve.

5.4 Installation of Automatic Dosing Pot

5.4.1 Shift the component for auto dosing system to the installation point as per

approved drawing.

5.4.2 Remove the packing and ensure that the system is free from transportation

damages.

5.4.3 For wall mounted controller panel the exact location panel and fixing holes to

be marked based on approved shop drawing, keeping panel in place and will be

fixed in an approved manner.

5.4.4 Provide drain point from the dosing tank to the nearest common drain.

5.4.5 Mount the dosing pump on top of the dosing tank by screws (provision for the

screws will be provided on the tank).

DOCUMENT No. REV DATE

Page 5 of 8

P103-STTS-GEC-ASI-MS-ELE-001 00 27-05-2018

STTS WIDEBODY AIRCRAFT FACILITY

METHOD STATEMENR FOR INSTALLATION OF CHILLED WATER PUMPS

5.4.6 Ensure that the suction valve of the dosing pump and the flexible tubing are in

straight position.

5.4.7 Install the low-level switch in the dosing tank as per supplier

recommendations.

5.4.8 Install the conductivity probe as indicated in the auto dosing system diagram.

5.4.9 Ensure that the probe is in continuous contact with moving water.

5.4.10 Ensure that the probe tip does not touch any metal parts.

5.4.11 Provide valves as per auto dosing system diagram.

5.4.12 Check adequate space is available for maintenance.

5.4.13 Ensure the power point availability near the system.

5.5 Installation of Pressurization unit

5.5.1 Prior to installation of the pressurization system unit, expansion tank and

accessories will be moved to the correct location by the team.

5.5.2 Before setting up the Chilled Water Pressurization system, check the operating

data to ensure that information on the name plate matches the required system

data.

5.5.3 Ensure flange type, nuts & bolts are matching.

5.5.4 Installation will be as per approved drawing and base frame to be fixed on the

floor.

5.5.5 Connect the pipe work & accessories among main pipe, expansion tank as per

approved shop drawing

5.5.6 Connect the incoming domestic pipe to inlet.

5.5.7 Install all associated necessary piping, valves as per approved shop drawing /

manufacturer’s requirement with suitable support as per the approved drawing.

DOCUMENT No. REV DATE

Page 6 of 8

P103-STTS-GEC-ASI-MS-ELE-001 00 27-05-2018

STTS WIDEBODY AIRCRAFT FACILITY

METHOD STATEMENR FOR INSTALLATION OF CHILLED WATER PUMPS

5.5.8 Make sure that piping & fittings are cleaned pressure tested before connecting

to Chilled Water Pressurization system.

5.5.9 All associated piping & valves fill system will be supported firmly

5.5.10 Any sharp edge of the supports shall be removed by filing.

5.5.11 Check level of the Water Pressurization system & expansion tank & associated

piping.

5.5.12 Power supply termination shall be done by competent technician.

5.5.13 Inspection Request to be raised for consultant approval.

DOCUMENT No. REV DATE

Page 7 of 8

P103-STTS-GEC-ASI-MS-ELE-001 00 27-05-2018

You might also like

- Method Statement For Drainage Pipes InstallationDocument11 pagesMethod Statement For Drainage Pipes InstallationAnandu Ashokan100% (4)

- Method Statement For Earthing and Lightning ProtectionDocument12 pagesMethod Statement For Earthing and Lightning ProtectionAnandu Ashokan100% (1)

- Method Statement For Wiring Accessories InstallationDocument9 pagesMethod Statement For Wiring Accessories InstallationAnandu AshokanNo ratings yet

- Method Statement For Water Heaters InstallationDocument9 pagesMethod Statement For Water Heaters InstallationAnandu Ashokan100% (1)

- Method Statement For Structured Cabling System InstallationDocument9 pagesMethod Statement For Structured Cabling System InstallationAnandu Ashokan50% (2)

- Risk Assessment For Installation of Water Supply PipeDocument18 pagesRisk Assessment For Installation of Water Supply PipeAnandu Ashokan89% (27)

- Risk Assessment For Installation of Sanitary WaresDocument14 pagesRisk Assessment For Installation of Sanitary WaresAnandu Ashokan67% (6)

- Risk Assessment For Installation of Drainage PipesDocument17 pagesRisk Assessment For Installation of Drainage PipesAnandu Ashokan97% (34)

- Risk Assessment For Installation of Toilet Exhaust FanDocument11 pagesRisk Assessment For Installation of Toilet Exhaust FanAnandu Ashokan67% (3)

- Method Statement For PPR Pipes and Fittings InstallationDocument9 pagesMethod Statement For PPR Pipes and Fittings InstallationAnandu AshokanNo ratings yet

- Risk Assessment For Installation of Fire Fighting SystemDocument20 pagesRisk Assessment For Installation of Fire Fighting SystemAnandu Ashokan93% (30)

- Risk Assessment For Installation of Ducts and AccessoriesDocument17 pagesRisk Assessment For Installation of Ducts and AccessoriesAnandu Ashokan82% (11)

- p103-Stts-gec-Asi-ms-ele-003 - Method Statement For Installation of LV Distribution Panels (MDB, Capacitor Bank, VFD, SMDB, DB)Document6 pagesp103-Stts-gec-Asi-ms-ele-003 - Method Statement For Installation of LV Distribution Panels (MDB, Capacitor Bank, VFD, SMDB, DB)Anandu AshokanNo ratings yet

- RA For Flushing of Chilled Water PipesDocument8 pagesRA For Flushing of Chilled Water PipesAnandu AshokanNo ratings yet

- Installation of Spiral DuctsDocument15 pagesInstallation of Spiral DuctsAnandu AshokanNo ratings yet

- Qatar Gas JSA for Tube Bundle WorkDocument4 pagesQatar Gas JSA for Tube Bundle WorkMohammad Fazal KhanNo ratings yet

- Method Statement For PEX Pipes and Fittings InstallationDocument9 pagesMethod Statement For PEX Pipes and Fittings InstallationAnandu AshokanNo ratings yet

- Method Statement For Cable Tray and Truncking InstallationDocument9 pagesMethod Statement For Cable Tray and Truncking InstallationAnandu AshokanNo ratings yet

- Method Statement For LV Cables, Wiring For Lighting and Power InstallationDocument11 pagesMethod Statement For LV Cables, Wiring For Lighting and Power InstallationAnandu Ashokan50% (2)

- RA For Installation of Air Colled ChillersDocument8 pagesRA For Installation of Air Colled ChillersAnandu Ashokan100% (2)

- Risk Assessment For Installation of Grill, Diffuser and LouversDocument13 pagesRisk Assessment For Installation of Grill, Diffuser and LouversAnandu Ashokan100% (7)

- Method Statement For Installation of BMS M Tower PDFDocument16 pagesMethod Statement For Installation of BMS M Tower PDFAndrew HivNo ratings yet

- Method Statement & Risk Assessment Installation of GI Duct WorksDocument17 pagesMethod Statement & Risk Assessment Installation of GI Duct WorksAbu Muhammed Khwaja100% (1)

- p103-Stts-gec-Asi-ms-ele-013 - Method Statement For Installation of Access Control SystemDocument5 pagesp103-Stts-gec-Asi-ms-ele-013 - Method Statement For Installation of Access Control SystemAnandu AshokanNo ratings yet

- MS For Installation of Chilled Water Pipes & FittingsDocument21 pagesMS For Installation of Chilled Water Pipes & FittingsAnandu AshokanNo ratings yet

- Method Statement LV Distribution Boards InstallationDocument9 pagesMethod Statement LV Distribution Boards InstallationAnandu Ashokan100% (1)

- Module 2Document36 pagesModule 2Khizar HayatNo ratings yet

- Method Statement For PVC Conduits InstallationDocument9 pagesMethod Statement For PVC Conduits InstallationAnandu AshokanNo ratings yet

- Tt18ke00 Troubleshooting PDFDocument277 pagesTt18ke00 Troubleshooting PDFRavinder SinghNo ratings yet

- Risk assessment of DDL plantDocument20 pagesRisk assessment of DDL plantRashid JamilNo ratings yet

- Method Statement For Fire Alarm and Emergency System InstallationDocument9 pagesMethod Statement For Fire Alarm and Emergency System InstallationAnandu Ashokan100% (1)

- Itp - Refrigerant Pipe & Ac Split InstallationDocument9 pagesItp - Refrigerant Pipe & Ac Split InstallationGultom Juliana LiliesNo ratings yet

- p103-Stts-gec-Asi-ms-ele-007 - Method Statement For Installation of Cable Tray & TrunkingDocument5 pagesp103-Stts-gec-Asi-ms-ele-007 - Method Statement For Installation of Cable Tray & TrunkingAnandu AshokanNo ratings yet

- Method Statement For Installation of VRF SystemDocument8 pagesMethod Statement For Installation of VRF SystemMohammed Abd AlhamedNo ratings yet

- MS For Installation of Drainage PipesDocument20 pagesMS For Installation of Drainage PipesAnandu Ashokan100% (1)

- MS For Installation of Drainage PipesDocument20 pagesMS For Installation of Drainage PipesAnandu Ashokan100% (1)

- MS Cover SheetDocument1 pageMS Cover SheetAnandu AshokanNo ratings yet

- MS For Installation of Duct & AccessariesDocument21 pagesMS For Installation of Duct & AccessariesAnandu Ashokan100% (1)

- MS Comments SheetDocument1 pageMS Comments SheetAnandu AshokanNo ratings yet

- Installation of Under Ground Chilled Water PipingDocument18 pagesInstallation of Under Ground Chilled Water PipingAnandu Ashokan100% (1)

- 1) Method Statement For Installation of HVAC Duct & Leak TestDocument12 pages1) Method Statement For Installation of HVAC Duct & Leak TestIzaaz Ahamed100% (1)

- LBS 007 LRED RAMS MEP HVAC 03 (Method Statement For Ventilation Fan)Document10 pagesLBS 007 LRED RAMS MEP HVAC 03 (Method Statement For Ventilation Fan)faizan khanNo ratings yet

- HSE FormsDocument36 pagesHSE FormsEdidiong100% (1)

- Method Statement For GI Conduits InstallationDocument9 pagesMethod Statement For GI Conduits InstallationAnandu AshokanNo ratings yet

- MST Installation of Pressurization UnitDocument10 pagesMST Installation of Pressurization Unitvictor100% (1)

- 1.MS HVAC Ducts and Accessories (26 11 2011)Document12 pages1.MS HVAC Ducts and Accessories (26 11 2011)721917114 47No ratings yet

- MS For Installation of Chilled Water FlushinDocument27 pagesMS For Installation of Chilled Water FlushinAnandu AshokanNo ratings yet

- Method Statement For Installation FAHUDocument10 pagesMethod Statement For Installation FAHUfidgetyNo ratings yet

- p103-Stts-gec-Asi-ms-hvac-009 Method Statement For Installation of Grills and DiffusersDocument6 pagesp103-Stts-gec-Asi-ms-hvac-009 Method Statement For Installation of Grills and DiffusersAnandu AshokanNo ratings yet

- Procedure For IEEE 1584 Based Arc Flash CalculationsDocument6 pagesProcedure For IEEE 1584 Based Arc Flash CalculationsWilber LucasNo ratings yet

- MS - Installation of MEP ServicesDocument28 pagesMS - Installation of MEP ServicesAnandu Ashokan100% (3)

- HVAC Split Unit Installation Procedure - Method Statement HQDocument7 pagesHVAC Split Unit Installation Procedure - Method Statement HQEngineer ZiaNo ratings yet

- MS For Installation of Sanitary WaresDocument22 pagesMS For Installation of Sanitary WaresAnandu AshokanNo ratings yet

- MS For Installation of Sanitary WaresDocument22 pagesMS For Installation of Sanitary WaresAnandu AshokanNo ratings yet

- Method Statement For Testing, Adjusting & Balancing of CHW SystemsDocument10 pagesMethod Statement For Testing, Adjusting & Balancing of CHW SystemsAbdülhamit KAYYALİNo ratings yet

- Installation & Testing of Sanitary WaresDocument3 pagesInstallation & Testing of Sanitary WaresDong Vanra100% (2)

- MS - Installation of Water Supply PipeDocument20 pagesMS - Installation of Water Supply PipeAnandu Ashokan100% (1)

- MS - Installation of Water Supply PipeDocument20 pagesMS - Installation of Water Supply PipeAnandu Ashokan100% (1)

- FHC Installation Method StatementDocument9 pagesFHC Installation Method StatementMeriam DacunesNo ratings yet

- Method Statement For Installation of HVAC DampersDocument11 pagesMethod Statement For Installation of HVAC DampersITE MEPNo ratings yet

- Installation of Fahu's and Ahu'sDocument7 pagesInstallation of Fahu's and Ahu'sAnandu AshokanNo ratings yet

- Method Statement For Pipe Support Fabrication and Installation 6423dp420 00 0030000 Rev01 PDFDocument21 pagesMethod Statement For Pipe Support Fabrication and Installation 6423dp420 00 0030000 Rev01 PDFfurkanNo ratings yet

- Fire Protection Piping Installation and Testing Feb 12 2014 PDFDocument104 pagesFire Protection Piping Installation and Testing Feb 12 2014 PDFArshath FleminNo ratings yet

- 1.MST 48 - DX Split System, AC Unit and Refrigerant Pipe Rev.00Document12 pages1.MST 48 - DX Split System, AC Unit and Refrigerant Pipe Rev.00jaffrinNo ratings yet

- RAMS EvaluationDocument3 pagesRAMS EvaluationAnandu AshokanNo ratings yet

- Mos Hvac Ductwork Chilled Water Pipework 1650884167Document56 pagesMos Hvac Ductwork Chilled Water Pipework 1650884167Prabesh ShresthaNo ratings yet

- p103 Stts Gec Asi Ms Ele 014 - Method Statement For Installation of CCTV SystemDocument7 pagesp103 Stts Gec Asi Ms Ele 014 - Method Statement For Installation of CCTV SystemAnandu AshokanNo ratings yet

- MS For Installation of FF Pipes FittingsDocument23 pagesMS For Installation of FF Pipes FittingsAnandu Ashokan100% (1)

- MOS Insrtallation of VRFDocument22 pagesMOS Insrtallation of VRFsuban hari kumarNo ratings yet

- MS-G-003 - General Method Statement For Horizontal PumpDocument19 pagesMS-G-003 - General Method Statement For Horizontal PumpNGUYEN VINHNo ratings yet

- p103-Stts-gec-Asi-ms-hvac-003method Statement For Installation of Air Handling UnitsDocument6 pagesp103-Stts-gec-Asi-ms-hvac-003method Statement For Installation of Air Handling UnitsAnandu AshokanNo ratings yet

- p103-Stts-gec-Asi-ms-ele-008 - Method Statement For Installation of Earthing & Lightning ProtectionDocument7 pagesp103-Stts-gec-Asi-ms-ele-008 - Method Statement For Installation of Earthing & Lightning ProtectionAnandu AshokanNo ratings yet

- 1.0 Method Statement Above Ground - Drainage SystemDocument19 pages1.0 Method Statement Above Ground - Drainage Systemمقاول تكييف كهرباء وصحيNo ratings yet

- MS For Installation of Grills, Diffuser & LouversDocument21 pagesMS For Installation of Grills, Diffuser & LouversAnandu AshokanNo ratings yet

- MS For Installation of Grills, Diffuser & LouversDocument21 pagesMS For Installation of Grills, Diffuser & LouversAnandu AshokanNo ratings yet

- MS For MEP IsolationDocument19 pagesMS For MEP IsolationAnandu Ashokan67% (3)

- Tiling WorksDocument21 pagesTiling WorksGhayas JawedNo ratings yet

- MS For Installation of Toilet Exhaust FanDocument20 pagesMS For Installation of Toilet Exhaust FanAnandu AshokanNo ratings yet

- MS For Installation of Toilet Exhaust FanDocument20 pagesMS For Installation of Toilet Exhaust FanAnandu AshokanNo ratings yet

- K to 12 Plumbing GuideDocument20 pagesK to 12 Plumbing GuidePapadars100% (3)

- Ventilation Fan Installation Method StatementDocument4 pagesVentilation Fan Installation Method Statementsamsul maarifNo ratings yet

- MS For Installation of SMDB, DB PanelsDocument20 pagesMS For Installation of SMDB, DB PanelsAnandu AshokanNo ratings yet

- p103 Stts Gec Asi Ms Ele 010 - Method Statement For Installation of Wiring AccessoriesDocument6 pagesp103 Stts Gec Asi Ms Ele 010 - Method Statement For Installation of Wiring AccessoriesAnandu AshokanNo ratings yet

- p103-Stts-gec-Asi-ms-ele-009 - Method Statement For Installation of Light Fitting FixtureDocument5 pagesp103-Stts-gec-Asi-ms-ele-009 - Method Statement For Installation of Light Fitting FixtureAnandu AshokanNo ratings yet

- Method Statement For Installatio of Water Booster PumpsDocument9 pagesMethod Statement For Installatio of Water Booster PumpsDiana Abu Hassan Hatoum100% (1)

- Underground Drainage Piping Installation MethodDocument18 pagesUnderground Drainage Piping Installation MethodMohammed Mostafa El HaddadNo ratings yet

- DX SplitDocument29 pagesDX Splitsiva_nagesh_2No ratings yet

- MEPF-Testing and Commissioning ChecklistDocument90 pagesMEPF-Testing and Commissioning ChecklistADEN LIUNo ratings yet

- Chilled Water Pipe Insulation Method Statement - Method Statement HQDocument3 pagesChilled Water Pipe Insulation Method Statement - Method Statement HQابوزيد عبد الجوادNo ratings yet

- 1b. MS 02 Installation of FencingDocument11 pages1b. MS 02 Installation of FencingADDINo ratings yet

- Light FittingsDocument35 pagesLight FittingsAnandu AshokanNo ratings yet

- Mathod Statement of Duct InsulationDocument14 pagesMathod Statement of Duct InsulationAhmed AlyNo ratings yet

- METHOD STATEMENT T & C General TestsDocument62 pagesMETHOD STATEMENT T & C General TestsRahul Divakaran60% (5)

- Pas 222Document28 pagesPas 222Aline GrilloNo ratings yet

- Bus Duct Installation - Method of StatementDocument13 pagesBus Duct Installation - Method of StatementTalha Altaf100% (1)

- Tubod National High School Tubod, Surigao Del Norte 1st Quarterly Assessment in T.L.E. Grade 8 S. Y. 2019 - 2020 Horticulture - Crop ProductionDocument4 pagesTubod National High School Tubod, Surigao Del Norte 1st Quarterly Assessment in T.L.E. Grade 8 S. Y. 2019 - 2020 Horticulture - Crop ProductionMaria Isabel Ignalig100% (1)

- Chiller Installation Method StatementDocument8 pagesChiller Installation Method StatementFark Off100% (1)

- Sump Pump Method of StatementDocument10 pagesSump Pump Method of StatementKhaled NaguibNo ratings yet

- Grundfos Chilled Water Pumps Testing & Commissioning Method StatementDocument10 pagesGrundfos Chilled Water Pumps Testing & Commissioning Method Statementshanu YahiyaNo ratings yet

- DCC T&C Ms-PlumbingDocument11 pagesDCC T&C Ms-Plumbing721917114 47100% (1)

- UntitledDocument313 pagesUntitledfarhan fauziNo ratings yet

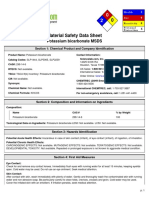

- Msds Potassium Bicarbonate (Apar Powder)Document5 pagesMsds Potassium Bicarbonate (Apar Powder)ReniNo ratings yet

- Nitto - MOS Pressure TestDocument6 pagesNitto - MOS Pressure TestNajwa AmirahNo ratings yet

- Safety Data Sheet: WarningDocument11 pagesSafety Data Sheet: WarningjoanaNo ratings yet

- Here are the answers to the pre-test:1. B2. A 3. C4. B5. A6. D7. A8. C 9. C10. A11. D12. B13. ADocument30 pagesHere are the answers to the pre-test:1. B2. A 3. C4. B5. A6. D7. A8. C 9. C10. A11. D12. B13. Afe delgadoNo ratings yet

- SDS 791351002 TiAl6V4 Gd23 Type 2 EnglishDocument9 pagesSDS 791351002 TiAl6V4 Gd23 Type 2 EnglishAkshay DolasNo ratings yet

- Benzil PDFDocument5 pagesBenzil PDFAijaz NawazNo ratings yet

- MsdsDocument5 pagesMsdsFA Ines100% (1)

- Presentation Masks PDFDocument42 pagesPresentation Masks PDFGrafica TurboblenderNo ratings yet

- Hazardous Substances in RefineriesDocument35 pagesHazardous Substances in RefineriesRuqiyya Israfilova100% (2)

- Citric Acid Anhydrous - MSDSDocument6 pagesCitric Acid Anhydrous - MSDSJHUPEL ABARIALNo ratings yet

- MST125-BbCc ASSIGNMENTDocument13 pagesMST125-BbCc ASSIGNMENTFaye ManaulNo ratings yet

- Sefox 8000 Series Hotmelt Msds EngDocument4 pagesSefox 8000 Series Hotmelt Msds EngAljameel ShowroomNo ratings yet

- Safety Data Sheet: Veritas 800 Marine 30Document7 pagesSafety Data Sheet: Veritas 800 Marine 30Om Prakash RajNo ratings yet

- Ca (NO3) 2Document5 pagesCa (NO3) 2laila purnamaNo ratings yet

- Waseef Ullah WPR CVDocument6 pagesWaseef Ullah WPR CVShahid BhattiNo ratings yet

- Frick 55 Gallon Refrigeration Oil 11Document4 pagesFrick 55 Gallon Refrigeration Oil 11ANDRESNo ratings yet

- Tra Offloading AndriggingDocument11 pagesTra Offloading AndriggingAjaz AhmedNo ratings yet

- Occupational Safety and Health Standards: Regulatory RequirementsDocument53 pagesOccupational Safety and Health Standards: Regulatory RequirementsAviects Avie JaroNo ratings yet

- STATEMENT OF THE PROBLEM (Edited)Document2 pagesSTATEMENT OF THE PROBLEM (Edited)Yeoj SecnarevNo ratings yet