Professional Documents

Culture Documents

Kirit Type

Uploaded by

NAMECopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kirit Type

Uploaded by

NAMECopyright:

Available Formats

GENERAL NOTES: All sections shall comply with the following standards: HEALTH & SAFETY

UKB's + UKC's BS EN 10025-2; BS4-1 11. Inspections: All excavations are to be inspected by

GENERAL UKPFC's BS EN 10025-2; BS4-1 1. All works to be carried out in compliance in the Engineer and/ or the Building Control Officer.

1. Where issued, William Behan Design Partnerships Master UKA's BS EN 10025-2; BS EN 10056-1 accordance with current Heath & Safety Legislation. Minimum notice of 24 hours is to be given when

Structural Specification shall override the specifications on Structural tee's BS EN 10025-2; BS4-1 excavations are ready for inspection.

this and subsequent drawings for this project. SHS's, CHS's, RHS's BS EN 100210-1; BS EN 10210-2 DRAINAGE

2. No dimensions shall be scaled from drawings. All 12. The soffit of the existing footings is to be levelled off

dimensions shall be established on site. b. Structural hollow sections i.e. square, rectangular .No projecting portions of the existing footings are to

1. Additional services not identified on this drawing may be trimmed except as shown on the drawings or

3. The Contractor shall notify the Engineer of any and circular hollow sections shall be generally

Grade S355, Sub Grade JOH unless noted

be present on or adjoining the site. The exact directed by the Engineer.

discrepancies between (a) the structural plans and

sections and (b) the structural drawings and those of the otherwise on the drawings. Cold formed sections locations and levels of all existing services must be

13. Placing Concrete: The concrete for the underpinning

Architect before implementing the work. are not permitted for use on the main frame. verified by the Contractor prior to commencing the

is to be RC35 concrete and poured continuously to

4. The Contractor shall notify the Architect and Engineer of c. Steel grating for open type flooring shall be works.

75mm below the soffit of the existing footing. The

any discrepancies between William Behan Design galvanised Grade S275 to BS EN 10025 unless 2. For exact location of proposed services, service

concrete is to be fully compacted using a mechanical

Partnerships drawings and site conditions before noted otherwise on the drawings. Open grid openings, external ducting and lighting refer to

vibrator.

implementing the work. flooring pattern to be 41/100. Building Service Engineer drawings.

5. This drawing shall be read with all Architects drawings for d. Structural stainless steel sections, plates and 3. Concrete encasement: 14. Adjacent sections shall be connected using T12

construction details, plumbing, drainage, electrical work, grating shall be Grade 1.4307 (304L) or 1.4404 All uPVC pipework with less than 1200mm dowel bars 800mm long, 400mm embedment each

heating work, insulation, damp proof details, ventilation, (316L) to BS EN 10088. side, at 300mm vertical centres.

cover to have minimum 150mm Grade C16/20

finishes, joinery etc. Design shall be in accordance with Steel concrete encasement. 15. Concrete cover to reinforcement shall be 35mm for

6. Any temporary works necessary shall be the sole Construction Institute's publication No. SCI P291 cast against shutter or the top surface of the

Concrete surround to have minimum 25mm

responsibility of the main Contractor. Structural Design of Stainless Steel. basement slab, 50mm for cast against blinding and

thick

7. All works to be carried out in accordance with the TGD 75mm for cast against earth.

Parts A-M. 2. The structural steelwork supplier shall take all site movement joint at max. 3000mm c/c.

dimensions necessary, produce shop fabrication 4. All pipework passing through foundations to be 16. The top 75mm of the pin is to be filled to the full

drawings and submit them to the Engineer for his sleeved using 300mm section of pipe cast into the depth and width of the void with a 3:1 sharp sand:

FOUNDATIONS inspection. No fabrication to be carried out foundation with rocker joints provided within 1m from cement mixed dry pack mixed hand damp and

without the Engineers agreement. Unless shown face of the foundation. rammed in solid.

1. All foundations are subject to site conditions and may be otherwise on the drawings the Contractor shall be 5. All gully traps located in top soil areas to have min.

varied as the works proceed. responsible for the design of the connections to 100mm concrete surround.

2. All foundation are subject to the approval of the Local satisfy the loads shown on the drawings or 6. Location of all building R.W.P's and S.V.P's to be

Authority and the Engineer. The Engineer may require to calculable from the information given. conformed by Contractor prior to construction.

inspect the formation of any base prior to the blinding or 3. All welding shall be carried out by appropriately 7. The contractor should pay particular attention to

concrete work. certified welders.

clauses of the William Behan Design Partnership's

3. Following approval of the founding surface the excavation 4. All bolts shall be Grade 8.8 bolts unless noted

specification regarding the inclusion of a CCTV

shall be bottomed out as necessary and foundation cast otherwise.

immediately or blinded immediately with Grade C12/15 5. All beams with end cast into concrete shall be survey of all underground drainage on completion of

Dmax 20mm concrete. supplied with 2No. 50x50x5mm RSA end cleats works. In addition the Contractor is to pressure test

welded to their web. all constructed sewers and watermains prior to

6. All structural steelwork shall be cleaned of all rust, connection to public services.

CONCRETE millscale, grease etc. 8. All testing to be to the satisfaction of the appropriate

7. All structural steelwork shall be shot cleaned to SA

local authority representative / William Behan Design

1. Concrete shall be Grade C30/37 Dmax 20 unless noted Partnership.

2

otherwise. 9. Minimum cover to underground services to be in

2. Lean mix concrete shall be Grade C12/15 Dmax 20 rich phosphate primer or similar approved.

8. All materials and workmanship shall comply accordance with planning conditions. All sewers to

unless noted otherwise. be laid with a min. cover of 1200mm in roads and

3. Ready mixed concrete may be used provided that it shall with BS EN 1993-1-1:2005 Eurocode 3: Design

of Steel Structures. driveways, 900mm in open spaces and footpaths not

be produced at an approved depot. All constituents for

each mix shall be added at the manufacturers depot. No 9. Unless otherwise noted all structural steelwork adjacent to carriageways and 600mm in gardens /

extra water or other material shall be added after the to be painted with intumescent paint system to grassed areas. Where it is not possible to achieve

concrete has left the depot. provide 1hr protection with pain specification to these covers, pipes shall be bedded and surrounded

4. Calcium Chloride or admixtures containing Calcium be agreed with Engineer prior to application in concrete 150mm thick U.N.O.

Chloride will not be permitted. with paint supplier certificate provided.

5. Acceptable safe load tables must be provided by the STRUCTURAL UNDERPINNING SPECIFICATION

supplier of any concrete lintels.

1. To be read in conjunction with the preliminaries and

6. Steel mesh reinforcement fabric shall comply with BS

4482 and BS 4483 and shall be Grade 500B. All laps to BRICKWORK AND BLOCKWORK general conditions.

be minimum 400mm. 2. Workmanship: The work shall be carried out in

7. All reinforced concrete shall be well vibrated in its 1. Nominal mortar mixes by volume are accordance with the Engineers drawings and

formwork using mechanical pokers of appropriate type. appropriate for sand graded to BS 1200. instructions and to the approval of the Architect and

8. All steel reinforcement shall be detailed in accordance 2. the Building Control officer.

with EN 1992-1-1:2005. mortar U.N.O. 3. Any other sequence of operations or method of

9. All chairs and spacers to be provided by main contractor. 3. Facing bricks shall be to the Architects choice working proposed by the Contractor is to be

10. All materials and workmanship shall comply with and shall be suitable for the purpose. submitted to the Architect and copied to the Engineer

EN1992-1-1-2005 Eurocode 2; Design of concrete 4. Bricks below DPC level shall be suitable for the and agreed in writing a min. of 14 days before work

structures. purpose. is to be commenced on site.

11. Approval must be obtained for the position of any 5. The laying of single frog units frog down shall

construction joint required by the contractor and for the

4. Contractor's responsibilities: The Contractor shall be

not be permitted in load bearing walling, double responsible for the safety of the underpinning

methods of forming and preparing the joints before the

frogged units shall be laid with the larger frog structure and provide all necessary shoring, strutting

works start on site.

12. When directed all tests on wet or hardened concrete shall

uppermost. and bracing to insure its safety at all times.

be carried out in accordance with BS 1881. 6. 5. Services: The Contractor is also to carry out a survey

U.N.O.

of the property and adjacent area to establish the

HARDCORE 7. All materials and workmanship shall comply

location of obstructions such as service runs and

with EN 1996-1-1:2005 Eurocode 6 - Design of

drains. Any obstruction found is to be brought to the

1. Hardcore beneath ground supported floors should be at masonry structures.

attention of the Architect/ Engineer. The Contractor is

least 150mm in thickness. Hardcore shall be placed and 8. All aggregate used for the new blockwork

to allow for any temporary support to the services or

compacted. In layers of not exceeding 225mm, in supplied to site shall be free of pyrites and any

accordance with the Building regulations (TGD C 'Site obstructions during the underpinning.

other deleterious or swelling material with

preparation and resistance to moisture') and shall conform confirmation letter provided by block supplier 6. The Contractor is to provide drawings indicating his

to S.R.21:2004-A1:2007 'Guidance on the use of BS and issued to the Architect and Engineer. proposed methodology including the proposed

EN13242:2002 - Aggregates for unbound and 9. Wall ties to be placed at max. 450mm vertical sequence of underpinning a minimum of 14 days

Hydraulically Bound Materials for use in Civil Engineering c/c and at max. 600mm horizontal before work has commenced.

Work and Road Construction (Incorporating Amendment c/c.Additional wall ties to be placed at max. 7. Construction Sequence: The underpinning is to be

1:2007) undertaken in short sections not exceeding 1m in

225mm vertical c/c.

length. The underpinning is to be undertaken on a 'hit

STRUCTURAL STEEL WORK

and miss' sequence.

TIMBER 8. The sequence of the construction shall be such that

1. All structural steelwork shall be manufactured from steel any given section of retaining wall will be completed,

complying with the following criteria: 1. All timber shall be minimum Grade C24 unless and a minimum period of 48 hours lapsed before an

noted otherwise. Service moisture content shall adjacent excavation commenced to form another

a. Hot rolled sections i.e. universal beams, universal not exceed 18%. Moisture content on erection section of retaining wall.

columns, asymmetric steel beams, rolled steel joists, shall be within 3% of service moisture content. 9. Excavations: Excavation shall be to the depth and

structural tees, rolled steel channels, parallel flange 2. All roof and mansard timbers shall be treated width shown on the drawings. However, where tree

channels, rolled steel angles and plates shall be generally with organic solvent by double vacuum

Grade S275 or S355 (Where noted on the drawings)

roots and encountered new underpins are to extend

process. 600mm below the last trace of any root activity. The

3. All timber in contact with external walls shall be

Steel Sub Grades shall be: sides of the excavations shall be adequately shored

treated with organic solvent by double vacuum

Base plates: S275 JR and propped to prevent subsidence or slip of the soil.

process.

Soil faces behind the pin and at the formation level

Internal Steelwork 4. Joist hangers built into new blockwork shall be

shall be undisturbed.

cavity wall type hangers. All joist hangers shall

be heavy duty type fabricated in accordance 10. In the event that the ground is unstable, lateral

T < 40mm, = BS EN 10025-2-S275 JR+AR

with BS 6178 Part 1: 1982 from 2.5mm mild propping shall be provided as required to the rear of

T > 40mm, = BS EN 10025-2-S275 JO+AR

T < 22.5mm,= BS EN 10025-2-S355 JR+AR steel and shall hot dip galvanised to BS 729. the excavation and to the sides of the excavated

T > 22.5mm,= BS EN 10025-2-S355 JO+AR 5. All double joists shall be bolted together with working trench. The front and side faces of the

excavation shall be propped using trench sheeting or

External Steelwork staggered top and bottom. plywood, timber boards and acrow props as

6. All materials and workmanship shall comply appropriate. Sacrificial back - shutters shall be used

T < 22.5mm,= BS EN 10025-2-S275 JR+AR to the rear face of the excavation (i.e. underneath the

with EN 1995-1-1:2005 Eurocode 5 - Design of

T > 22.5mm,= BS EN 10025-2-S275 JO+AR wall) if required. Cementitious grout will be poured

Timber Structures.

T < 12.5mm,= BS EN 10025-2-S355 JR+AR behind the back - shutters to fill up the voids behind

T > 12.5mm,= BS EN 10025-2-S355 JO+AR

7. All timber to be strapped together and down to

masonry as per current Building regulations the back - shutters.

and Technical Guidance Document 'A'.

Structural Hollow Sections:

Internal and external steelwork = BS EN 10025-1-S355 JOH

All dimensions in millimeter (mm) Rev Date Description By Chkd

unless otherwise noted. C1 31/01/17 Construction Issue AS WB William Behan Design Partnership S16020 OLD ORCHARD COTTAGE

All dimensions and levels to be

C2 02/02/17 Construction Issue AS WB

confirmed by Architect.

LONDON DUBLIN

Setting out to be confirmed on site.

Do not scale from this drawing.

Chester House, Fulham Green 23, Old Navan Road General Notes

81-83 Fulham High Street Castleknock,

The Contractor is responsible for Fulham, London, SW6 3JA Dublin 15,

verifying all site dimensions before Ph: 0203 542 1515 Ireland

commencing any work. Mob: 0044 753 126 8327 Mob. 0879914753 1:50 @ A1 Construction S-001 C2

All dimensions in millimeter (mm) Rev Date Description By Chkd

unless otherwise noted. C1 31/01/17 Construction Issue AS WB William Behan Design Partnership S16020 OLD ORCHARD COTTAGE

All dimensions and levels to be

C2 02/02/17 Construction Issue AS WB

confirmed by Architect.

C3 09/04/17 Revised as Clouded AS WB LONDON DUBLIN

Setting out to be confirmed on site.

Do not scale from this drawing.

Chester House, Fulham Green 23, Old Navan Road Connection Forces

81-83 Fulham High Street Castleknock,

The Contractor is responsible for Fulham, London, SW6 3JA Dublin 15,

verifying all site dimensions before Ph: 0203 542 1515 Ireland

commencing any work. Mob: 0044 753 126 8327 Mob. 0879914753 1:50 @ A1 Construction S-002 C3

NOTES:

ALL DIMENSION IN MM UNLESS OTHERWISE NOTED

ALL DIMENSION AND LEVEL TO BE CONFORMED BY ARCHITECT

SETTING OUT TO BE CONFIRMED ON SITE

15mm AEROFIL Joint

Vertical movement Filler by servicised.Finishes to allow

joint. for movement to architects details.

MJ

225

450

Steel Beam

450

Ties adjacent to joints

To be max. 150mm from edge & at 20mm Deflection head

225mm vertical crs. with compressible Channel welded

225

to bottom flange

300

300

materials to architects

details. of beam

Usually 225mm to

Movement joints (MJ) in

Usually 225mm to

suit block courses

brickwork at 12m max

450

suit block courses

Propretary head restraint

crs along the wall and sliding ties @ 450 fixed to

beam

at 6m from a corner. Channels welded to Wall ties @ 450mm

crs. vertically

De-bonded ties. column web

300mm Cavity

450

wall construction

300mm Long HEMAX S/S to architects

FLAT-TIES at 225mm vertical Ties adjacent to joints detail

crs. with one end debonded To be max. 150mm from edge & at

225mm vertical crs.

Typical head restrained:

Steel Column

225 225 225 900 225 blockwork to steel beam

Typical connection detail:

Typical Layout of Wall TIes Indicating Maximum blockwork to columns

12mm AEROFIL Joint

Spacing for Cavity Wall Construction Filler by servicised.Finishes to allow

Incoming blockwork

Scale: 1:50

partitions to be fully

for movement to architects details. bonded in.

Density & position of ties to comply with BS 5268 Part 1 2005

Straight joints (SJ) in

For cavity walls in which both leaves are 90mm or thicker ties should be

used at a rate not less than 2.5 per square meter in a staggered pattern blockwork at 6m max

(900mm horizontal x 450mm vertical c/c) and have 50mm embedment.

crs along the wall and

These should be evenly distributed over the wall area except around 3m from a corner

openings & should preferably be staggered.

In cases where insulation board is incorporated within the cavity &

restrained by ties with insulation retaining clips it may be necessary to

reduce the horizontal spacing of the ties to 600mm.

At vertical edges of an opening or unreturned or unbounded edges or

adjacent to columns & vertical expansion joints additional ties should be

used at a rate of one per 300mm height & located not more than 225mm

from edge.

All dimensions in millimeter (mm) Rev Date Description By Chkd

unless otherwise noted. C1 31/01/17 Construction Issue AS WB William Behan Design Partnership S16020 OLD ORCHARD COTTAGE

All dimensions and levels to be

C2 02/02/17 Construction Issue AS WB

confirmed by Architect.

LONDON DUBLIN

Setting out to be confirmed on site.

Do not scale from this drawing.

Chester House, Fulham Green 23, Old Navan Road Masonry Details

81-83 Fulham High Street Castleknock,

The Contractor is responsible for Fulham, London, SW6 3JA Dublin 15,

verifying all site dimensions before Ph: 0203 542 1515 Ireland

commencing any work. Mob: 0044 753 126 8327 Mob. 0879914753 AS SHOWN Construction S-003 C2

NOTES:

ALL DIMENSION IN MM UNLESS OTHERWISE NOTED

ALL DIMENSION AND LEVEL TO BE CONFORMED BY ARCHITECT

SETTING OUT TO BE CONFIRMED ON SITE

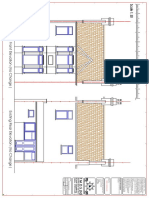

Legend: Wall Legend

(MC) Ref Description

Denotes moment connection

New masonry wall

Denotes pinned connection Non bearing stud wall -

ST1 100x44mm C24 studs

at 400mm c/c

Steel Column Schedule

Ref Description

C1 203X203X46 UC

C2 203X203X60 UC

C3 203X203X60 UC

C4 100X100X10 SHS

C5 203X203X60 UC

C6 203X203X60 UC

C7 203X203X60 UC

C8 203X203X46 UC

C9 203X203X46 UC

C10 203X203X46 UC

P7 P10 P3

Strip Foundation

FND7 FND6 FND5 FND4

FND3 FND1 1300W x 900D Mass Concrete Strip Foundation

FND2 1000W x 900D Mass Concrete Strip Foundation

7 10

C

3

C

C

FND3 600W x 900D Mass Concrete Strip Foundation

FND18

FND4 600W x 900D Mass Concrete Strip Foundation

8

P9 C

FND5 600W x 900D Mass Concrete Strip Foundation

FND6 600W x 900D Mass Concrete Strip Foundation

FND7 600W x 900D Mass Concrete Strip Foundation

FND1

FND8 1000W x 900D Mass Concrete Strip Foundation

FND8

FND17

FND19

FND2

FND9 600W x 900D Mass Concrete Strip Foundation

Step

FND10 600W x 900D Mass Concrete Strip Foundation

FND21

FND22

FND26

FND20

FND11 1000W x 900D Mass Concrete Strip Foundation

FND12 600W x 900D Mass Concrete Strip Foundation

FND13 600W x 900D Mass Concrete Strip Foundation

9

P8

C

FND14 600W x 900D Mass Concrete Strip Foundation

FND27

1

FND15 FND16

C

FND15 1000W x 900D Mass Concrete Strip Foundation

P6 P5

FND23 FND13 FND16 1000W x 900D Mass Concrete Strip Foundation

FND14

2

6

C

C

FND17 1075W x 900D Mass Concrete Strip Foundation

FND18 1075W x 900D Mass Concrete Strip Foundation

5

P1

FND25

FND9

FND19 600W x 900D Mass Concrete Strip Foundation

P2

C4

FND20 600W x 900D Mass Concrete Strip Foundation

FND10

FND12

FND24 600W x 900D Mass Concrete Strip Foundation

FND21

P4

FND22 600W x 900D Mass Concrete Strip Foundation

FND11 FND23 600W x 900D Mass Concrete Strip Foundation

FND24 600W x 900D Mass Concrete Strip Foundation

FND25 600W x 900D Mass Concrete Strip Foundation

FND26 600W x 900D Mass Concrete Strip Foundation

FND27 600W x 900D Mass Concrete Strip Foundation

Pad Foundation

1000 x 1000 x 450Dp Pad Foundation

P1 With 1 No. Layers B1131 Mesh EW Bottom

1450 x 1450 x 500Dp Pad Foundation

P2 With 1 No. Layers B1131 Mesh EW Bottom

1450 x 1450 x 500Dp Pad Foundation

P3 With 1 No. Layers B1131 Mesh EW Bottom

1000 x 1000 x 450Dp Pad Foundation

P4 With 1 No. Layers B1131 Mesh EW Bottom

1450 x 1450 x 500Dp Pad Foundation

P5 With 1 No. Layers B1131 Mesh EW Bottom

1450 x 1450 x 500Dp Pad Foundation

P6 With 1 No. Layers B1131 Mesh EW Bottom

1450 x 1450 x 500Dp Pad Foundation

P7 With 1 No. Layers B1131 Mesh EW Bottom

1000 x 1000 x 450Dp Pad Foundation

P8 With 1 No. Layers B1131 Mesh EW Bottom

1000 x 1000 x 450Dp Pad Foundation

P9 With 1 No. Layers B1131 Mesh EW Bottom

1000 x 1000 x 450Dp Pad Foundation

P10

With 1 No. Layers B1131 Mesh EW Bottom

All dimensions in millimeter (mm) Rev Date Description By Chkd

unless otherwise noted. P1 21/11/16 Preliminary for Discussion AS WB William Behan Design Partnership S16020 OLD ORCHARD COTTAGE

All dimensions and levels to be

C1 31/01/17 Construction Issue AS WB

confirmed by Architect.

C2 02/02/17 Construction Issue AS WB LONDON DUBLIN

Setting out to be confirmed on site.

Do not scale from this drawing. C3 10/04/17 Revised as Clouded AS WB

Chester House, Fulham Green 23, Old Navan Road Foundation Layout

81-83 Fulham High Street Castleknock,

The Contractor is responsible for Fulham, London, SW6 3JA Dublin 15,

verifying all site dimensions before Ph: 0203 542 1515 Ireland

commencing any work. Mob: 0044 753 126 8327 Mob. 0879914753 1:50 @ A1 Construction S-050 C3

Finishes and build ups

to architects details.

Finishes and build ups to 300mm Cavity Wall to 300mm Cavity Wall Finishes and build ups

300mm Cavity Wall to architects details.

Finishes and build ups architects details Pretressed to architects details to architects details.

architects details 300mm Cavity

Pretressed concreted beam to architects details. Wall to concreted beam Pretressed concreted

and block flooring system. architects details and block flooring beam and block

Pretressed concreted beam

system. flooring system.

and block flooring system. Surface finishes to Surface finishes to

Surface finishes to

architects details architects details

architects details Surface finishes

to architects

details 150mm

Void Void (Min.) 150mm

150mm

Void Void Void (Min.)

Void (Min.) 150mm

Void

Void (Min.)

200 225

300 225

100 200 225

225 300

415mm wide

rising wall

35mm (minimum)

35mm ( minimum) compressible material.

35mm ( minimum)

compressible material

compressible material 35mm ( minimum)

compressible material

500 Min.

500 Min.

500 Min.

Mass concrete strip Mass concrete strip

Mass concrete strip

500 Min.

foundation to Formation Level to be foundation to Formation Level to be

foundation to Formation Level to be Mass concrete

formation level confirmed by site inspection formation level

formation level confirmed by site inspection Formation Level to be strip foundation to confirmed by site inspection

confirmed by site inspection formation level

300 300

500 500 500 500

500 500

Section G1-G1 Section G2-G2 Section G3-G3 Section G4-G4 Finishes and build ups to

Scale: 1:20 Scale: 1:20 Scale: 1:20 Scale: 1:20 architects details.

Pretressed concreted

beam and block

Finishes and build ups to 300mm Cavity Wall to Finishes and build ups 300mm Cavity Wall flooring system.

architects details. architects details 300mm Cavity Wall Finishes and build ups to architects details. to architects details

to architects details to architects details.

Pretressed concreted Pretressed concreted

beam and block Pretressed concreted beam and block

flooring system. beam and block flooring system. 150mm

Surface finishes to Surface finishes to Void Void Void (Min.)

flooring system.

architects details Surface finishes to architects details

architects details

215

150mm 150mm

Void (Min.) Void Void

Void (Min.)

Void 150mm

Void (Min.)

225 200 100 225 200 100

415mm wide rising wall 200 300 225 415mm wide

415mm wide rising wall 35mm ( minimum)

rising wall compressible material

35mm (minimum) 35mm (minimum)

500 Min.

compressible material. 35mm (minimum) compressible material. Mass concrete strip

compressible material. foundation to Formation Level to be

formation level confirmed by site inspection

Mass concrete strip

500 Min.

Mass concrete strip

500 Min.

500 Min.

foundation to foundation to 300 300

Formation Level to be formation level Mass concrete strip Formation Level to be formation level

confirmed by site inspection foundation to Formation Level to be confirmed by site inspection

formation level confirmed by site inspection

300 300 300 300

500 500

Section G5-G5 Section G7-G7 Section G10-G10

Scale: 1:20 Section G6-G6 Scale: 1:20

Scale: 1:20 Scale: 1:20

Finishes and build ups to Finishes and build ups to

architects details. architects details.

Finishes and build ups 300mm Cavity Wall to Pretressed concreted Pretressed concreted

to architects details. architects details beam and block beam and block

300mm Cavity Finishes and build ups to

Pretressed concreted flooring system. flooring system.

Wall to architects architects details.

beam and block details

flooring system. Pretressed concreted beam

Surface finishes to and block flooring system.

architects details

Surface finishes to 150mm Void Void

150mm

Void Void Void (Min.)

architects details Void (Min.)

150mm

Void (Min.) Void 215

215

150mm

Void

Void (Min.)

225 200 100

415mm wide rising wall 100 200 225

415mm wide

rising wall

35mm ( minimum) 35mm ( minimum)

35mm (minimum) compressible material compressible material

compressible material.

35mm (minimum)

compressible material.

500 Min.

500 Min.

Mass concrete strip Mass concrete strip

foundation to Formation Level to be foundation to Formation Level to be

Mass concrete strip

500 Min.

confirmed by site inspection formation level confirmed by site inspection

foundation to formation level

500 Min.

Formation Level to be formation level Mass concrete strip

confirmed by site inspection foundation to 300 300

Formation Level to be 300 300

formation level confirmed by site inspection

300 300

300 300

Section G8-G8 Section G9-G9 Section G11-G11 Section G12-G12

Scale: 1:20 Scale: 1:20 Scale: 1:20

Scale: 1:20

All dimensions in millimeter (mm) Rev Date Description By Chkd

unless otherwise noted. C1 31/01/17 Construction Issue AS WB William Behan Design Partnership S16020 OLD ORCHARD COTTAGE

All dimensions and levels to be

C2 02/02/17 Construction Issue AS WB

confirmed by Architect.

C3 10/04/17 Revised as Clouded AS WB LONDON DUBLIN

Setting out to be confirmed on site.

Do not scale from this drawing.

Chester House, Fulham Green 23, Old Navan Road Foundation - Sections & Details 1

81-83 Fulham High Street Castleknock,

The Contractor is responsible for Fulham, London, SW6 3JA Dublin 15,

verifying all site dimensions before Ph: 0203 542 1515 Ireland

commencing any work. Mob: 0044 753 126 8327 Mob. 0879914753 1:50 @ A1 Construction S-051 C3

215mm Masonry

wall

Finishes and build ups Finishes and build ups

Finishes and build ups Finishes and build ups to

to architects details. to architects details.

215 to architects details. architects details.

Pretressed concreted beam Pretressed concreted 215

Pretressed concreted beam Pretressed concreted beam

and block flooring system. beam and block

and block flooring system. and block flooring system.

flooring system.

150mm 150mm

Finishes and build ups to Void Void 150mm 150mm

Finishes and build ups to Void (Min.) Void (Min.) Void Void

architects details. Void (Min.) Void (Min.)

architects details.

Pretressed concreted 450

Pretressed concreted beam and block 450

beam and block flooring system.

flooring system.

Void

150mm

150mm Void

Void Void Void (Min.)

Void (Min.)

35mm ( minimum)

35mm ( minimum)

compressible material

225 425 compressible material

215

500 Min.

500 Min.

Mass concrete

Mass concrete

strip foundation to Formation Level to be

confirmed by site inspection strip foundation to Formation Level to be

formation level

formation level confirmed by site inspection

35mm ( minimum) 35mm ( minimum) 550 550

35mm ( minimum) 550 550

compressible material

compressible material compressible material

500 Min.

500 Min.

Mass concrete strip

Mass concrete strip foundation to Formation Level to be

foundation to

formation level

Formation Level to be

confirmed by site inspection

formation level confirmed by site inspection Section G15-G15 Section G16 - G16

Scale: 1:20

Scale: 1:20

650 650

300 300

Section G13-G13 Section G14-G14

Scale: 1:20

Scale: 1:20 Finishes and build ups to architects details. 300mm Cavity Wall to

300mm Cavity Wall to Finishes and build ups to

architects details

architects details architects details.

Pretressed concreted beam

and block flooring system. Pretressed concreted beam

and block flooring system.

Surface finishes to

architects details Surface finishes to

architects details

150mm

Void 150mm

Void (Min.) Void

Void (Min.)

225 200 100

100 200 225

415mm wide rising wall

Finishes and build ups to 415mm wide rising wall

Finishes and build ups to architects details.

architects details.

Pretressed concreted

Pretressed concreted beam and block

beam and block 35mm (minimum)

flooring system. 35mm (minimum)

flooring system. compressible material.

compressible material.

150mm Mass concrete strip

500 Min.

150mm Void Void

500 Min.

Void (Min.)

Void Void Void (Min.)

foundation to Mass concrete strip

Formation Level to be formation level foundation to Formation Level to be

215 confirmed by site inspection

formation level confirmed by site inspection

215

300 300

300 300

35mm ( minimum)

Section G19-G19 Section G20-G20

35mm ( minimum) compressible material

compressible material Scale: 1:20 Scale: 1:20

500 Min.

Mass concrete

500 Min.

Mass concrete strip foundation to Formation Level to be

strip foundation to Formation Level to be formation level confirmed by site inspection

formation level confirmed by site inspection

300 300 Detail at top of foundation:

300 300 Foundation to be notched around pipe.

Lay 65mm Dp P.C plaPP lintel over.

Pipe to be laid on 50mm minimum

polystyrene bed & surround.

Section G18-G18 Compressive

150

material 140mm Dp

R.C. lintel

Section G17-G17 Scale: 1:20 Below invert level

Detail through foundation

50mm minimum thick polystyrene

or similar soft filler to pipe

100

Thames water

Scale: 1:20 Detail at underside of foundation.

drain Note :

18mm Thk plywood boxing to 150min. 150 min.

give 50mm clearance to pipe Concrete surround to mature a minimum

with 150mm thick gen1 concrete of 24 hours prior to pouring of footings

surround.

Typical Details of Existing / New Drain Runs

Through Footings

Scale: 1:50

All dimensions in millimeter (mm) Rev Date Description By Chkd

unless otherwise noted. C1 31/01/17 Construction Issue AS WB William Behan Design Partnership S16020 OLD ORCHARD COTTAGE

All dimensions and levels to be

C2 02/02/17 Construction Issue AS WB

confirmed by Architect.

C3 10/04/17 Revised as Clouded AS WB LONDON DUBLIN

Setting out to be confirmed on site.

Do not scale from this drawing.

Chester House, Fulham Green 23, Old Navan Road Foundation - Sections & Details 2

81-83 Fulham High Street Castleknock,

The Contractor is responsible for Fulham, London, SW6 3JA Dublin 15,

verifying all site dimensions before Ph: 0203 542 1515 Ireland

commencing any work. Mob: 0044 753 126 8327 Mob. 0879914753 AS SHOWN Construction S-052 C3

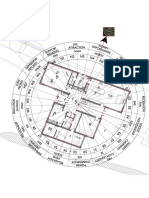

NOTES:

ALL DIMENSION IN MM UNLESS OTHERWISE NOTED

ALL DIMENSION AND LEVEL TO BE CONFORMED BY ARCHITECT

SETTING OUT TO BE CONFIRMED ON SITE

Legend: Wall Legend

(MC) Ref Description

Denotes moment connection

New masonry wall

Denotes pinned connection Non bearing stud wall -

ST1 100x44mm C24 studs

GF1

Denotes span of pretressed at 400mm c/c

concrete beam and block floor

construction.

Steel Column Schedule

Ref Description

C1 203X203X46 UC

C2 203X203X60 UC

C3 203X203X60 UC

C4 100X100X10 SHS

C5 203X203X60 UC

C6 203X203X60 UC

C7 203X203X60 UC

C8 203X203X46 UC

C9 203X203X46 UC

215mm Masonry C10 203X203X46 UC

wall

Lintel Schedule

L1 L2 L3 L4 L5 L6 L7 450L x 215W Pier

(over) (over) (over) (over) (over) (over) (over) Ref Description

L1 Catnic Lintel CG110/100

L2 Catnic Lintel CG110/100

L3 Catnic Lintel CG110/100

10

L4 Catnic Lintel CG110/100

3

7

C

C

C L5 Catnic Lintel CG110/100

L6 Catnic Lintel CG110/100

L7 Catnic Lintel CG110/100

Up

L8 Catnic Lintel CX110/100

Does Not Exist

8

L9

C

L10 Catnic Lintel CH110/100

ST1

L11 Catnic Lintel CH110/100

L12 Catnic Lintel CH110/100

L13 Catnic Lintel CX110/100

ST1 L14 Catnic Lintel CX110/100

L15 2/ 215 x 100 Precast Concrete Lintels

L16 2/ 150 x 100 Precast Concrete Lintels

ST1

Step

(over)

L15

GF1 GF1 GF1 GF1 GF1 GF1 GF1 GF1

ST1

ST1

ST1

9

C

1

L10

C

L8

ST1

(over) 2

C

(over)

6

C

ST1 ST1 ST1

5

C

4

C

(over)

(over)

L11

L12

GF1

450L x 215W Pier 450L x 215W Pier

All dimensions in millimeter (mm) Rev Date Description By Chkd

unless otherwise noted. P1 21/11/16 Preliminary for Discussion AS WB William Behan Design Partnership S16020 OLD ORCHARD COTTAGE

All dimensions and levels to be

C1 31/01/17 Construction Issue AS WB

confirmed by Architect.

C2 02/02/17 Construction Issue AS WB LONDON DUBLIN

Setting out to be confirmed on site.

Do not scale from this drawing. C3 10/04/17 Revised as Clouded AS WB

Chester House, Fulham Green 23, Old Navan Road Ground Floor Layout

81-83 Fulham High Street Castleknock,

The Contractor is responsible for Fulham, London, SW6 3JA Dublin 15,

verifying all site dimensions before Ph: 0203 542 1515 Ireland

commencing any work. Mob: 0044 753 126 8327 Mob. 0879914753 1:50 @ A1 Construction S-100 C3

NOTES:

ALL DIMENSION IN MM UNLESS OTHERWISE NOTED

ALL DIMENSION AND LEVEL TO BE CONFORMED BY ARCHITECT

SETTING OUT TO BE CONFIRMED ON SITE

Floor Span Symbol Legend Legend: Wall Legend

Symbol Description (MC) Ref Description

250x47mm C24 joists Denotes moment connection

J1 New masonry wall

at 400mm c/c with full

depth solid bridging at Denotes pinned connection Non bearing stud wall -

max. 1200mm c/c

ST1 100x44mm C24 studs

195x47mm C24 joists at 400mm c/c

R1

at 300mm c/c with full

depth solid bridging at

max. 1200mm c/c Padstones

PS1 450L X 250D X 215W Concrete Padstone

PS2 450L X 250D X 215W Concrete Padstone

PS3 450L X 250D X 215W Concrete Padstone

PS4 450L X 250D X 215W Concrete Padstone

PS5 450L X 250D X 215W Concrete Padstone

PS6 450L X 250D X 215W Concrete Padstone

PS7 450L X 250D X 215W Concrete Padstone

215 mm PS8 450L X 250D X 215W Concrete Padstone

)

/U

er n

nd m

(C

inner leaf

U olu

10

7

450L x 215W PS9 450L X 250D X 215W Concrete Padstone

C

C

Pier (Under)

PS1 PS10 450L X 250D X 215W Concrete Padstone

PS11 450L X 250D X 215W Concrete Padstone

3

C

PS12 450L X 250D X 100W Concrete Padstone

215 mm Double up PS13 450L X 250D X 215W Concrete Padstone

ST1 inner leaf timber joists

PS14 450L X 250D X 215W Concrete Padstone

8 Double up

PS15 450L X 250D X 215W Concrete Padstone

ST1

C timber joists

(MC) ST1 ST1 215 mm

PS16 450L X 250D X 215W Concrete Padstone

Double up inner leaf

Up

J1

timber joists J1 J1 J1 PS17 450L X 250D X 215W Concrete Padstone

PS6

PS18 Does Not Exist

(over)

PS19 450L X 250D X 215W Concrete Padstone

L16

J1

ST1

Double up Double up J1

B29

PS20 450L X 250D X 215W Concrete Padstone

B7

Up

Double up

B5

timber joists timber joists

timber joists

(over)

PS21 450L X 250D X 215W Concrete Padstone

B36

B4

J1 ST1

ST1

PS7 B12 PS22 450L X 250D X 215W Concrete Padstone

B8

B13

PS16

J1

ST1 ST1

Steel Beam Schedule

ST1 Ref Description

Double up J1 B1 Does Not Exist

B6

Double up

Double up timber joists

timber joists B2 203 X 203 X 46 UC With 10mm Bottom Plate

timber joists

(MC) B3 254 X 254 X 89 UC

B4 203 X 203 X 46 UC With 10mm Bottom Plate

9

C

ST1 B11 ST1 215 mm B5 254 X 254 X 73 UC

215 mm inner leaf B6 254 X 254 X 73 UC

inner leaf

ST1

ST1

J1

PS4 PS5 B7 254 X 254 X 73 UC

B9 B10

void B8 254 X 254 X 89 UC

2

B9 203 X 203 X 46 UC With 10mm Bottom Plate

6

C

B3

C

B10 203 X 203 X 46 UC With 10mm Bottom Plate

)

n

/U

m B11 254 X 254 X 73 UC

(C

u

ol

er

1

C 203 X 203 X 46 UC

C

L14 B12

nd

5

U

C

(over) B13 254 X 254 X 73 UC

4 B14 203 X 203 X 46 UC

C

B15 203 X 203 X 86 UC

B16 203 X 203 X 52 UC

J1

B17 152 X 152 X 30 UC

B18 203 X 203 X 46 UC

B19 203 X 203 X 46 UC

B20 152 X 152 X 30 UC

450L x 215W Pier

B21 203 X 203 X 52 UC

B22 203 X 203 X 86 UC

PS3 PS2 B23 203 X 203 X 46 UC

B2

B24 152 X 152 X 23 UC

B25 203 X 203 X 46 UC

L13 B26 203 X 203 X 46 UC

(over) B27 203 X 203 X 46 UC

B28 203 X 203 X 60 UC

B29 254 X 254 X 107 UC

B30 203 X 203 X 60 UC

B31 203 X 203 X 60 UC

B32 203 X 203 X 46 UC

B33 203 X 203 X 46 UC

B34 203 X 203 X 46 UC

B35 203 X 203 X 46 UC

B36 203 X 203 X 46 UC With 10mm Bottom Plate

Lintel Schedule Steel Column Schedule

Ref Description Ref Description

L1 Catnic Lintel CG110/100 C1 203X203X46 UC

L2 Catnic Lintel CG110/100 C2 203X203X60 UC

L3 Catnic Lintel CG110/100 203X203X60 UC

C3

L4 Catnic Lintel CG110/100

L5 Catnic Lintel CG110/100 C4 100X100X10 SHS

L6 Catnic Lintel CG110/100 C5 203X203X60 UC

L7 Catnic Lintel CG110/100 C6 203X203X60 UC

L8 Catnic Lintel CX110/100 C7 203X203X60 UC

L9 Does Not Exist C8 203X203X46 UC

L10 Catnic Lintel CH110/100

C9 203X203X46 UC

L11 Catnic Lintel CH110/100

L12 Catnic Lintel CH110/100 C10 203X203X46 UC

L13 Catnic Lintel CX110/100

L14 Catnic Lintel CX110/100

L15 2/ 215 x 100 Precast Concrete Lintels

L16 2/ 150 x 100 Precast Concrete Lintels

All dimensions in millimeter (mm) Rev Date Description By Chkd

unless otherwise noted. P1 21/11/16 Preliminary for Discussion AS WB William Behan Design Partnership S16020 OLD ORCHARD COTTAGE

All dimensions and levels to be

C1 31/01/17 Construction Issue AS WB

confirmed by Architect.

C2 02/02/17 Construction Issue AS WB LONDON DUBLIN

Setting out to be confirmed on site.

Do not scale from this drawing. C3 Revised as Clouded AS WB

Chester House, Fulham Green 23, Old Navan Road First Floor Layout

81-83 Fulham High Street Castleknock,

The Contractor is responsible for 10/04/17 Fulham, London, SW6 3JA Dublin 15,

verifying all site dimensions before Ph: 0203 542 1515 Ireland

commencing any work. Mob: 0044 753 126 8327 Mob. 0879914753 1:50 @ A1 Construction S-200 C3

Floor Finishes to

architects details Timber blocking bolted

Floor Finishes to

to web of UC with M12

architects details 30x5mm heavy duty strap at 1200mm c/c Floor Finishes to bolts with 50x50x5mm

and fixed to joists/noggins with No. architects details square plate washers

12x50mm woodscrews at 100mm c/c. Top at 400mm c/c,

Floor Finishes to architects 22mm Plywood deck screwed to of joists notched locally to allow strap to be

Floor Finishes to architects details staggered

joists/noggins with No. 12 x 50 level with top of floor strap bent down

details wood screws at 75mm c/c. 30x5mm heavy duty strap at

behind timber blocking (install prior to 22mm Plywood deck

30 x 5mm Galvanised mild steel 22mm Plywood deck screwed to blocking). 1200mm c/c and fixed to

30 x 5mm Galvanised mild steel 22mm Plywood deck screwed joists/noggins with No. 12 x 50 screwed to

restraint straps at 1200mm c/c. 415mm Cavity wall joists/noggins with No.

restraint straps at 1200mm c/c. to joists/noggins with No. 12 x wood screws at 75mm c/c. joists/noggins with No.

Strap turned down into wall and construction to architects 22mm Plywood deck screwed 12x50mm woodscrews at

Strap turned down into wall and 50 wood screws at 75mm c/c. 12 x 50 wood screws at

fixed to top of joists/noggings with details to joists/noggins with No. 12 x 100mm c/c

fixed to top of joists/noggings with 75mm c/c.

12x50mm woodscrews at 100mm 50 wood screws at 75mm c/c.

12x50mm woodscrews at 100mm c/c.

c/c.

12mm Web

stifffeners welded to

beam with 6mm F.W.

B8 47 x 250mm (C24) timber joist

PS1 Padstone B9

300mm Cavity wall 47 x 250mm (C24) timber joist supported onto joist hangers

300mm Cavity wall B1 Galvanised UC with 10mm

construction to B8 supported onto joist hangers fully nailed into timber blocking

construction to plate welded to underside of beam

architects details architects details 300mm Cavity wall fully nailed into timber blocking

Beam fixed to padstone to support external masonry Heavy duty joist hanger fixed to timber blocking

Solid timber noggins between construction to

architects details and wrapped over flange of beam and fixed to

joist at bearing position. Solid timber noggins between Back of joist fully blocked

anchors. Solid timber noggins between joists manufacturers specification. Bridging to ends of

joist at bearing position. Timber blocking bolted to web of UC at bearing position out to ensure full rigidity

joists at beam location.

215mm wide pier locally with M12 bolts with 50x50x5mm square for joist hanger fixing

47x250mm (C24) timber plate washers at 400mm c/c, staggered

joist at 400mm c/c. under padstone.

47x250mm (C24) timber Section L3 - L3 Section L5 - L5

joist at 400mm c/c.

Section L1 - L1 Section L2 - L2 Scale: 1:20

Section L4 - L4 Scale: 1:20

Scale: 1:20 Scale: 1:20

Scale: 1:20

Floor finishes to architects details.

Floor Finishes to

architects details

Floor Finishes to architects Heavy duty wall hanger fixed to timber blocking and

details wrapped over flange of beam. Joist hanger to be

30x5mm heavy duty strap at 1200mm c/c and fixed to

Floor Finishes to New non load bearing stud wall fixed in accordance with manufacturer's specification.

joists/noggings with No. 12x50mm woodscrews at 100mm c/c 22mm Plywood deck screwed to

architects details and bent down behind timber blocking (install prior to blocking). 30 x 5mm Galvanised mild steel

restraint straps at 1200mm c/c. joists/noggins with No. 12 x 50 22mm Plywood deck screwed to joists/noggins

Timber blocking bolted to web of UC wood screws at 75mm c/c.

Strap turned down into wall and with No. 12 x 50 wood screws at 75mm c/c.

with M12 bolts with 50x50x5mm square

22mm Plywood deck screwed fixed to top of joists/noggings with

30x5mm heavy duty strap at plate washers at 400mm c/c, staggered

to joists/noggins with No. 12 x 12x50mm woodscrews at 100mm 300mm Cavity wall 30 x 5mm Galvanised mild steel restraint straps at 1200mm

1200mm c/c and fixed to

50 wood screws at 75mm c/c. c/c. construction to architects c/c. Strap turned down into wall and fixed to top of

joists/noggins with No. 22mm Plywood deck screwed to

details joists/noggins notched locally to allow strap to be level with top

12x50mm woodscrews at joists/noggins with No. 12 x 50 wood of floor strap bent down behind timber blocking (install prior to

100mm c/c screws at 75mm c/c. blocking)

300mm Cavity wall

construction to

architects details

B2

B11

B7 47 x 250mm (C24) timber joist Solid timber noggins 47x250mm (C24) timber joist at

supported onto joist hangers 47 x 250mm (C24) timber B2 Galvanised UC with 10mm plate 400mm c/c.

between joist at bearing

fully nailed into timber blocking at 400mm c/c. welded to underside of beam to

Back of joist fully blocked position.

support external masonry. Solid timber noggins between

out to ensure full rigidity

for joist hanger fixing

Heavy duty joist hanger fixed to timber

blocking and wrapped over flange of beam

Timber blocking bolted to web of UC

with M12 bolts with 50x50x5mm square

Solid timber noggins between

joists at bearing position

47x250mm (C24) timber Section L8 - L8 Timber blocking bolted to web of beam with

joist at bearing position.

joist at 400mm c/c. Scale: 1:20

and fixed to manufacturers specification. plate washers at 400mm c/c, staggered

Bridging to ends of joists at beam location. washers at 400mm c/c staggered.

Section L6 - L6 Section L7 - L7

Scale: 1:20 Scale: 1:20 Section L9 - L9

Scale: 1:20

Floor Finishes to Floor finishes to architects details.

architects details

Floor Finishes to Heavy duty wall hanger fixed to timber blocking and

architects details Timber blocking bolted to web of UC wrapped over flange of beam. Joist hanger to be

30x5mm heavy duty strap at 1200mm c/c

Timber blocking bolted to web of UC with M12 bolts with 50x50x5mm square fixed in accordance with manufacturer's specification.

and fixed to joists/noggins with No.

with M12 bolts with 50x50x5mm square 12x50mm woodscrews at 100mm c/c. plate washers at 400mm c/c, staggered

22mm Plywood deck screwed to joists/noggins with

30x5mm heavy duty strap at plate washers at 400mm c/c, staggered

No. 12 x 50 wood screws at 75mm c/c.

1200mm c/c and fixed to

joists/noggins with No. 22mm Plywood deck screwed

22mm Plywood deck screwed 415mm Cavity wall 30 x 5mm Galvanised mild steel restraint straps at 1200mm

12x50mm woodscrews at to joists/noggins with No. 12 x

to joists/noggins with No. 12 x 50 wood screws at 75mm c/c. construction to architects c/c. Strap turned down into wall and fixed to top of joist notched

100mm c/c 47x250mm (C24) Timber joist

50 wood screws at 75mm c/c. details locally to allow strap to be level with top of floor strap bent

at 400mm c/c

down behind timber blocking (install prior to blocking)

DNE

B6 47 x 250mm (C24) timber joist

supported onto joist hangers

B3 B4 47x250mm (C24) timber joist at

fully nailed into timber blocking B4 Galvanised UC with 10mm plate

Back of joist fully blocked Solid timber noggins at bearing 47 x 250mm (C24) timber 400mm c/c.

out to ensure full rigidity positions welded to underside of beam to support

joist at 400mm c/c. external masonry.

for joist hanger fixing Solid timber noggins between

Solid timber noggins between joist at bearing position.

Heavy duty joist hanger fixed to timber Timber blocking bolted to web of beam with

blocking and wrapped over flange of beam joists at bearing position

and fixed to manufacturers specification. washers at 400mm c/c staggered.

Section L10 - L10 Bridging to ends of joists at beam loaction Section L11 - L11 Section L12 - L12

Scale: 1:20 Scale: 1:20 Scale: 1:20

Section L13 - L13

Scale: 1:20

Floor Finishes to architects 30 x 5mm Galvanised mild steel Floor Finishes to

details restraint straps at 1200mm c/c. architects details

Floor Finishes to Strap turned down into wall and

22mm Plywood deck screwed to 30 x 5mm Galvanised mild steel

architects details fixed to top of joist with 12x50mm

joists/noggins with No. 12 x 50 wood restraint straps at 1200mm c/c. woodscrews at 100mm c/c/ Top of

Timber blocking bolted to web of UC screws at 75mm c/c. Strap turned down into wall and joist notched locally to allow strap to 2No. 75 x 250mm (C24) 3No. 75 x 250mm (C24)

with M12 bolts with 50x50x5mm square fixed to top of joists/noggings with 22mm Plywood deck screwed to

60

60

be level with top of floor strap. timber joists timber joists

30x5mm heavy duty strap at plate washers at 400mm c/c, staggered 12x50mm woodscrews at 100mm joists/noggins with No. 12 x 50 wood

1200mm c/c and fixed to c/c. screws at 75mm c/c.

joists/noggins with No. 22mm Plywood deck screwed 47 x 250mm (C24) timber

12x50mm woodscrews at at 400mm c/c. Joists bolted together Joists bolted together

to joists/noggins with No. 12 x

100mm c/c 50 wood screws at 75mm c/c.

400mm c/c staggered with 400mm c/c staggered with

2No. 50x50x5mm washers 2No. 50x50x5mm washers

300mm Cavity wall construction to

architects details

300mm Cavity wall

60

60

construction to

architects details

47 x 250mm (C24) timber joist Solid timber noggins Solid timber noggins

B5 between joists at bearing

Heavy duty joist hanger fixed to timber supported onto joist hangers between joist at bearing

fully nailed into timber blocking position. position.

blocking and wrapped over flange of beam

60

60

and fixed to manufacturers specification. 400

Bridging to ends of joists at beam location. 47x250mm (C24) timber Heavy duty wall hanger 400 400 400 400 400

joist at 400mm c/c. installed in accordance with

Back of joist fully blocked

manufacturers specification

out to ensure full rigidity

for joist hanger fixing

Section L14 - L14 Section L16 - L16

Scale: 1:20 Scale: 1:20

Typical Double / Triple

Joist Detail

Section L15 - L15 Scale: 1:20

Scale: 1:20

All dimensions in millimeter (mm) Rev Date Description By Chkd

unless otherwise noted. C1 31/01/17 Construction Issue AS WB William Behan Design Partnership S16020 OLD ORCHARD COTTAGE

All dimensions and levels to be

C2 02/02/17 Construction Issue AS WB

confirmed by Architect.

C3 10/04/17 Revised as Clouded AS WB LONDON DUBLIN

Setting out to be confirmed on site.

Do not scale from this drawing.

Chester House, Fulham Green 23, Old Navan Road First Floor - Sections & Details

81-83 Fulham High Street Castleknock,

The Contractor is responsible for Fulham, London, SW6 3JA Dublin 15,

verifying all site dimensions before Ph: 0203 542 1515 Ireland

commencing any work. Mob: 0044 753 126 8327 Mob. 0879914753 AS SHOWN Construction S-201 C3

NOTES:

ALL DIMENSION IN MM UNLESS OTHERWISE NOTED

ALL DIMENSION AND LEVEL TO BE CONFORMED BY ARCHITECT

SETTING OUT TO BE CONFIRMED ON SITE

Floor Span Symbol Legend Legend: Wall Legend

Symbol Description (MC) Ref Description

250x47mm C24 joists Denotes moment connection

J1 New masonry wall

at 400mm c/c with full

depth solid bridging at Denotes pinned connection Non bearing stud wall -

max. 1200mm c/c

ST1 100x44mm C24 studs

195x47mm C24 joists at 400mm c/c

R1

at 300mm c/c with full

depth solid bridging at

max. 1200mm c/c Padstones

PS1 450L X 250D X 215W Concrete Padstone

PS2 450L X 250D X 215W Concrete Padstone

PS3 450L X 250D X 215W Concrete Padstone

PS4 450L X 250D X 215W Concrete Padstone

PS5 450L X 250D X 215W Concrete Padstone

PS6 450L X 250D X 215W Concrete Padstone

PS7 450L X 250D X 215W Concrete Padstone

PS8 450L X 250D X 215W Concrete Padstone

Double up roof rafters at hip. Cranked position

in frame (typ) PS9 450L X 250D X 215W Concrete Padstone

PS10 450L X 250D X 215W Concrete Padstone

PS11 450L X 250D X 215W Concrete Padstone

(MC) (MC) PS12 450L X 250D X 100W Concrete Padstone

3

7

C

C

PS13 450L X 250D X 215W Concrete Padstone

R1

R1

R1

PS14 450L X 250D X 215W Concrete Padstone

Double up timber rafters

around roof lights PS15 450L X 250D X 215W Concrete Padstone

R1

8 ROOF ROOF ROOF

C

B28

R1 ROOF LIGHTS PS15 PS9 PS16 450L X 250D X 215W Concrete Padstone

R1

LIGHTS LIGHTS LIGHTS

R1

B27

(MC)

B30

(High (Low ROOF

B15 PS19 B18 LIGHTS PS17 450L X 250D X 215W Concrete Padstone

(MC) level) level)

B14 B16 B17 PS18 Does Not Exist

Cranked position (MC) ROOF PS8

FRAME 2 ROOF

in frame (typ) LIGHTS LIGHTS PS19 450L X 250D X 215W Concrete Padstone

R1

FRAME 3

R1

R1

PS20 450L X 250D X 215W Concrete Padstone

R1

PS21 450L X 250D X 215W Concrete Padstone

(MC) (MC) PS22

PS22 450L X 250D X 215W Concrete Padstone

B27

B33 (MC) B34 PS21 B35 (MC) B32

R1

FRAME 1

Steel Beam Schedule

R1

Ref Description

B28

PS20

R1

R1

ROOF ROOF

LIGHTS LIGHTS B1 Does Not Exist

Cranked position 170x47 (C24) timber chord B2 203 X 203 X 46 UC With 10mm Bottom Plate

in frame (typ) (MC) B21 at each rafter positions B3 254 X 254 X 89 UC

(MC) B23 B22 B20 PS17 PS10 B4 203 X 203 X 46 UC With 10mm Bottom Plate

B27

B19 PS11

(MC) B5 254 X 254 X 73 UC

(High (Low ROOF

R1

R1

254 X 254 X 73 UC

R1

B6

R1

level) level) LIGHTS

9

B31

C

B30

B7 254 X 254 X 73 UC

R1

Double up timber rafters B8 254 X 254 X 89 UC

around roof lights ROOF ROOF ROOF

LIGHTS B9 203 X 203 X 46 UC With 10mm Bottom Plate

LIGHTS LIGHTS

B10 203 X 203 X 46 UC With 10mm Bottom Plate

2

C

(MC) (MC) (MC) B11 254 X 254 X 73 UC

6

203 X 203 X 46 UC

C

B12

B13 254 X 254 X 73 UC

5

C

B14 203 X 203 X 46 UC

B26

B25

B15 203 X 203 X 86 UC

PS12 B24

B16 203 X 203 X 52 UC

B17 152 X 152 X 30 UC

R1 R1 203 X 203 X 46 UC

B18

4

C

B19 203 X 203 X 46 UC

B20 152 X 152 X 30 UC

B21 203 X 203 X 52 UC

B22 203 X 203 X 86 UC

B23 203 X 203 X 46 UC

PS13 PS14 B24 152 X 152 X 23 UC

B25 203 X 203 X 46 UC

B26 203 X 203 X 46 UC

B27 203 X 203 X 46 UC

B28 203 X 203 X 60 UC

450L x 215W Pier 450L x 215W Pier B29 254 X 254 X 107 UC

(under) (under) B30 203 X 203 X 60 UC

B31 203 X 203 X 60 UC

B32 203 X 203 X 46 UC

170x47 (C24) timber chord

at each rafter positions B33 203 X 203 X 46 UC

B34 203 X 203 X 46 UC

B35 203 X 203 X 46 UC

B36 203 X 203 X 46 UC With 10mm Bottom Plate

Steel Column Schedule

Ref Description

C1 203X203X46 UC

C2 203X203X60 UC

C3 203X203X60 UC

C4 100X100X10 SHS

C5 203X203X60 UC

C6 203X203X60 UC

C7 203X203X60 UC

C8 203X203X46 UC

C9 203X203X46 UC

C10 203X203X46 UC

All dimensions in millimeter (mm) Rev Date Description By Chkd

unless otherwise noted. P1 21/11/16 Preliminary for Discussion AS WB William Behan Design Partnership S16020 OLD ORCHARD COTTAGE

All dimensions and levels to be

C1 31/01/17 Construction Issue AS WB

confirmed by Architect.

C2 02/02/17 Construction Issue AS WB LONDON DUBLIN

Setting out to be confirmed on site.

Do not scale from this drawing. C3 10/04/17 Revised as Clouded AS WB

Chester House, Fulham Green 23, Old Navan Road Roof Layout

81-83 Fulham High Street Castleknock,

The Contractor is responsible for Fulham, London, SW6 3JA Dublin 15,

verifying all site dimensions before Ph: 0203 542 1515 Ireland

commencing any work. Mob: 0044 753 126 8327 Mob. 0879914753 1:50 @ A1 Construction S-300 C3

22mm Plywood deck screwed

to rafters/noggings with No. 12

x 50 wood screws at 75mm

c/c.

22mm Plywood deck screwed to 22mm Plywood deck screwed to

rafters/noggings with No. 12 x 50 rafters/noggings with No. 12 x 50

Roof finishes to wood screws at 75mm c/c. 22mm Plywood deck

wood screws at 75mm c/c. 22mm Plywood deck screwed to

architects details screwed to rafters/noggings

rafters/noggings with No. 12 x 50

with No. 12 x 50 wood

wood screws at 75mm c/c.

screws at 75mm c/c.

Roof Finishes to Roof Finishes to

30x5mm heavy duty strap at architects details architects details

1200mm c/c and fixed to Roof Finishes to Roof Finishes to

joists/noggins with No. 12x50mm architects details architects details

woodscrews at 100mm c/c. Rafter Rafter

Rafter

Galvanised Framing Galvanised Framing Rafter

47x195mm (C24) timber Galvanised Framing

Anchor Anchor

joist at 300mm c/c. Anchor

Galvanised Framing

Notched into steel beam 100 x 75 Wall plate 100 x 75 Wall plate Anchor

215 x 75 Wall plate

5 30 x 5 Galvanised M.S Straps at 1200mm 100 x 75 Wall plate

B1 Timber blocking bolted to 30 x 5 Galvanised M.S Straps at 1200mm

web of UC with M12 bolts c/c fixed to wall plate and plugged and c/c fixed to wall plate and plugged and 30 x 5 Galvanised M.S Straps at 1200mm

with 50x50x5mm square screwed to wall using 5 No. 12 screws. Eaves to screwed to wall using 5 No. 12 screws. Eaves to 30 x 5 Galvanised M.S Straps at 1200mm c/c fixed to wall plate and plugged and

plate washers at 400mm architects details architects details c/c fixed to wall plate and plugged and Eaves to screwed to wall using 5 No. 12 screws.

c/c, staggered screwed to wall using 5 No. 12 screws. Eaves to architects details

architects details

Section R2 - R2

Scale: 1:20

Section R3 - R3

Section R1 - R1 Scale: 1:20 Section R5 - R5

Scale: 1:10 Section R4 - R4 Scale: 1:20 Roof Finishes to

Scale: 1:20 architects details

22mm Plywood deck

30x5mm heavy duty strap at 1200mm c/c turned screwed to rafters/noggings Roof finishes to 30x5mm heavy duty strap at

down behind wall and fixed to rafters/noggings with No. 12 x 50 wood architects details 1200mm c/c and fixed to

22mm Plywood deck 22mm Plywood deck screws at 75mm c/c.

with No. 12x50mm woodscrews at 100mm c/c rafters/noggins with No.

screwed to rafters/noggings Timber blocking bolted to web of UC Timber blocking bolted to web of UC

screwed to rafters/noggings 12x50mm woodscrews at

with No. 12 x 50 wood with M12 bolts with 50x50x5mm square with M12 bolts with 50x50x5mm square

with No. 12 x 50 wood Roof Finish to Roof Finishes to 100mm c/c

screws at 75mm c/c. 30x5mm heavy duty strap at plate washers at 400mm c/c, staggered plate washers at 400mm c/c, staggered

screws at 75mm c/c. architects details architects details 1200mm c/c and fixed to

22mm Plywood deck screwed to rafters/noggins with No. 22mm Plywood deck screwed 22mm Plywood deck screwed to

Roof Finishes to Roof Finishes to 47 x 195mm (C24) timber

rafters/noggings with No. 12 x 50 Rafter 12x50mm woodscrews at to rafters/noggings with No. 12 rafters/noggings with No. 12 x 50

architects details architects details rafters at 300mm c/c

wood screws at 75mm c/c. 100mm c/c bent down behind x 50 wood screws at 75mm c/c. wood screws at 75mm c/c.

Galvanised Framing timber blocking (install prior to B27

Rafter Rafter blocking)

Anchor

Galvanised Framing Galvanised Framing 100 x 75 Wall plate

Anchor Anchor

100 x 75 Wall plate 30 x 5 Galvanised M.S

100 x 75 Wall plate Straps at 1200mm c/c fixed

Eaves to to wall plate and plugged B28

30 x 5 Galvanised M.S 30 x 5 Galvanised M.S architects details and screwed to wall using Solid timber noggins at

C24 timber rafters at Straps at 1200mm c/c fixed 47 x 195mm (C24) timber 47 x 195mm (C24) timber

Straps at 1200mm c/c fixed 5 No. 12 screws. bearing position

Eaves to 300mm c/c Eaves to to wall plate and plugged rafters at 300mm c/c rafters at 300mm c/c

to wall plate and plugged

architects details architects details and screwed to wall using

and screwed to wall using Solid timber noggins Solid timber noggins at

5 No. 12 screws. Back of rafters fully blocked

5 No. 12 screws. between rafters at bearing bearing position

Solid timber noggins at out to ensure full rigidity for

position

Section R8 - R8 bearing position joist hanger fixing

Section R6- R6 Section R7- R7 Scale: 1:20

Scale: 1:20

Section R9 - R9 Section R11- R11

Scale: 1:20 Scale: 1:20

Section R10 - R10 Scale: 1:20

Scale: 1:20

Roof Finishes to

architects details

22mm Plywood deck screwed

30x5mm heavy duty strap at 30x5mm heavy duty strap at 1200mm c/c turned to rafters/noggings with No. 12 22mm Plywood deck screwed

1200mm c/c and fixed to down behind wall and fixed to rafters/noggings x 50 wood screws at 75mm to rafters/noggings with No. 12

rafters/noggins with No. with No. 12x50mm woodscrews at 100mm c/c c/c. x 50 wood screws at 75mm

Timber blocking bolted to web of UC

12x50mm woodscrews at c/c.

with M12 bolts with 50x50x5mm square Roof finishes to

100mm c/c Roof Finishes to

plate washers at 400mm c/c, staggered architects details

architects details

Roof Finishes to Roof finishes to

22mm Plywood deck screwed to 22mm Plywood deck screwed to 22mm Plywood deck screwed to architects details

47 x 195mm (C24) timber architects details

rafters/noggings with No. 12 x 50 rafters/noggings with No. 12 x 50 rafters/noggings with No. 12 x 50 30x5mm heavy duty strap at

rafters at 300mm c/c wood screws at 75mm c/c.

wood screws at 75mm c/c. wood screws at 75mm c/c. 1200mm c/c and fixed to

47x195mm (C24) timber joists/noggins with No. 12x50mm 30x5mm heavy duty strap at

joist at 300mm c/c. woodscrews at 100mm c/c. 1200mm c/c and fixed to

Notched into steel beam joists/noggins with No. 12x50mm 47x195mm (C24) timber

woodscrews at 100mm c/c. joist at 300mm c/c.

Timber blocking bolted to B1

8 Notched into steel beam

web of UC with M12 bolts

with 50x50x5mm square

plate washers at 400mm 1 Timber blocking bolted to

B30

c/c, staggered B2 web of UC with M12 bolts

Solid timber noggins at 30x5mm heavy duty strap at C24 timber rafters at with 50x50x5mm square

47 x 195mm (C24) timber C24 timber rafters at

bearing position 1200mm c/c turned down behind 300mm c/c plate washers at 400mm

rafters at 300mm c/c 300mm c/c

wall and fixed to rafters/noggings c/c, staggered

with No. 12x50mm woodscrews Solid timber noggins Solid timber noggins

Back of rafters fully blocked Solid timber noggins at

bearing position at 100mm c/c between rafters at bearing between rafters at bearing

out to ensure full rigidity for position

joist hanger fixing position

Section R14- R14 Section R15 - R15

Section R12- R12 Section R13- R13 Scale: 1:10 Section R16 - R16

Scale: 1:20 Scale: 1:20 Scale: 1:20

Scale: 1:10

30x5mm heavy duty strap at 1200mm c/c

turned down behind wall and fixed to

22mm Plywood deck screwed rafters/noggings with No. 12x50mm

to rafters/noggings with No. 12 22mm Plywood deck screwed

to rafters/noggings with No. 12 woodscrews at 100mm c/c

x 50 wood screws at 75mm

c/c. x 50 wood screws at 75mm 22mm Plywood deck screwed to

c/c. Proprietary wall plate

rafters/bridging with No. 12 x 50

fixed both sides of

wood screws at 75mm c/c.

Roof finishes to timber rafter

Roof finishes to 22mm Plywood deck screwed to

architects details

architects details Roof Finishes to rafters/noggings with No. 12 x 50

architects details wood screws at 75mm c/c. Connection Details indicateive

Timber plate fixed to steel only. Refer to Dwg. S- 002 fpr

30x5mm heavy duty strap at Connection Forces

1200mm c/c and fixed to 30x5mm heavy duty strap at 450 crs staggered

joists/noggins with No. at 1200mm c/c and fixed to

joists/noggins with No. 30x5mm heavy duty strap at 1200mm c/c 47x195 (C24) timber Timber details

12x50mm woodscrews at turned down behind wall and fixed to 47x195 (C24) timber

100mm c/c. 47x195mm (C24) timber 12x50mm woodscrews at rafters @ 300 crs omitted for

joist at 300mm c/c. 100mm c/c. 47x195mm (C24) timber rafters/noggings with No. 12x50mm rafters @ 300 crs

clarity

Notched into steel beam joist at 300mm c/c. woodscrews at 100mm c/c

Notched into steel beam

22mm Plywood deck screwed Roof Finishes to

9 Timber blocking bolted to to rafters/noggings with No. 12 architects details

B1 web of UC with M12 bolts 3 Timber blocking bolted to C24 timber rafters at 0 B3

with 50x50x5mm square B2 web of UC with M12 bolts 300mm c/c x 50 wood screws at 75mm c/c. B3 0

plate washers at 400mm with 50x50x5mm square

plate washers at 400mm Solid timber noggins

c/c, staggered

c/c, staggered between rafters at bearing

position

B35

C24 timber rafters at B35

300mm c/c

Solid timber noggins

between rafters at bearing

Section R17 - R17 Section R18 - R18 position

Scale: 1:10 Section R19- R19

Scale: 1:10 Scale: 1:20

Section R20- R20 Section R21 - R21

Scale: 1:10 Scale: 1:10

All dimensions in millimeter (mm) Rev Date Description By Chkd

unless otherwise noted. C1 31/01/17 Construction Issue AS WB William Behan Design Partnership S16020 OLD ORCHARD COTTAGE

All dimensions and levels to be

C2 02/02/17 Construction Issue AS WB

confirmed by Architect.

C3 10/04/17 Revised as Clouded AS WB LONDON DUBLIN

Setting out to be confirmed on site.

Do not scale from this drawing.

Chester House, Fulham Green 23, Old Navan Road Roof - Sections & Details

81-83 Fulham High Street Castleknock,

The Contractor is responsible for Fulham, London, SW6 3JA Dublin 15,

verifying all site dimensions before Ph: 0203 542 1515 Ireland

commencing any work. Mob: 0044 753 126 8327 Mob. 0879914753 AS SHOWN Construction S-301 C3

NOTES:

ALL DIMENSION IN MM UNLESS OTHERWISE NOTED

ALL DIMENSION AND LEVEL TO BE CONFORMED BY ARCHITECT

SETTING OUT TO BE CONFIRMED ON SITE

Lintel Schedule

Ref Description

L1 Catnic Lintel CG110/100

L2 Catnic Lintel CG110/100

L13 L3 Catnic Lintel CG110/100

B27 L4 Catnic Lintel CG110/100

B2 L5 Catnic Lintel CG110/100

7 7

B2 L6 Catnic Lintel CG110/100

L7 Catnic Lintel CG110/100

L8 Catnic Lintel CX110/100

L9 Does Not Exist

L10 Catnic Lintel CH110/100

L11 Catnic Lintel CH110/100

L12 Catnic Lintel CH110/100

L13 Catnic Lintel CX110/100

L14 Catnic Lintel CX110/100

L15 2/ 215 x 100 Precast Concrete Lintels

L14 L8 B4 L16 2/ 150 x 100 Precast Concrete Lintels

L10

9

C

C

East Elevation

Scale: 1:50

P8 Frame M.K.1 P9

Scale: 1:50

8 B2

B2 8

L7 L6 L5 L4 L3 L2 L1

B5

6

7

C

C

West Elevation

Scale: 1:50

P6

Frame M.K.2 P7

Scale: 1:50

0 B3

B3 0

L12 B7

L11

2 3

C C

Frame M.K.3

South Elevation P2 Scale: 1:50

P3

North Elevation Scale: 1:50

Scale: 1:50

All dimensions in millimeter (mm) Rev Date Description By Chkd

unless otherwise noted. P1 21/11/16 Preliminary for Discussion AS WB William Behan Design Partnership S16020 OLD ORCHARD COTTAGE

All dimensions and levels to be

C1 31/01/17 Construction Issue AS WB

confirmed by Architect.

C2 02/02/17 Construction Issue AS WB LONDON DUBLIN

Setting out to be confirmed on site.

Do not scale from this drawing. C3 10/04/17 Revised as Clouded AS WB

Chester House, Fulham Green 23, Old Navan Road Elevations

81-83 Fulham High Street Castleknock,

The Contractor is responsible for Fulham, London, SW6 3JA Dublin 15,

verifying all site dimensions before Ph: 0203 542 1515 Ireland

commencing any work. Mob: 0044 753 126 8327 Mob. 0879914753 1:50 @ A1 Construction S-400 C3

You might also like

- Pre-Cast Concrete Elements for Commercial & Residential BuildingsDocument10 pagesPre-Cast Concrete Elements for Commercial & Residential BuildingsMithun UdayanarayanaNo ratings yet

- Secant Pile Wall SpecificationDocument16 pagesSecant Pile Wall Specificationjinwook75No ratings yet

- Secant PilingDocument15 pagesSecant Pilingwalid abou kachfe100% (1)

- Gypsum Board, Fibrous Plaster and Calcium Silicate Ceiling SpecDocument8 pagesGypsum Board, Fibrous Plaster and Calcium Silicate Ceiling SpecKiran D AnvekarNo ratings yet

- 09 22 00 Acoustical Ceilings Index and SpecificationDocument9 pages09 22 00 Acoustical Ceilings Index and SpecificationKiran D AnvekarNo ratings yet

- 700 - Drainage Construction - 178Document18 pages700 - Drainage Construction - 178ruwan.smb1No ratings yet

- QDC/3136 Rev 0Document17 pagesQDC/3136 Rev 0Mohamed Ismath Kalideen100% (1)

- New Beams & Trimmers: Proposed Second Floor Plan Showing Roof Support Structure AboveDocument1 pageNew Beams & Trimmers: Proposed Second Floor Plan Showing Roof Support Structure Aboveelangeswaran mathynushanNo ratings yet

- Final: Special Specification For Steel Fabrication WorkDocument18 pagesFinal: Special Specification For Steel Fabrication Workpratik raiNo ratings yet

- TS For 33kv Transmission LineDocument19 pagesTS For 33kv Transmission LineRamaKrishna ANo ratings yet

- Sub-structure Section OverviewDocument3 pagesSub-structure Section Overviewaalignup arc & const. pvt ltdNo ratings yet

- Bailey Bridge Design Dwgs 39m Supstr+SubstrDocument16 pagesBailey Bridge Design Dwgs 39m Supstr+SubstrPrakash Singh RawalNo ratings yet

- Architectural, Structural & Mep Drawings FORDocument35 pagesArchitectural, Structural & Mep Drawings FORNana Barima100% (1)

- Hollow Core Slab PDFDocument4 pagesHollow Core Slab PDFStraus WaseemNo ratings yet

- 3 BedDocument36 pages3 Bedemmanuel SiawNo ratings yet

- MS For Concrete RepairsDocument2 pagesMS For Concrete RepairsMicheal B HaizenNo ratings yet

- Spesifikasi Teknik Mills ProjectDocument135 pagesSpesifikasi Teknik Mills ProjectPPK USB Gegerbitung GegerbitungNo ratings yet

- SpecificationDocument5 pagesSpecificationwalidNo ratings yet

- BO-BoQ For Balance Civil & FinishingDocument16 pagesBO-BoQ For Balance Civil & FinishingcubadesignstudNo ratings yet

- 09 20 00 Gypsum Board Etc CeilingDocument12 pages09 20 00 Gypsum Board Etc CeilingKiran D AnvekarNo ratings yet

- Secant Pile Wall SpecificationDocument16 pagesSecant Pile Wall SpecificationZein FarahNo ratings yet

- 18cf0ebb b546 426b 9ea7 067adbc8dd44 Production MergedDocument16 pages18cf0ebb b546 426b 9ea7 067adbc8dd44 Production MergeddbowengarciaNo ratings yet

- 6 Tender Drawing (Structure)Document56 pages6 Tender Drawing (Structure)thandarwinNo ratings yet

- 17.3 Precast Concrete: Nam Theun 1 Hydropower ProjectDocument1 page17.3 Precast Concrete: Nam Theun 1 Hydropower Projectyzh wangNo ratings yet

- Cast in Place ConcreteDocument16 pagesCast in Place ConcreteabdouNo ratings yet

- Cutting, Coring and Patching - MSTDocument3 pagesCutting, Coring and Patching - MSTwafikmh4No ratings yet

- PHMNSC1 - CY02 - Vol2Specs-10 Drainage - Rev00Document8 pagesPHMNSC1 - CY02 - Vol2Specs-10 Drainage - Rev00Rajah Al HacinoNo ratings yet

- T - Proc Notices Notices 040 K Notice Doc 38070 195060157Document305 pagesT - Proc Notices Notices 040 K Notice Doc 38070 195060157Iverson EnojoNo ratings yet

- HB 12350Document21 pagesHB 12350Pawan Kumar PrajapatNo ratings yet

- 2019.03.20 Woke ST Specs PDFDocument11 pages2019.03.20 Woke ST Specs PDFjeremiahNo ratings yet

- Civil Final 2020Document35 pagesCivil Final 2020Shakil KhanNo ratings yet

- Louver SpecDocument10 pagesLouver SpecCyril J PadiyathNo ratings yet

- 5) CP02 GBB 12 Annex D PDFDocument4 pages5) CP02 GBB 12 Annex D PDFAce NovoNo ratings yet

- Pricing For Al Mutared - 123Document39 pagesPricing For Al Mutared - 123Amro HarasisNo ratings yet

- Pile SpecificationsDocument16 pagesPile SpecificationsHarshini Reddy B.100% (1)

- 22 - Technical Specification Part VI-Civil & Structural WorksDocument32 pages22 - Technical Specification Part VI-Civil & Structural Worksah.bassioniNo ratings yet

- Aluminium Curtain WalDocument28 pagesAluminium Curtain WaljatinNo ratings yet

- SECTION 03 41 00 Structural Precast Concrete Part 1 - GeneralDocument16 pagesSECTION 03 41 00 Structural Precast Concrete Part 1 - Generalraja qammarNo ratings yet

- Basrah Sports City Manholes SpecDocument4 pagesBasrah Sports City Manholes Specabdullah sahibNo ratings yet

- Specifications for Earthwork Formation RVNLDocument32 pagesSpecifications for Earthwork Formation RVNLkartick adhikaryNo ratings yet

- HandRail Specsgf For CfvdrfsDocument3 pagesHandRail Specsgf For CfvdrfsTarek TarekNo ratings yet

- RMP Kiosk Guidelines - 1Document10 pagesRMP Kiosk Guidelines - 1John Mark LungubNo ratings yet

- NCDE-RYD-NBS-XX-SP-A-E60 - Precast Composite Concrete Stairs - Construction - C1 - 0Document4 pagesNCDE-RYD-NBS-XX-SP-A-E60 - Precast Composite Concrete Stairs - Construction - C1 - 0johnNo ratings yet